This document provides an overview of automobile basics, including:

- A brief history of early automobile development from the 1860s to 1900s.

- Henry Ford's innovations like interchangeable parts and assembly line production that reduced costs to $200 per vehicle.

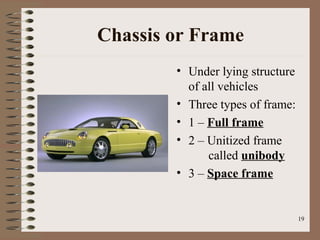

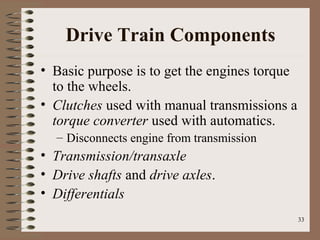

- The four basic parts of vehicles: engine, chassis, drive train, and body.

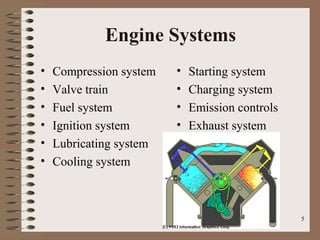

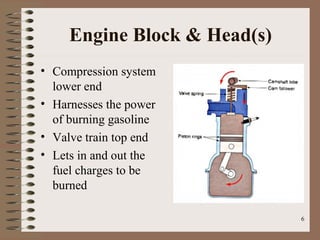

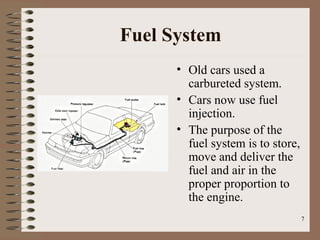

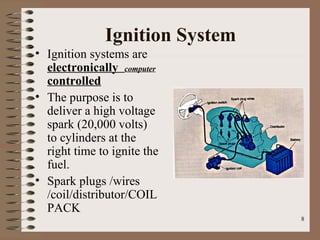

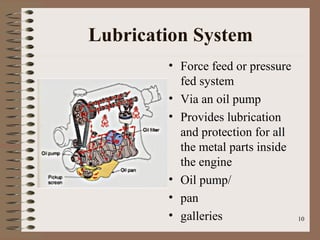

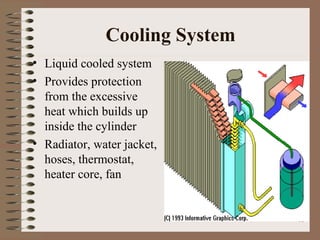

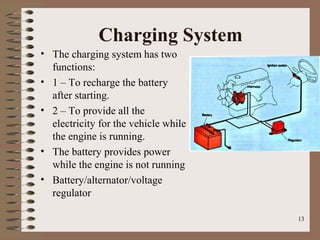

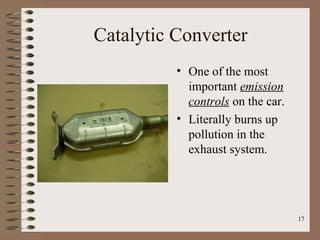

- Descriptions of key engine systems like fuel, ignition, cooling, and emission controls.

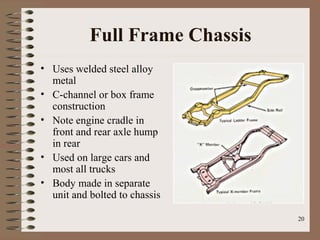

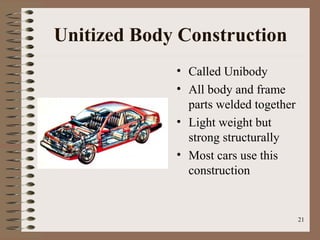

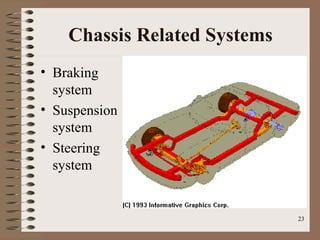

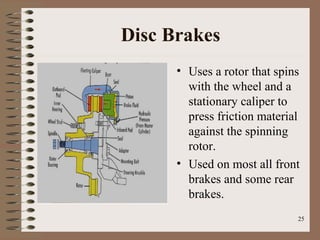

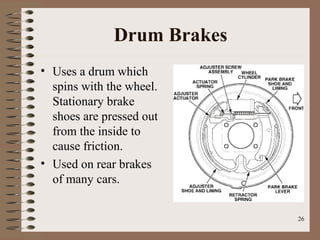

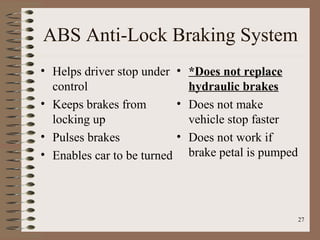

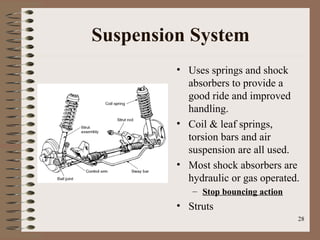

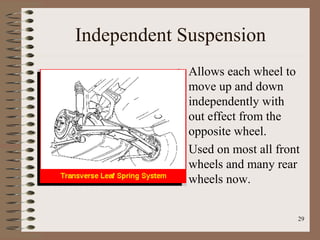

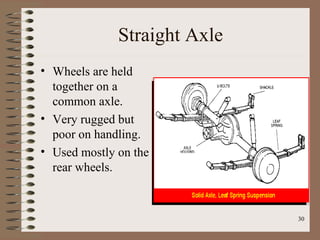

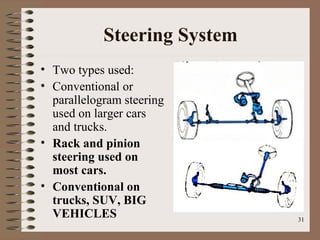

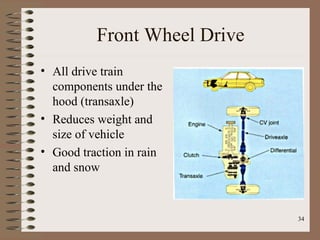

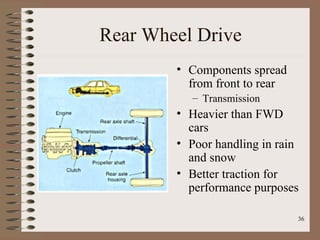

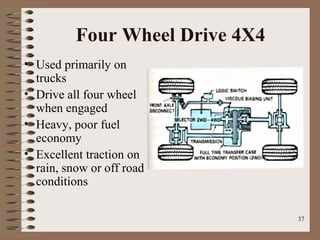

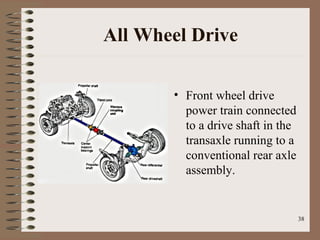

- Different types of vehicle frames, bodies, drivetrains, braking, suspension, and steering systems.