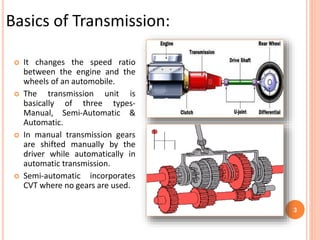

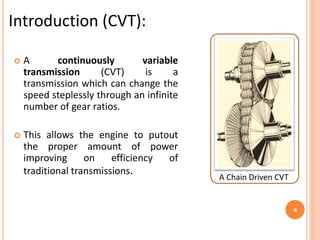

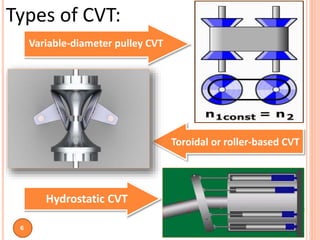

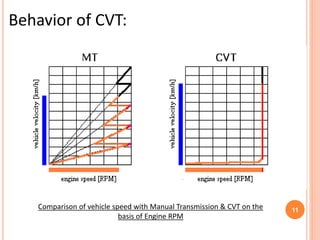

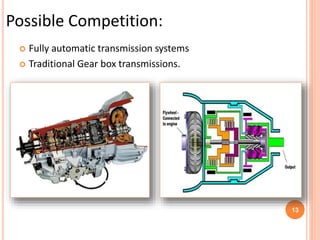

The document is a presentation on continuously variable transmission (CVT), addressing its basics, types, history, and applications in automobiles. It highlights advantages such as improved fuel economy and better acceleration, alongside drawbacks like higher costs and complexity. The conclusion suggests the potential for CVT technology to evolve with further research and funding.