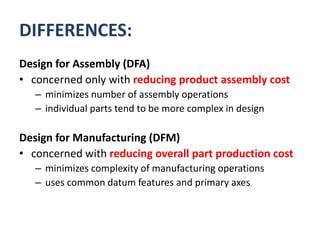

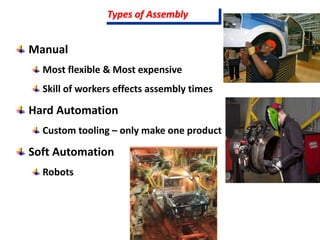

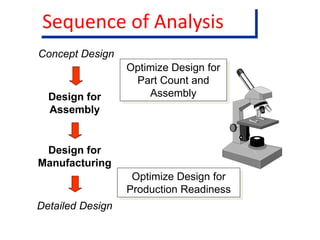

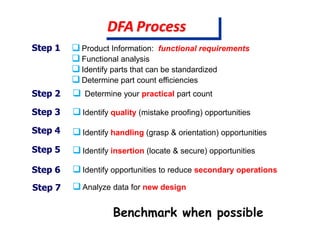

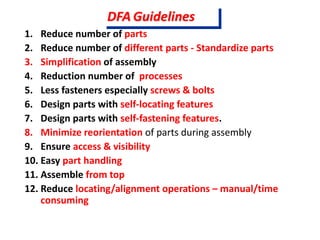

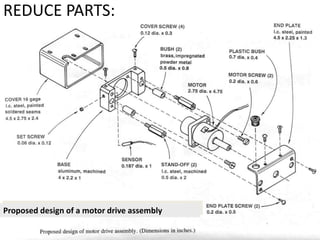

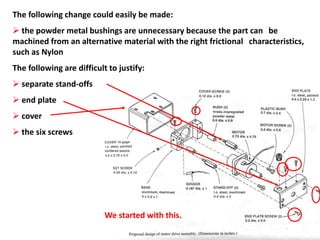

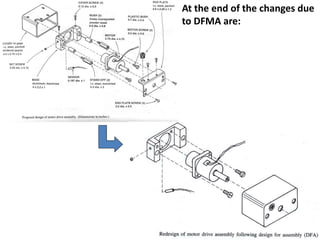

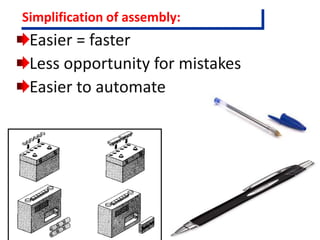

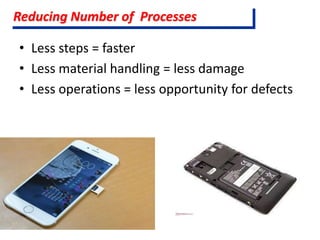

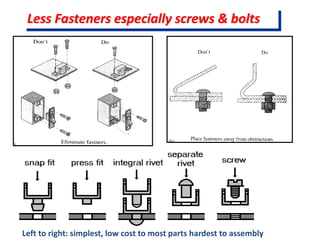

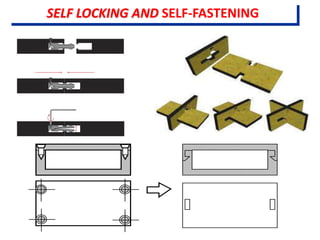

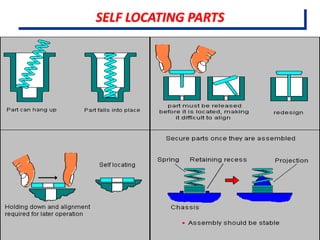

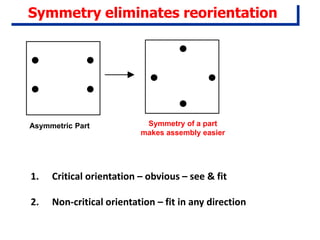

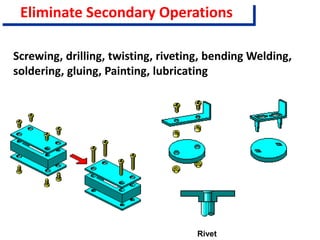

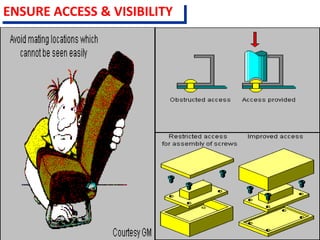

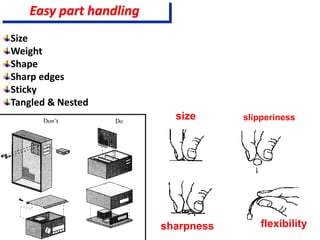

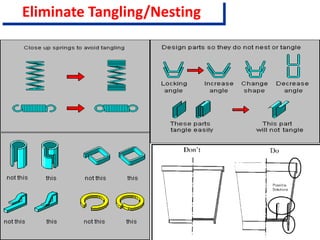

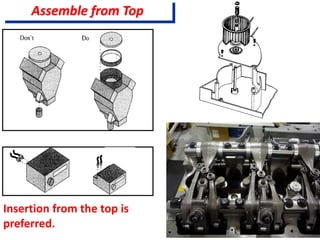

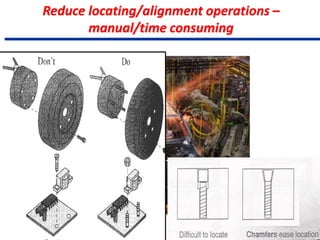

This document summarizes a seminar on design for manufacturing and assembly processes. It discusses how design for manufacturing (DFM) aims to minimize production costs and time to market while maintaining quality. DFM strategies include reducing part counts and selecting appropriate manufacturing methods. Design for assembly (DFA) specifically focuses on minimizing assembly costs by reducing assembly operations and making individual parts easier to assemble. The document provides guidelines for DFA, such as reducing part counts, standardizing parts, simplifying assembly, and designing self-locating and self-fastening parts.