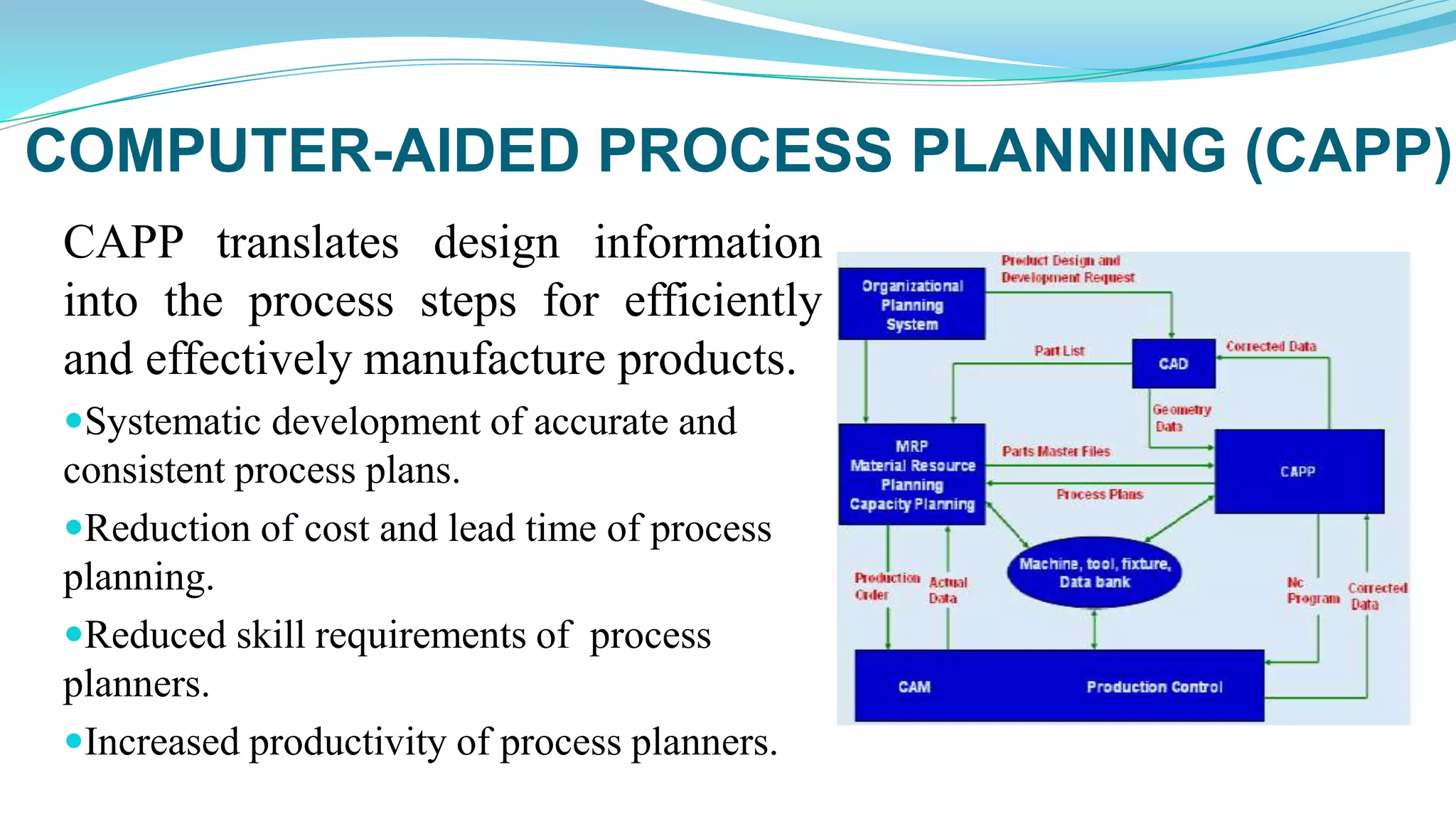

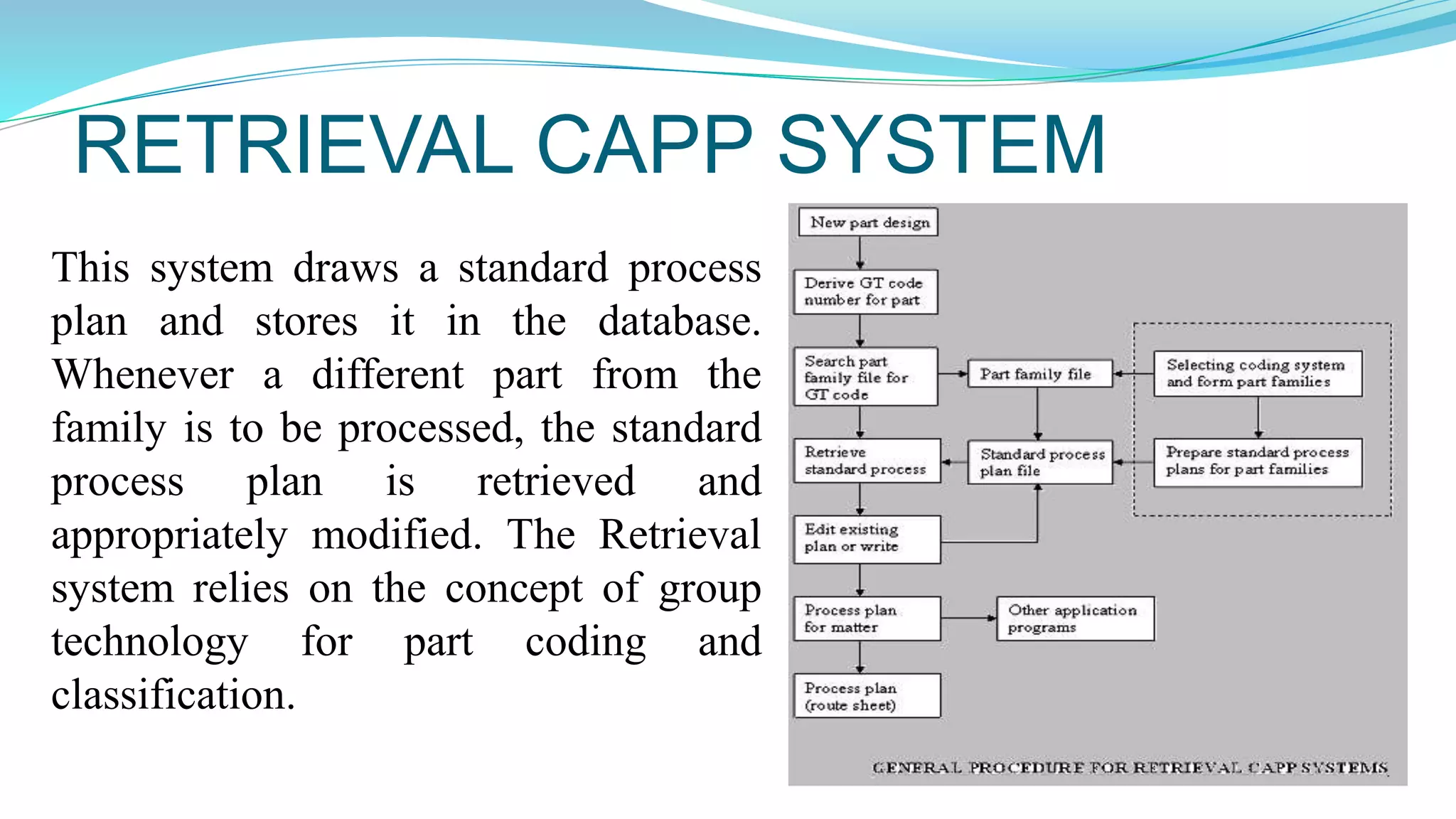

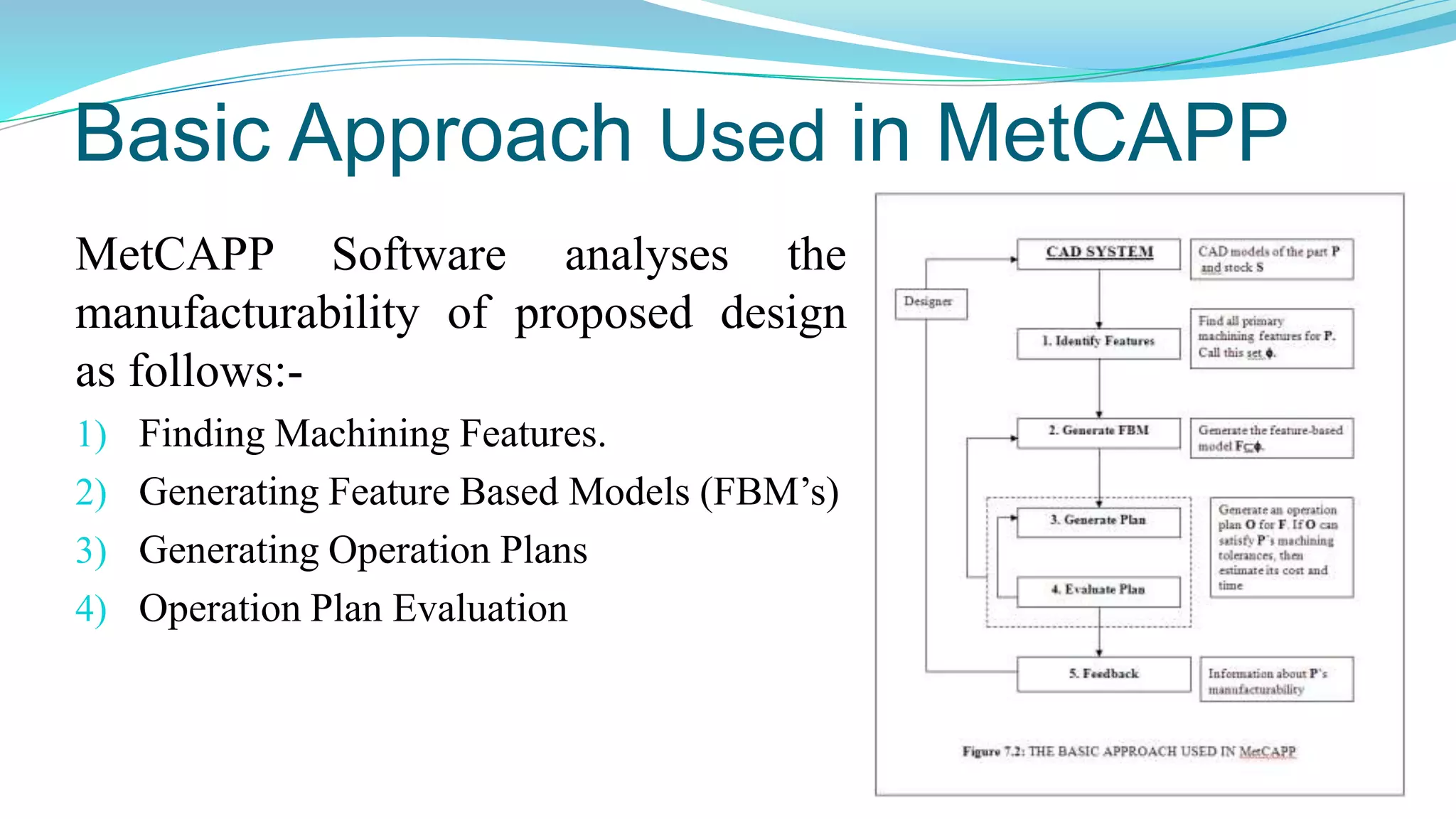

The seminar presentation discusses computer-aided process planning (CAPP) and its significance in modern manufacturing, particularly through the Metcapp software, which translates design information into efficient manufacturing processes. Metcapp enhances productivity and reduces costs by automating feature recognition and generating operation plans, while also offering insights into different CAPP systems. Ultimately, the presentation emphasizes that effective use of CAPP can provide manufacturers with a competitive advantage.