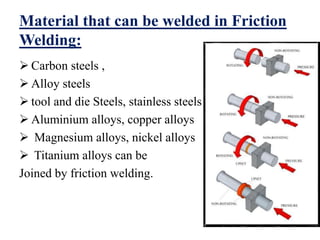

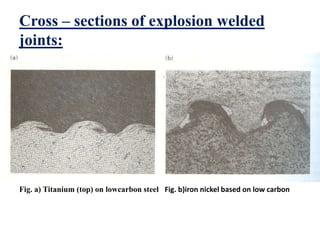

The document provides an overview of friction and explosion welding processes, detailing the principles, advantages, and disadvantages of each method. Friction welding involves joining materials through high-speed rotation and axial pressure, suitable for various metals but limited to small parts and flat shapes. Explosion welding enables the bonding of dissimilar metals via controlled detonation, offering unique applications but requiring extensive knowledge of explosives for safe execution.