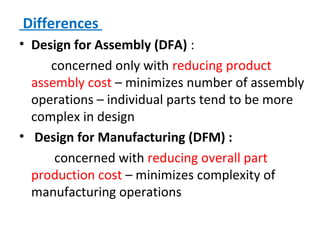

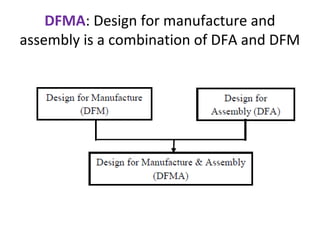

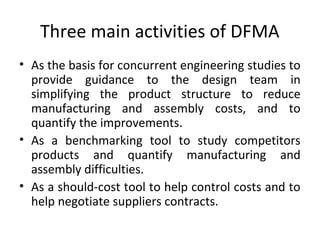

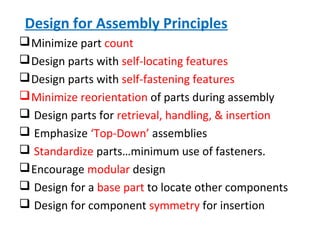

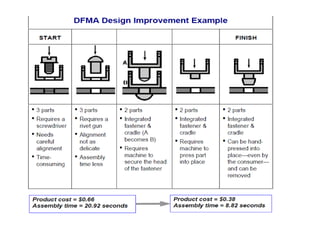

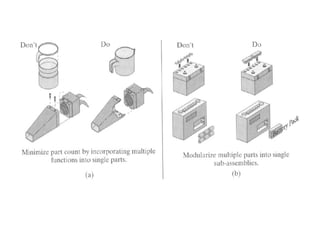

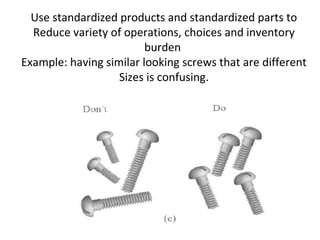

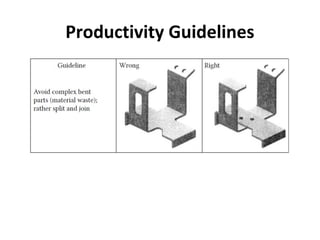

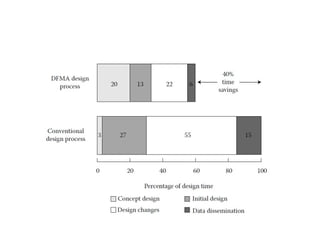

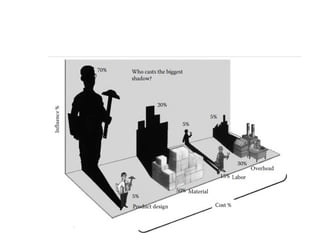

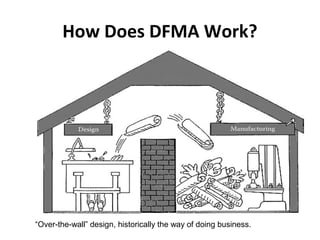

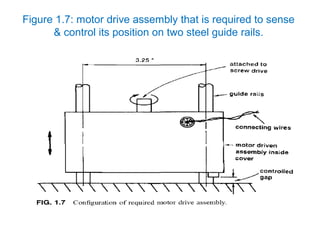

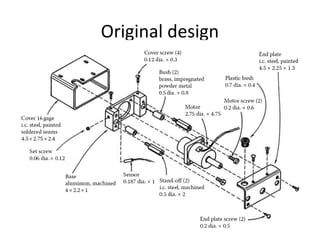

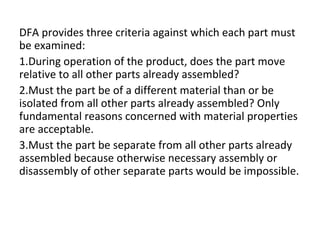

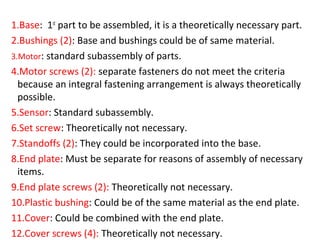

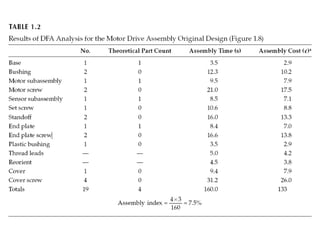

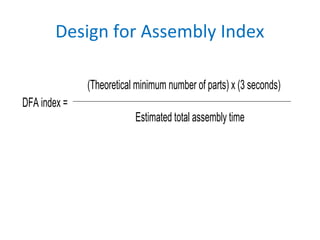

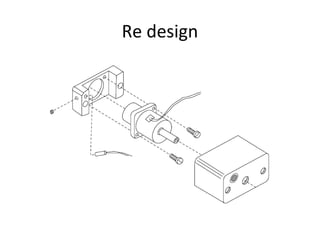

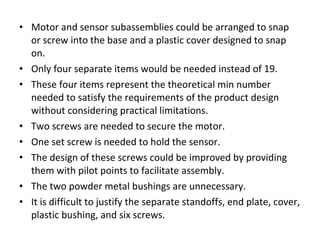

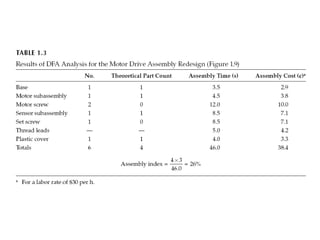

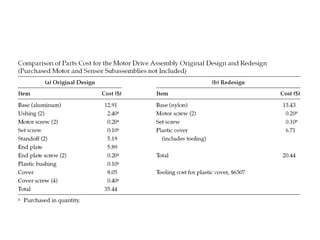

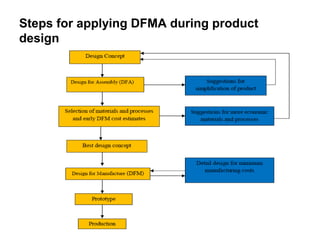

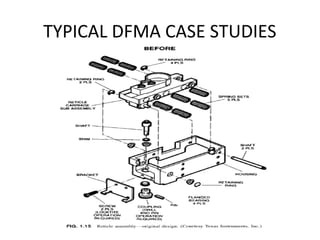

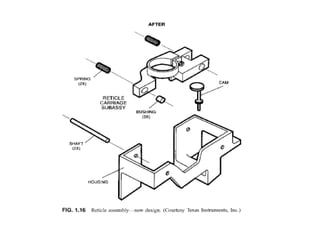

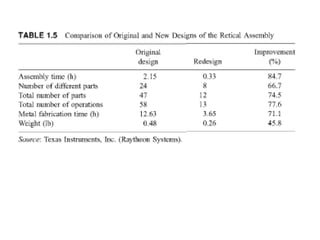

The document discusses design for manufacturing and assembly (DFMA). It covers the fundamentals of DFMA, including design for manufacture, design for assembly, and differences between the two. It also provides examples of applying DFMA principles and guidelines to redesign a motor drive assembly to reduce the number of parts from 19 to 4. Reasons for not implementing DFMA are listed, such as lack of time, low volume production, and refusal to use DFMA tools. Advantages of applying DFMA during design include reduced cost, time to market, and improved quality.