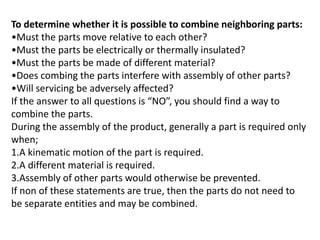

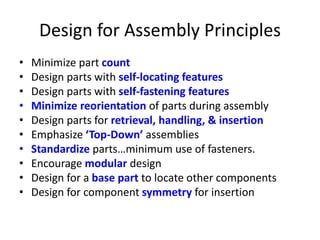

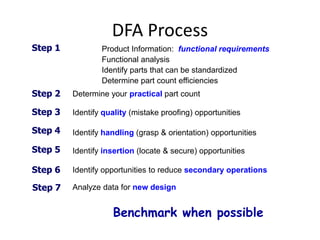

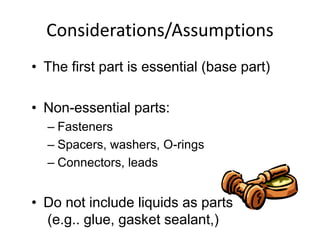

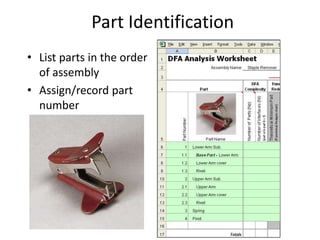

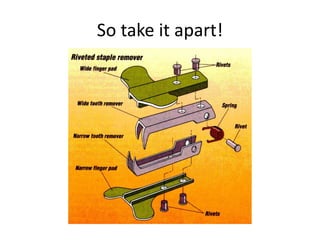

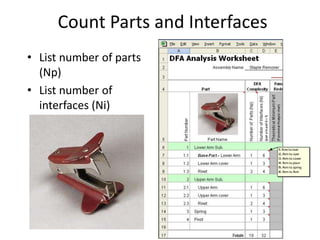

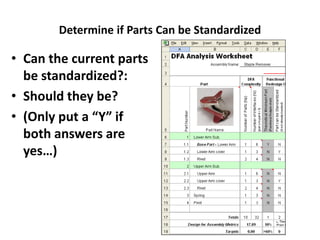

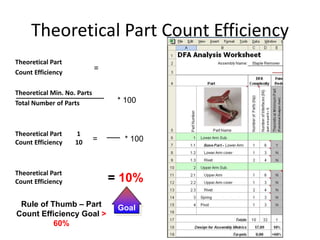

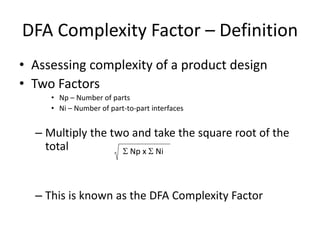

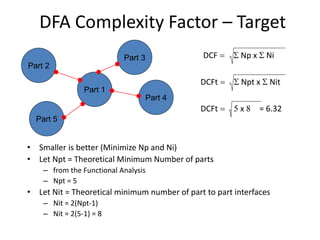

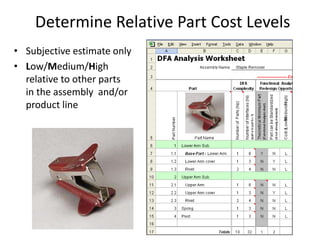

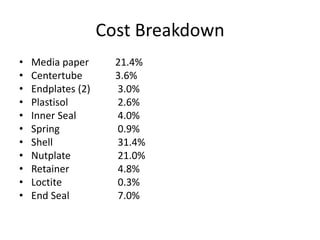

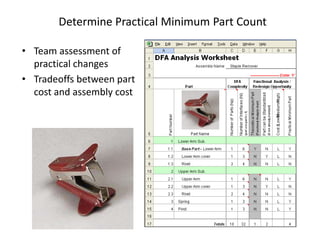

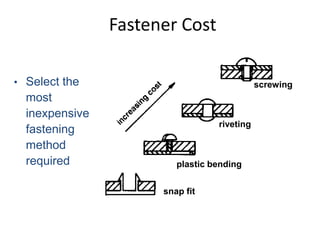

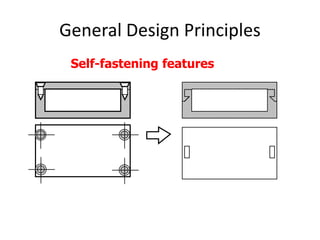

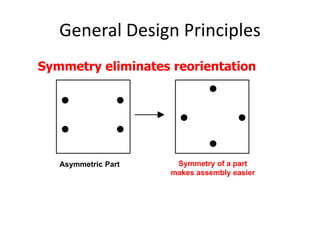

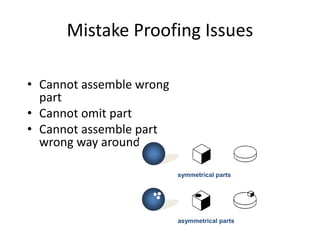

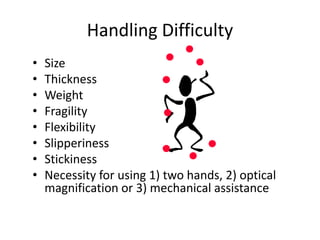

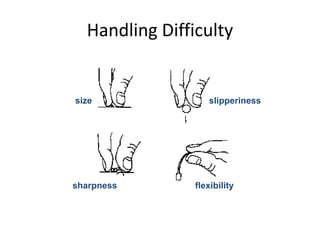

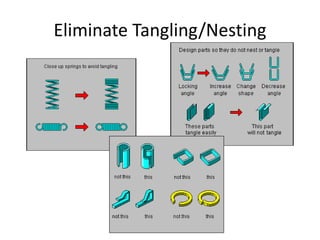

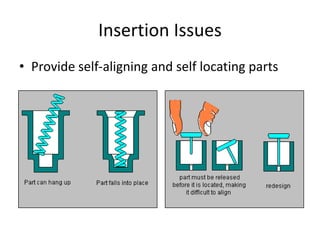

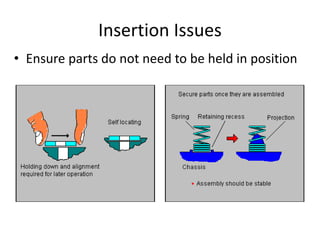

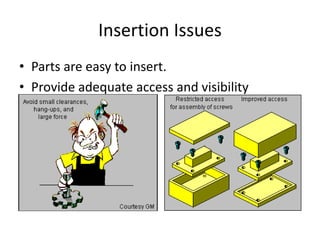

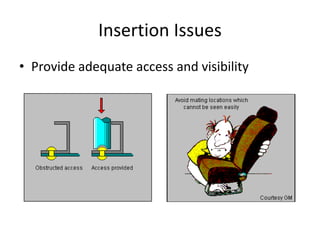

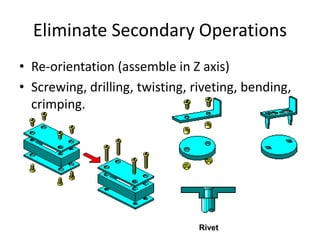

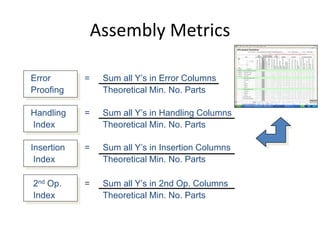

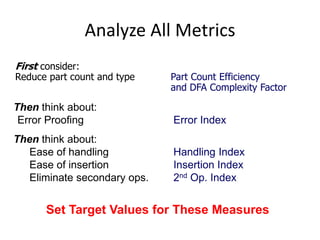

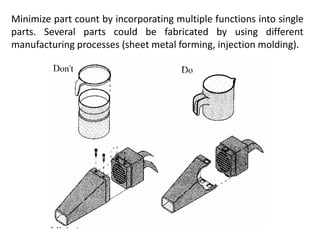

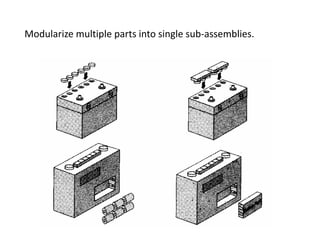

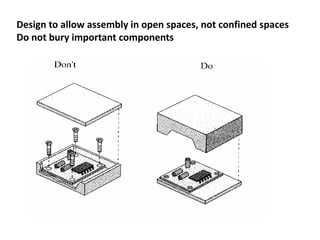

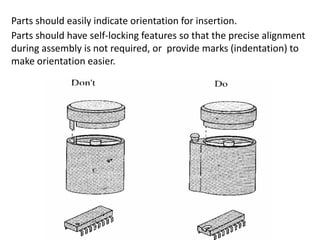

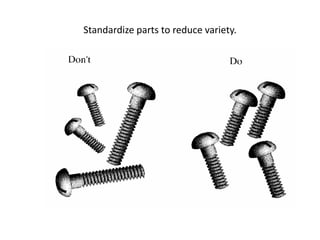

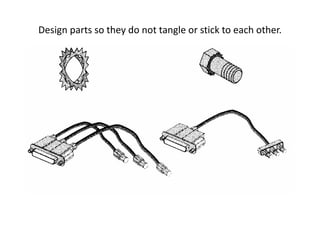

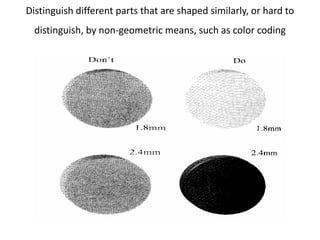

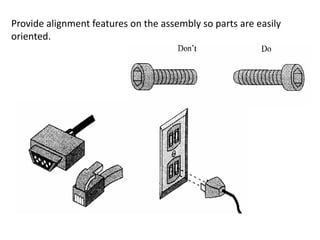

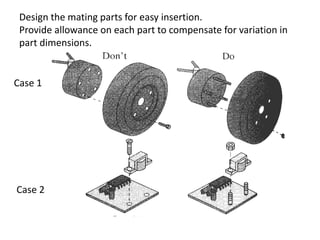

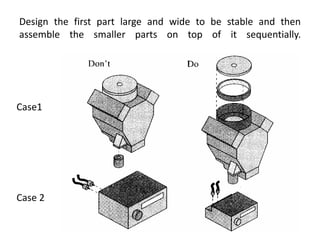

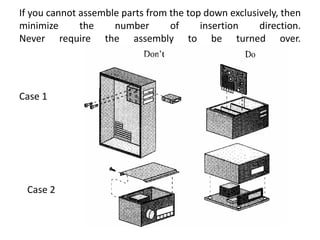

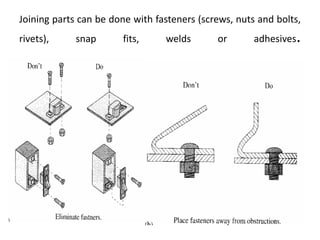

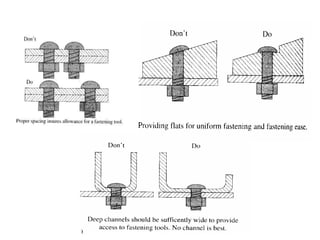

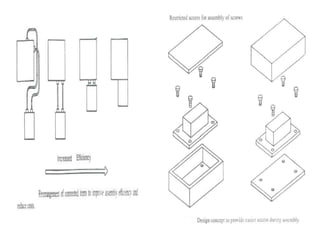

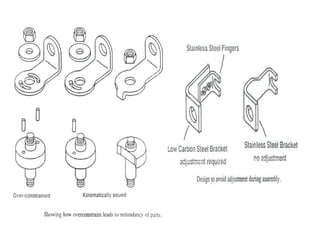

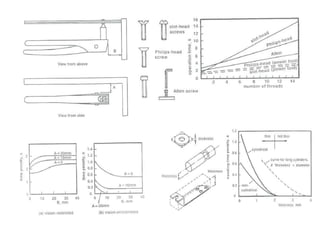

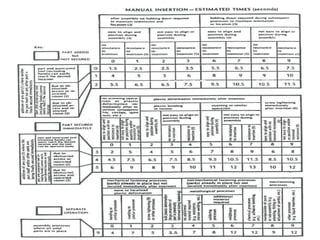

The document provides guidelines for designing products for manual assembly. It discusses minimizing part counts, using symmetry and self-locating features to guide insertion, avoiding nested parts, and designing for top-down assembly. The guidelines aim to reduce assembly time and costs by making products easy to handle, insert parts, and avoid secondary operations like holding parts in place.