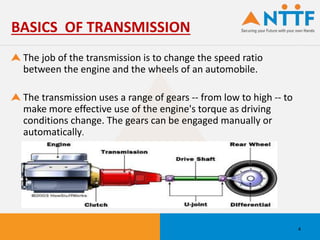

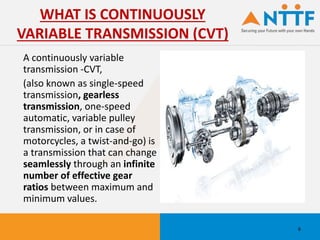

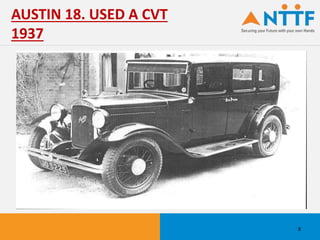

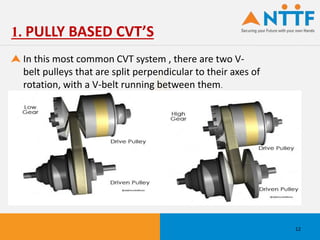

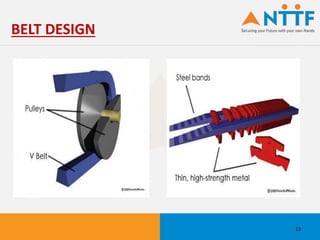

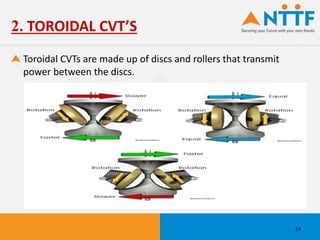

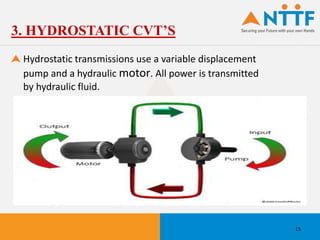

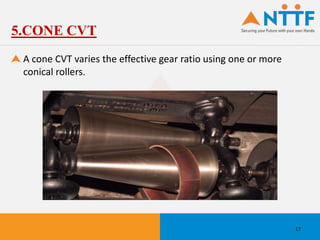

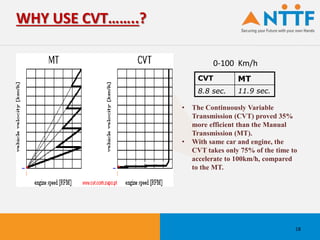

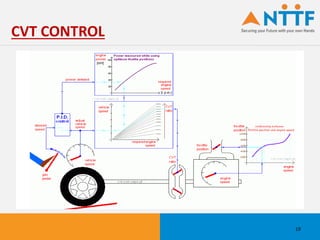

This document provides an overview of continuously variable transmissions (CVTs). It discusses the history of CVTs, including early sketches by Leonardo Da Vinci. It describes the main components and designs of CVTs, such as pulley-based, toroidal, and hydrostatic systems. The document outlines the advantages of CVTs, such as improved acceleration and fuel efficiency, as well as disadvantages like higher costs. It also discusses future applications of CVTs in electric vehicles and how the technology continues to develop.