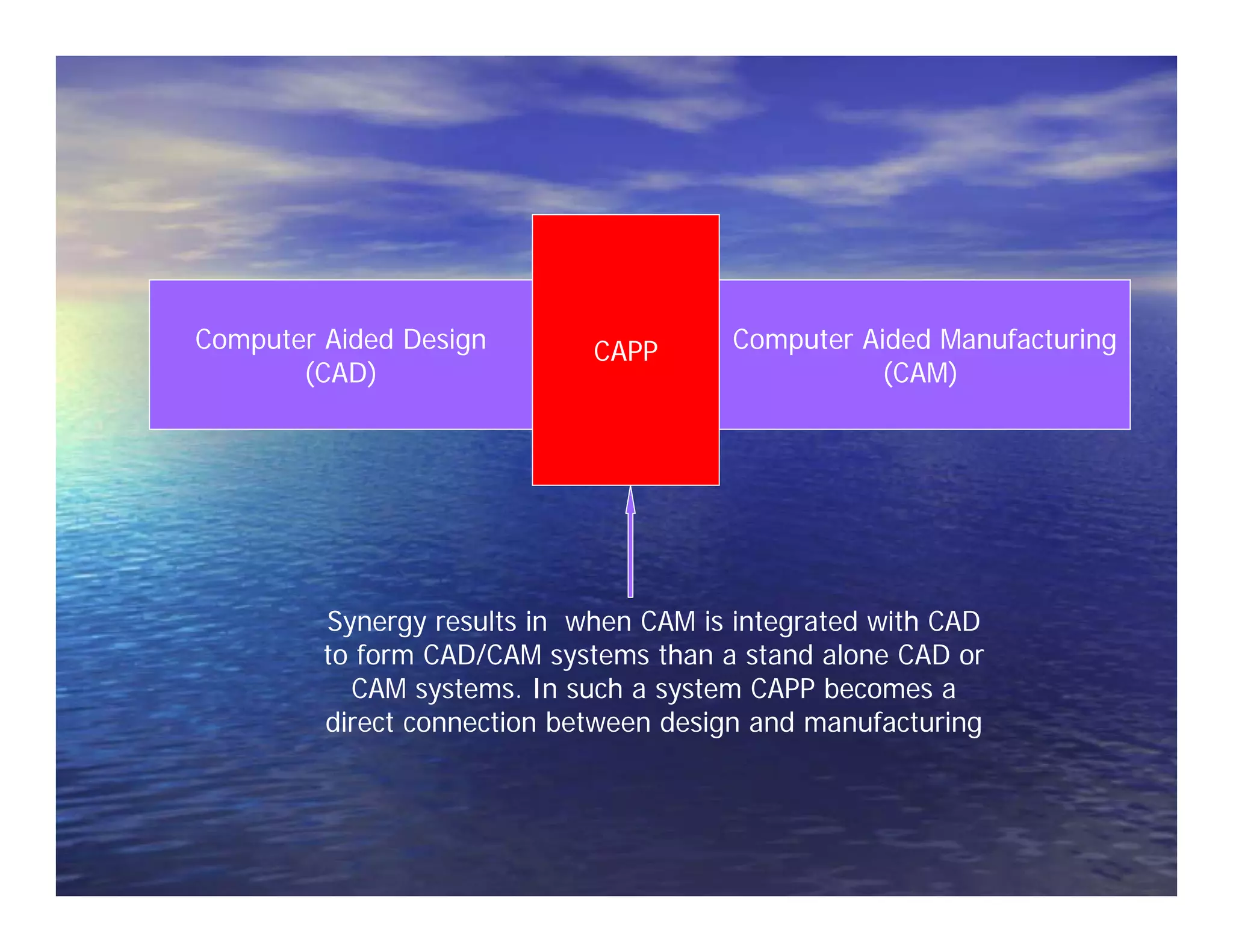

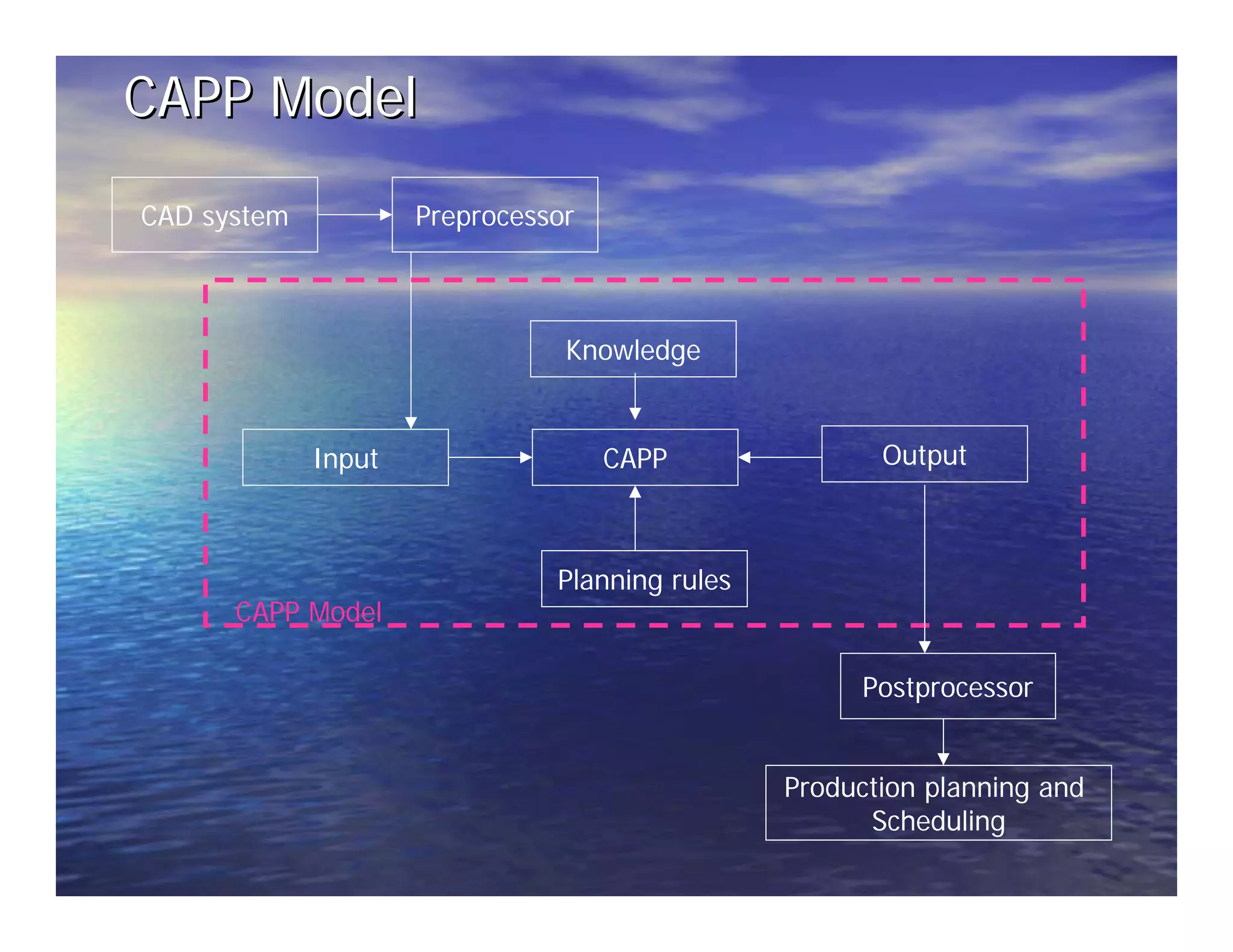

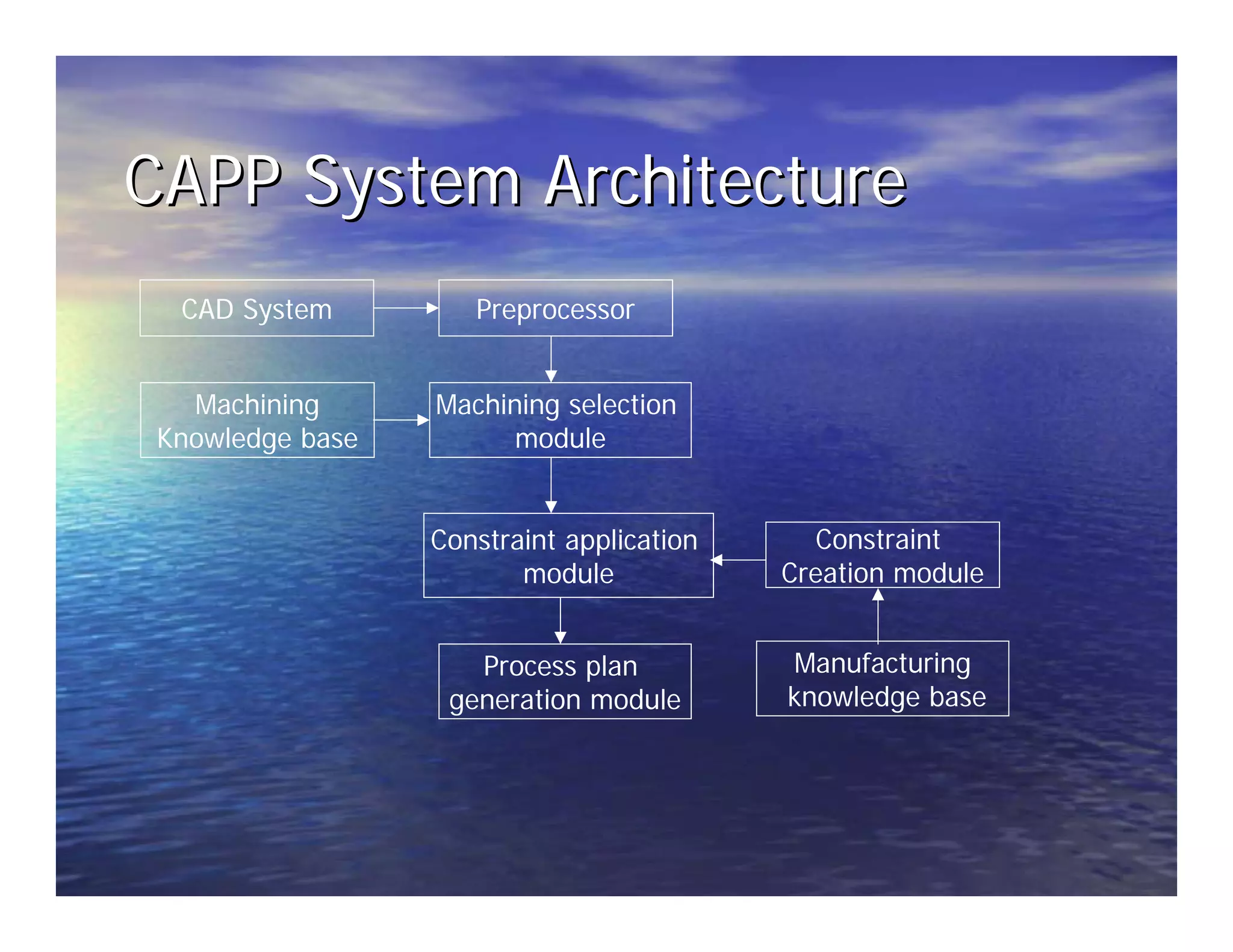

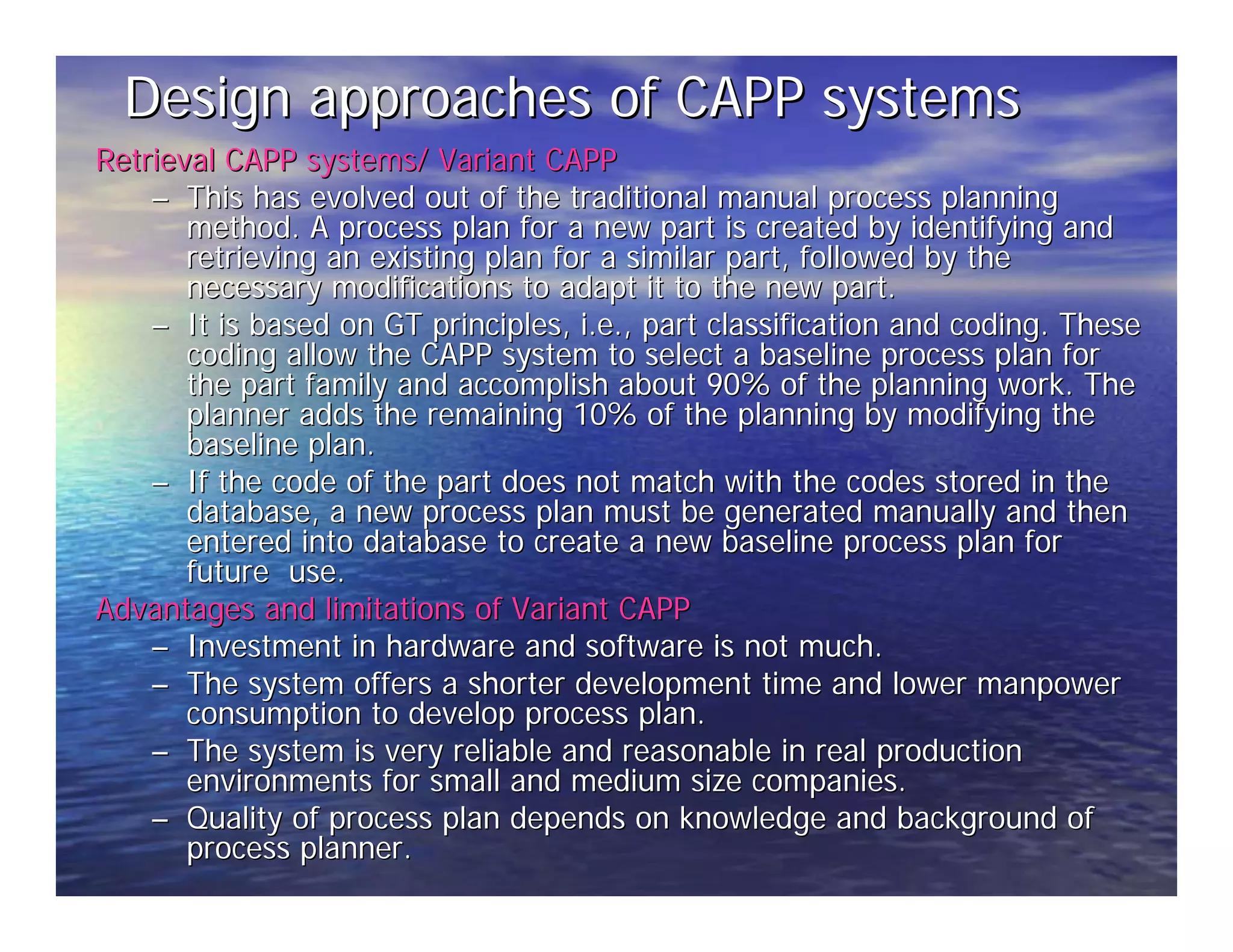

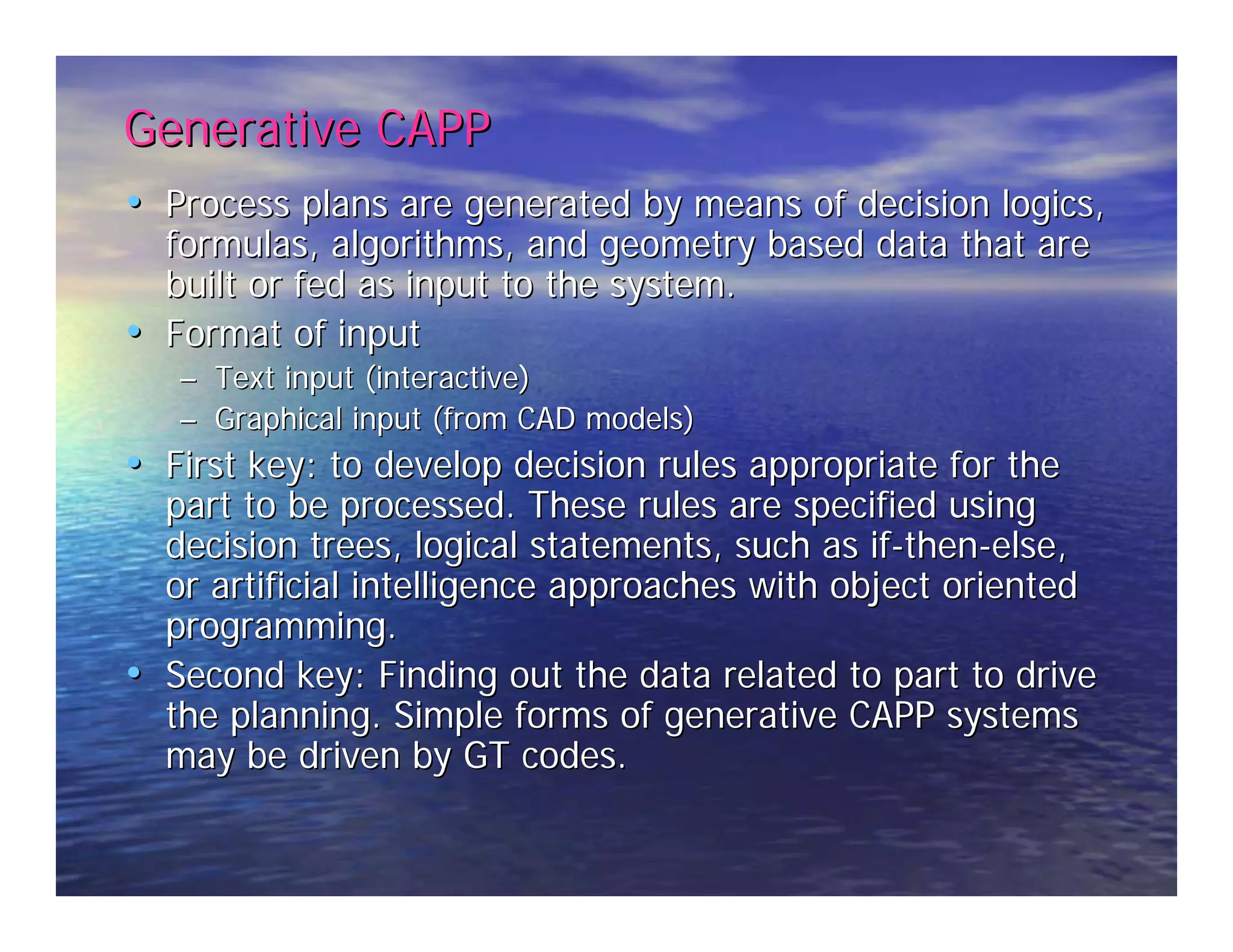

This document discusses Computer Aided Process Planning (CAPP). CAPP systems automate the process of generating route sheets that list the sequence of operations required to manufacture a product. This helps standardize plans and reduce inconsistencies compared to manual process planning. CAPP integrates with CAD and CAM systems to facilitate the connection between design and manufacturing. There are two main types of CAPP systems - retrieval CAPP systems that modify existing plans, and generative CAPP systems that automatically generate new plans based on part data and decision rules.