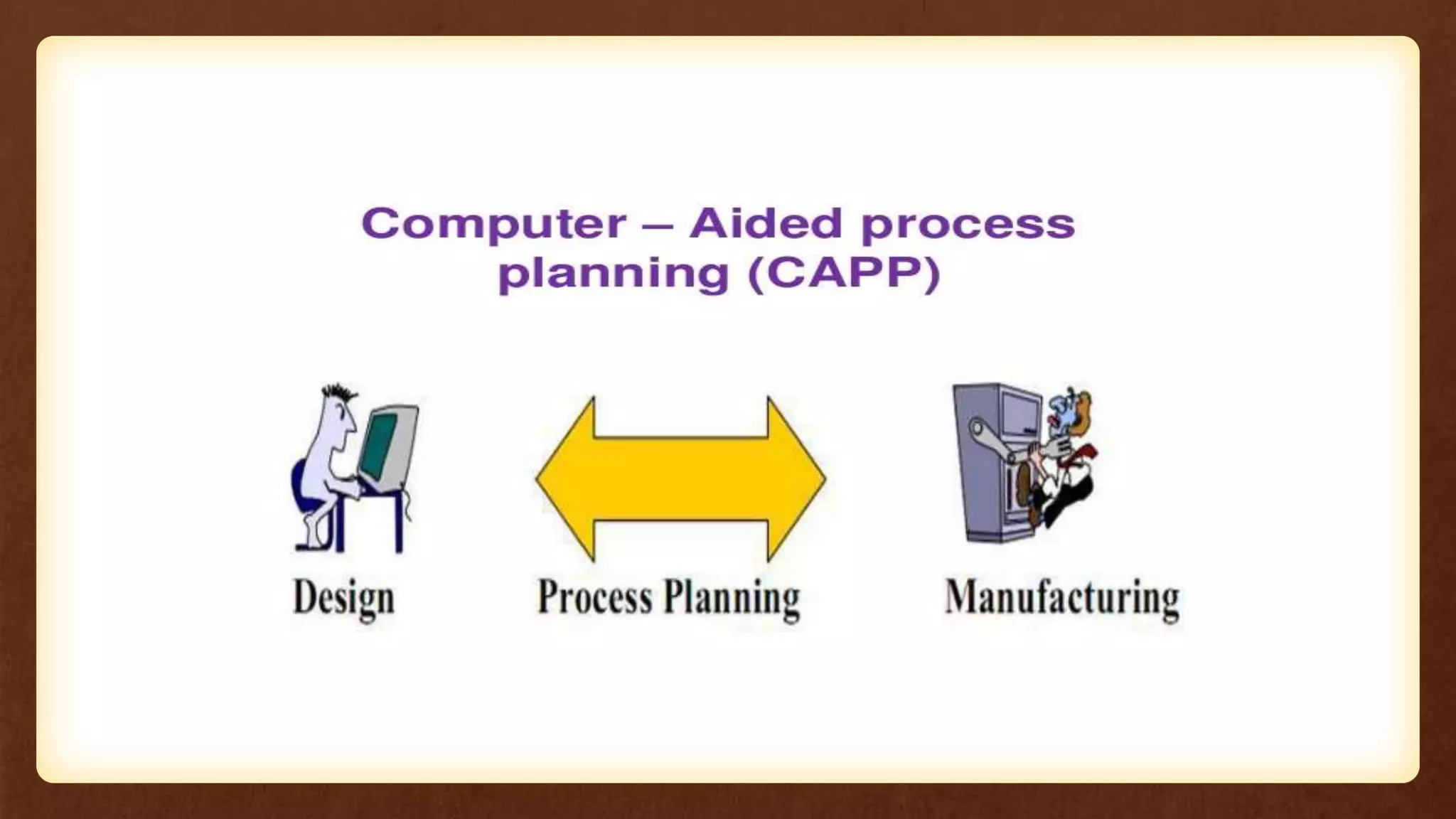

Computer Aided Process Planning (CAPP) is used to develop manufacturing plans based on cost, time, availability and other factors. CAPP provides instructions for producing designed parts and links CAD to CAM. There are two main types of CAPP systems: variant systems use standard plans while generative systems automatically generate plans. CAPP determines the instructions and parameters needed to manufacture a part.