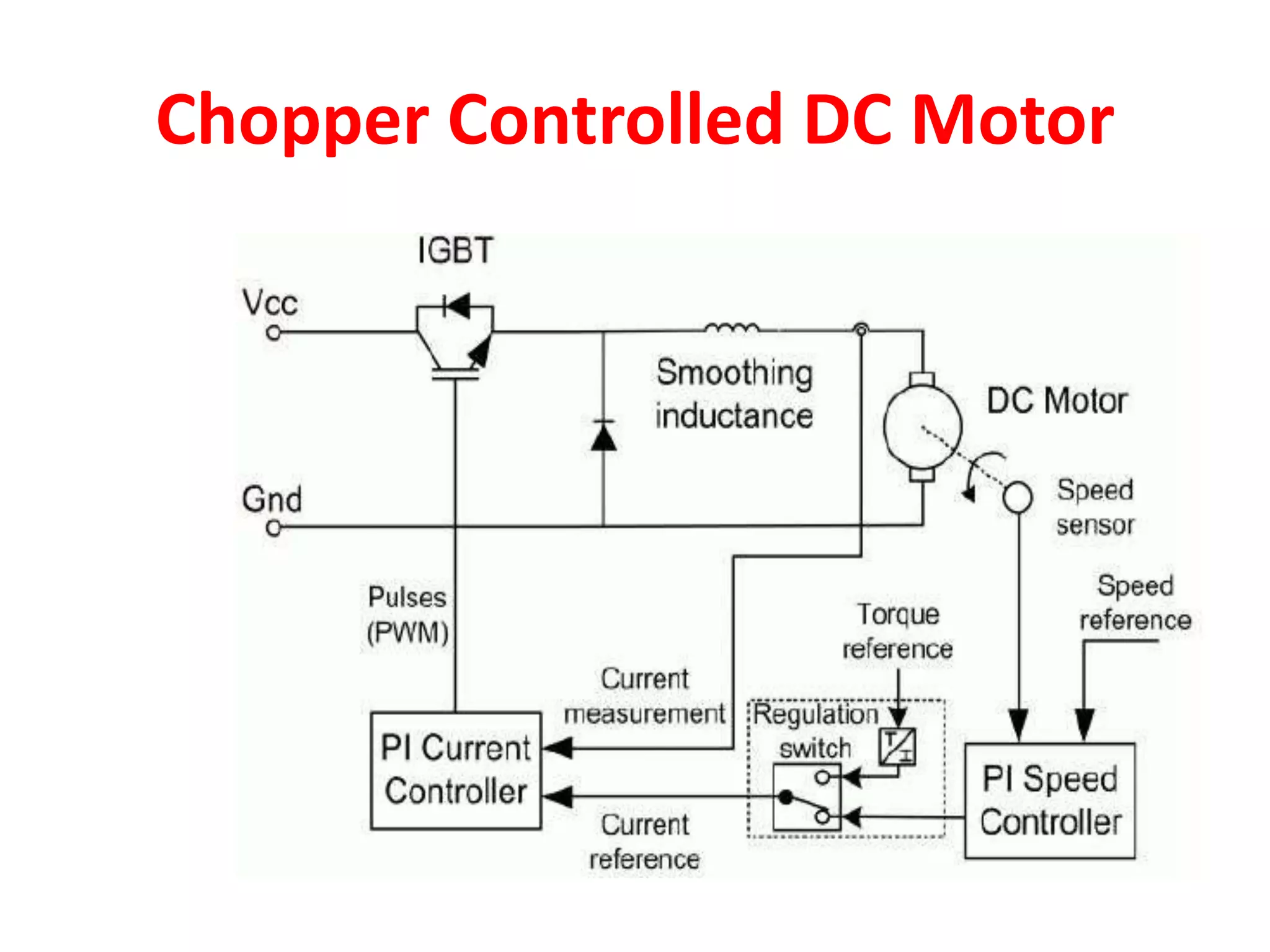

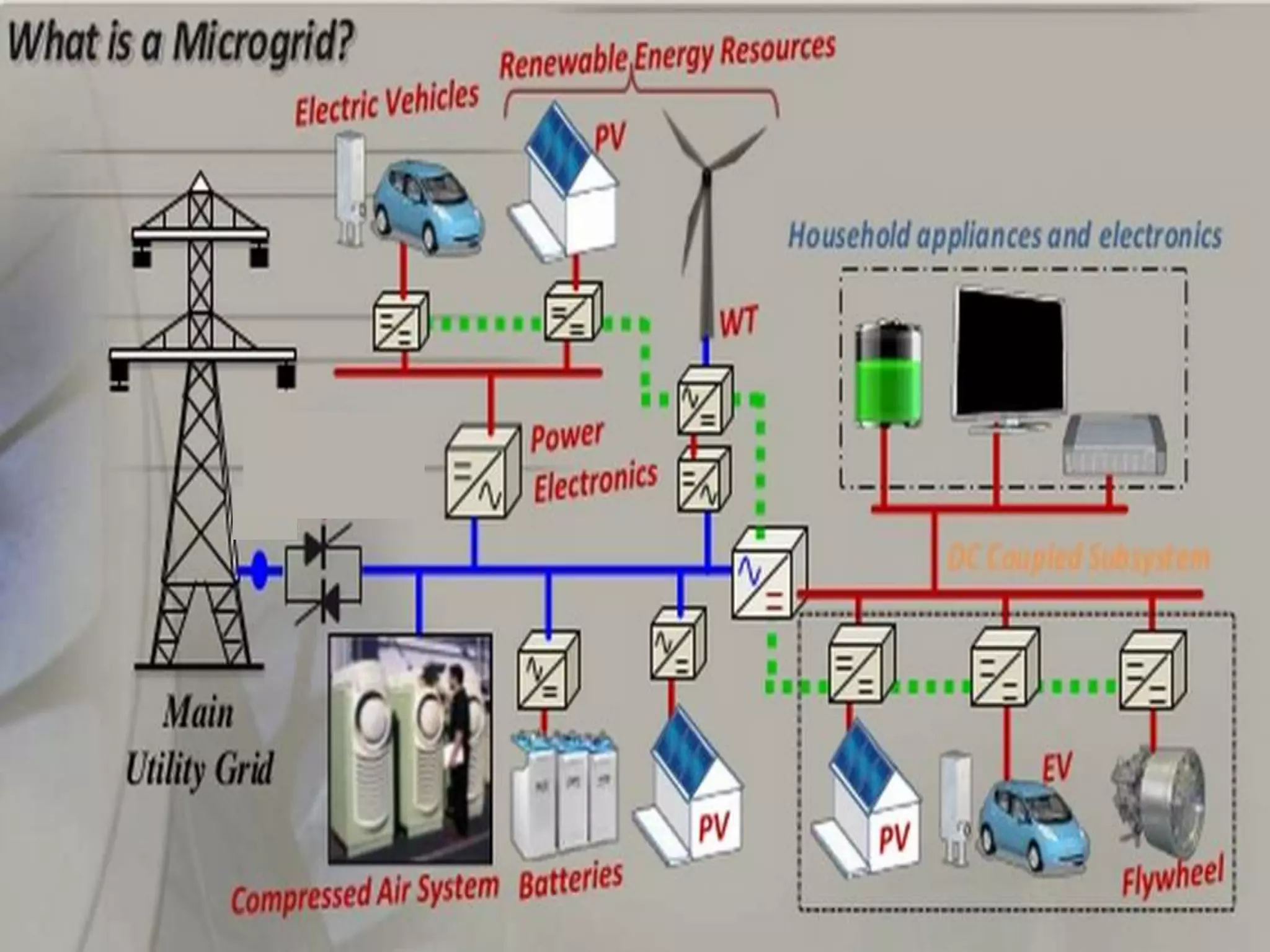

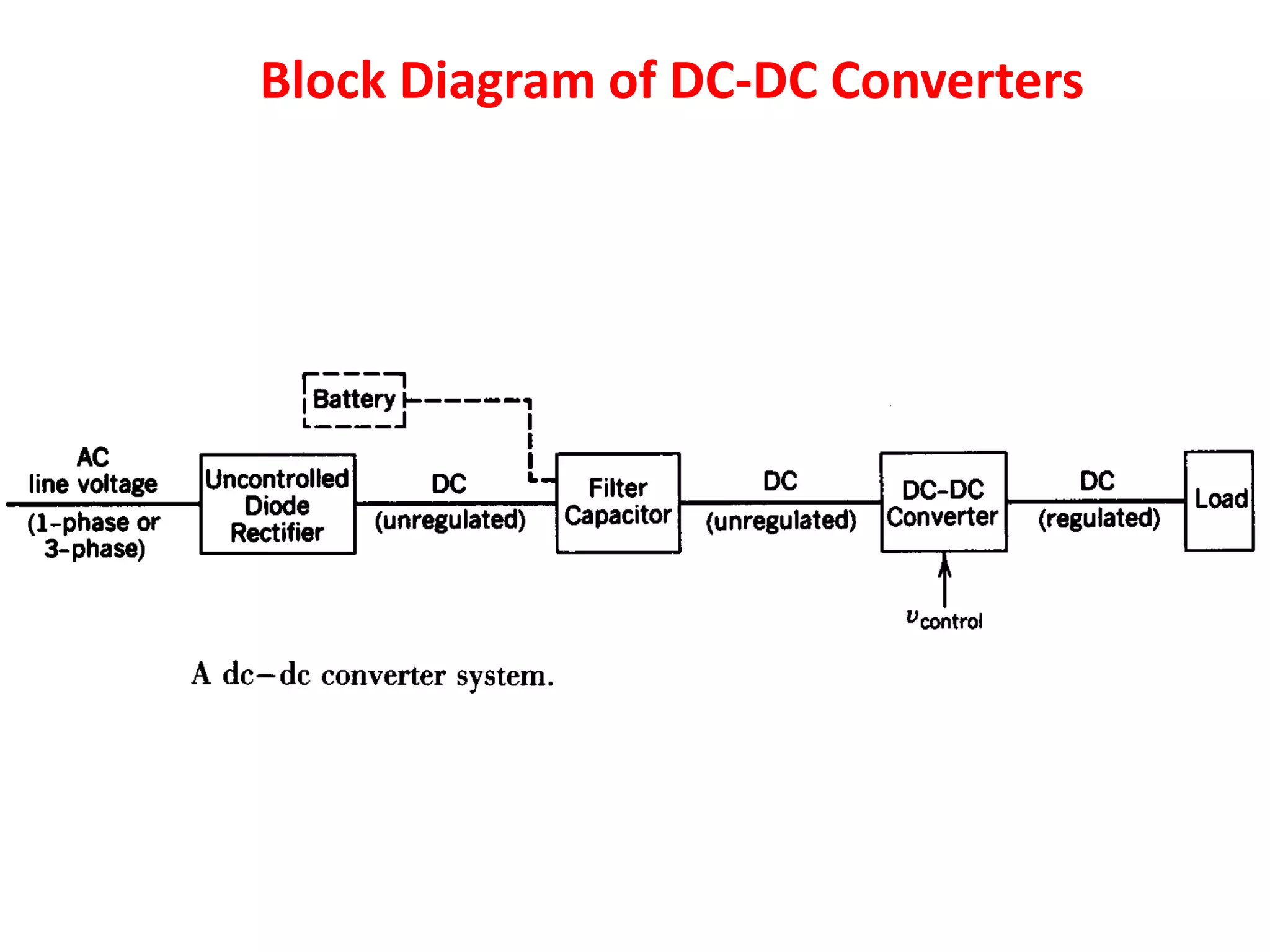

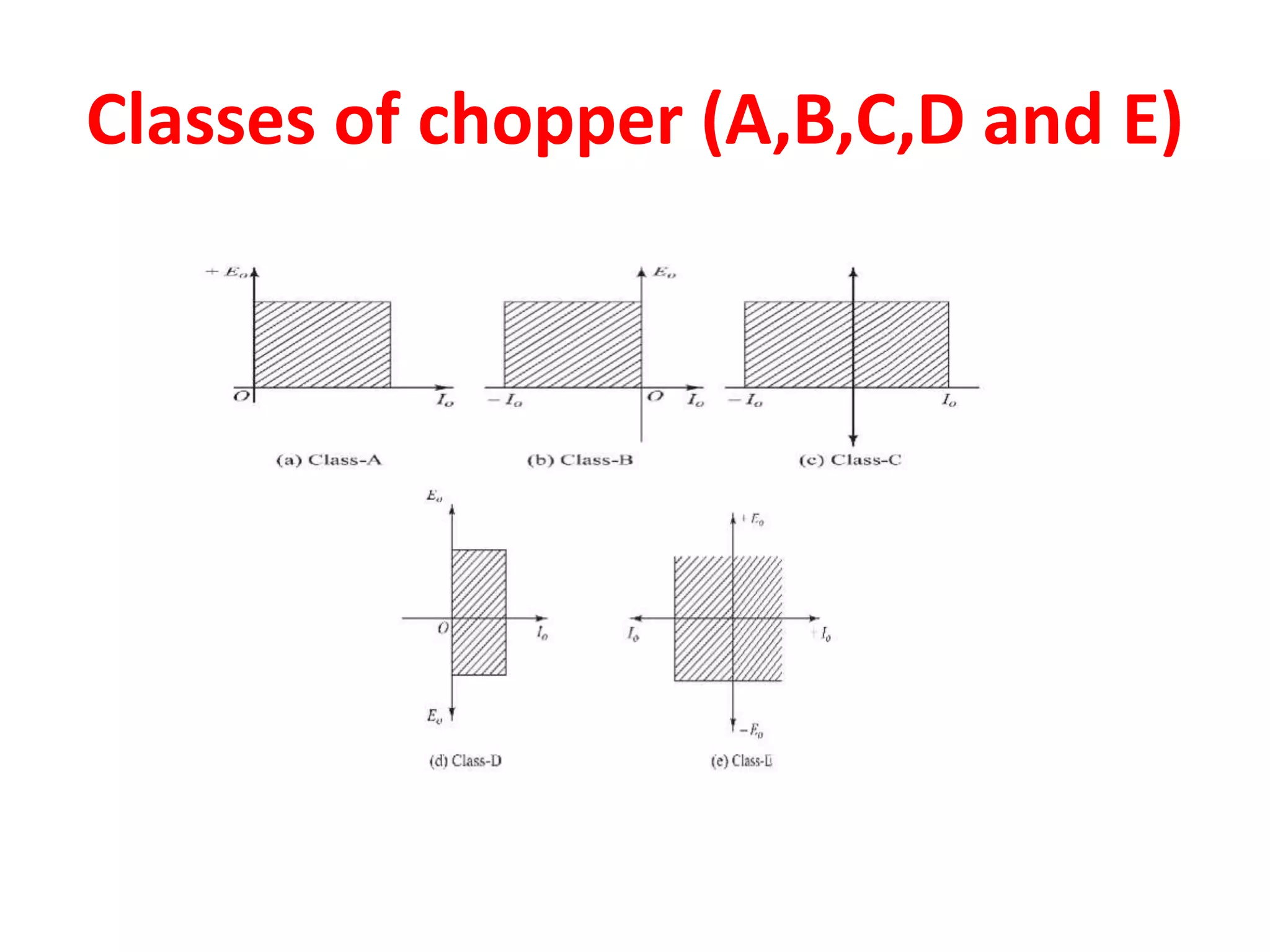

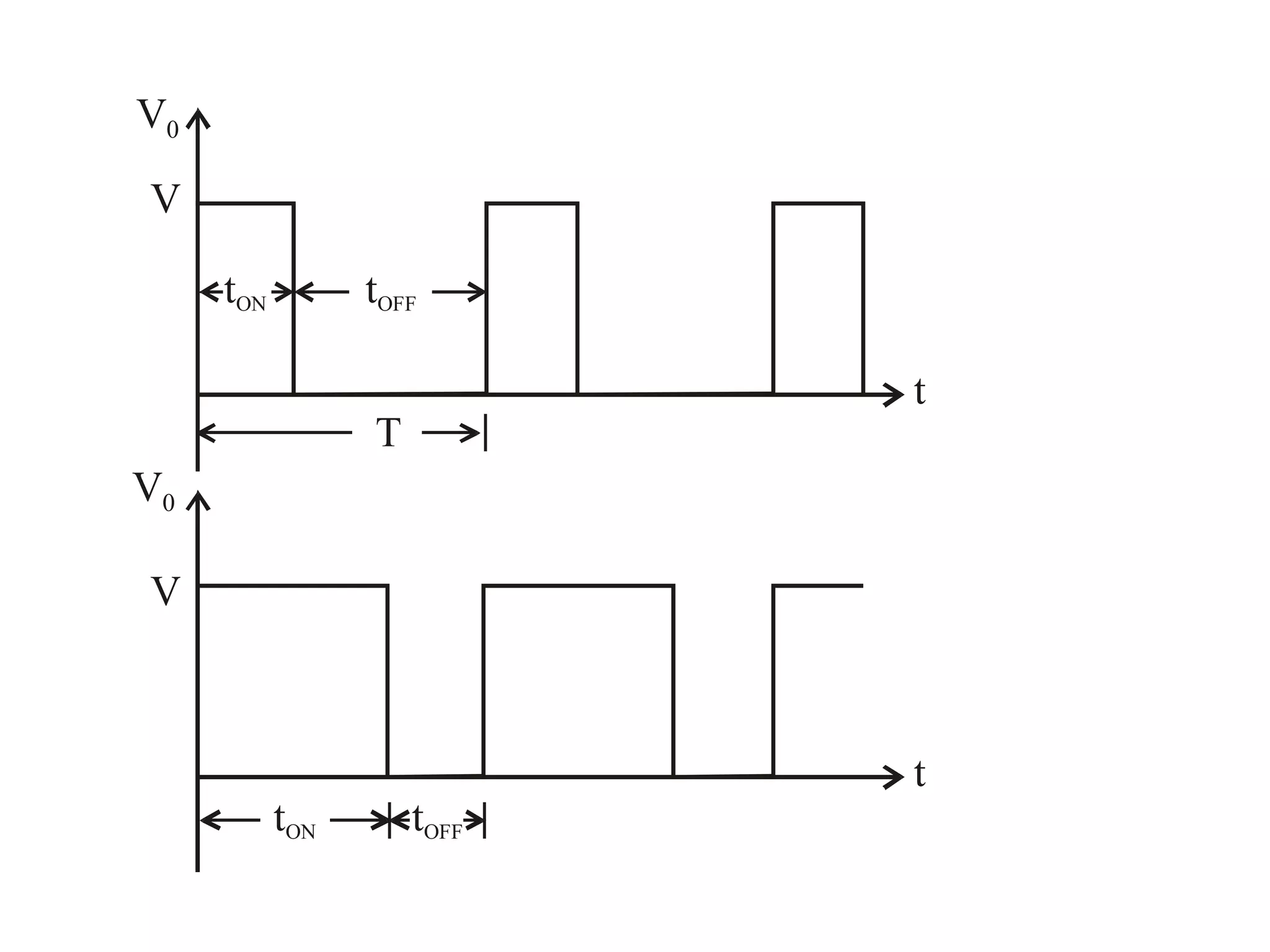

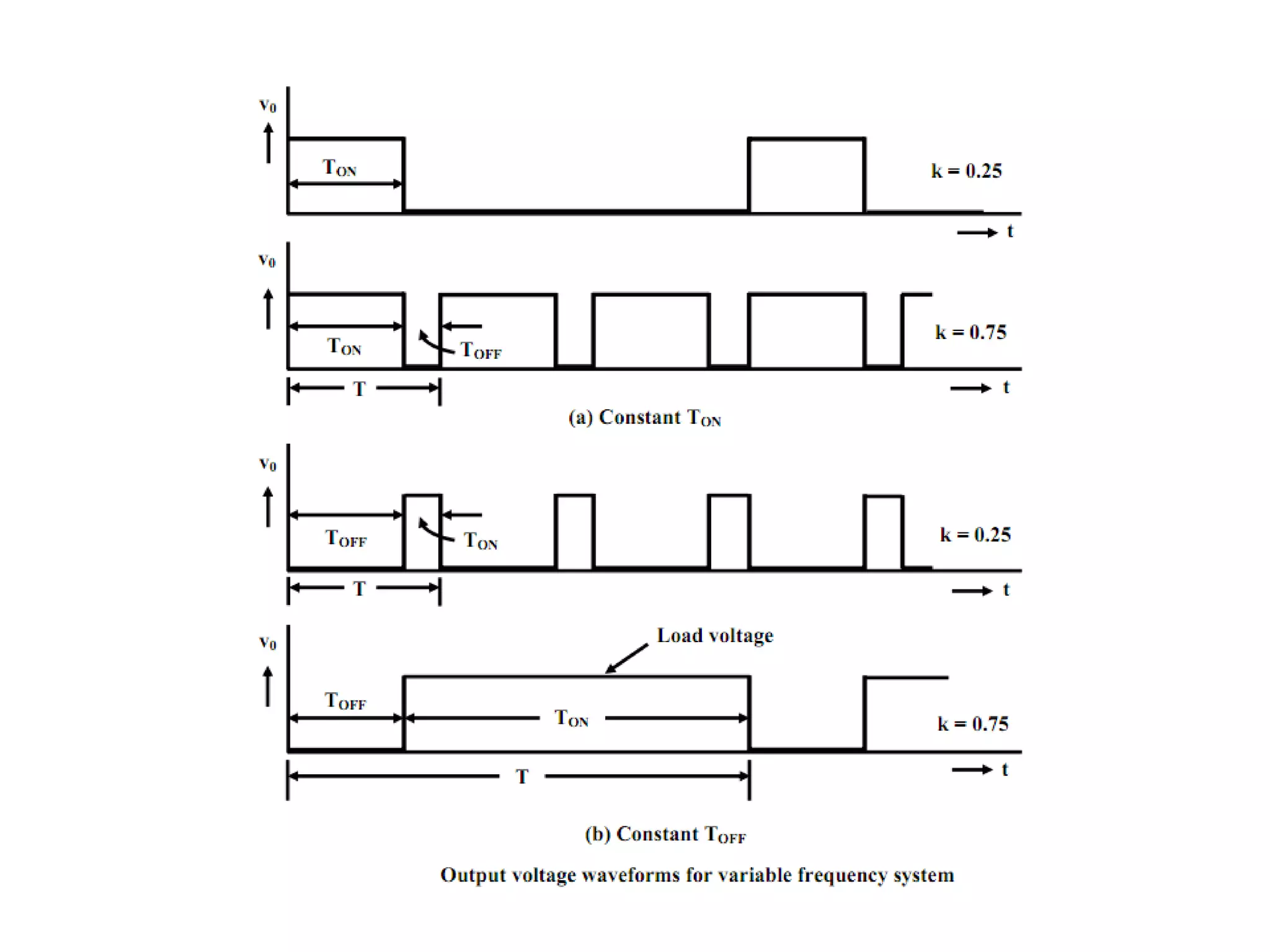

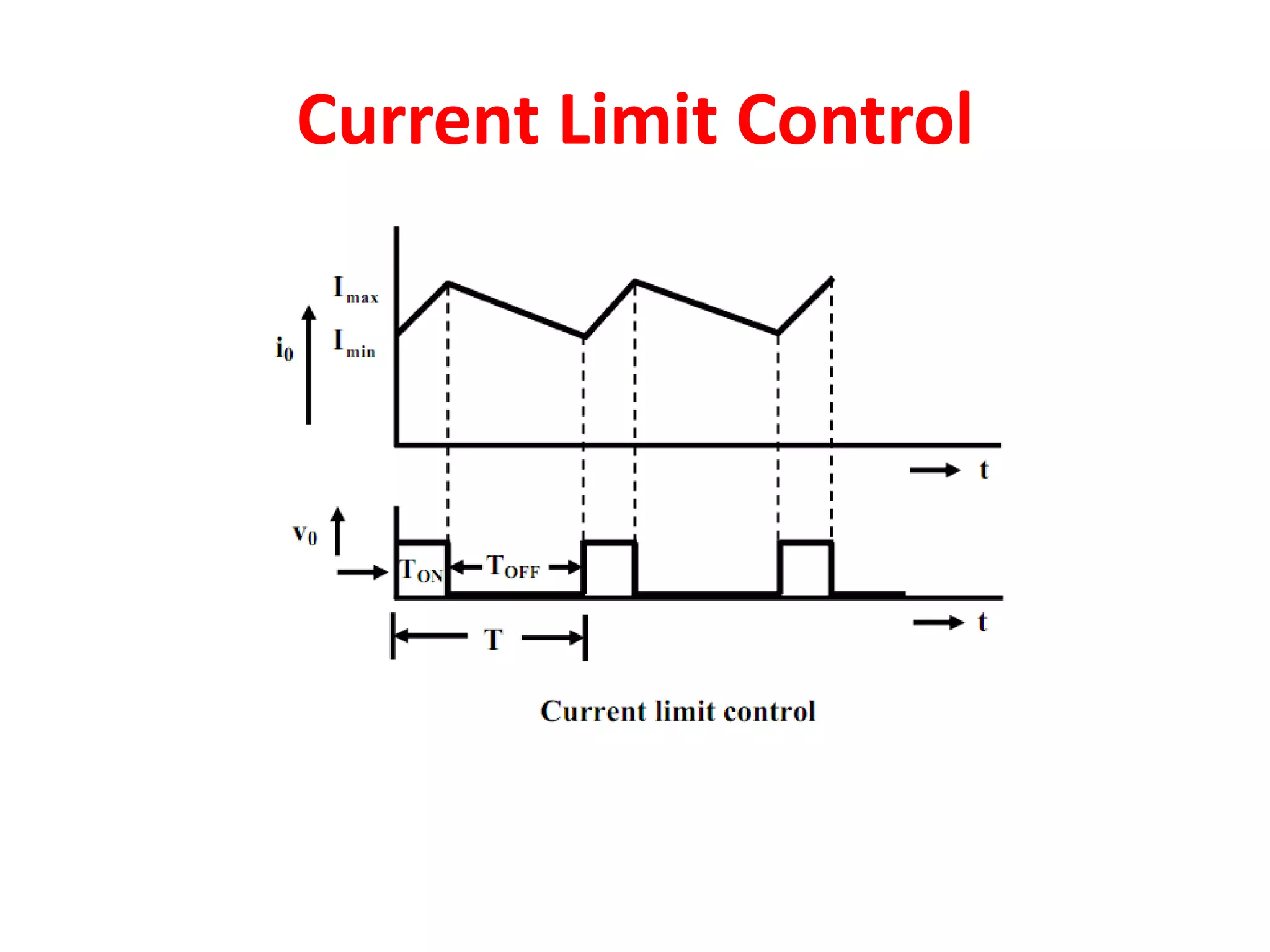

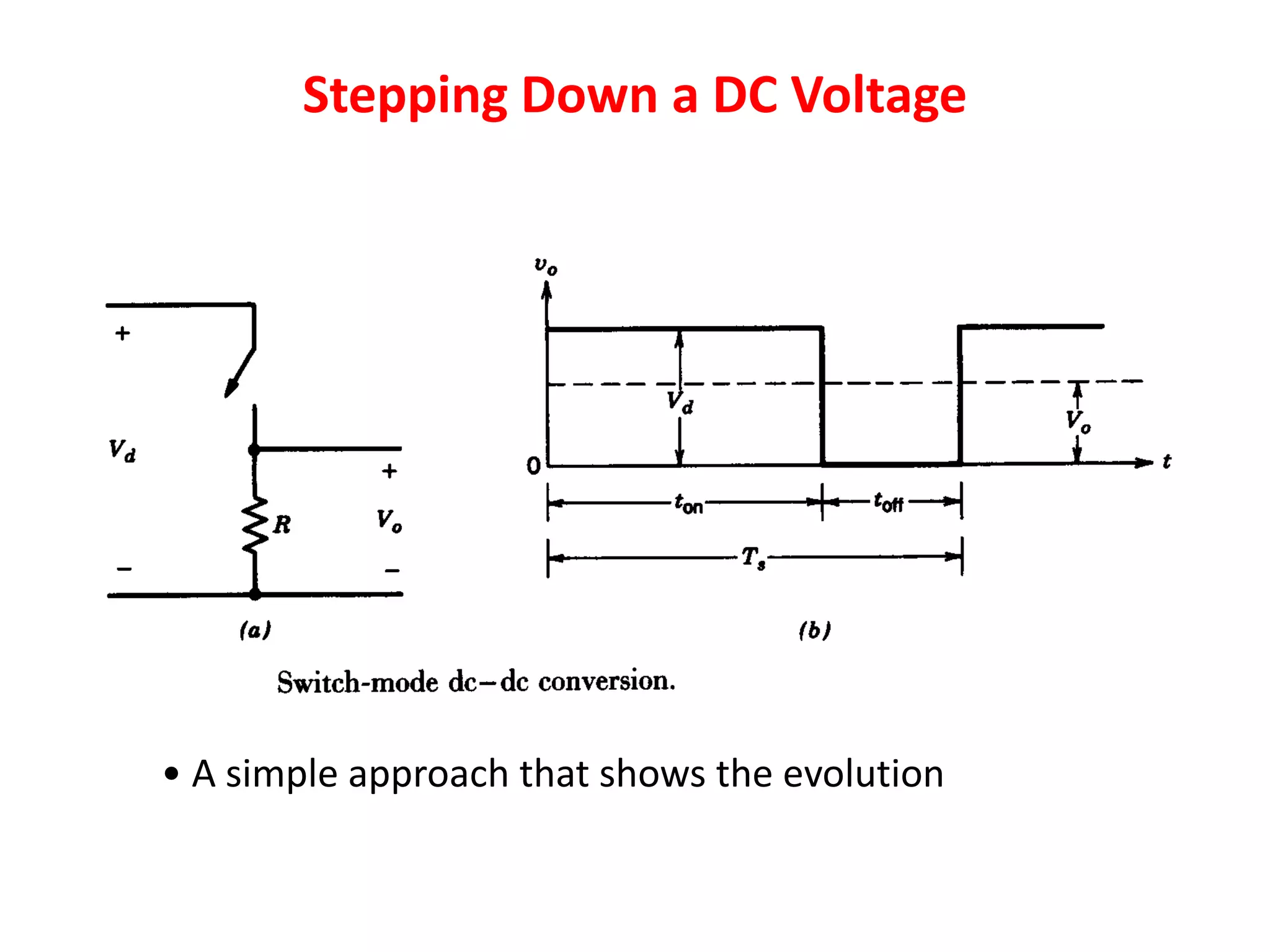

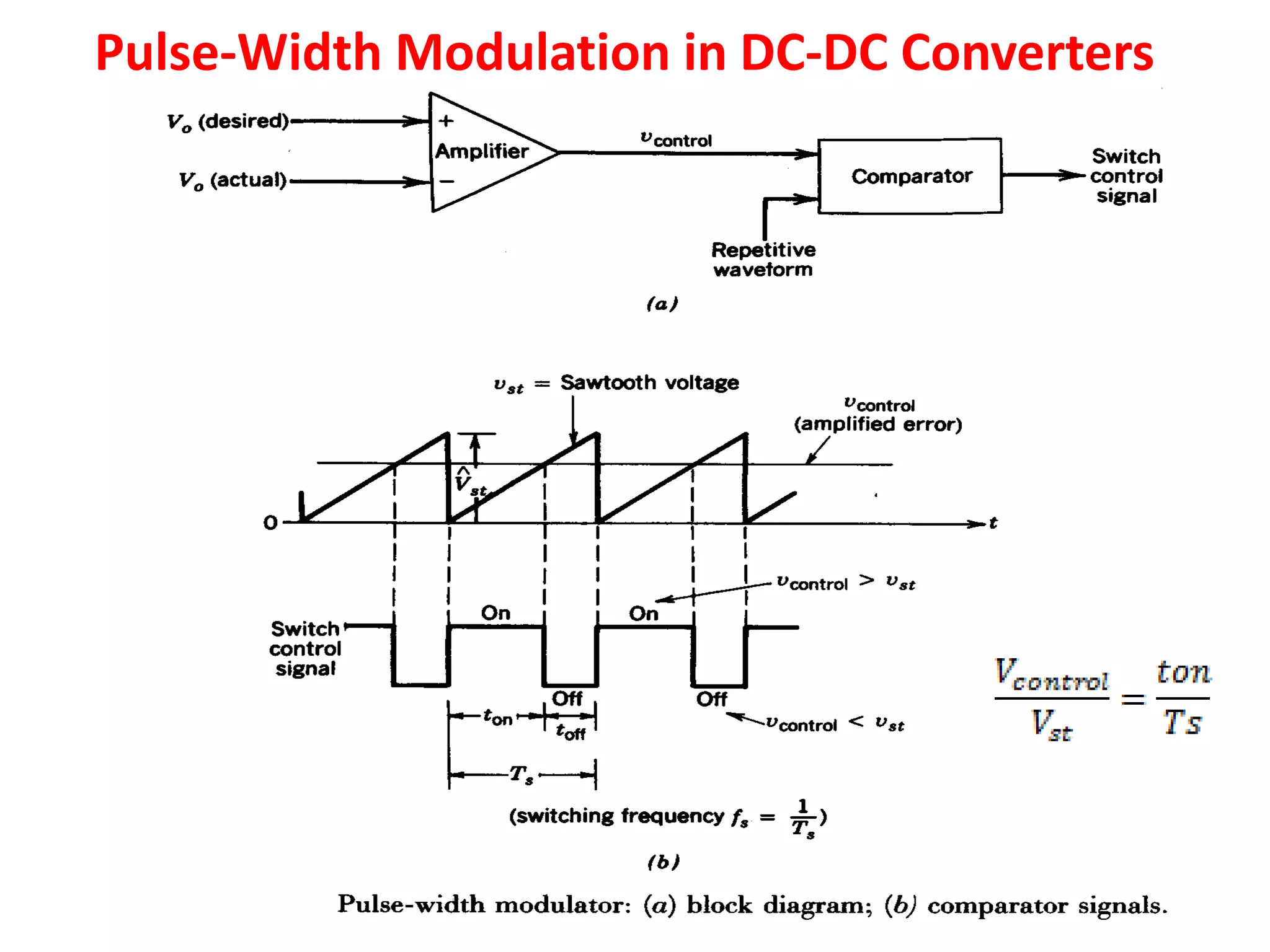

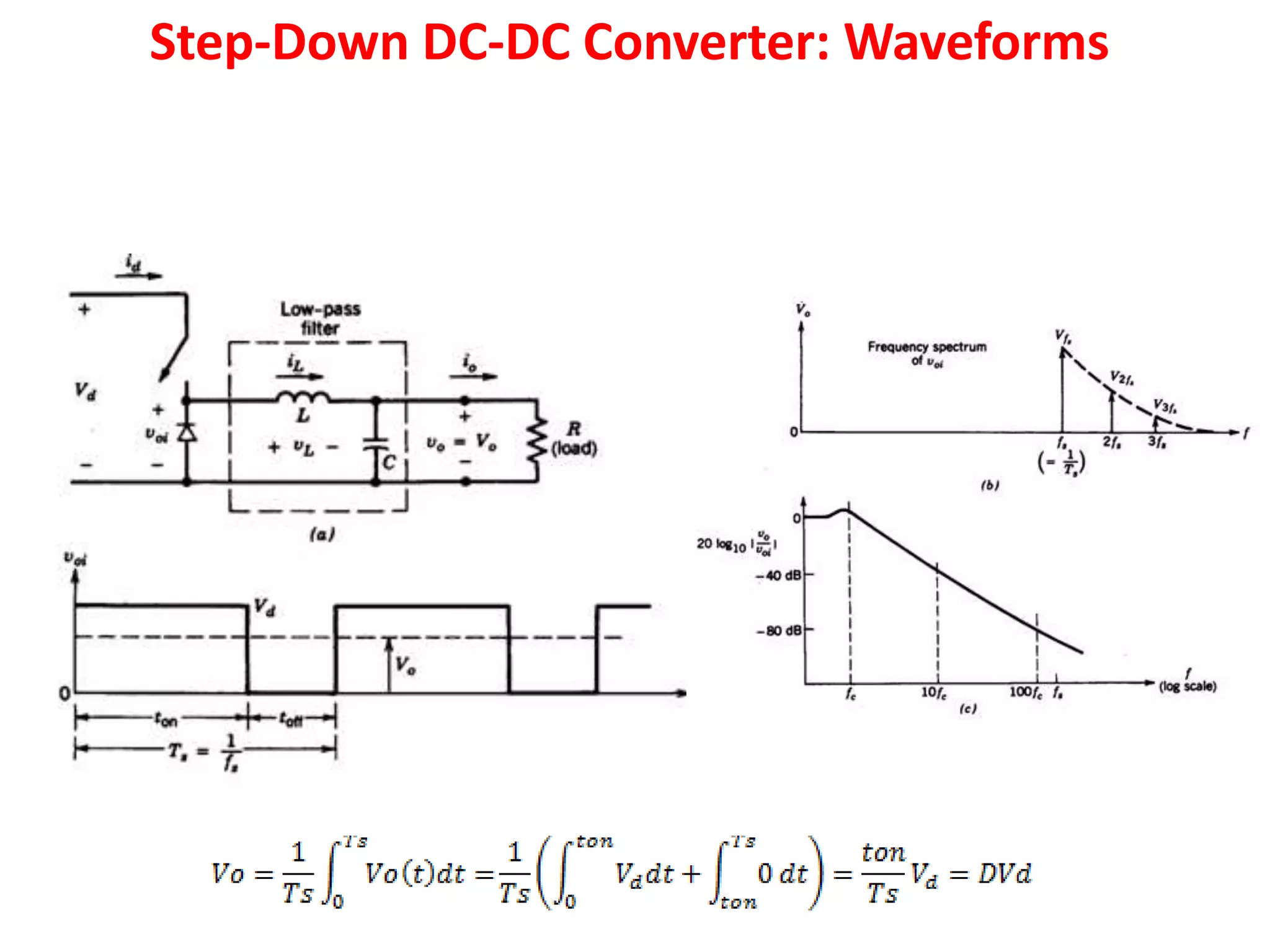

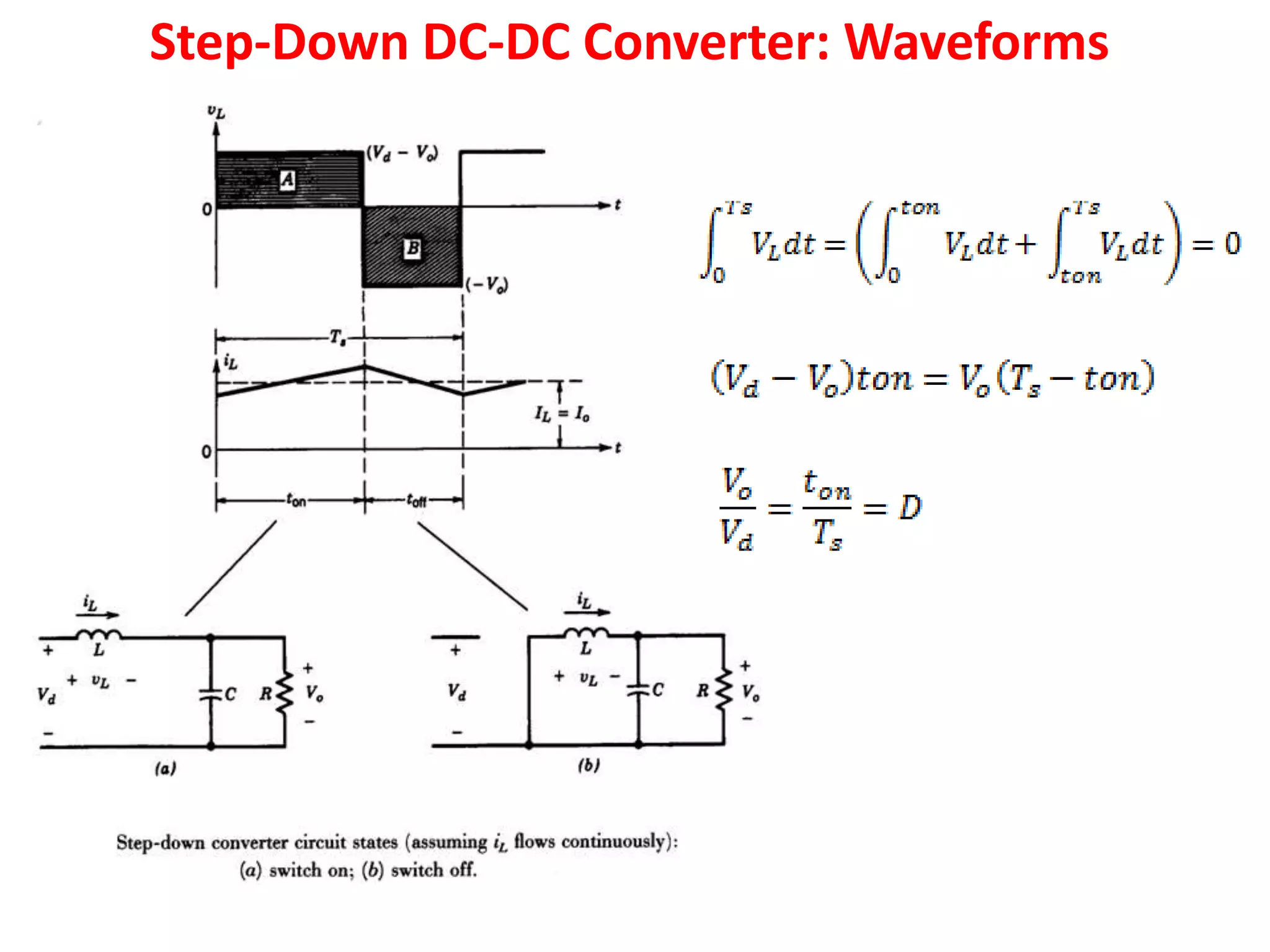

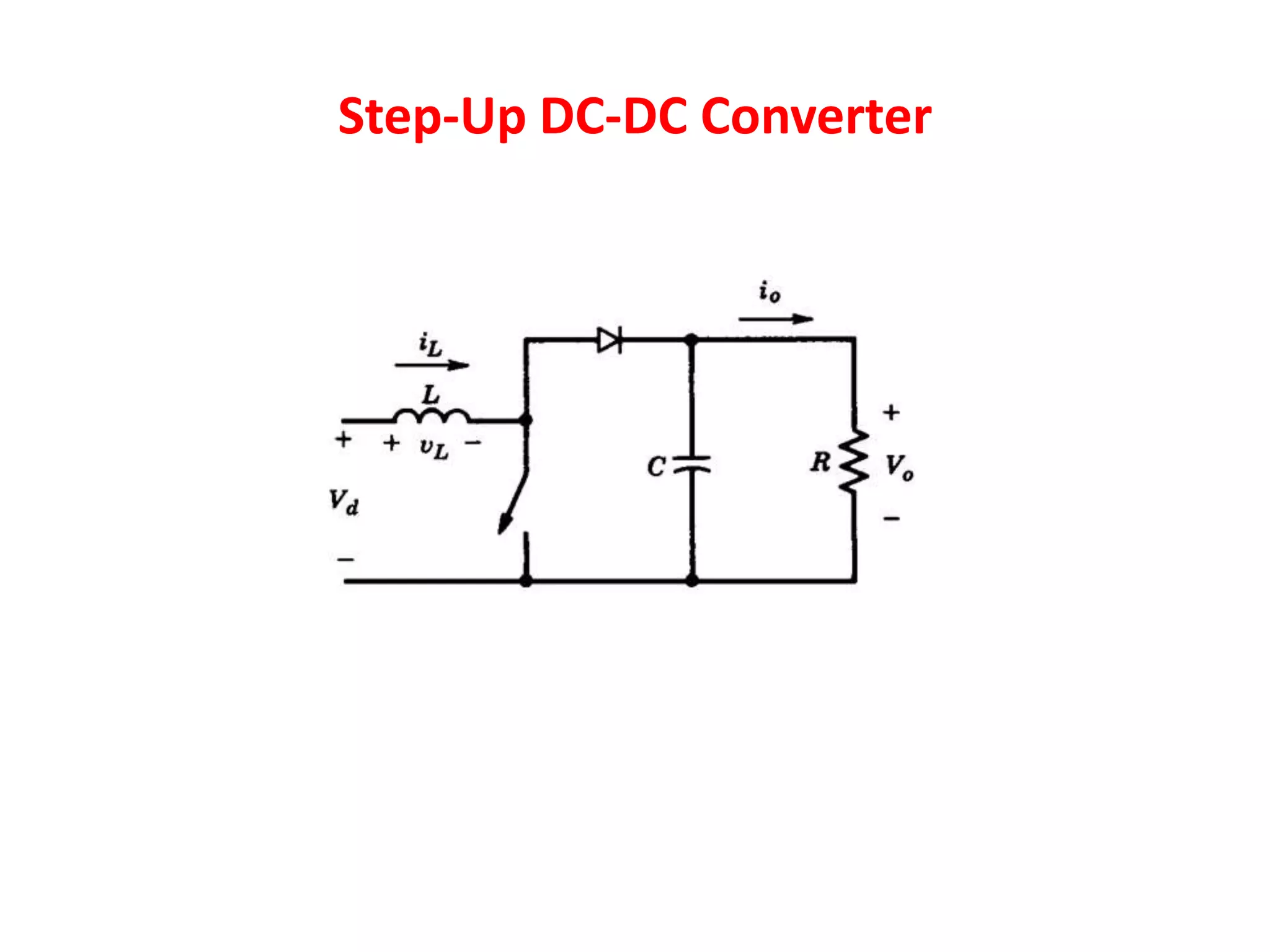

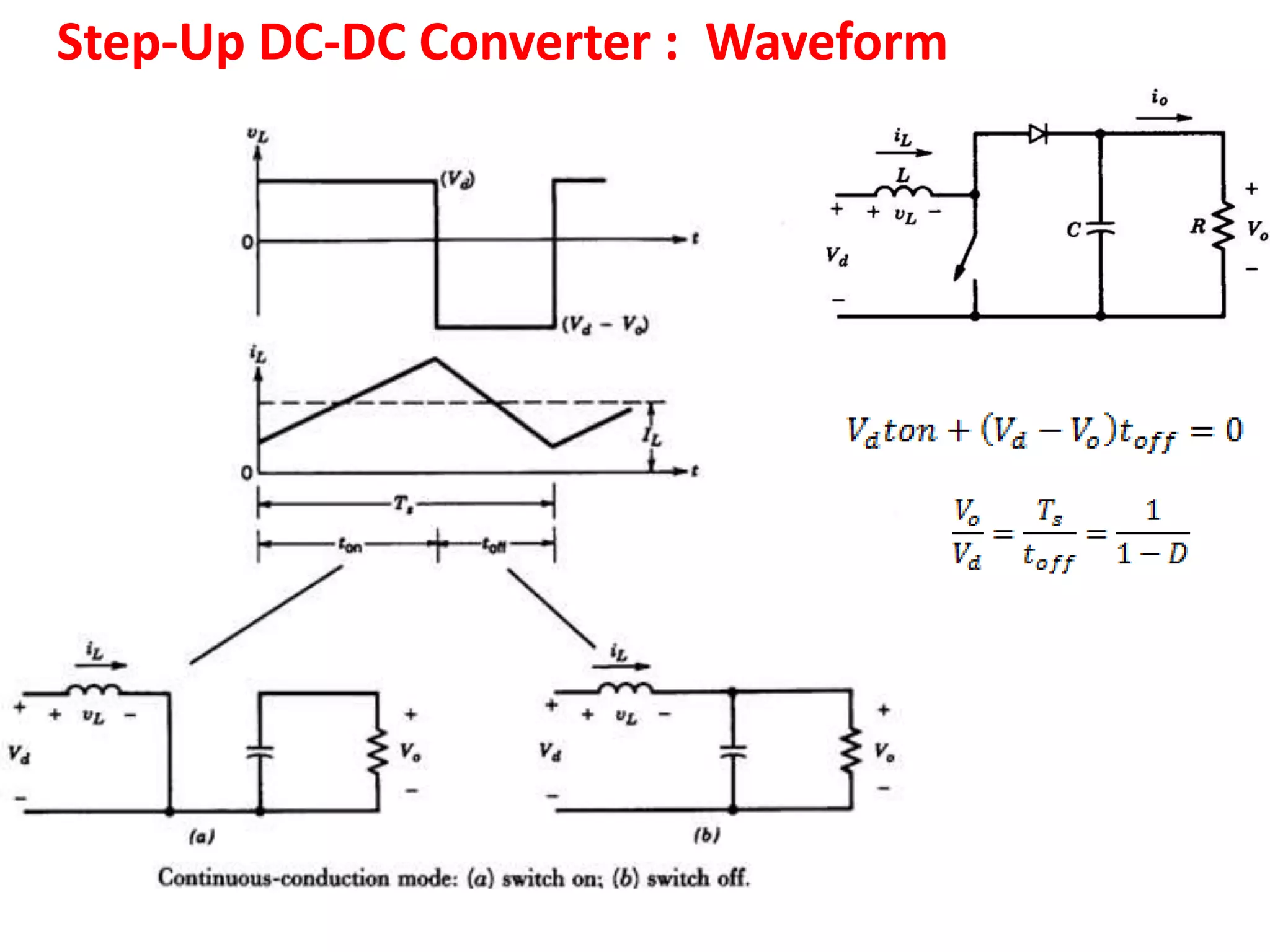

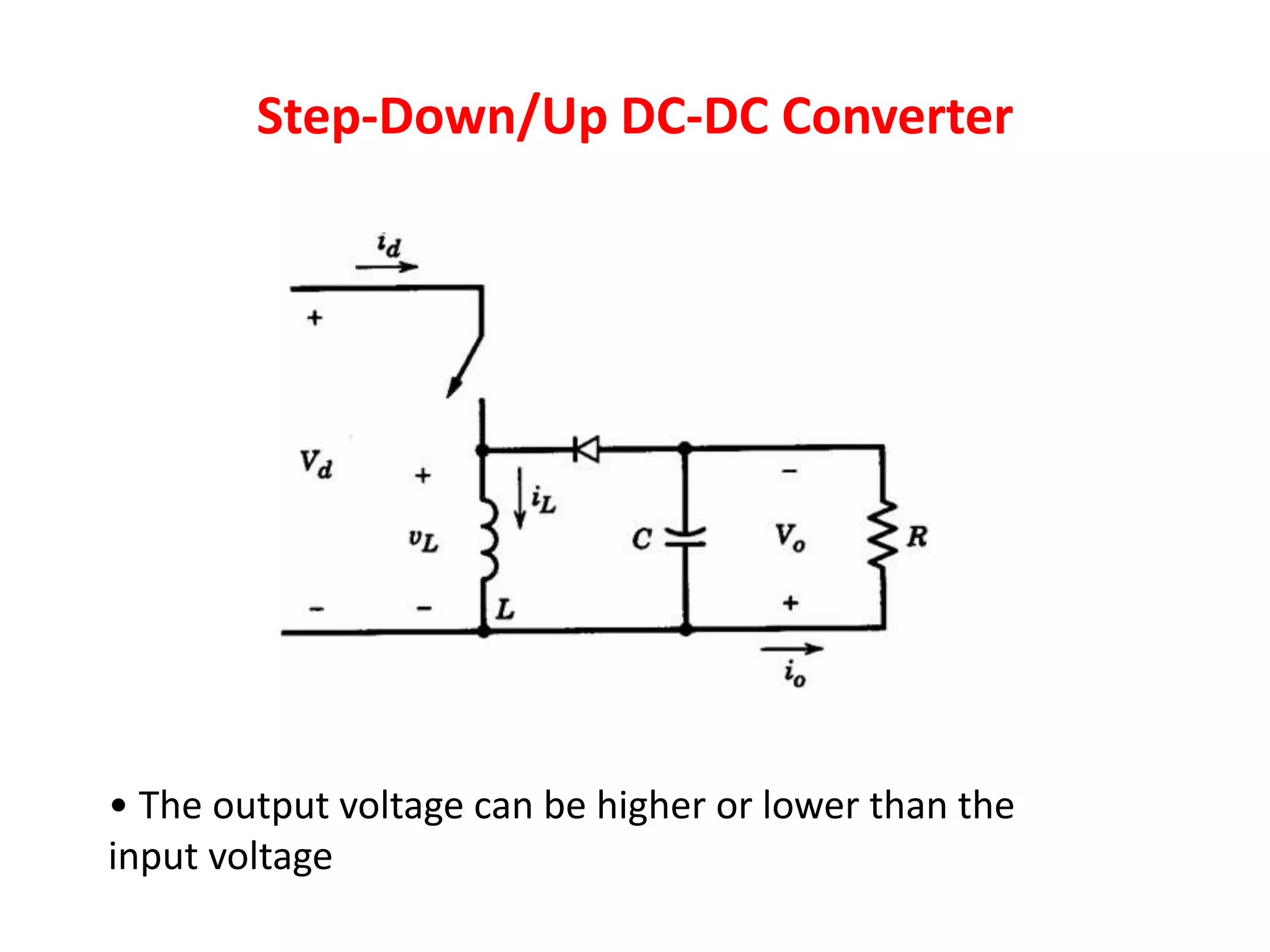

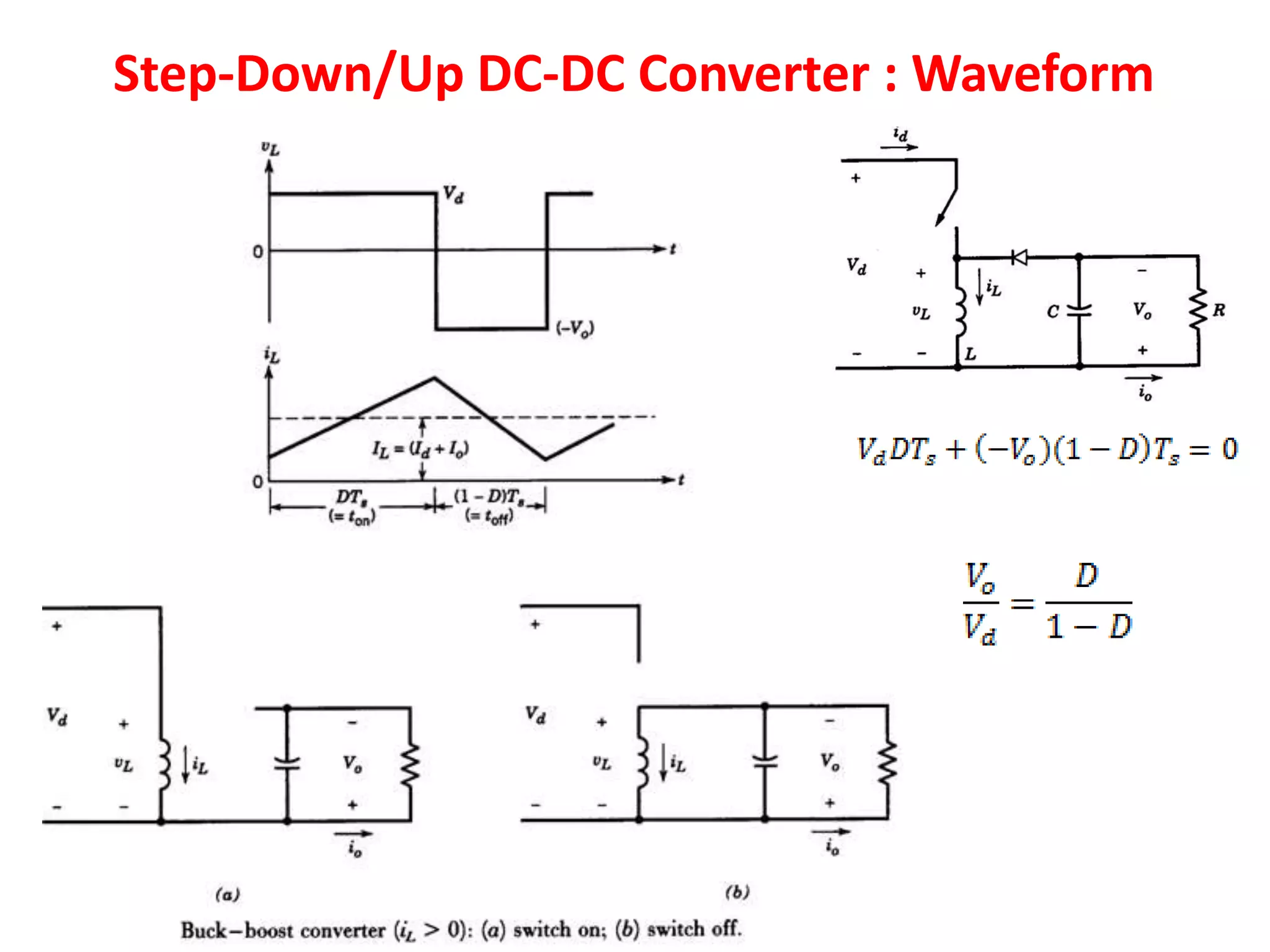

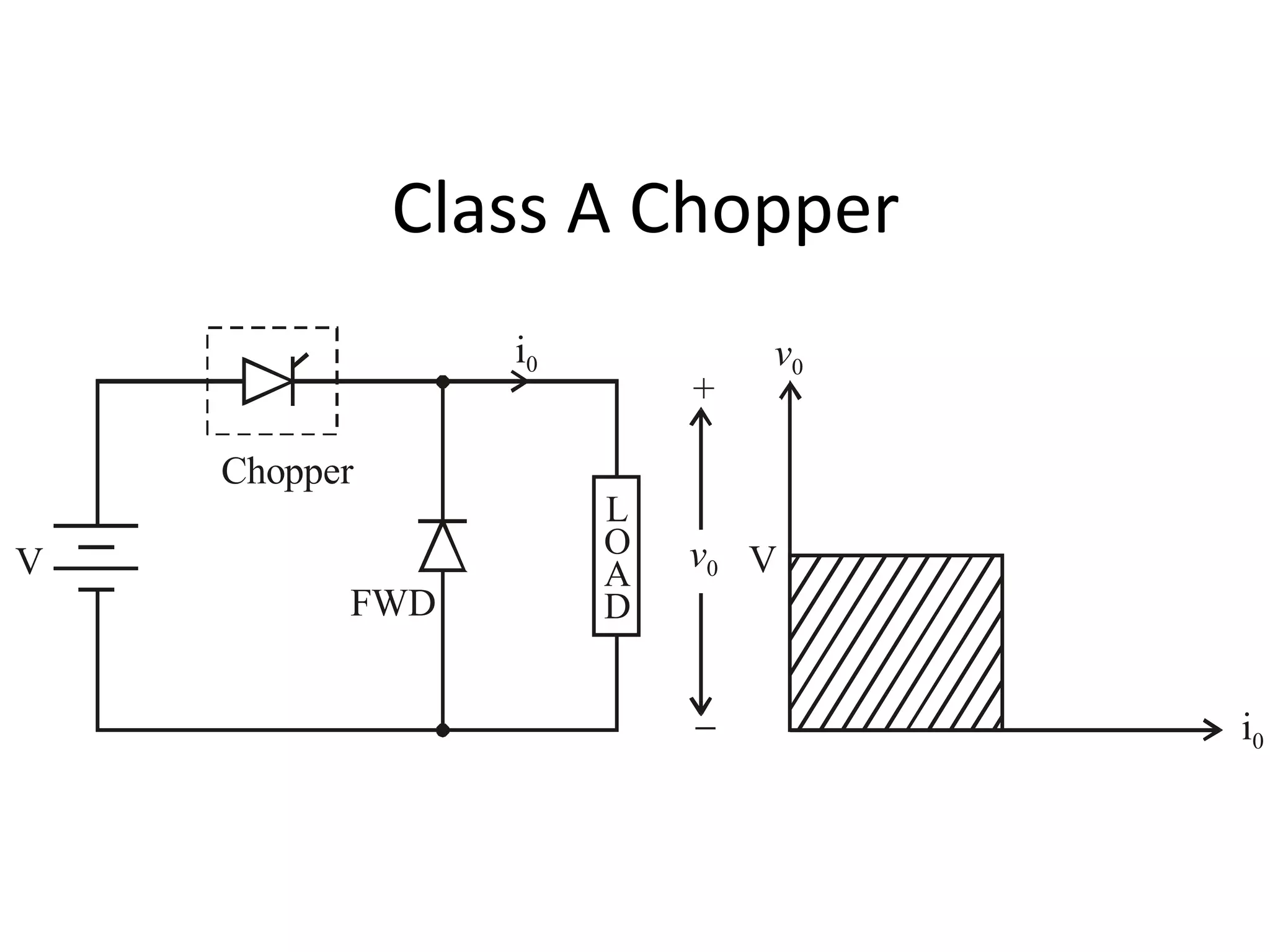

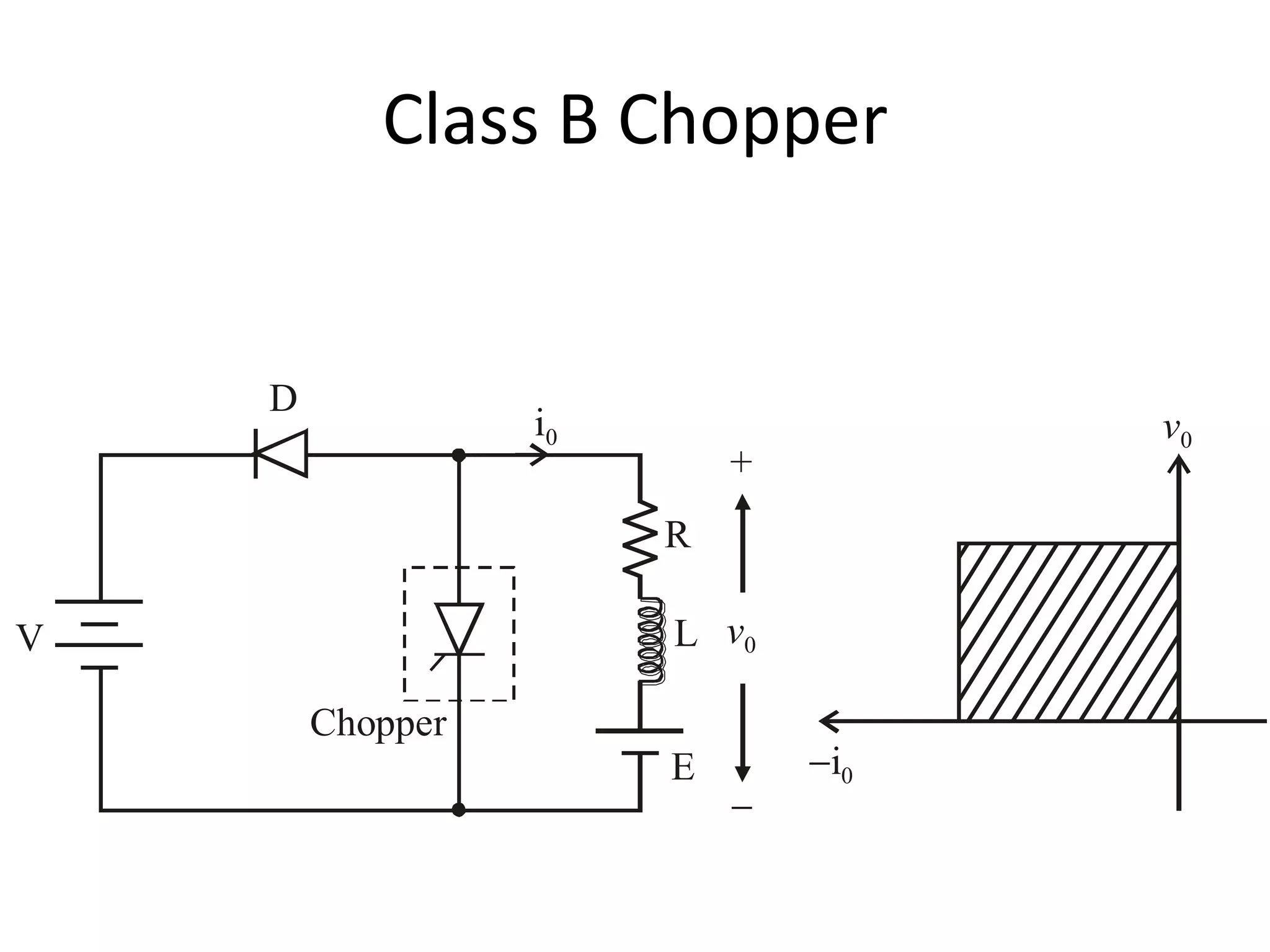

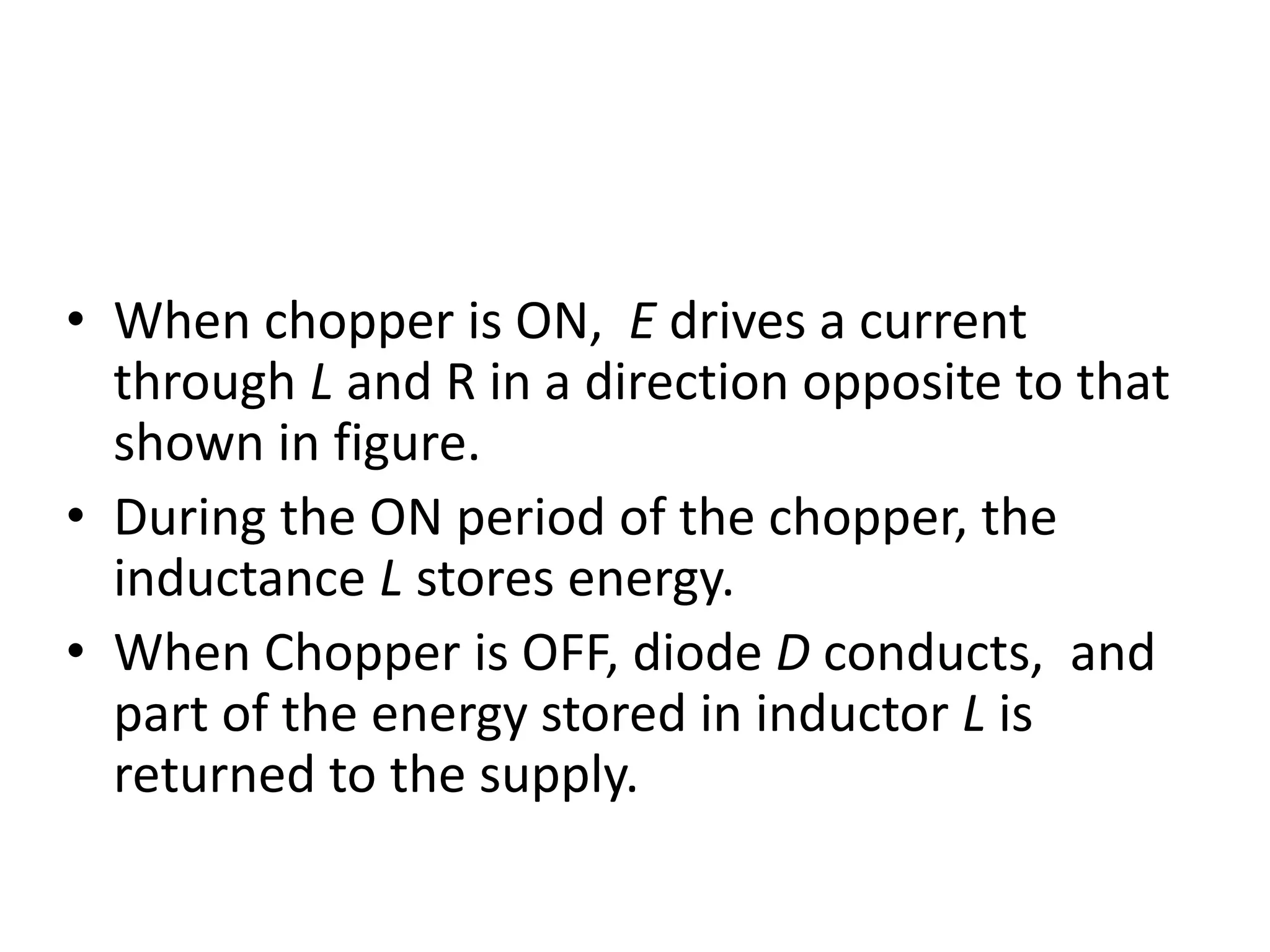

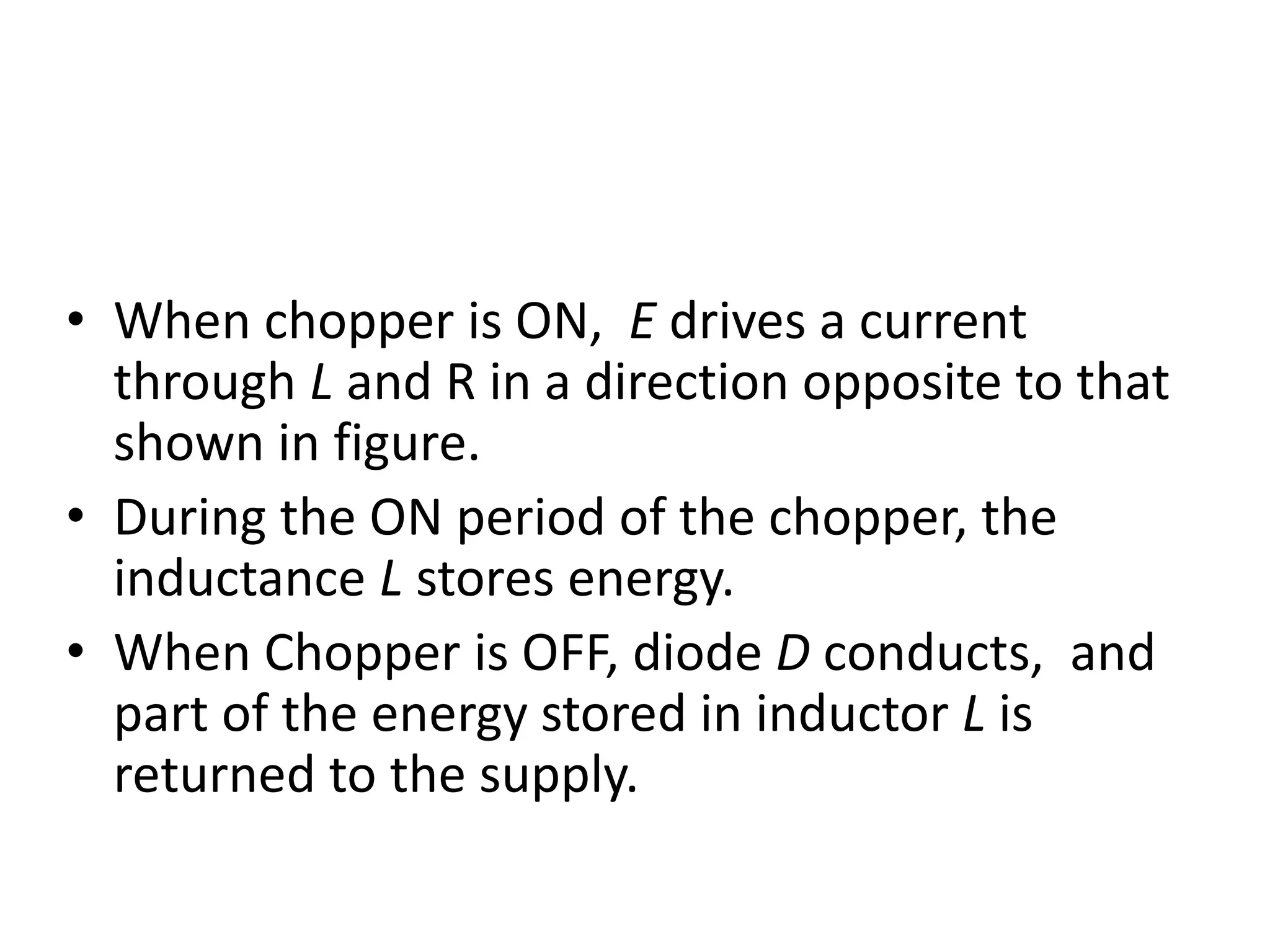

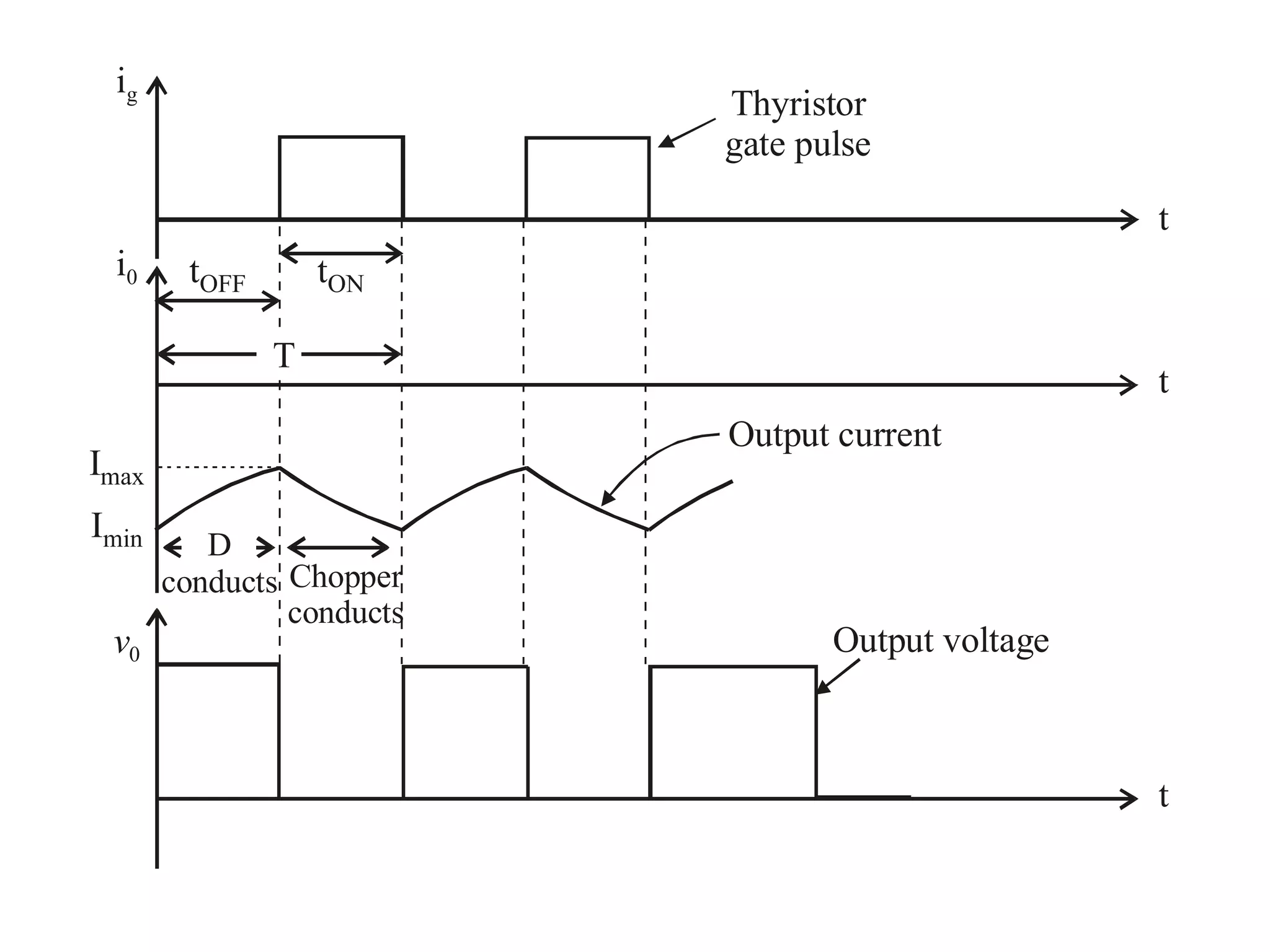

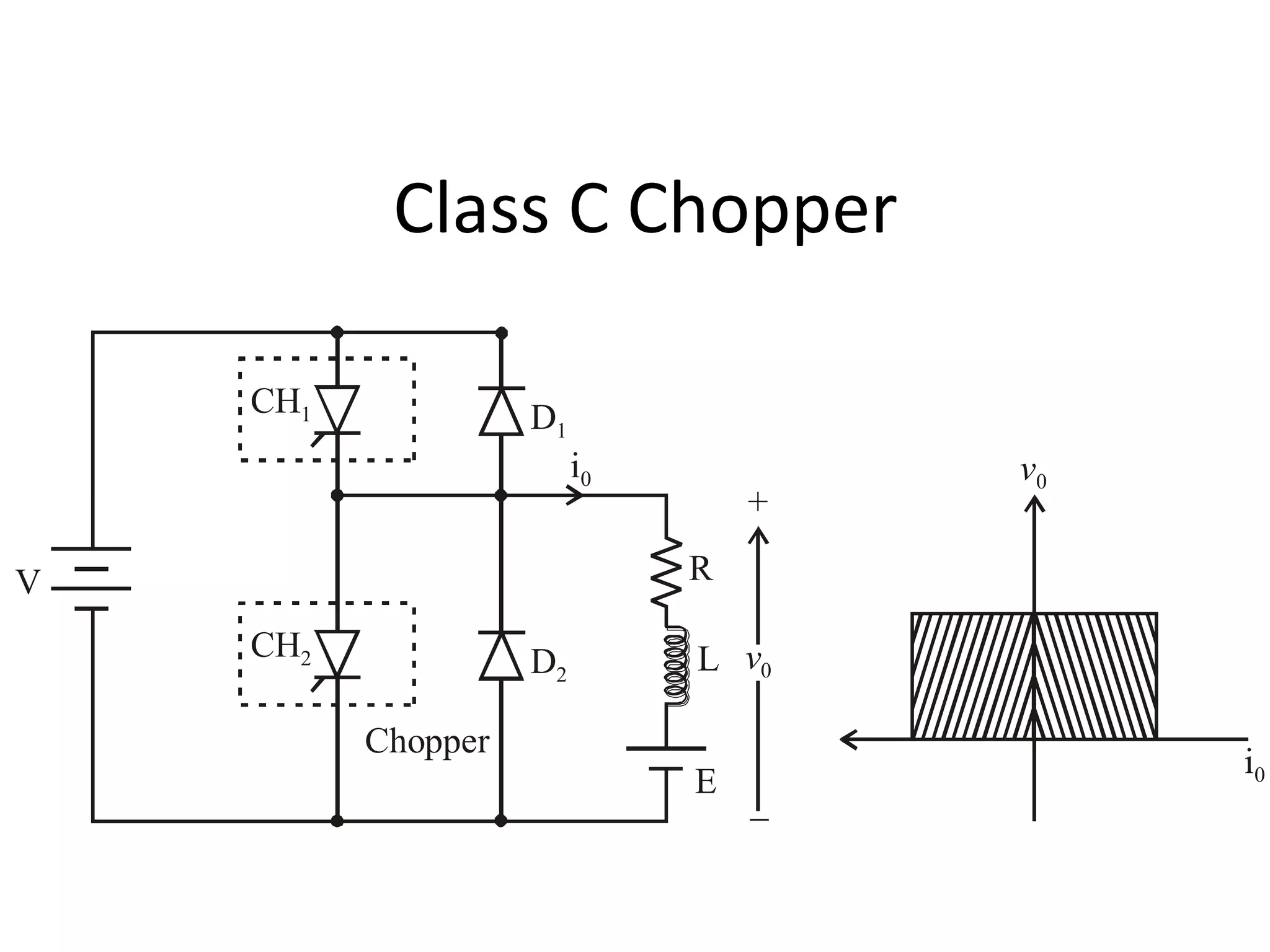

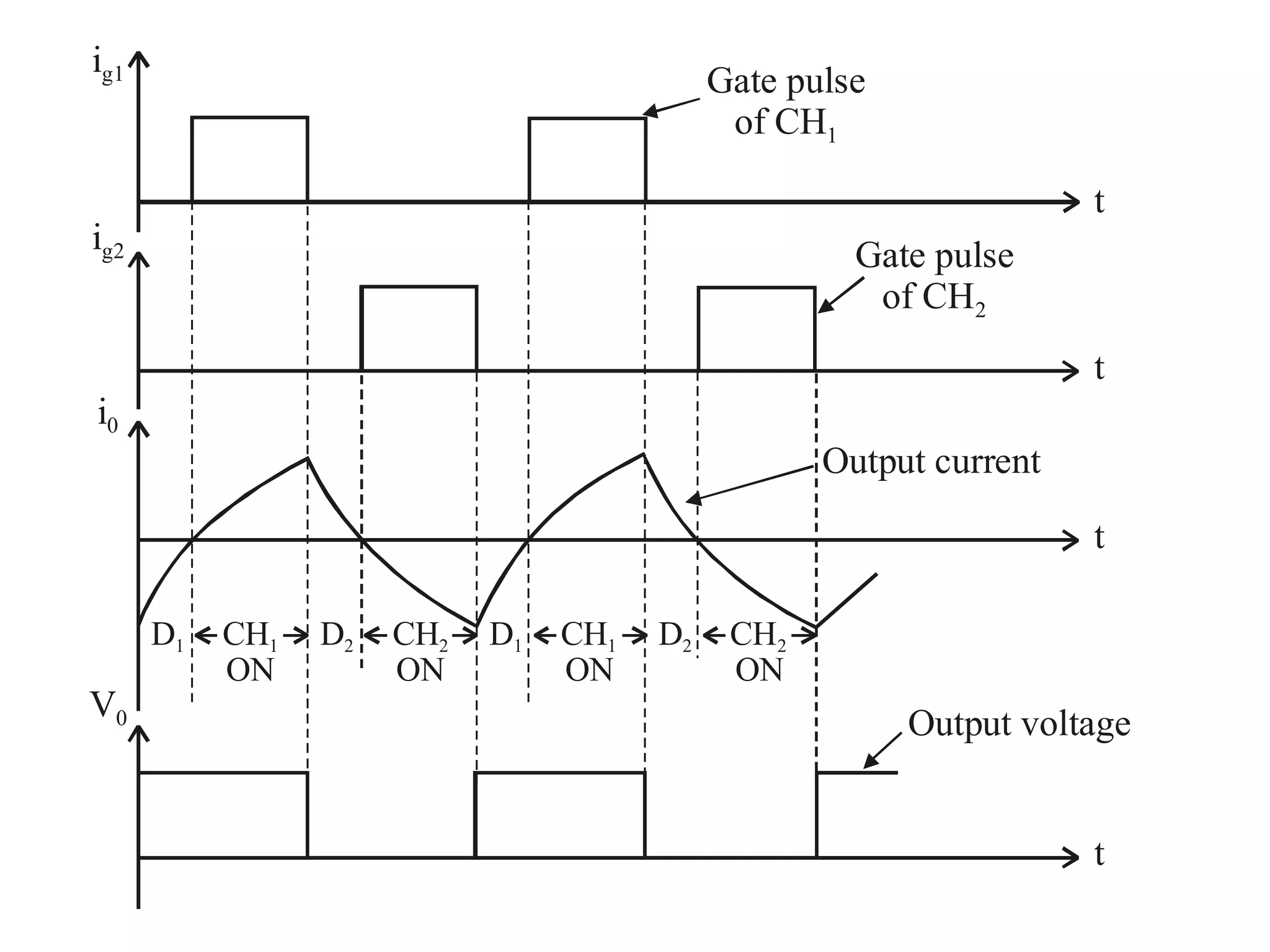

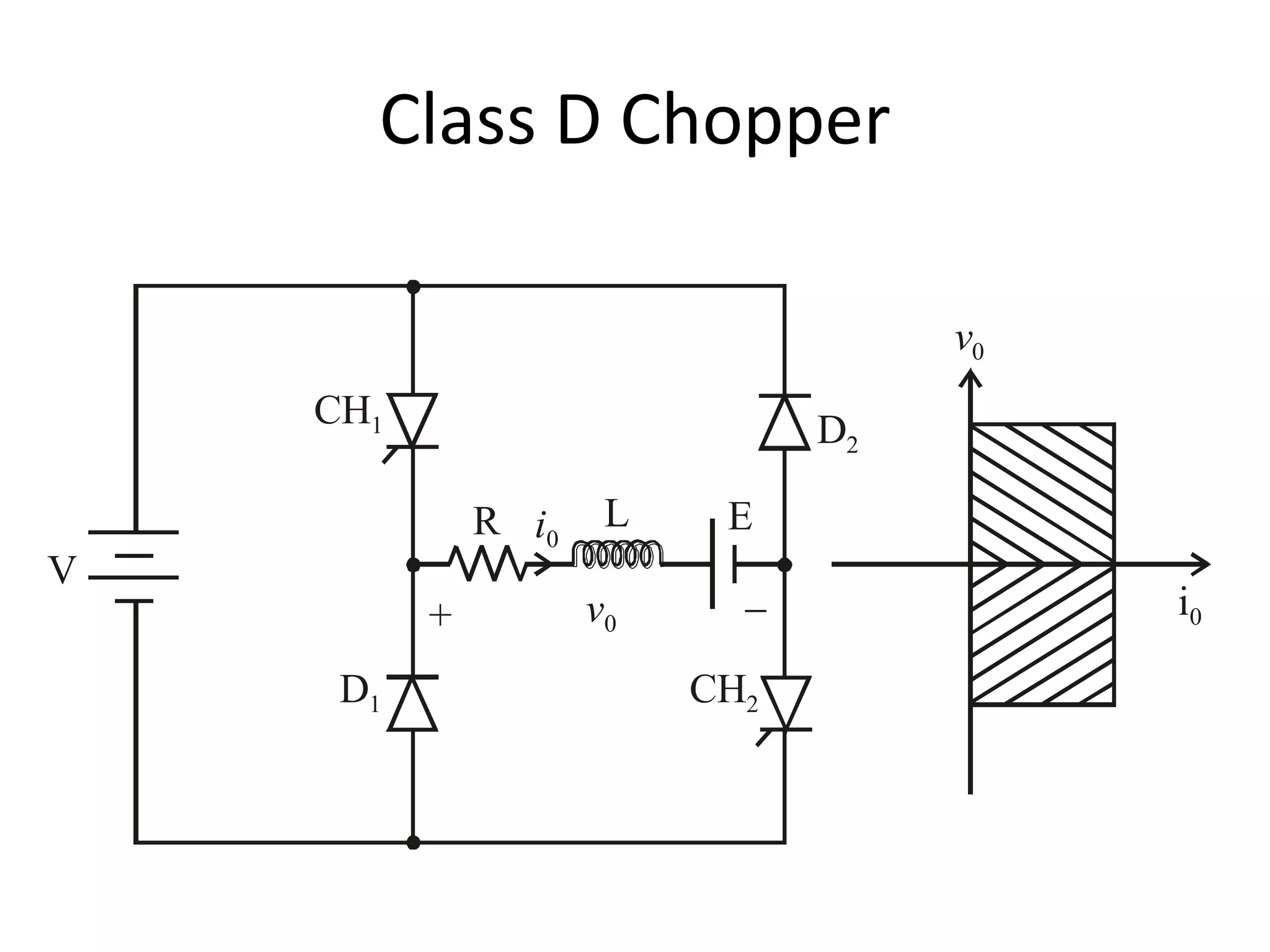

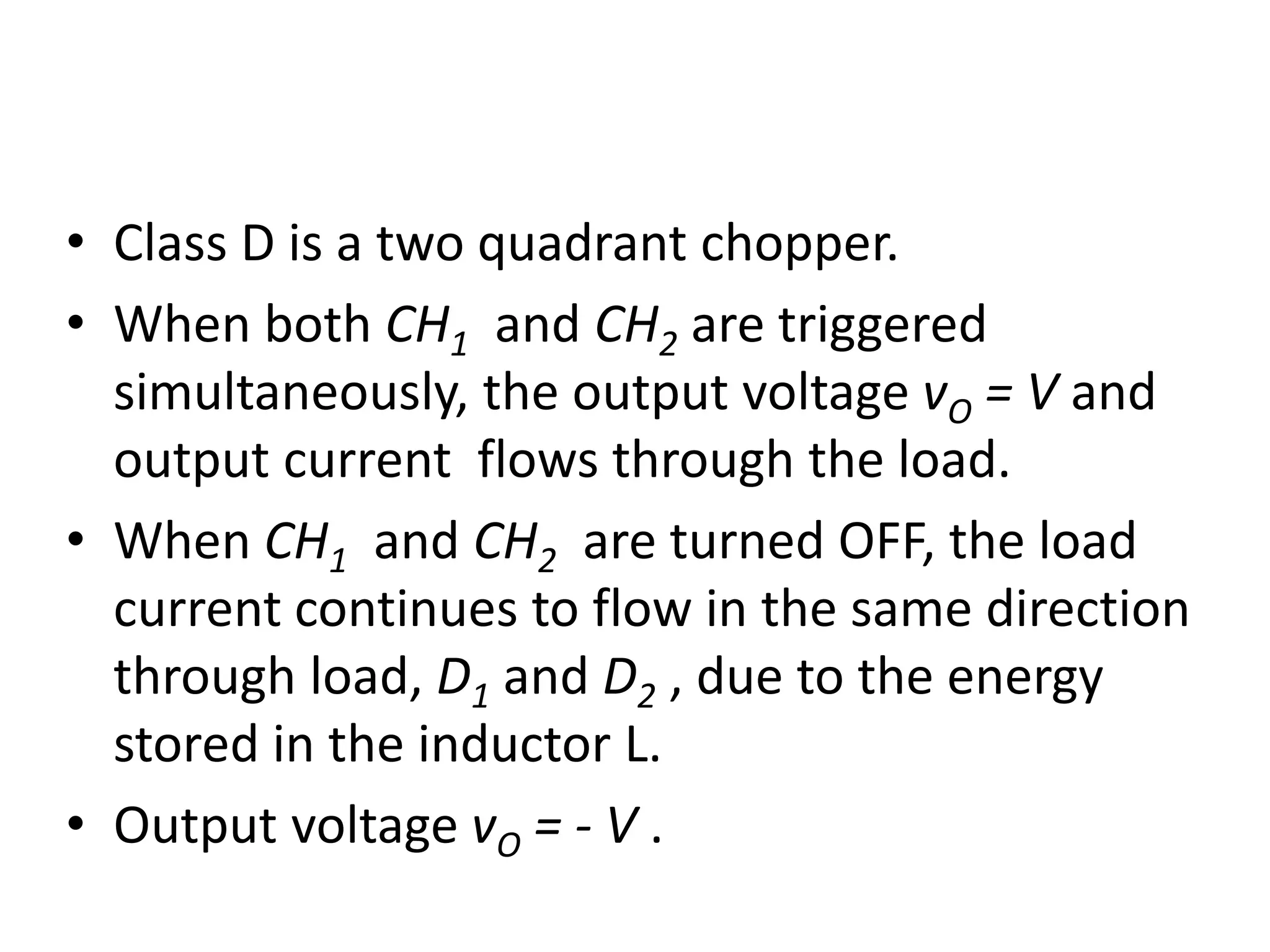

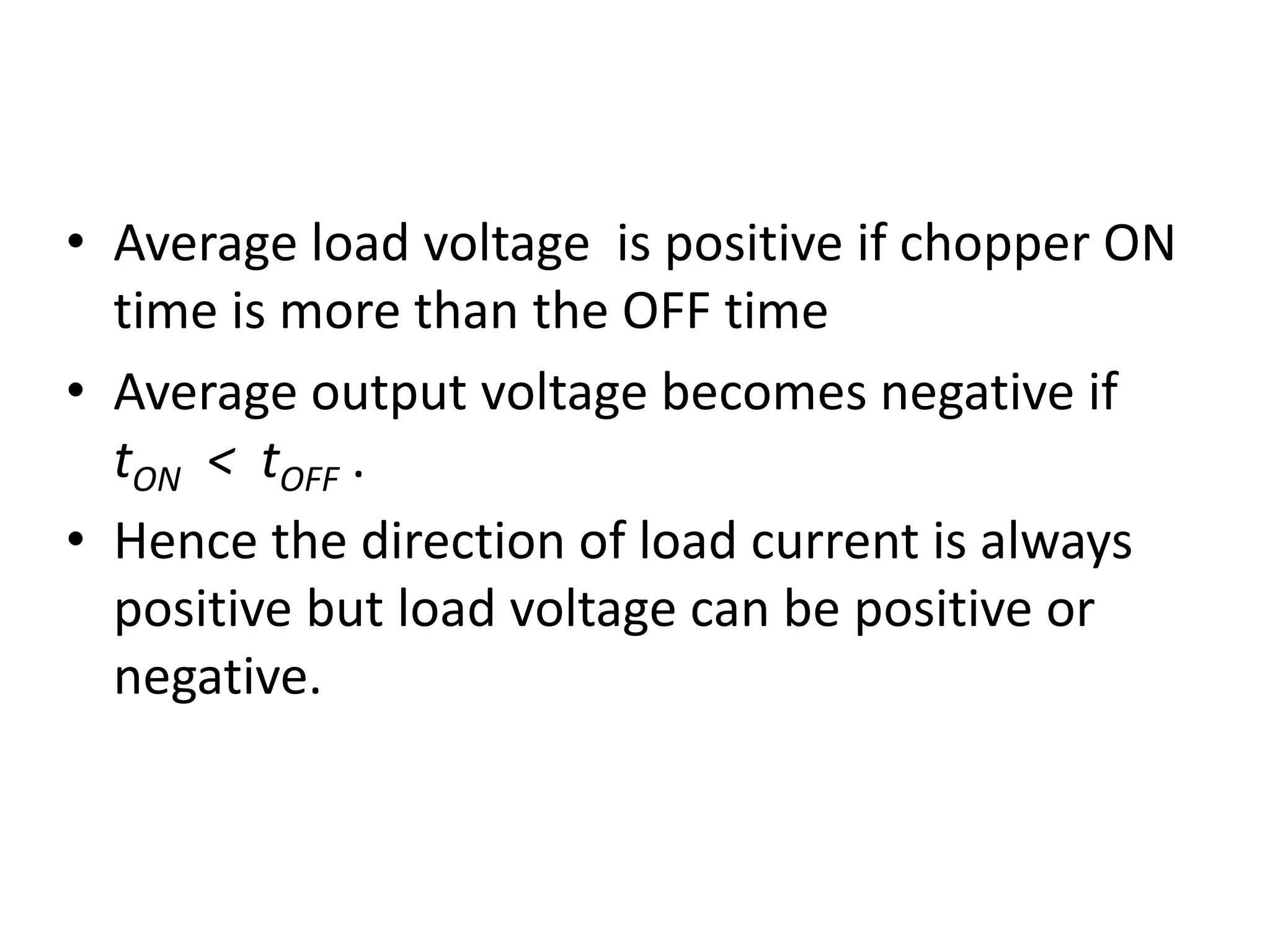

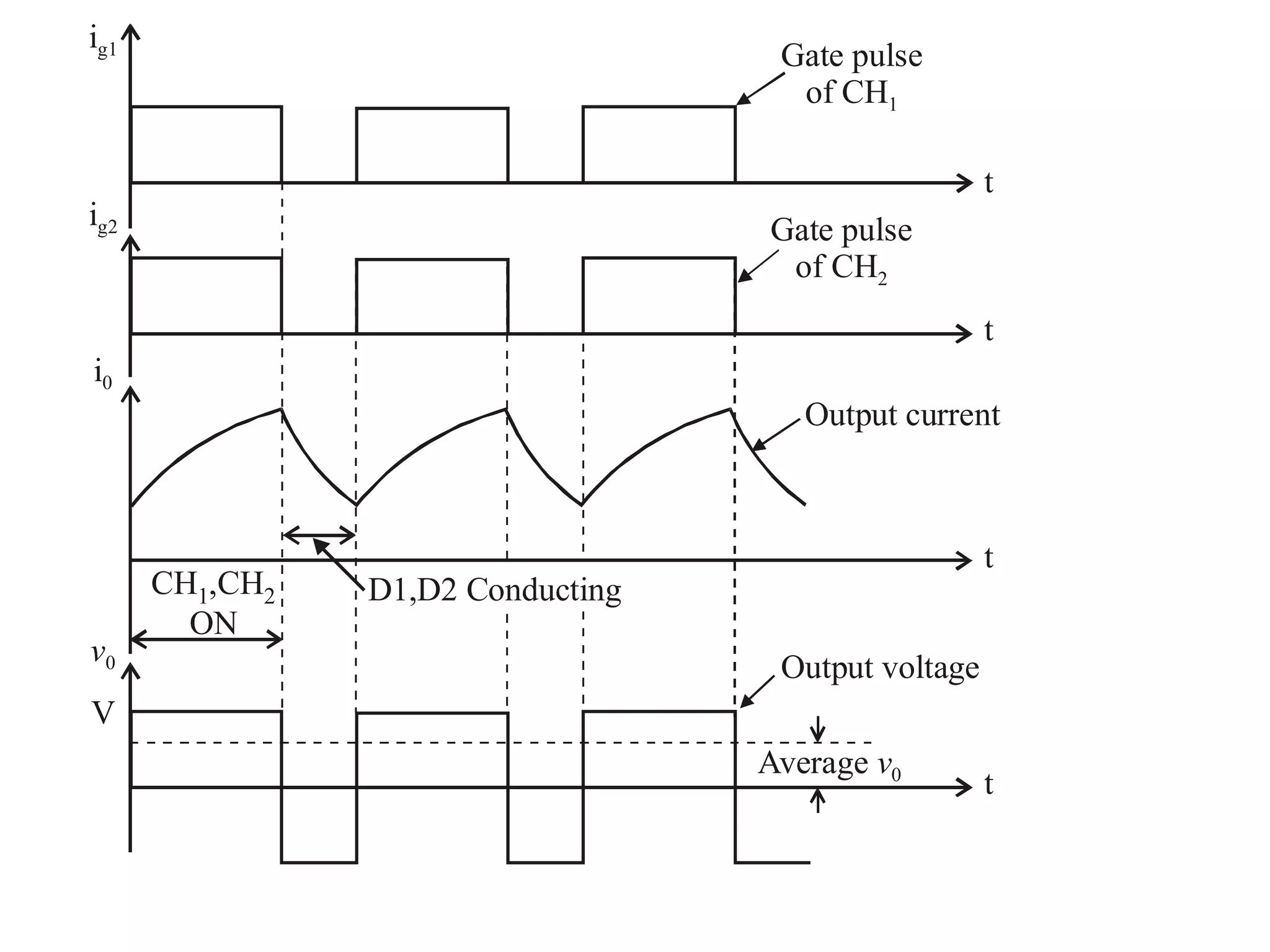

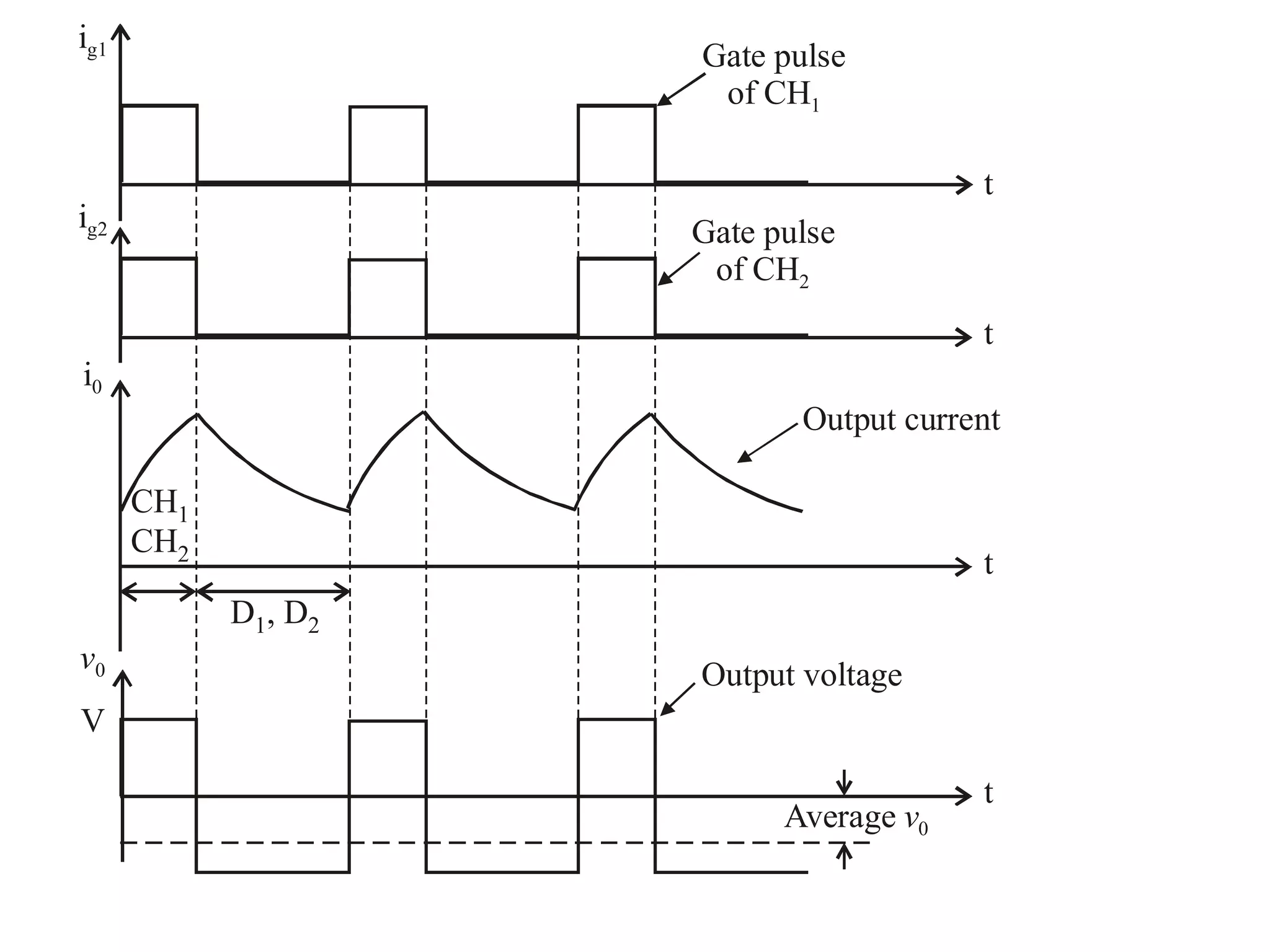

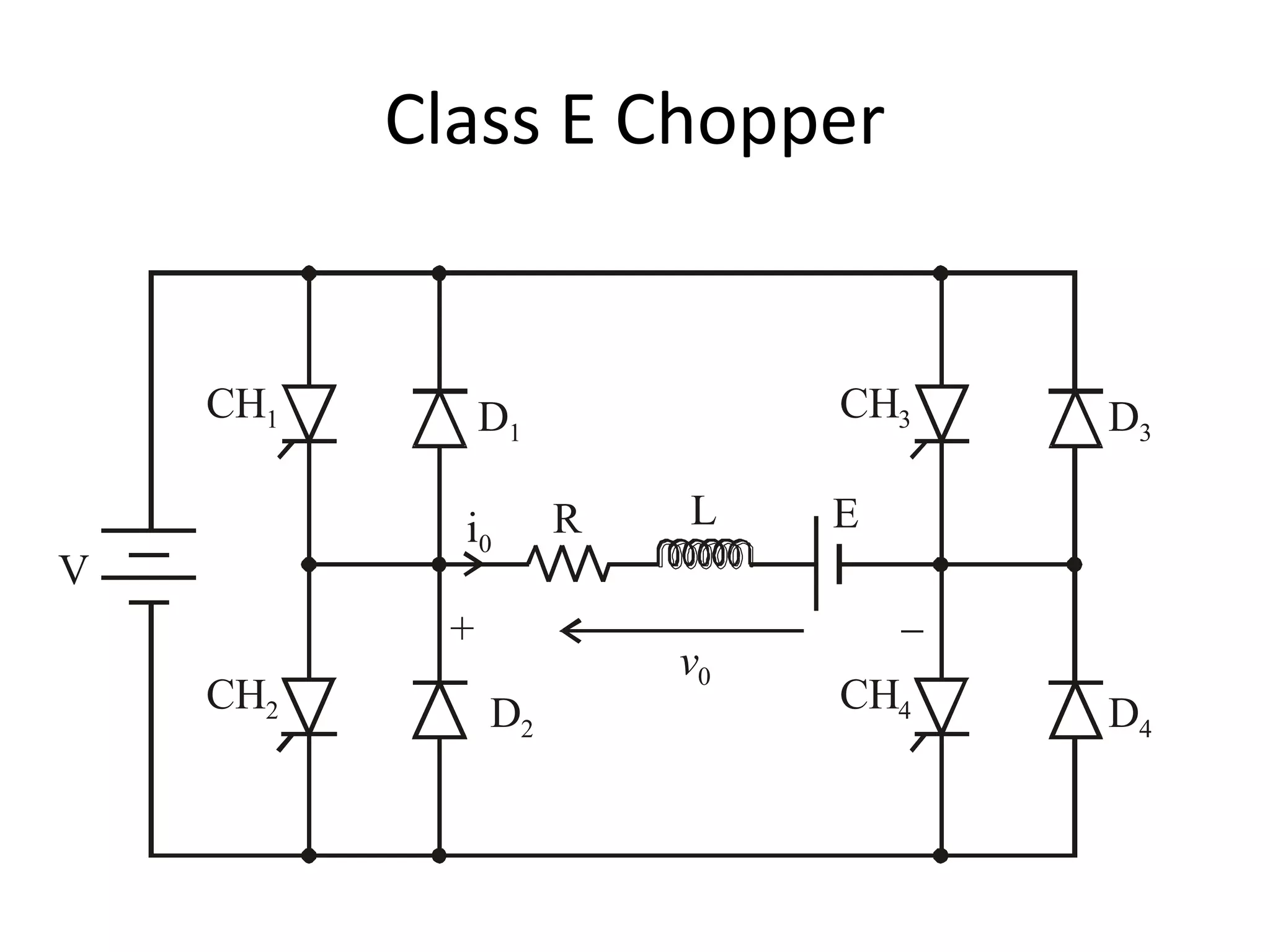

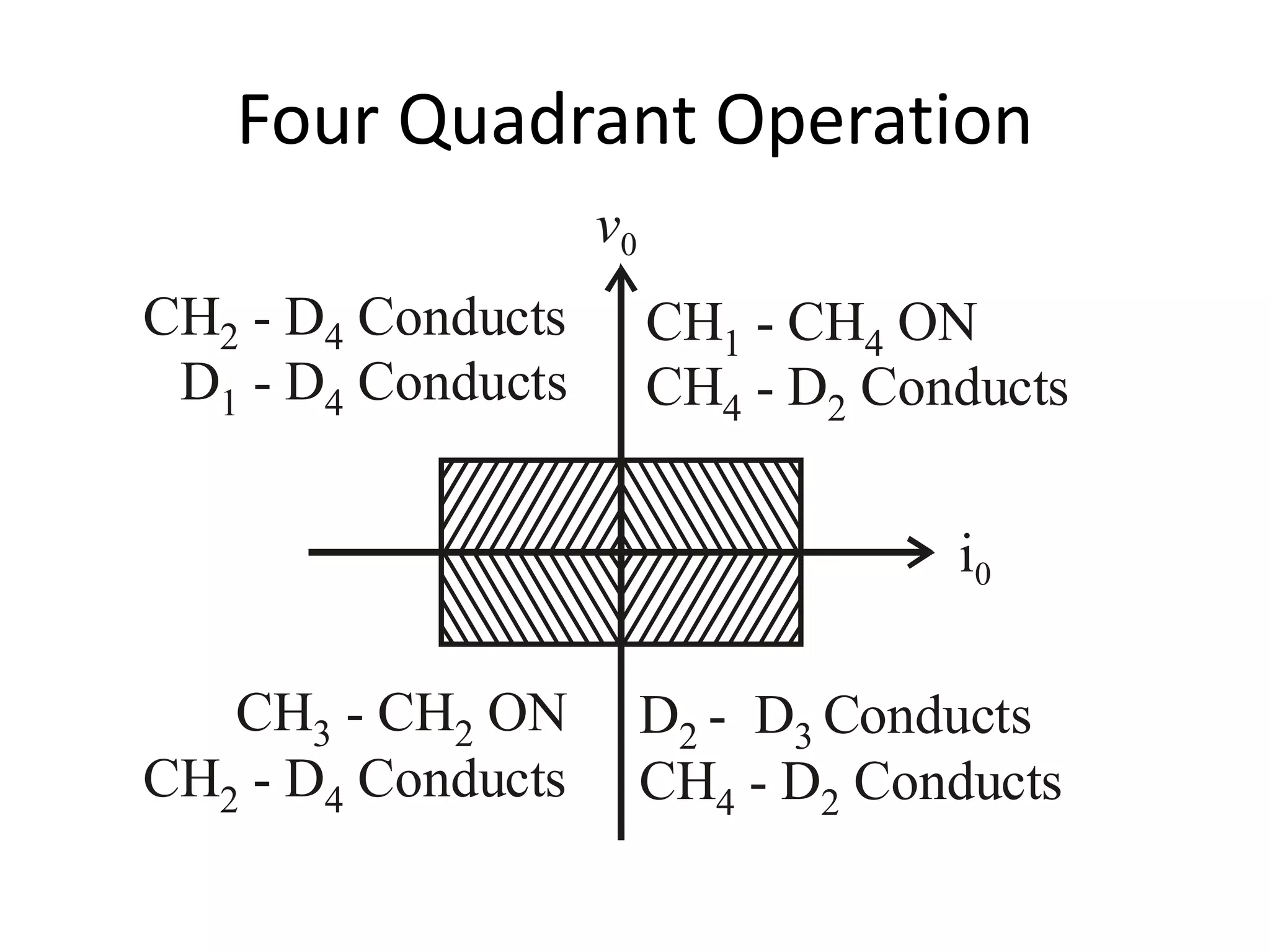

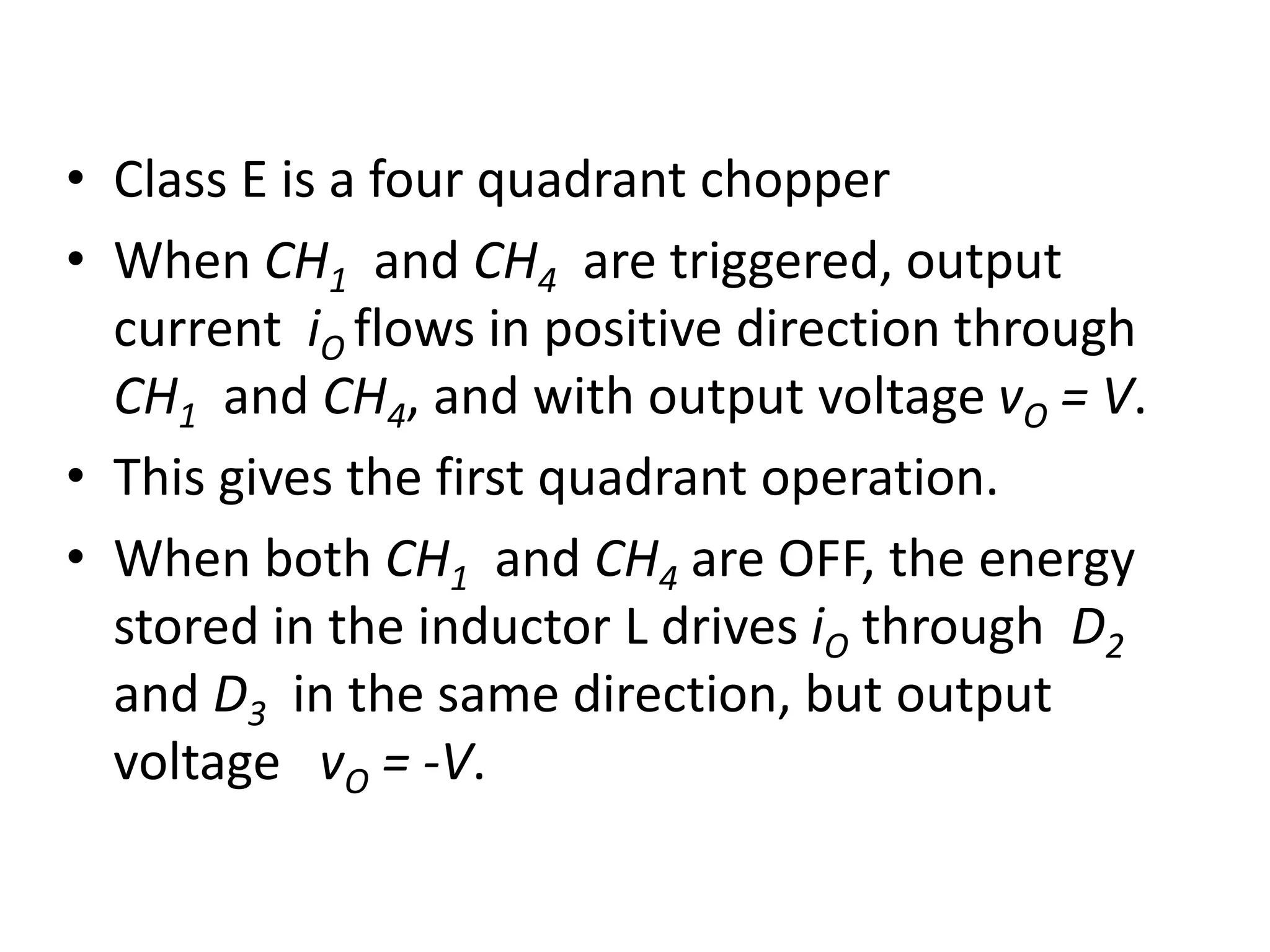

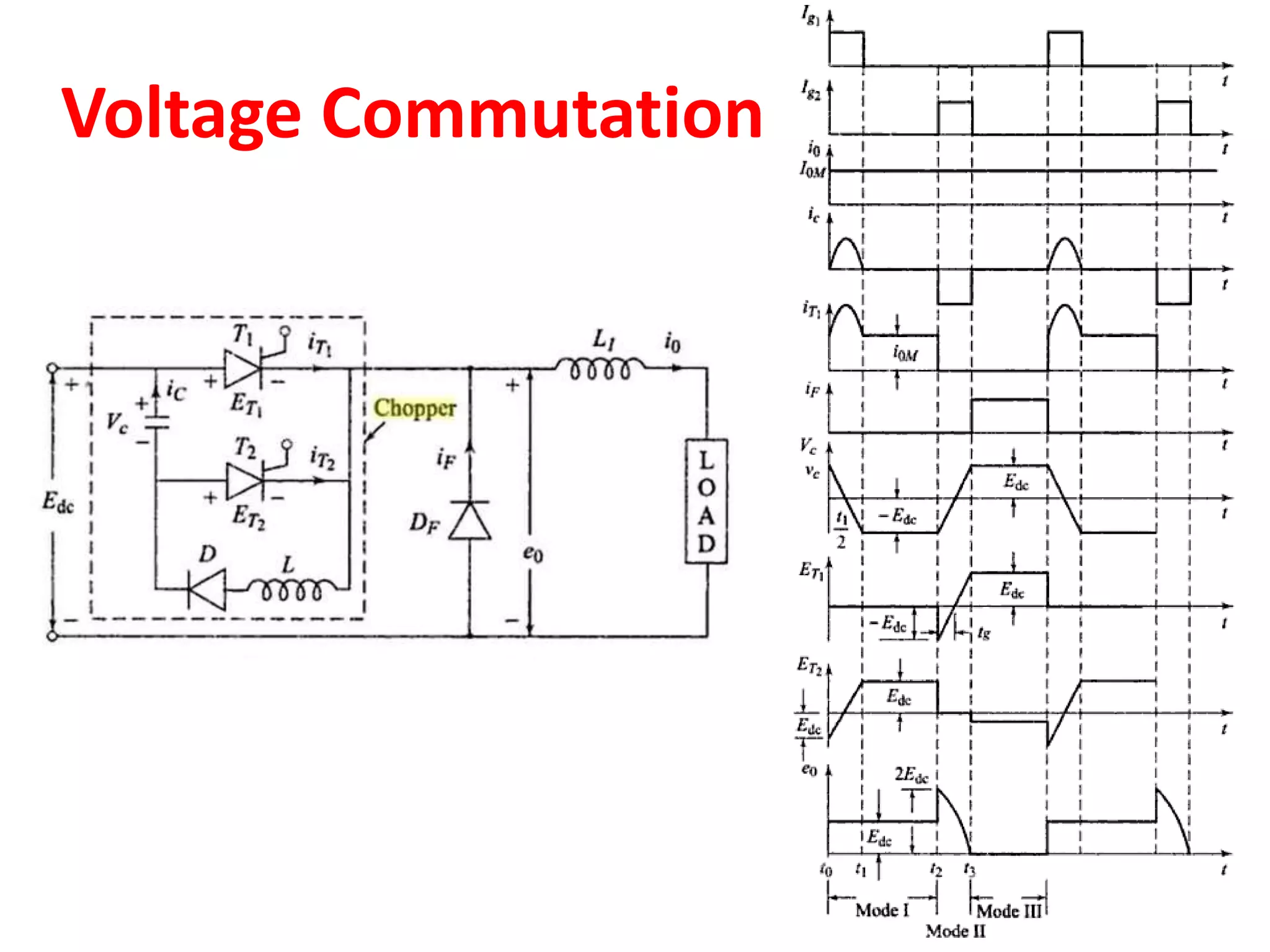

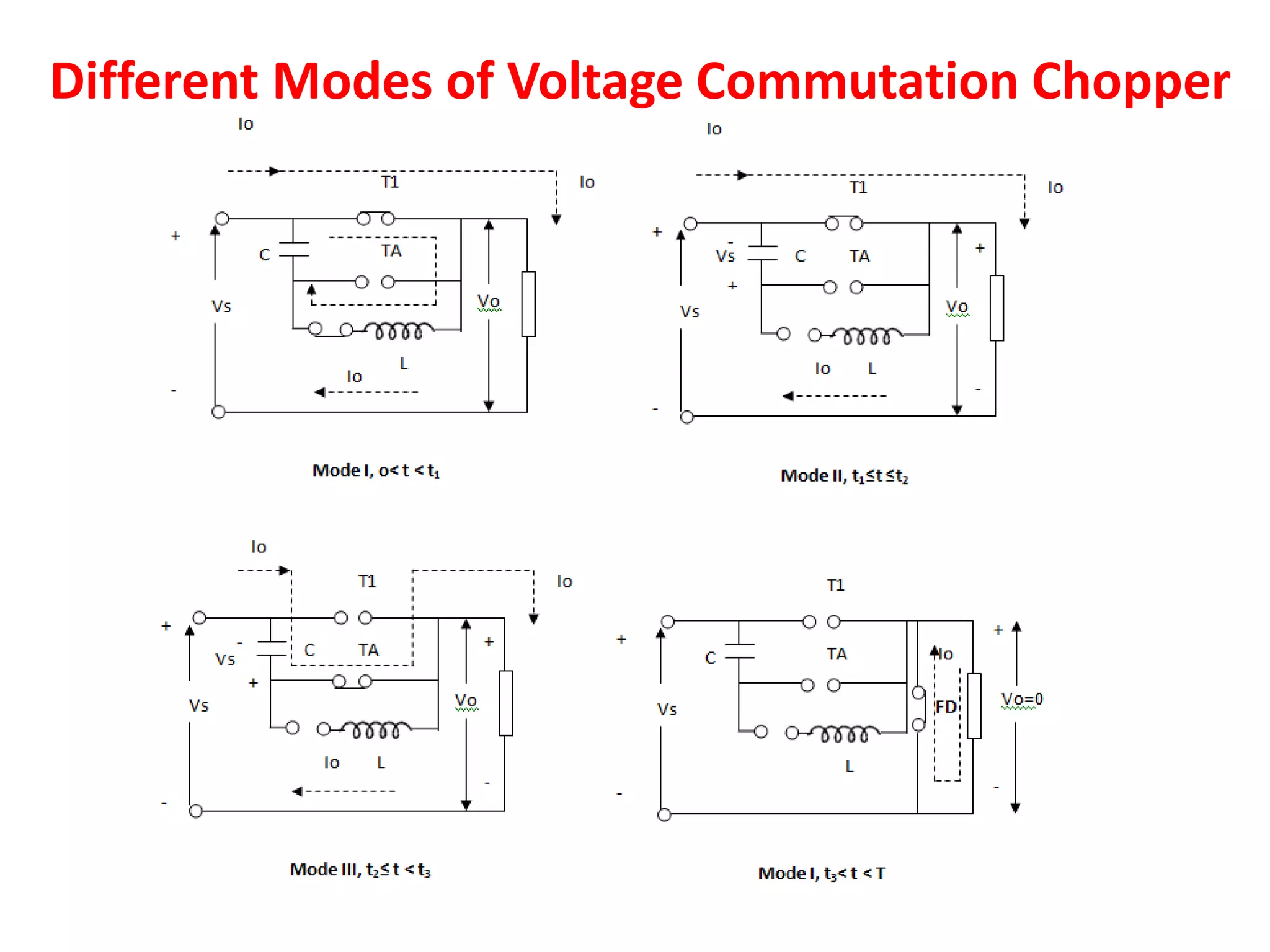

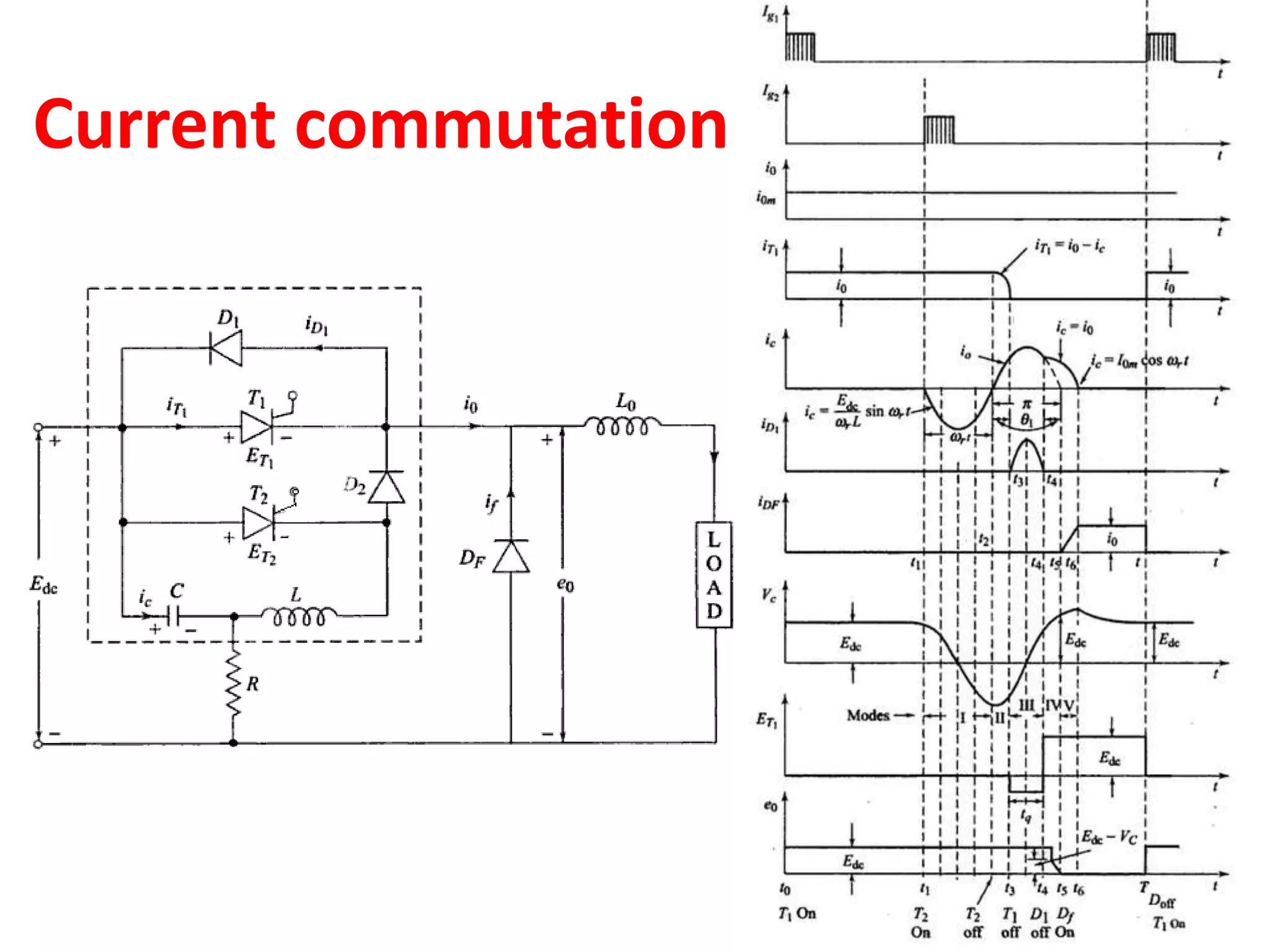

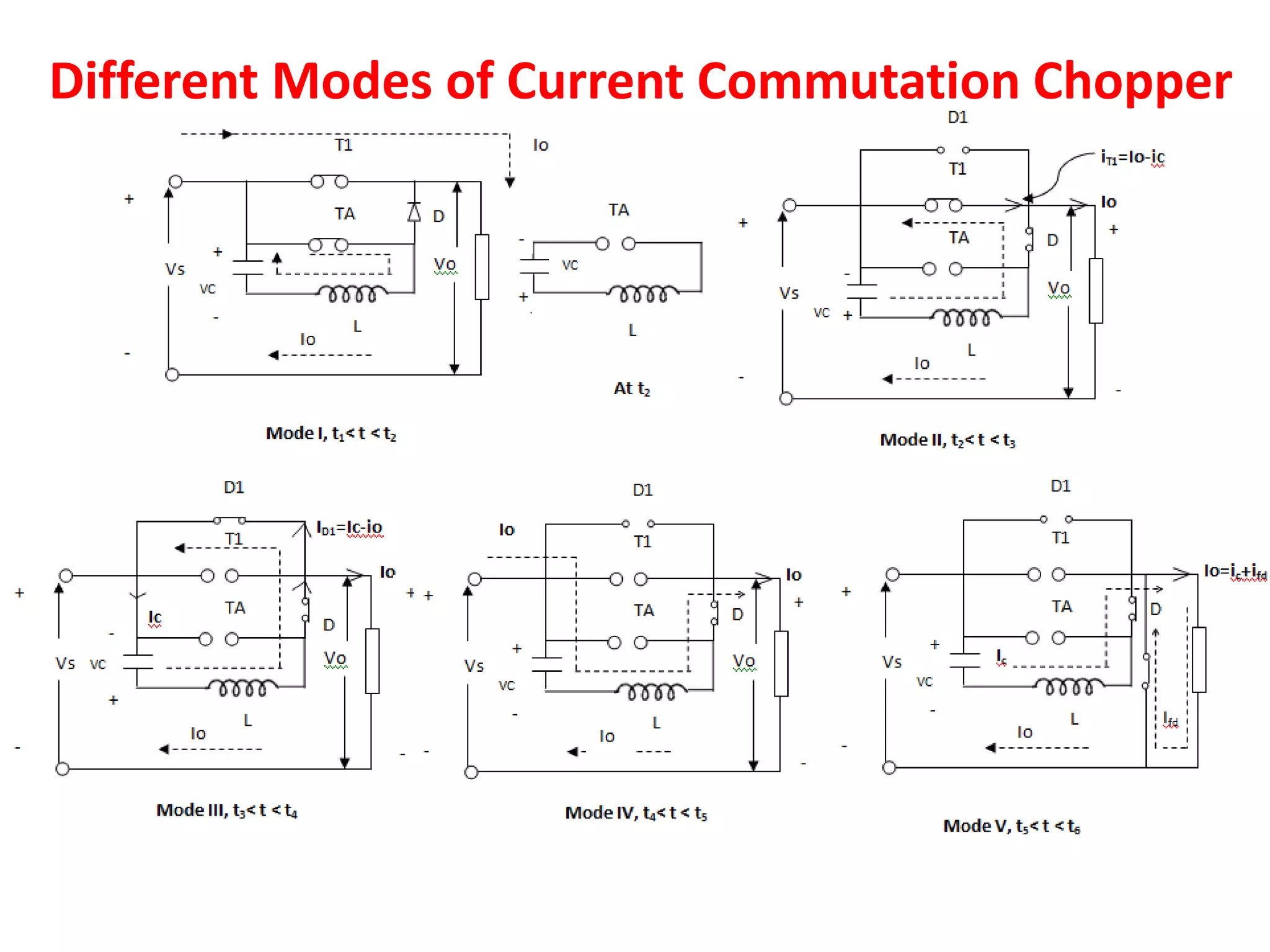

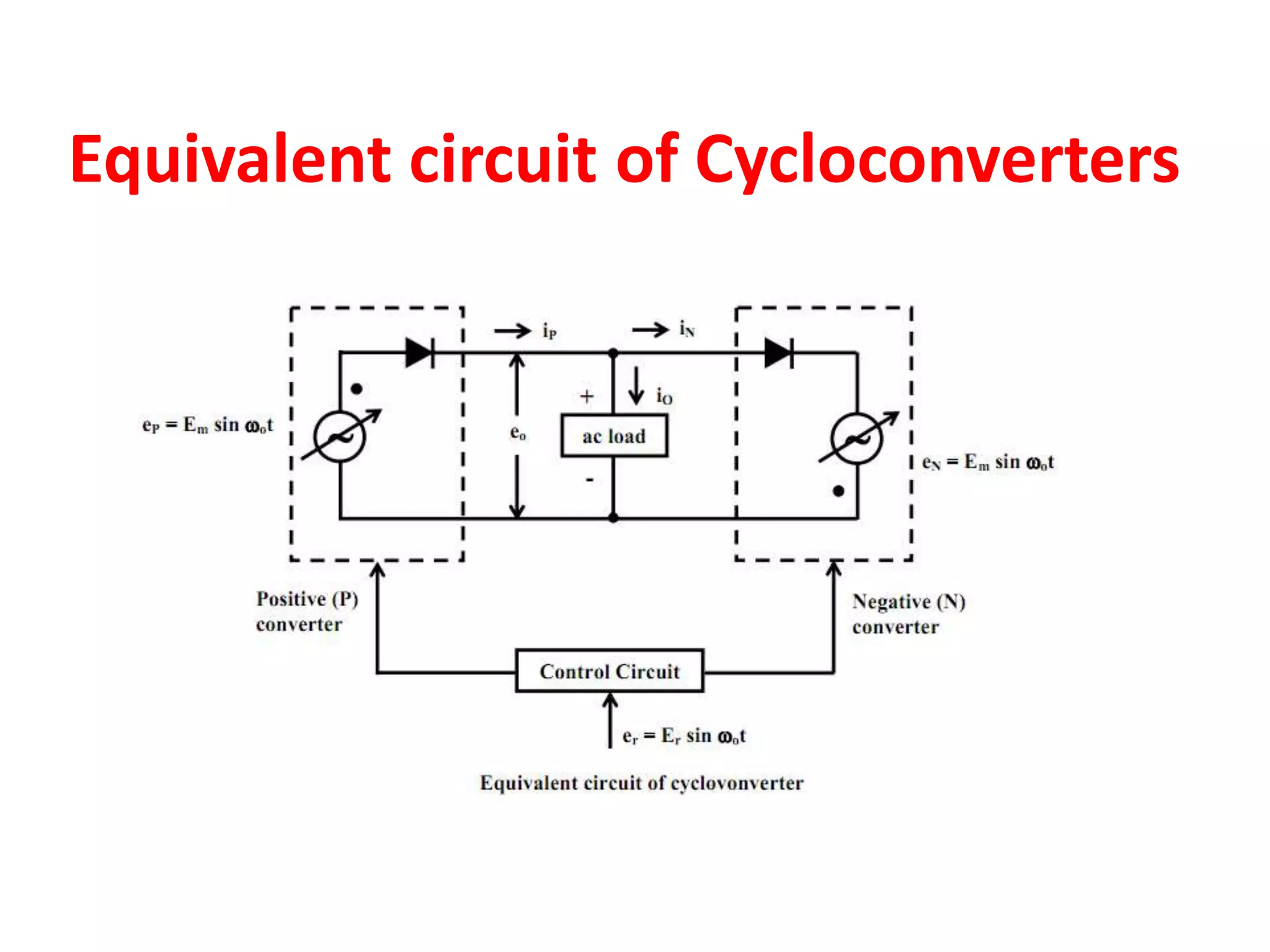

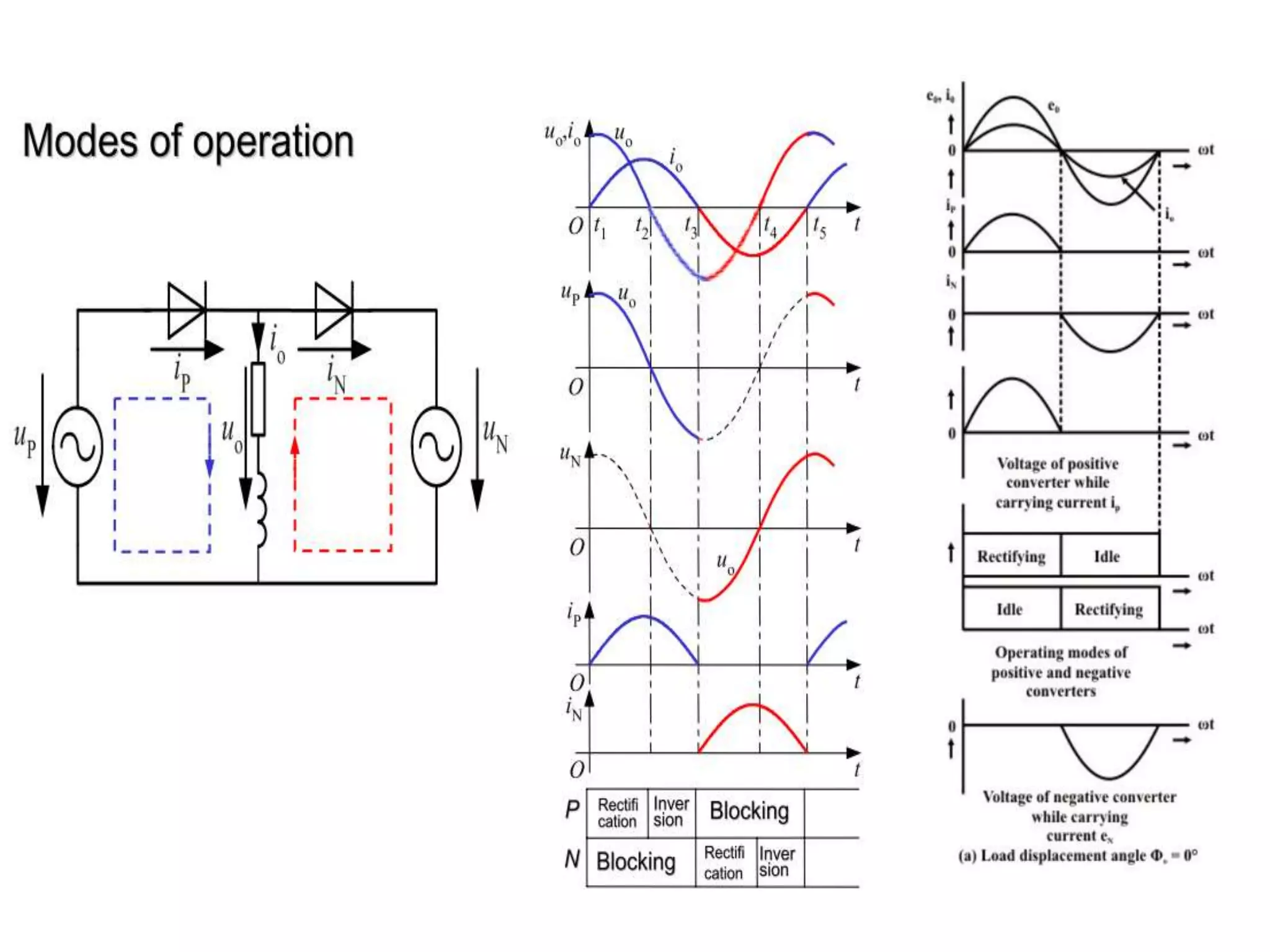

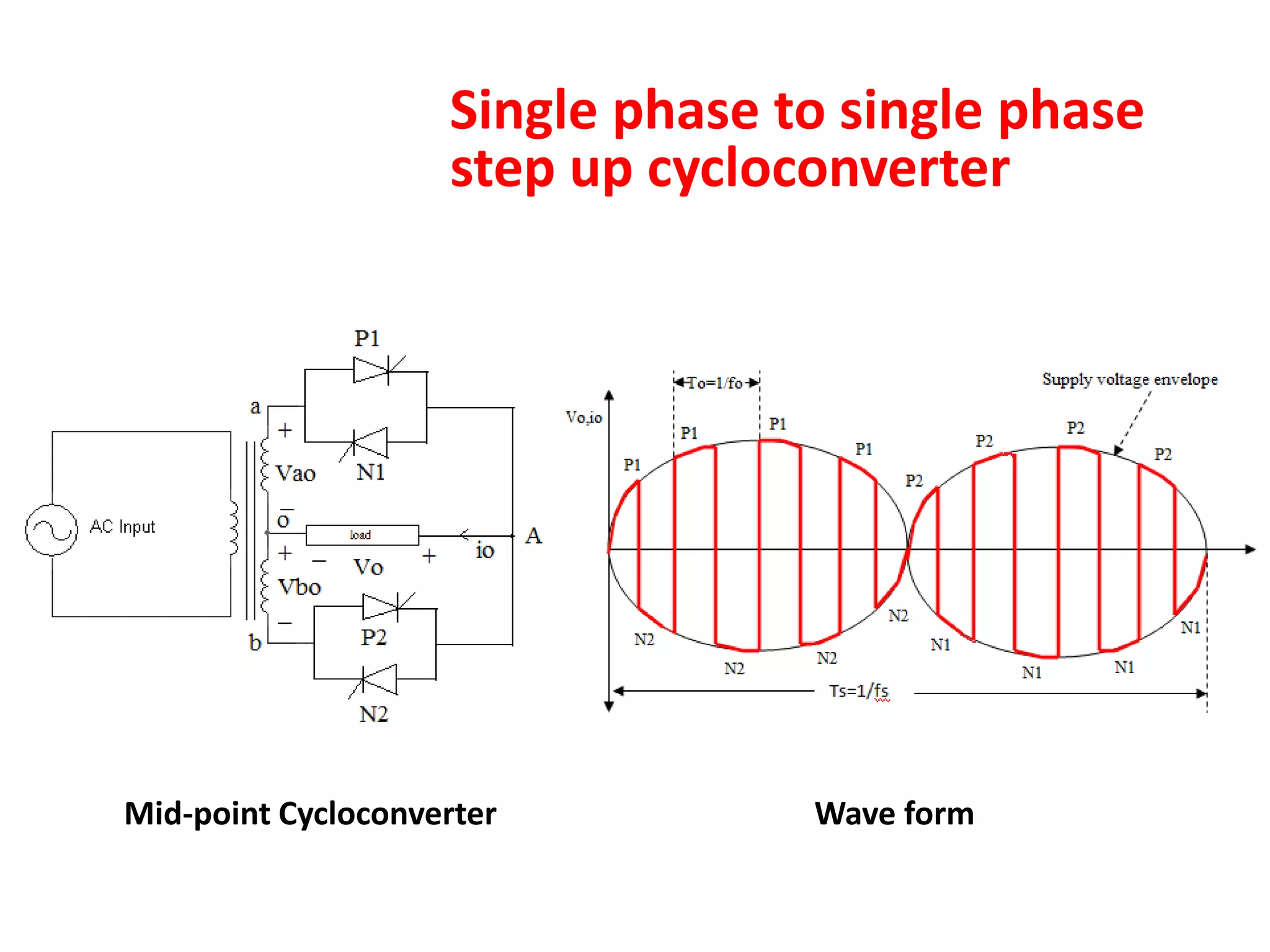

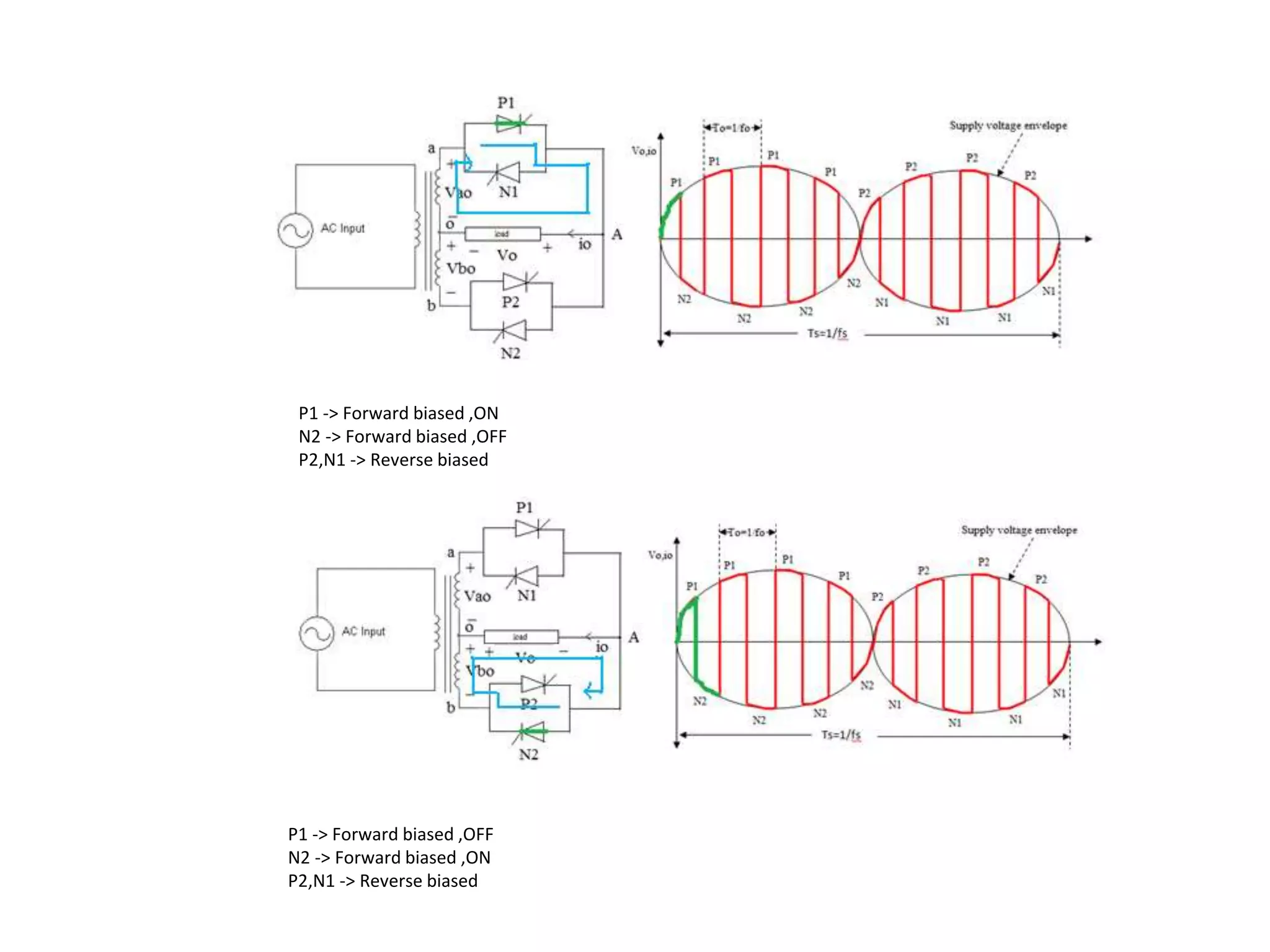

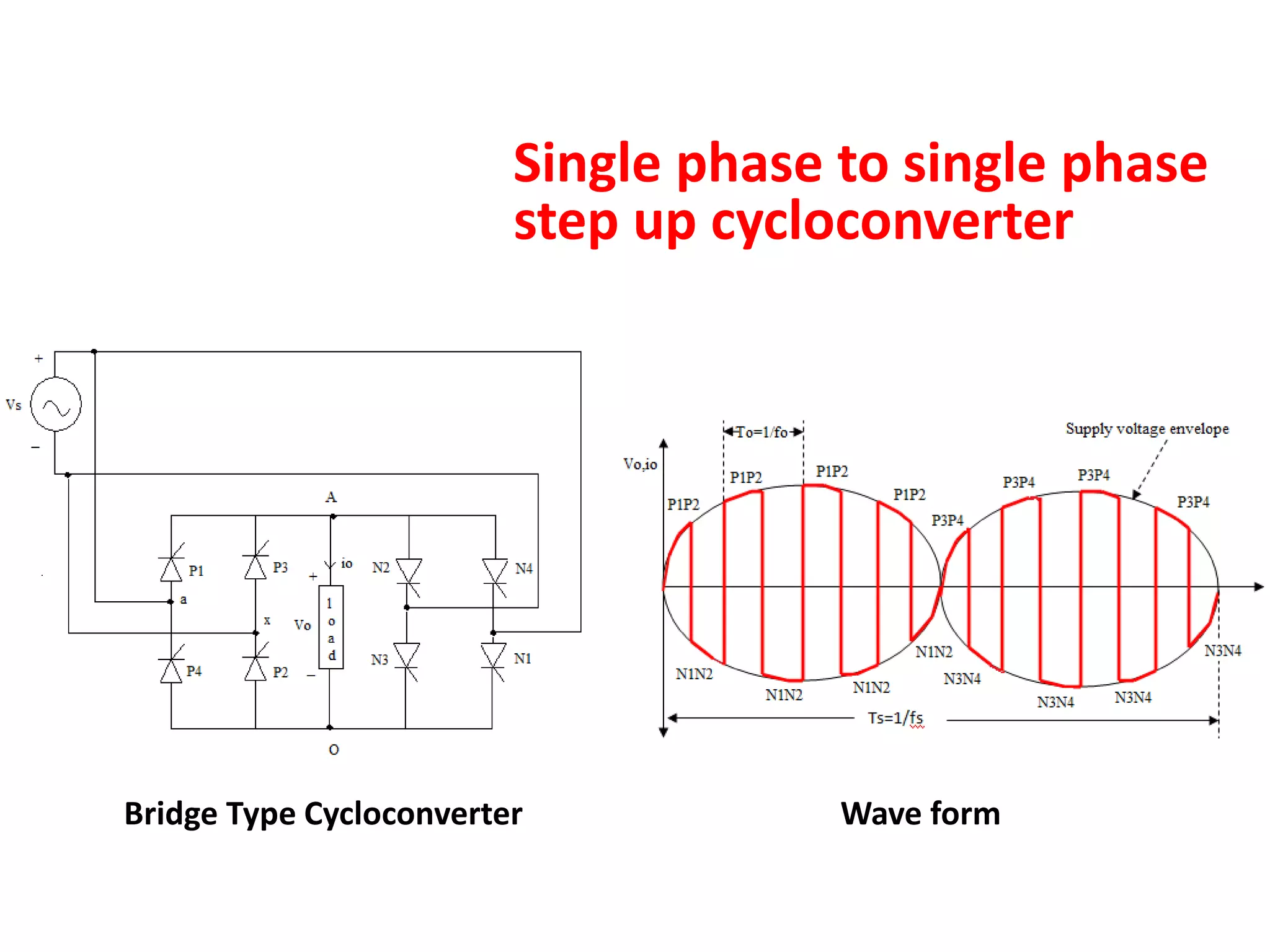

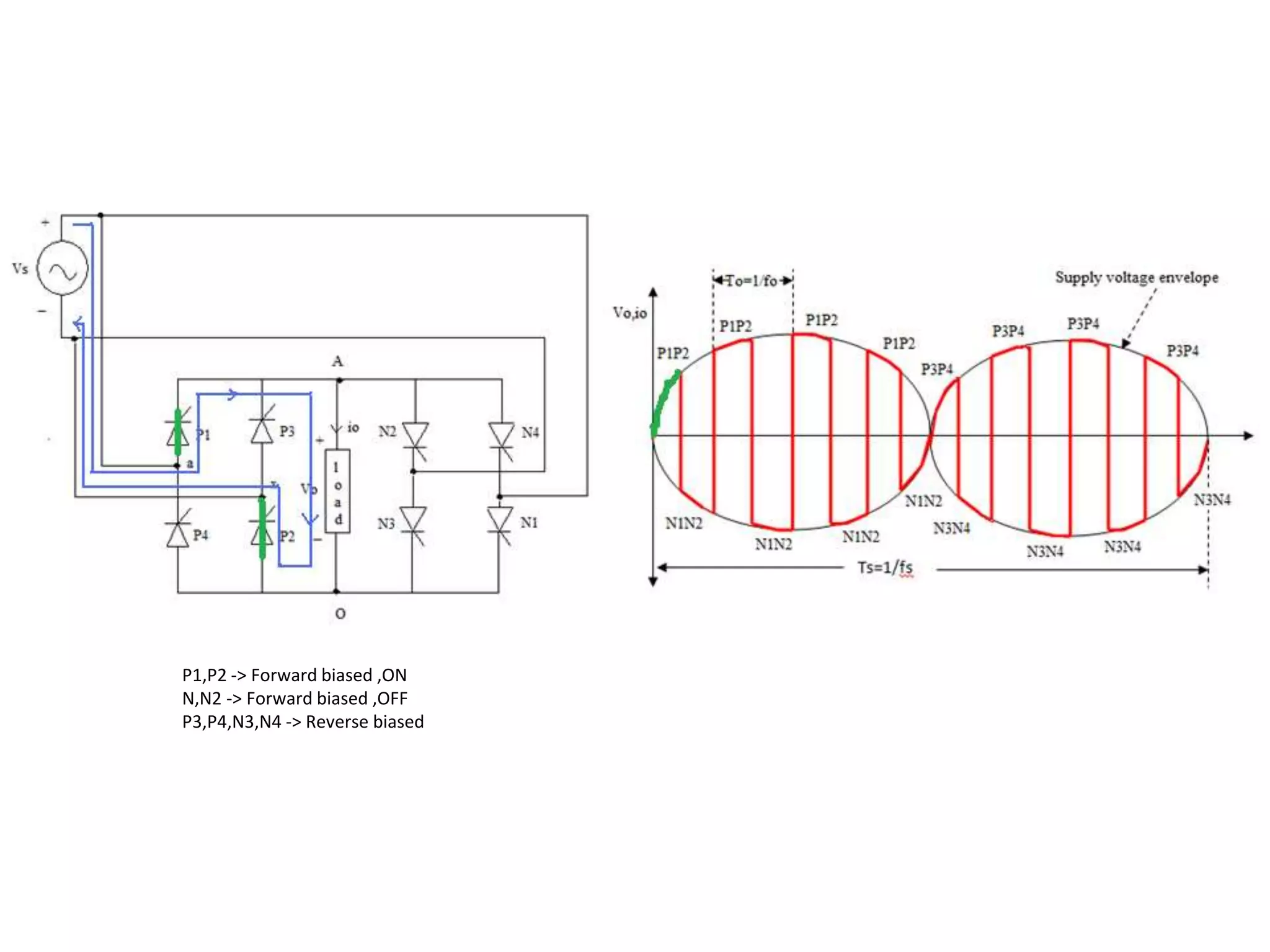

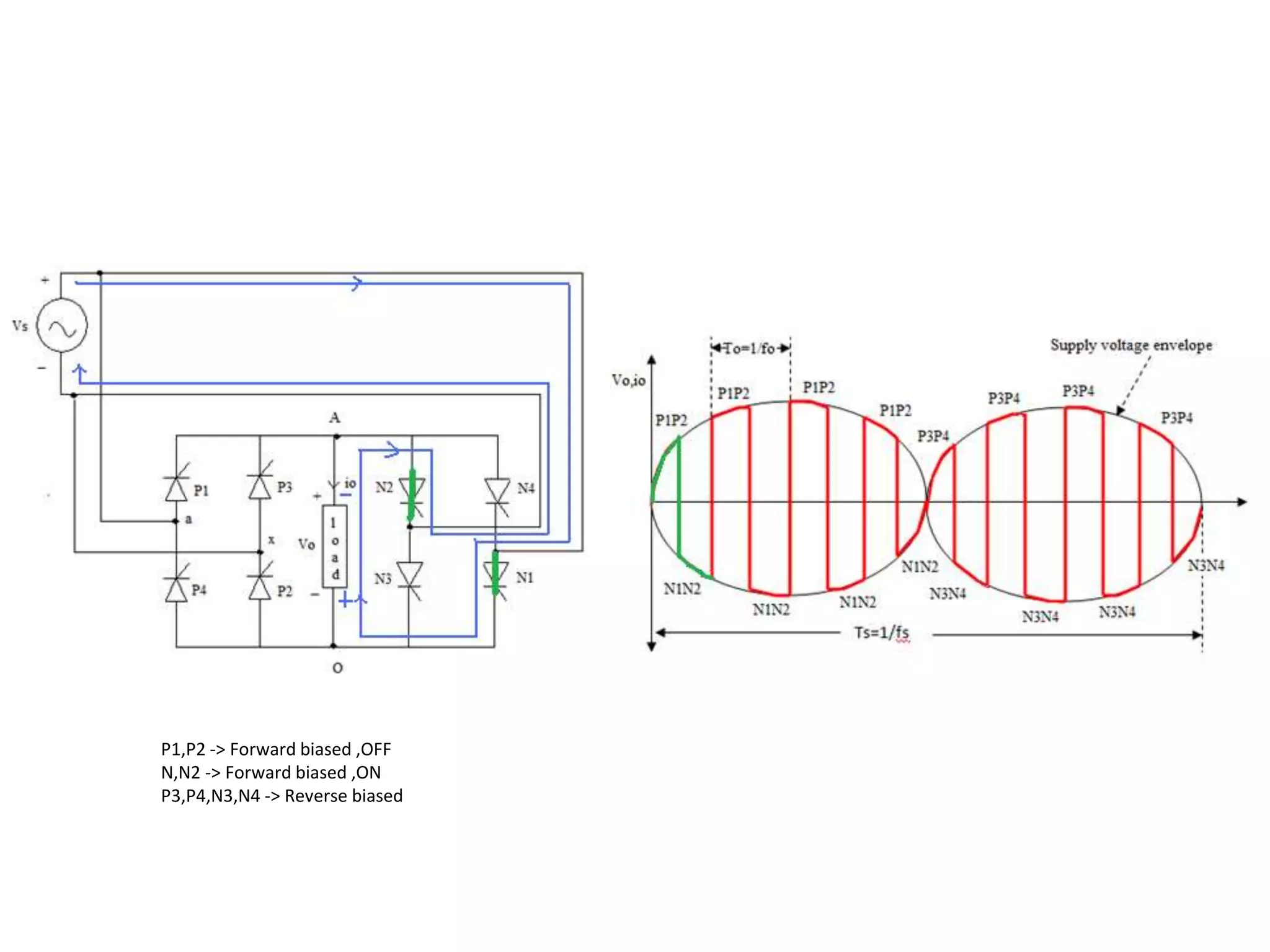

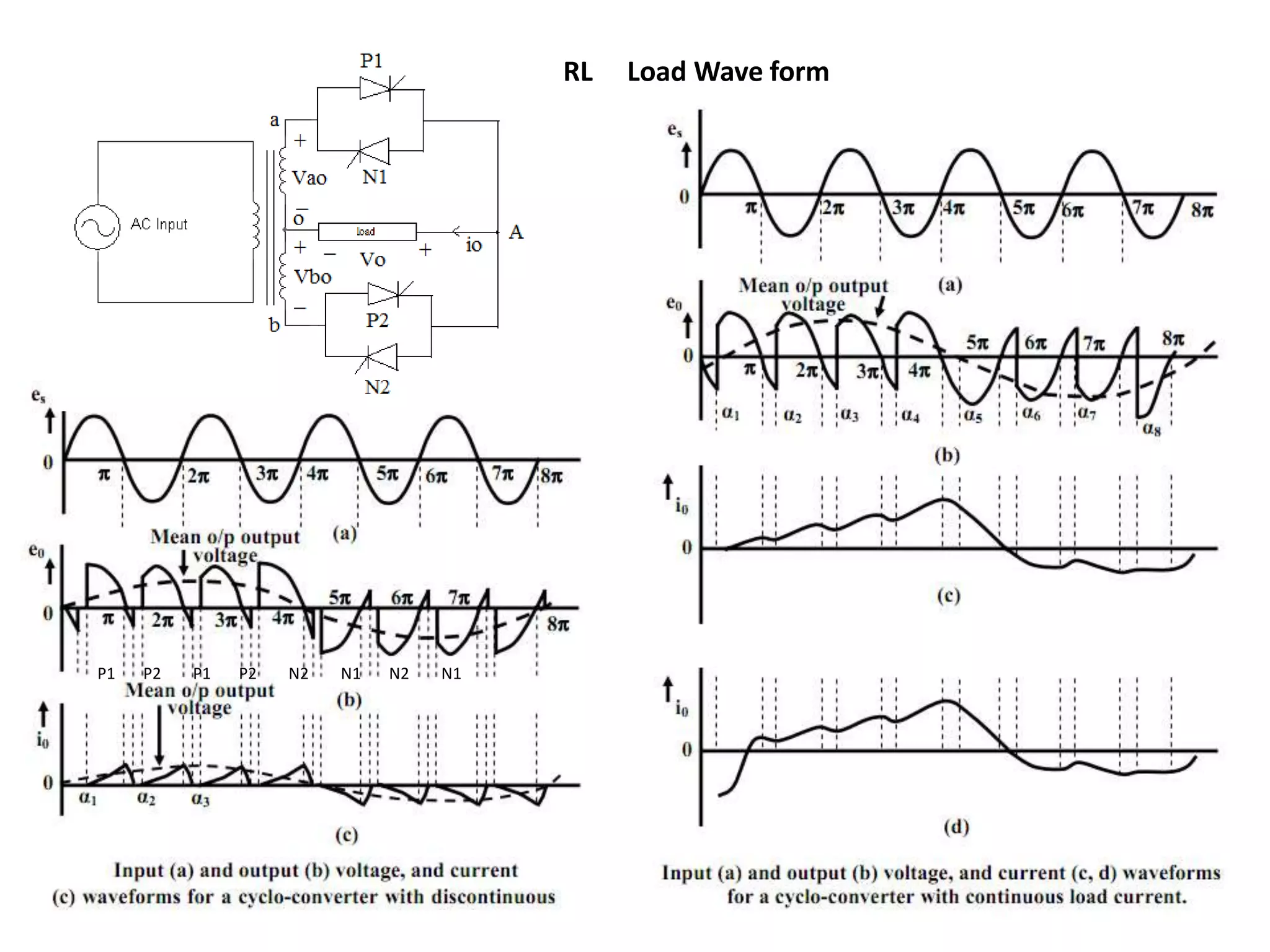

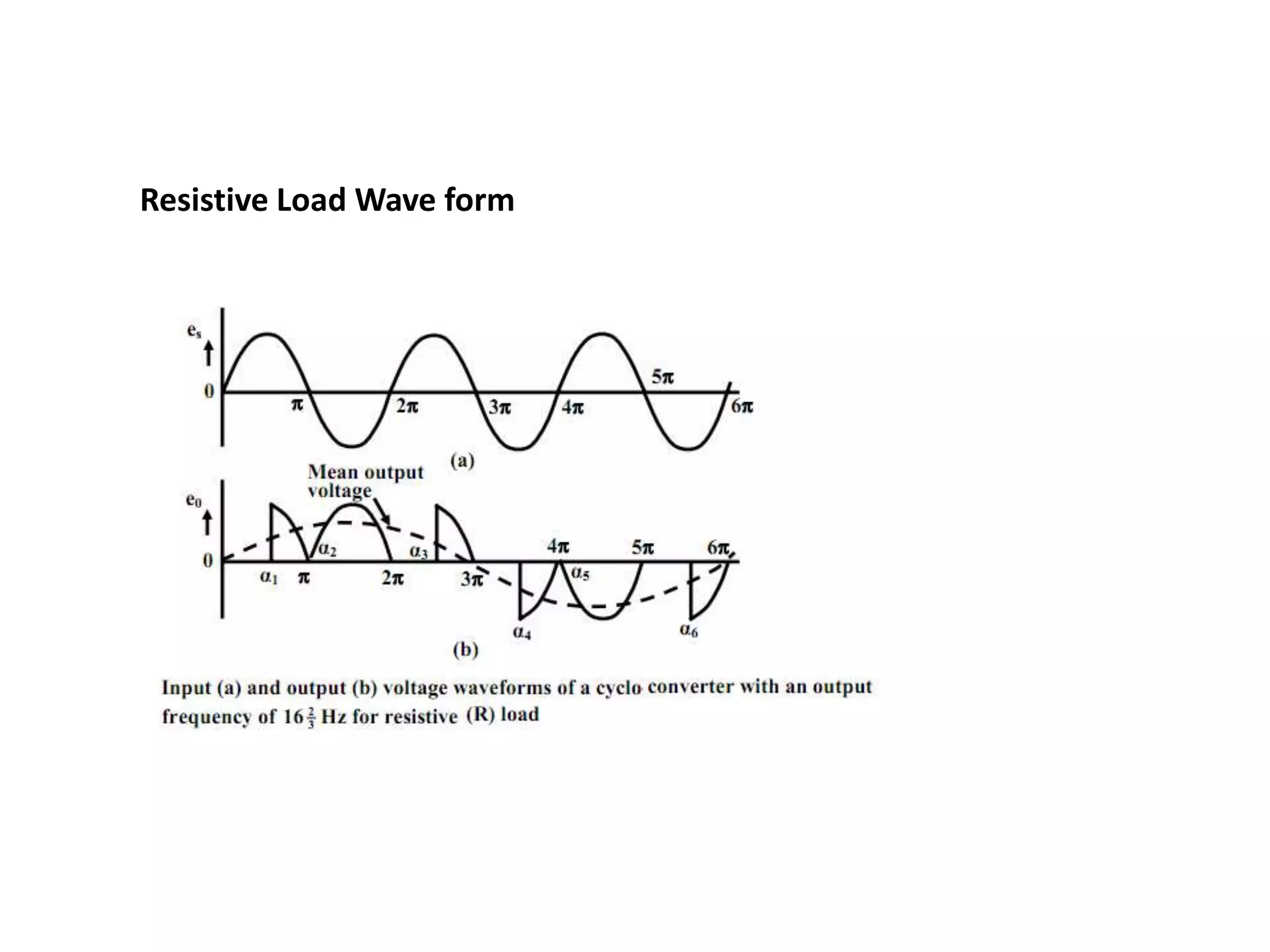

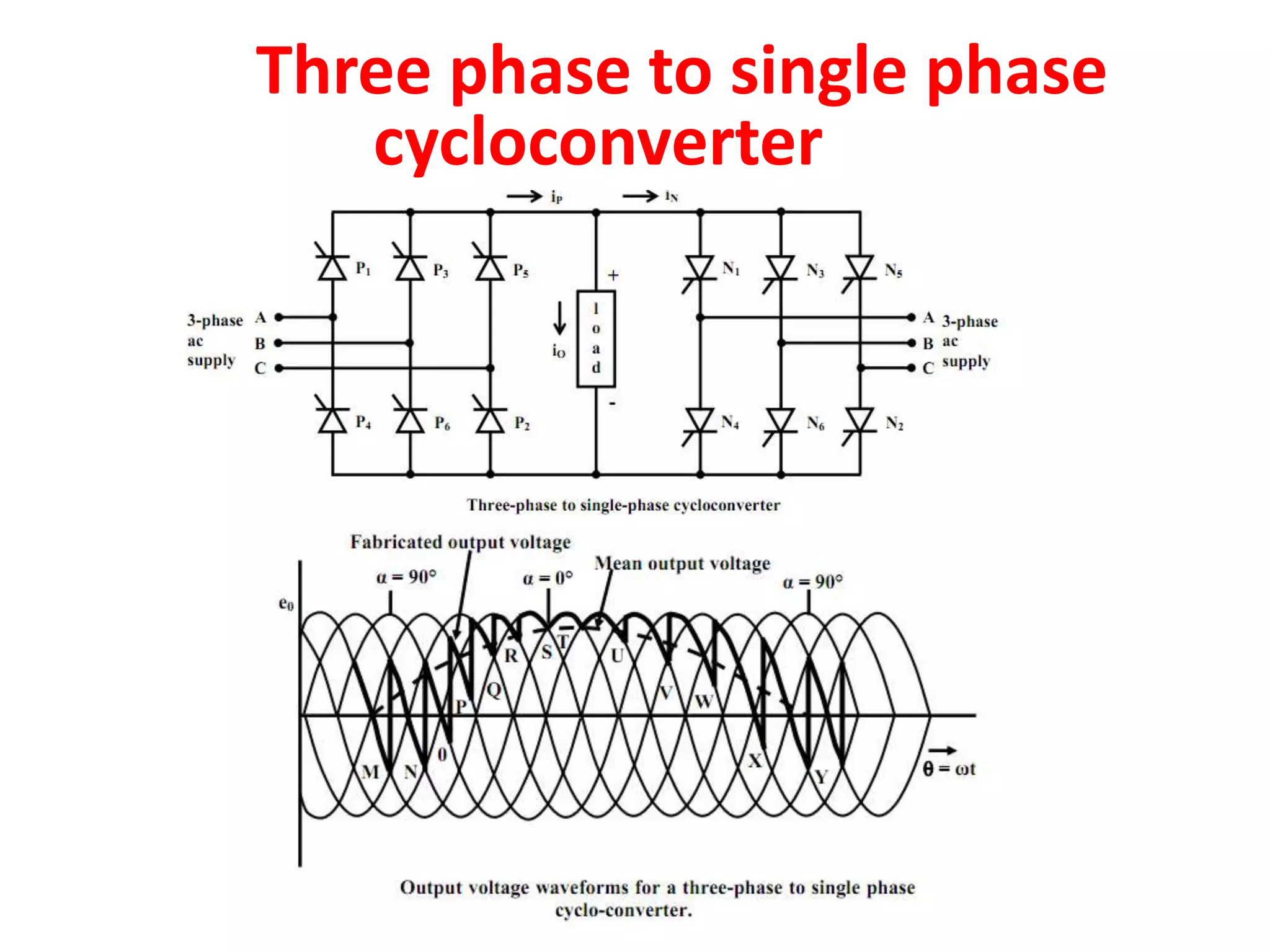

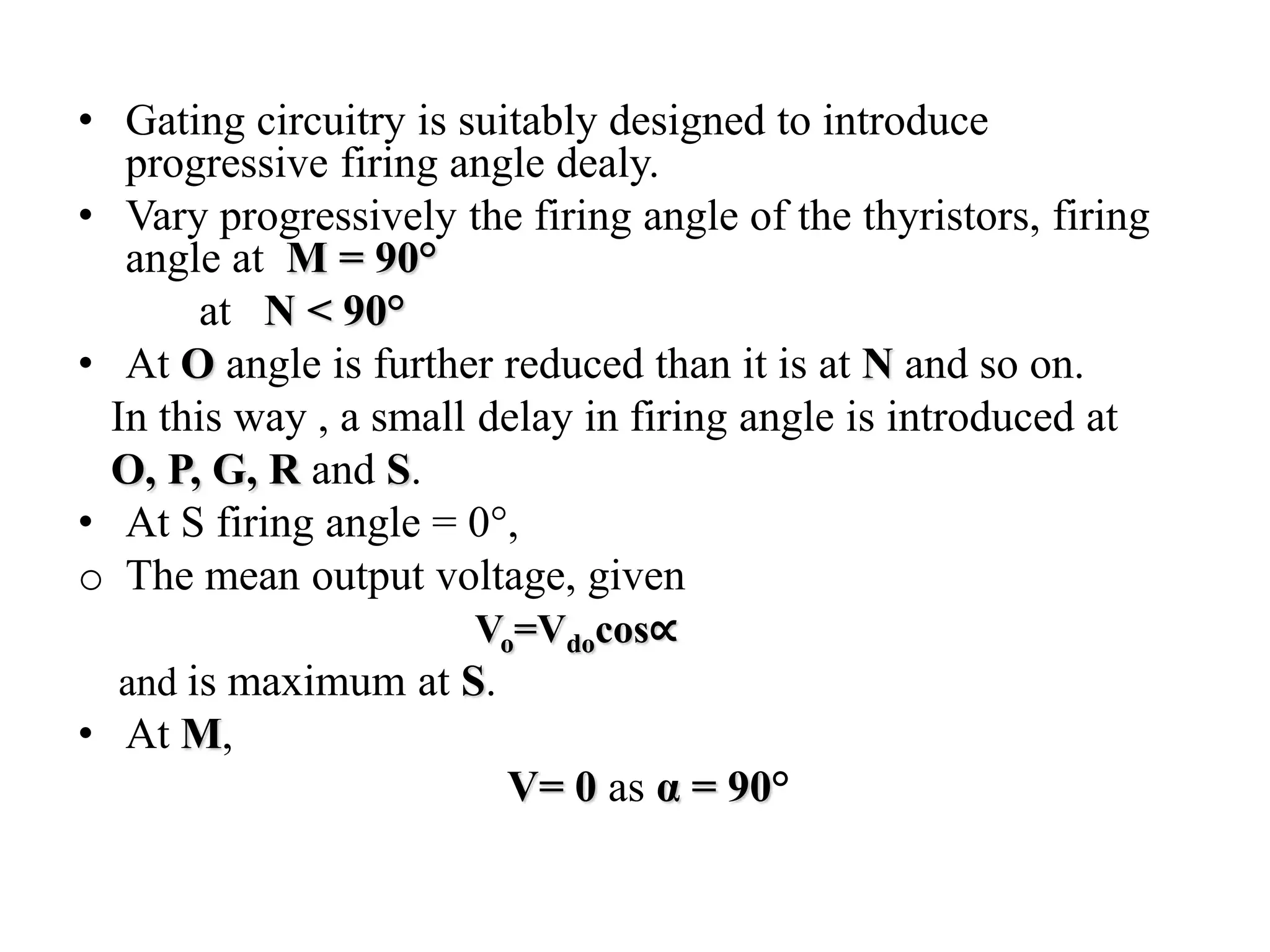

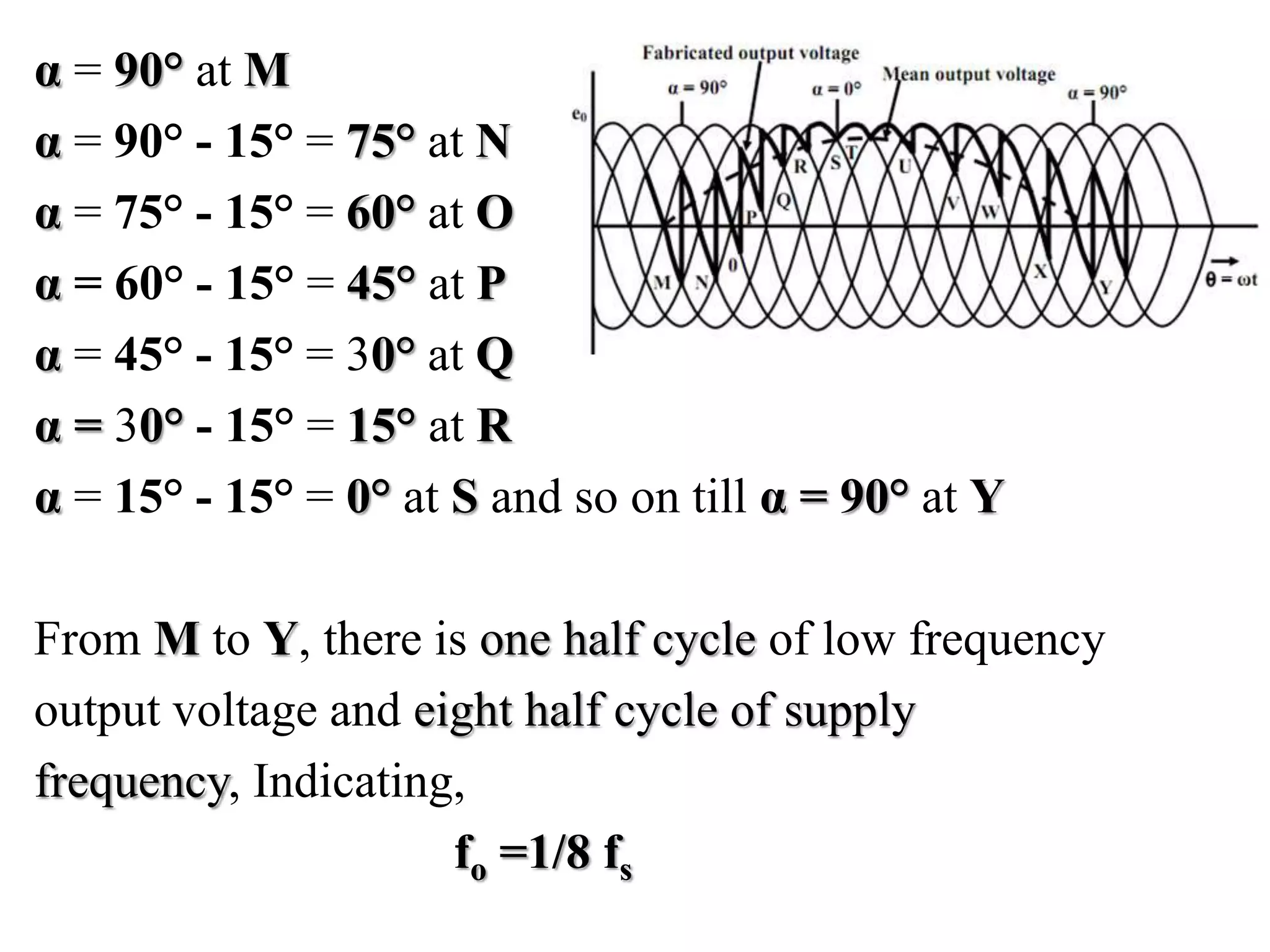

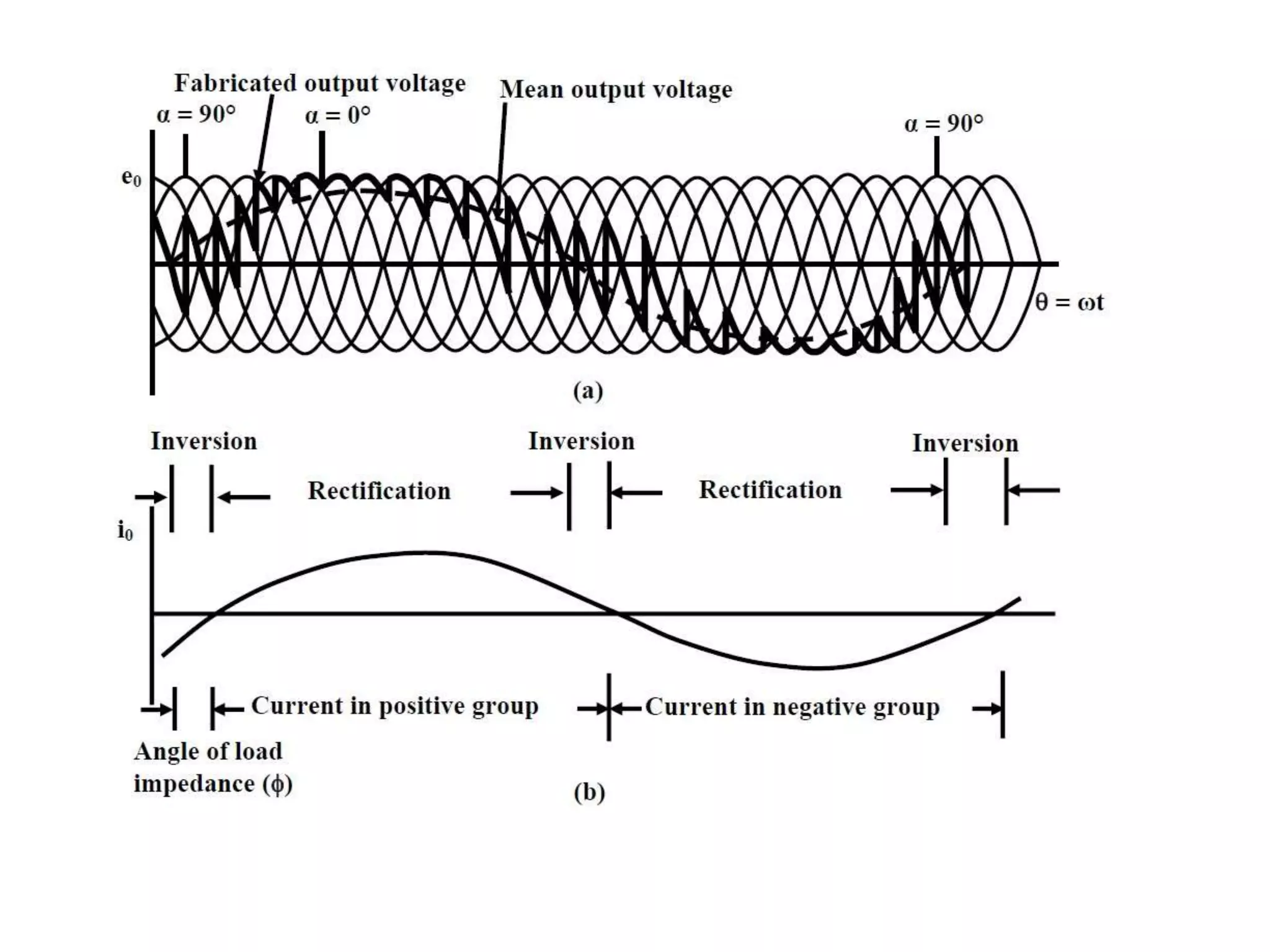

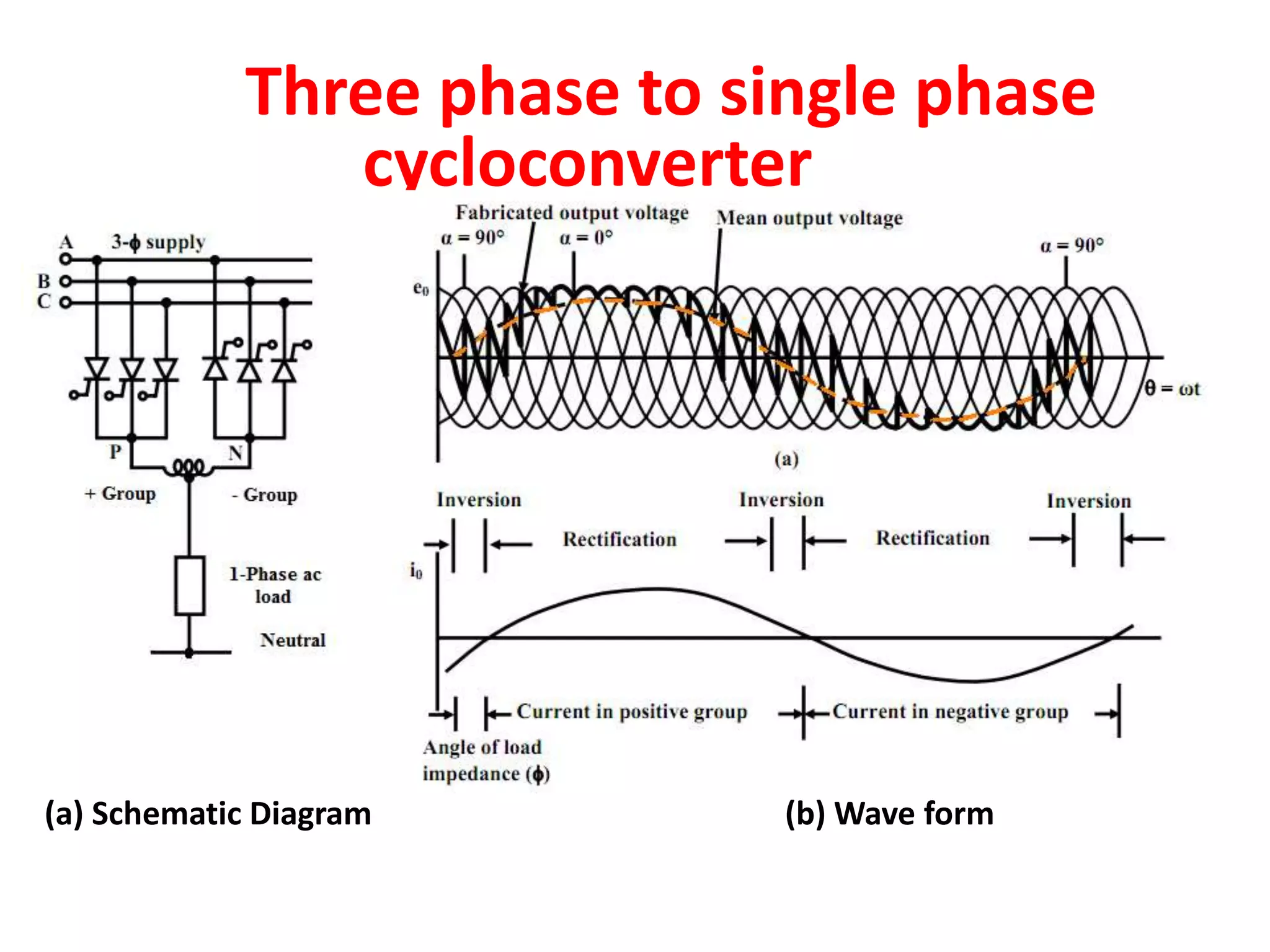

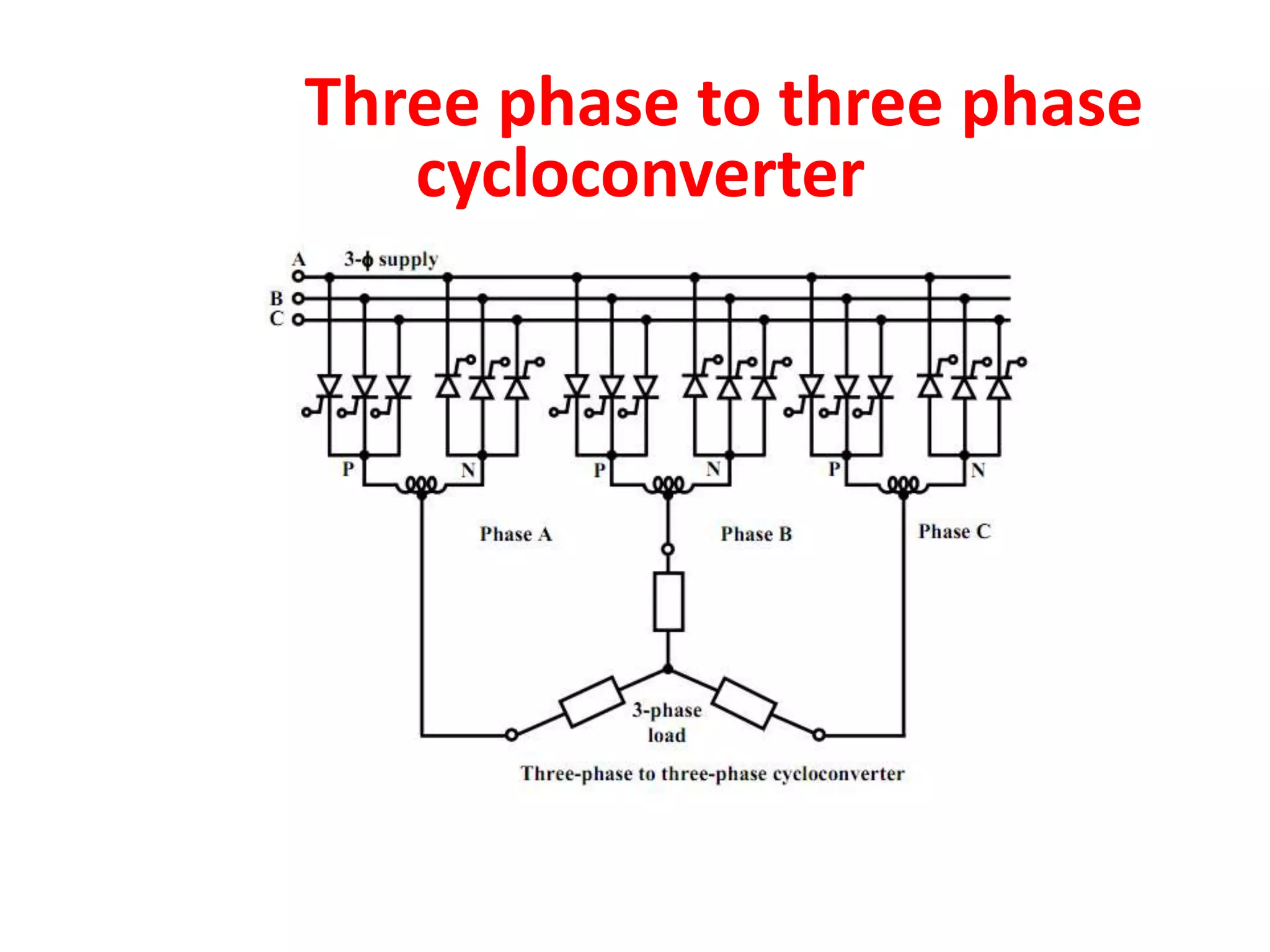

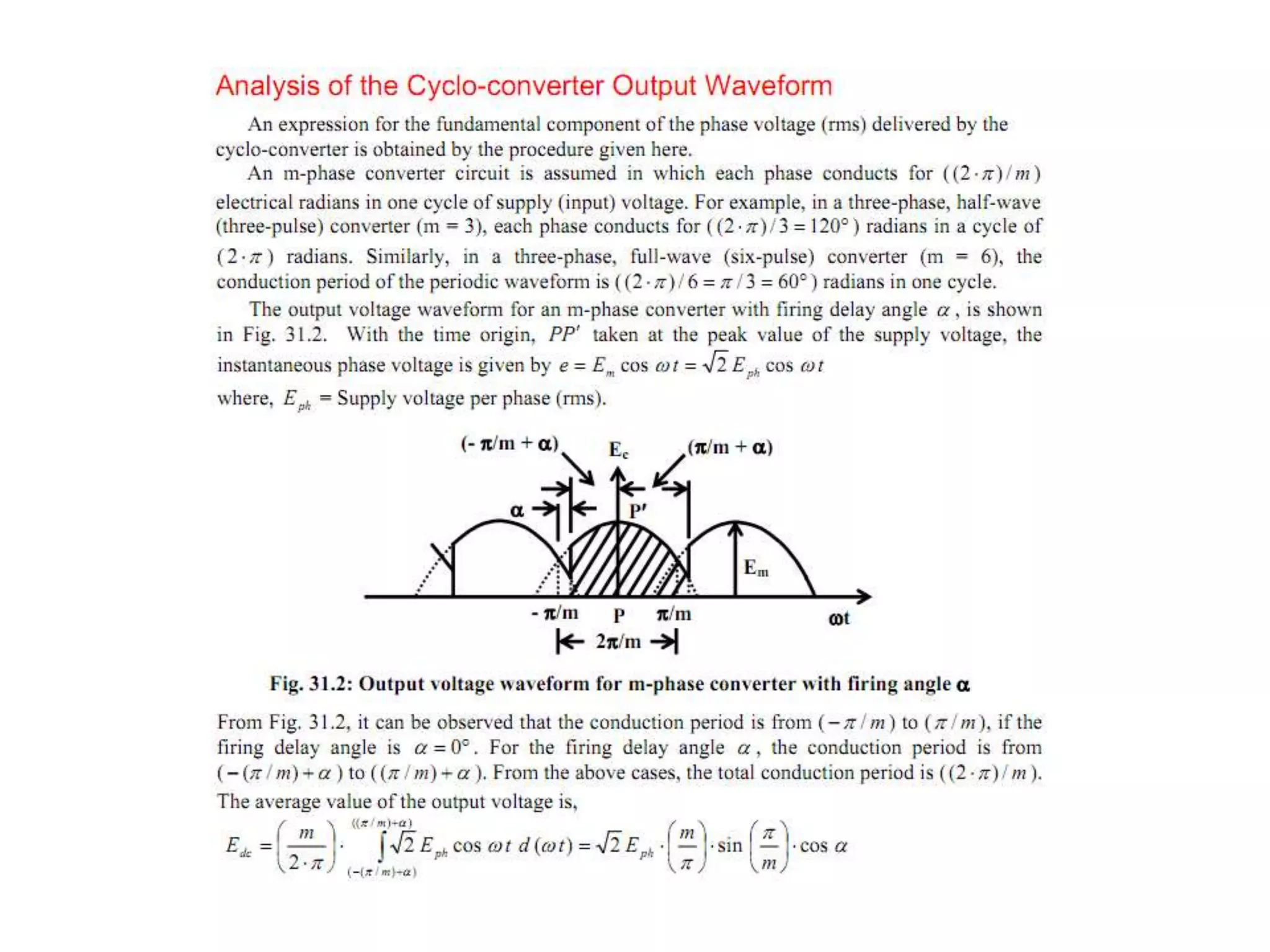

This document discusses different types of choppers and cycloconverters used in DC-DC conversion. It describes the basic operation and characteristics of various classes of choppers (A, B, C, D, E) and explains step-down, step-up, and buck-boost chopper configurations. The document also covers cycloconverter types, components, waveforms, and applications. Advantages include direct AC-AC conversion in a single stage while disadvantages are their complexity and limited output frequency range.