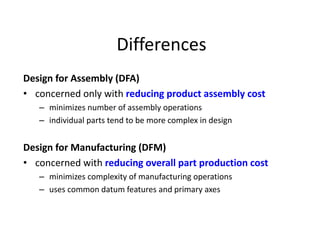

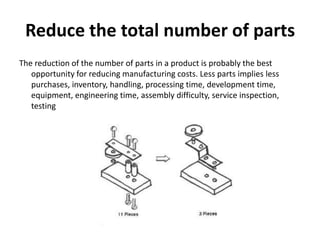

Design for Manufacturing and Assembly (DFMA) is a methodology used to minimize product cost through design and process improvements. DFMA integrates product design and process planning to design products that are easily and economically manufactured. The goal of DFMA is to reduce material, overhead, and labor costs, shorten product development times, and utilize standardization to reduce costs. Key principles of DFMA include reducing the total number of parts, developing modular designs, using standard components, designing parts for multi-functionality and multi-use, and minimizing assembly directions.