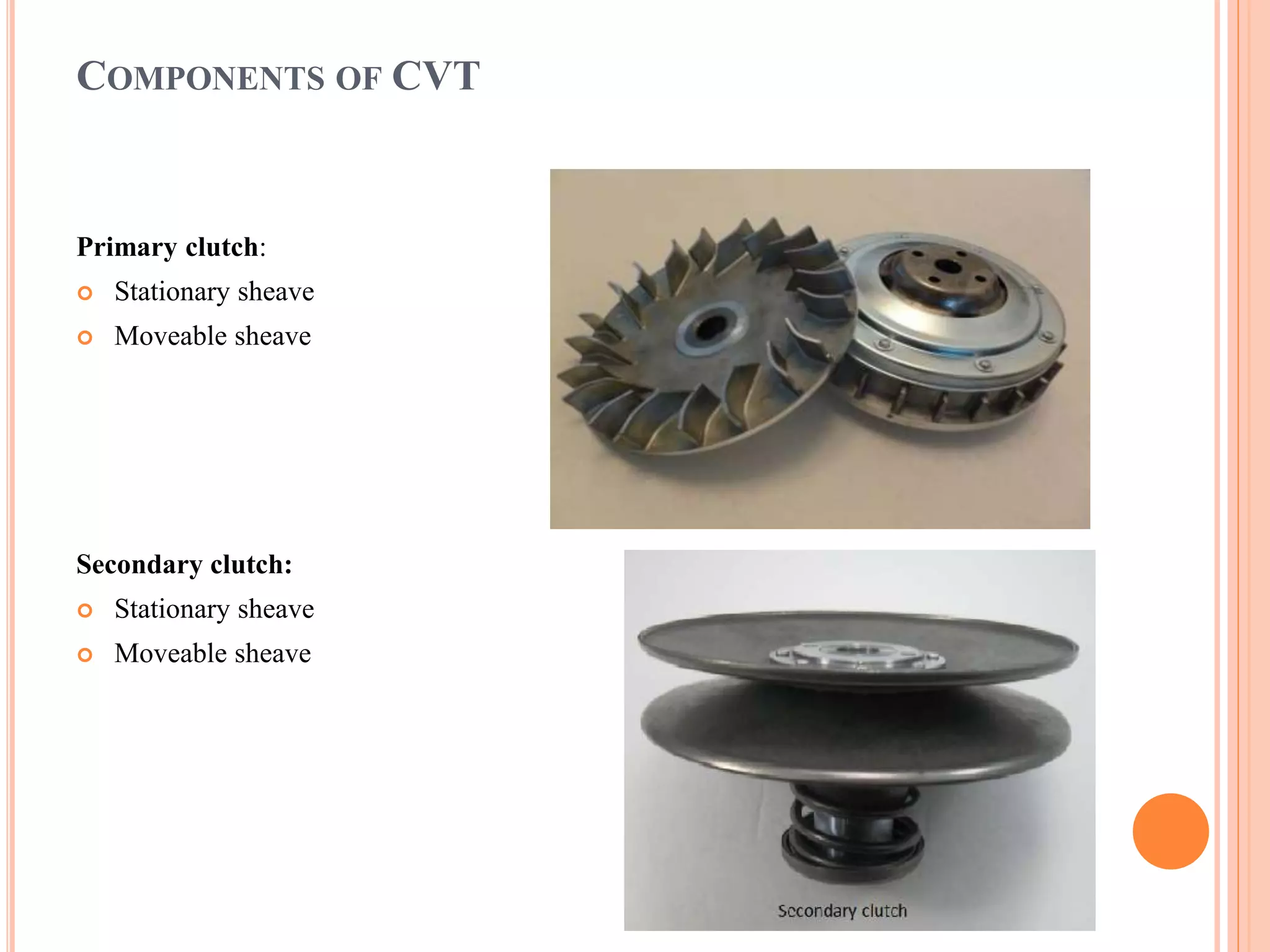

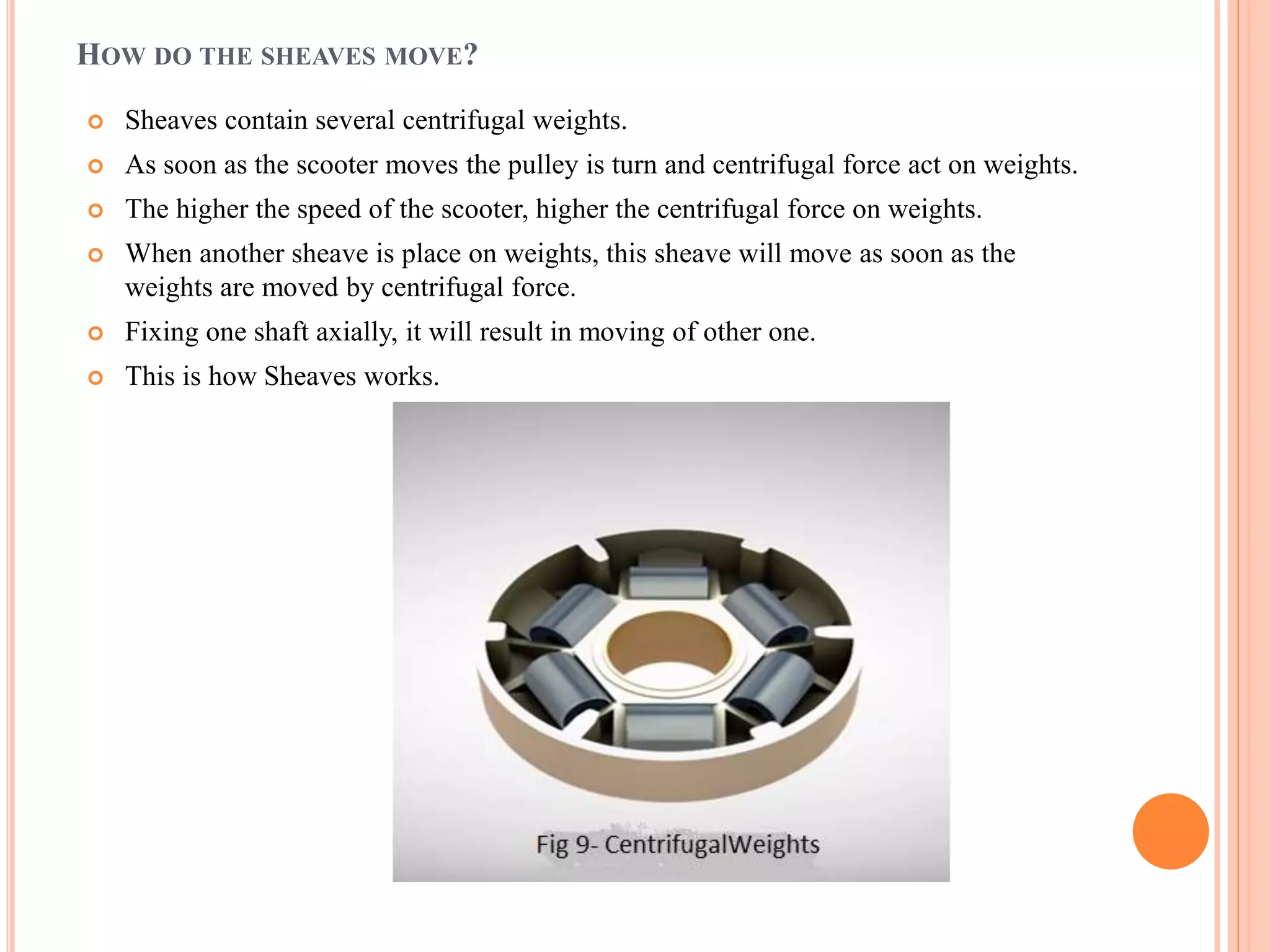

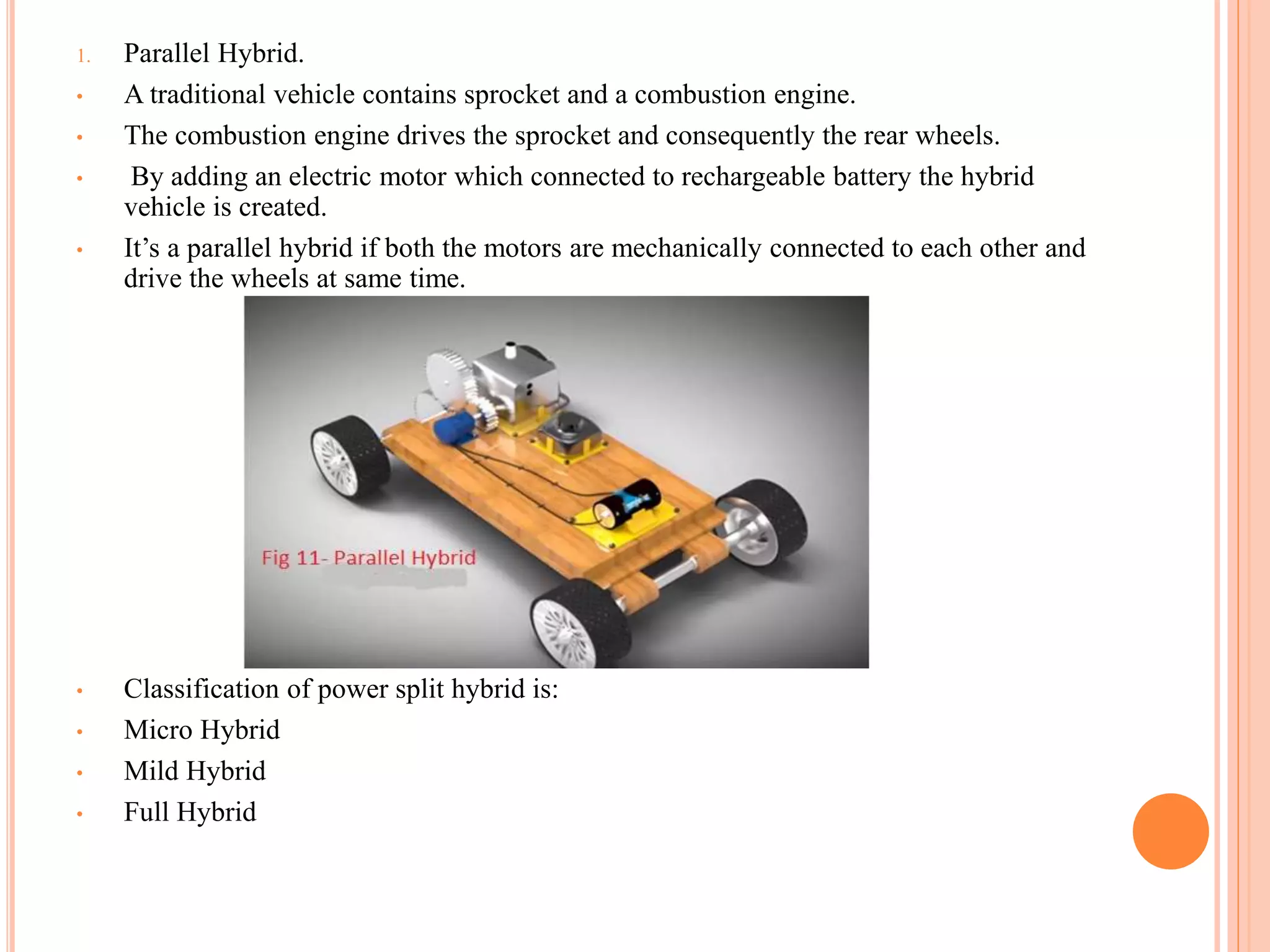

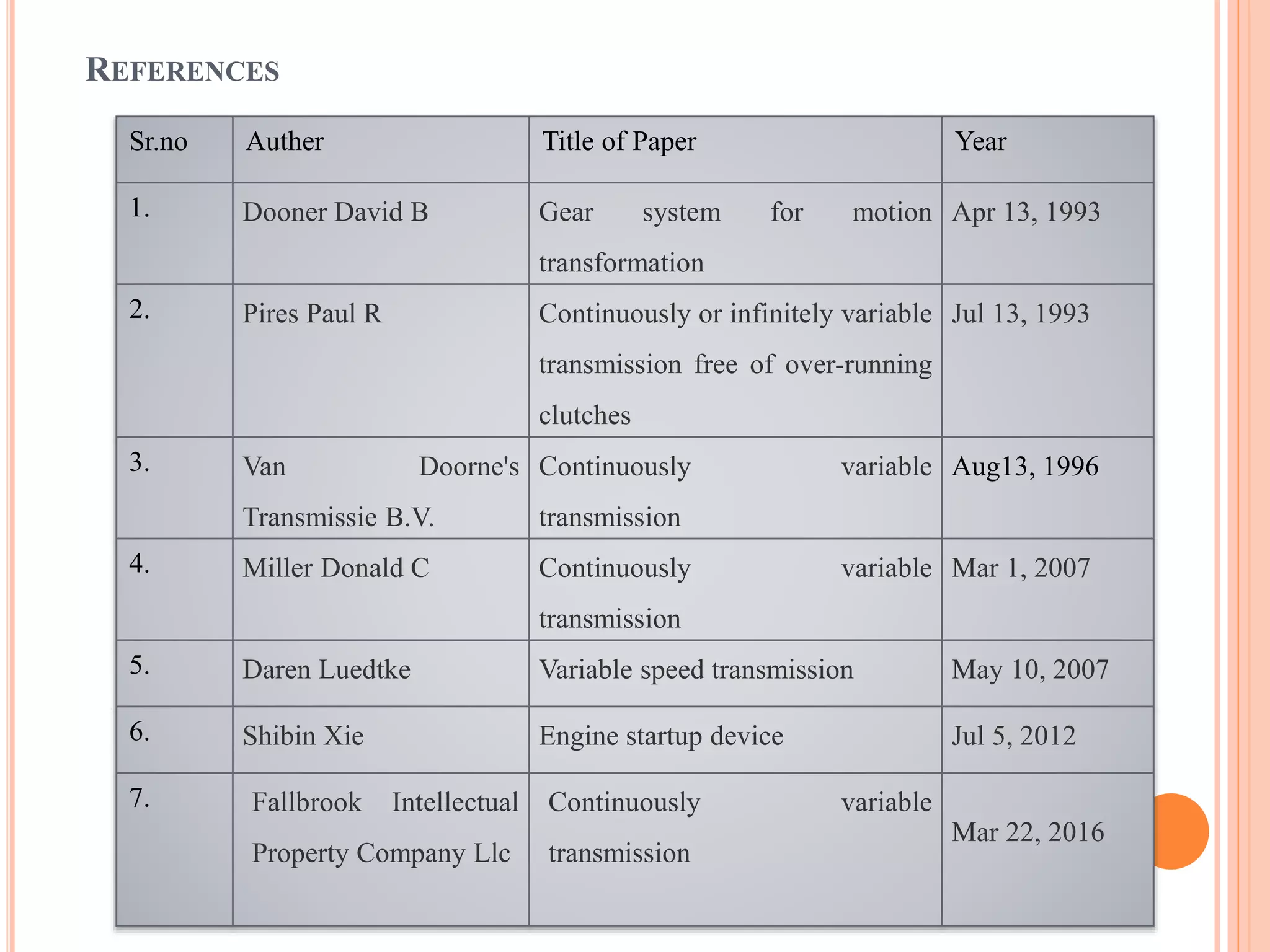

This document provides an overview of continuously variable transmissions (CVTs) and hybrid electric vehicles (HEVs). It discusses the history and development of CVTs, including early inventions. The key components of CVTs are described, including the primary and secondary clutches and different types of belts. The document explains how CVTs work by varying the gear ratio through movement of the sheaves. Research and applications of CVTs are expanding, and they are beginning to be used more widely in vehicles. Hybrid vehicles combine an internal combustion engine with electric motors and batteries, and can have parallel or series configurations. CVTs may be beneficial for improving fuel efficiency in vehicles.