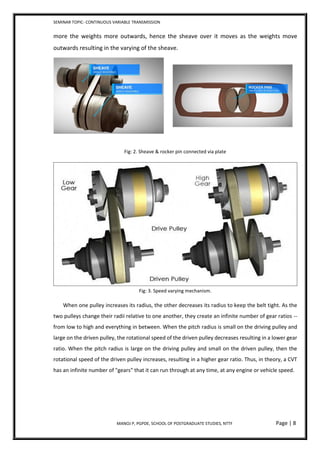

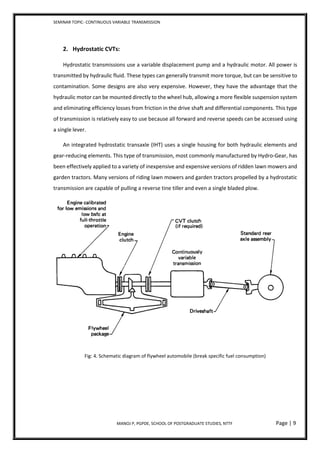

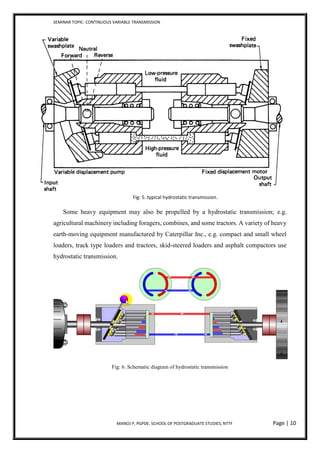

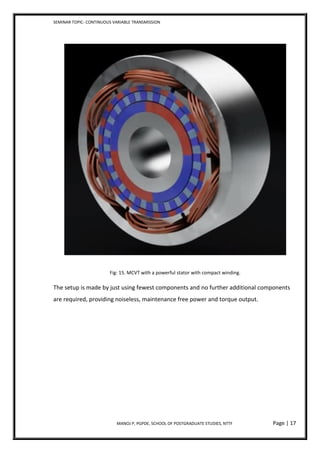

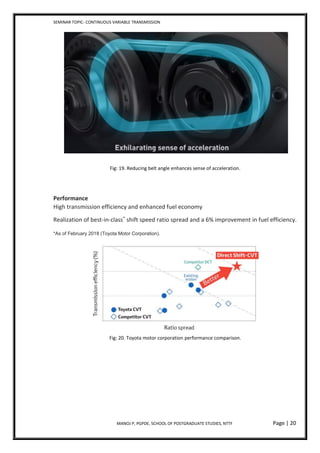

The seminar report by Manoj P focuses on continuously variable transmission (CVT), which allows for an infinite range of gear ratios, enhancing engine performance and fuel efficiency compared to traditional manual transmissions. It discusses various types of CVTs, including variable diameter pulley, hydrostatic, and frictional transmissions, while also evaluating their advantages and disadvantages. The report highlights recent advancements in CVT technology and their applications in modern vehicles, particularly hybrid models.