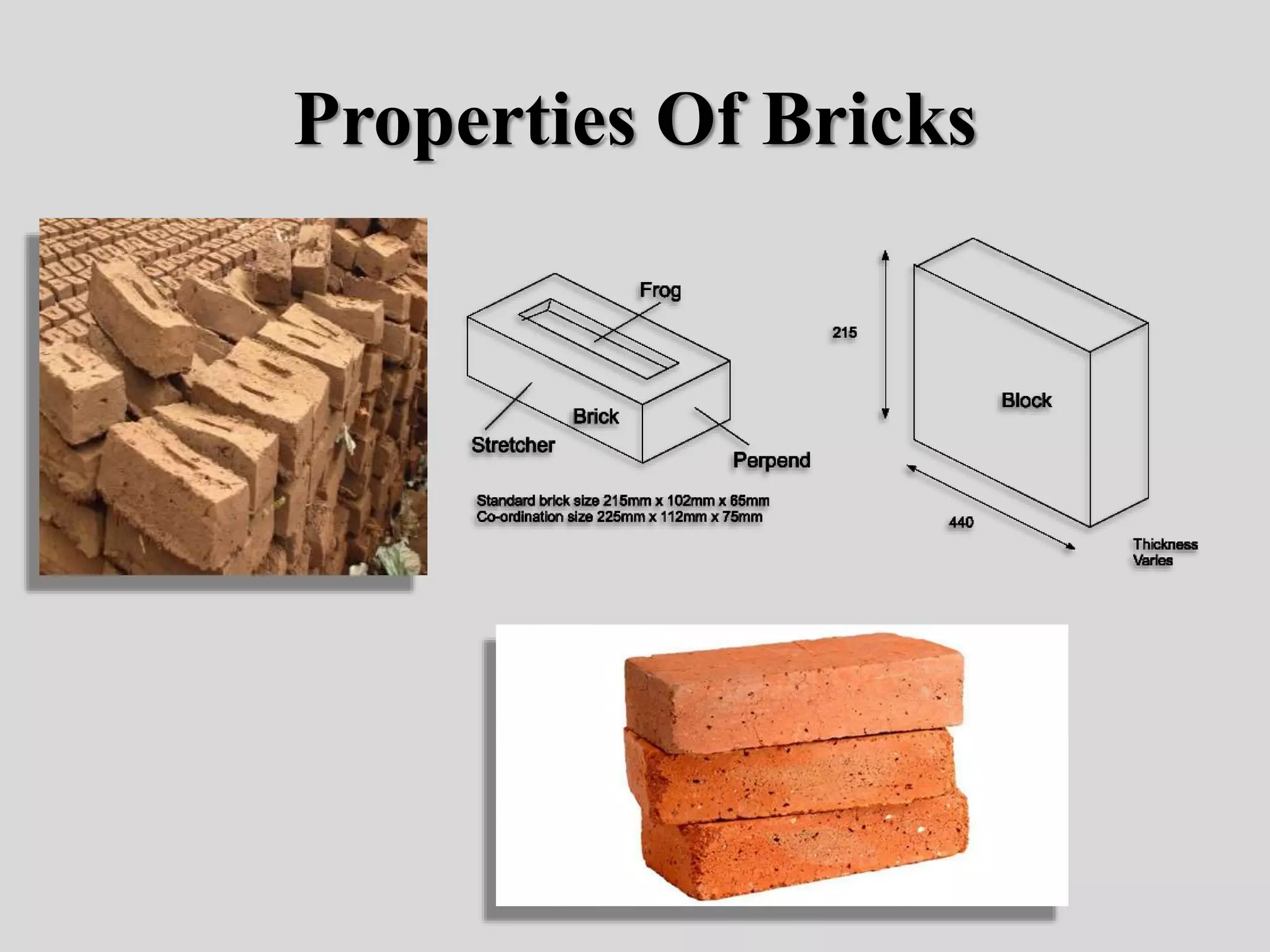

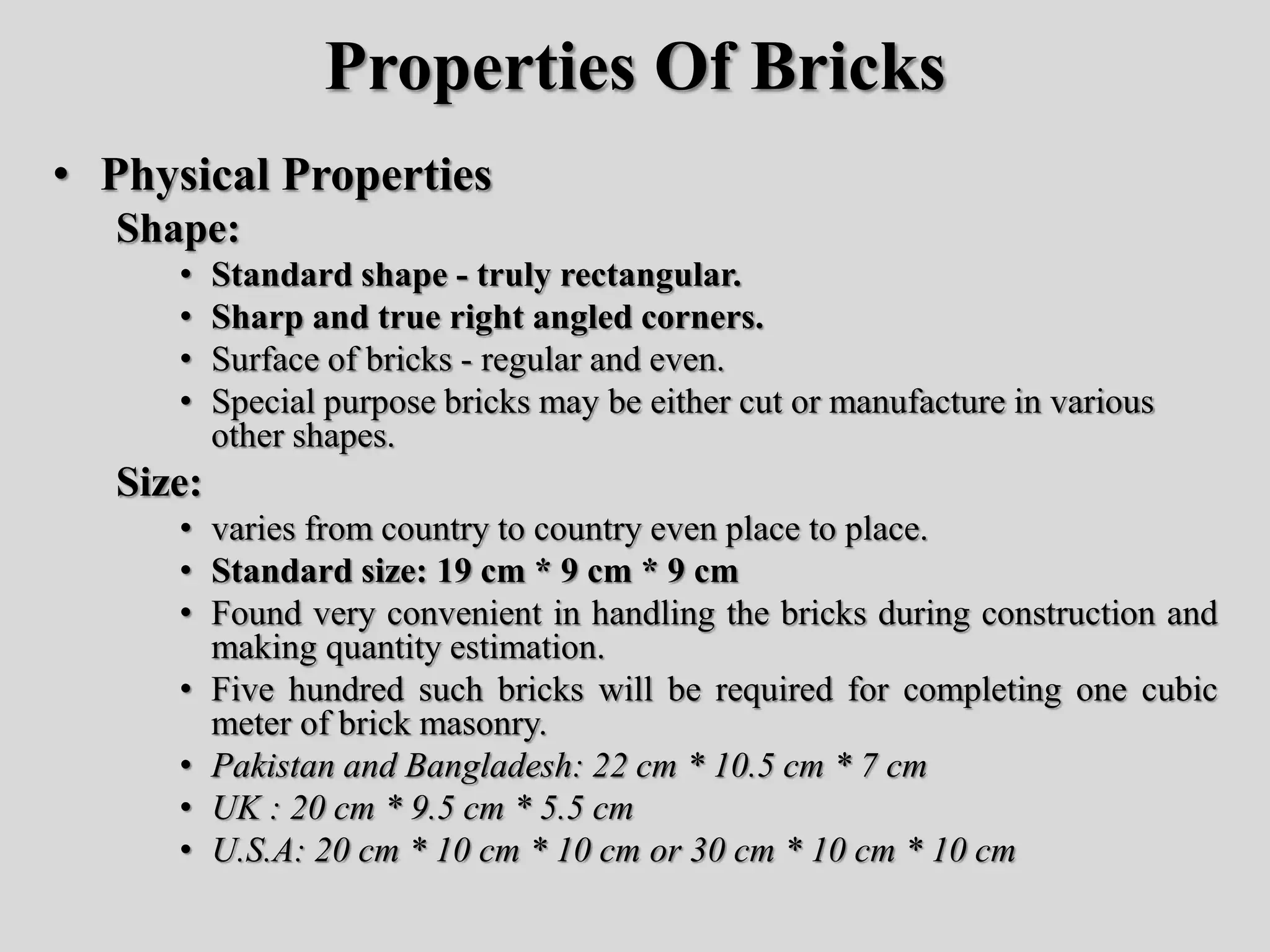

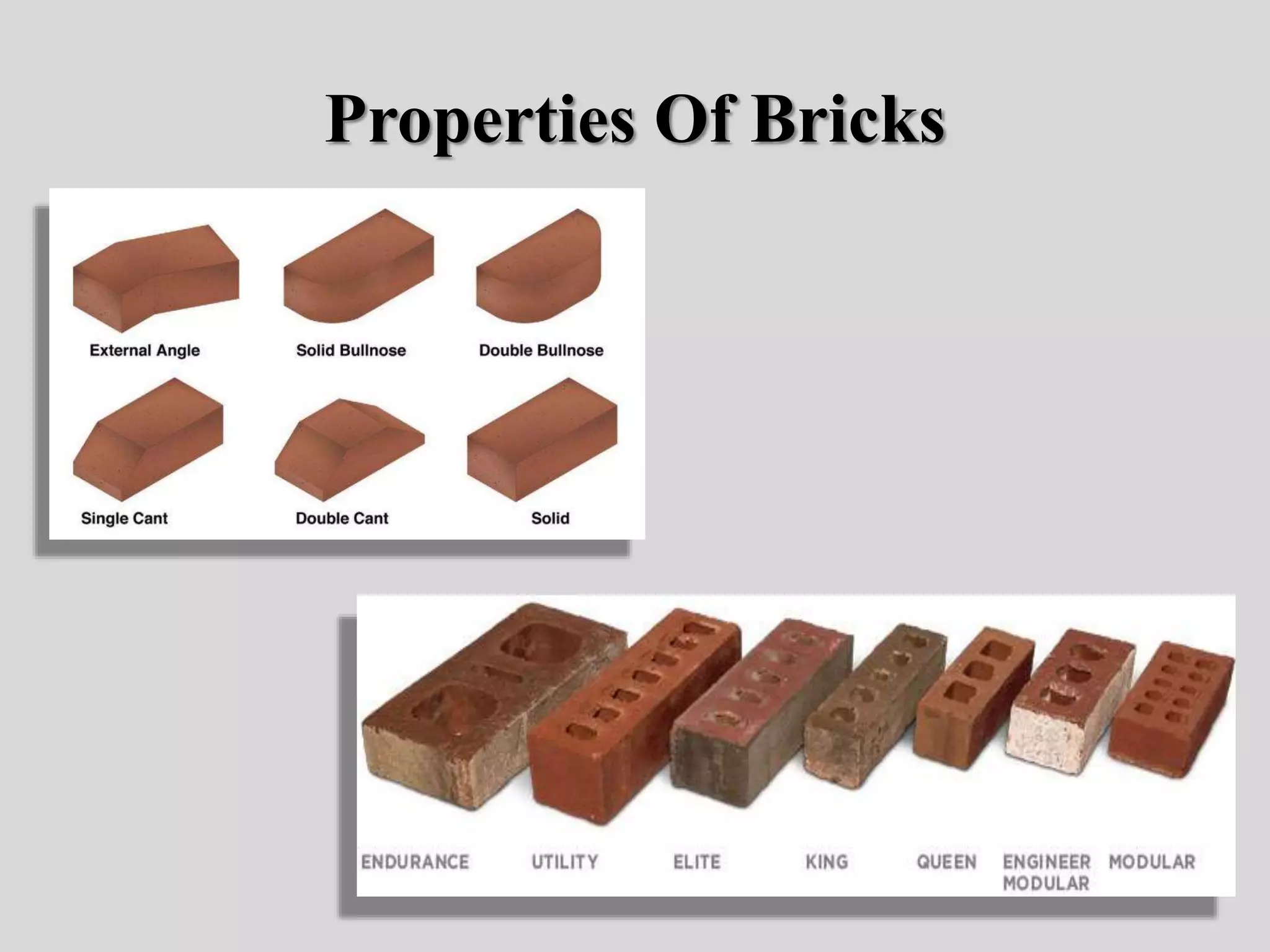

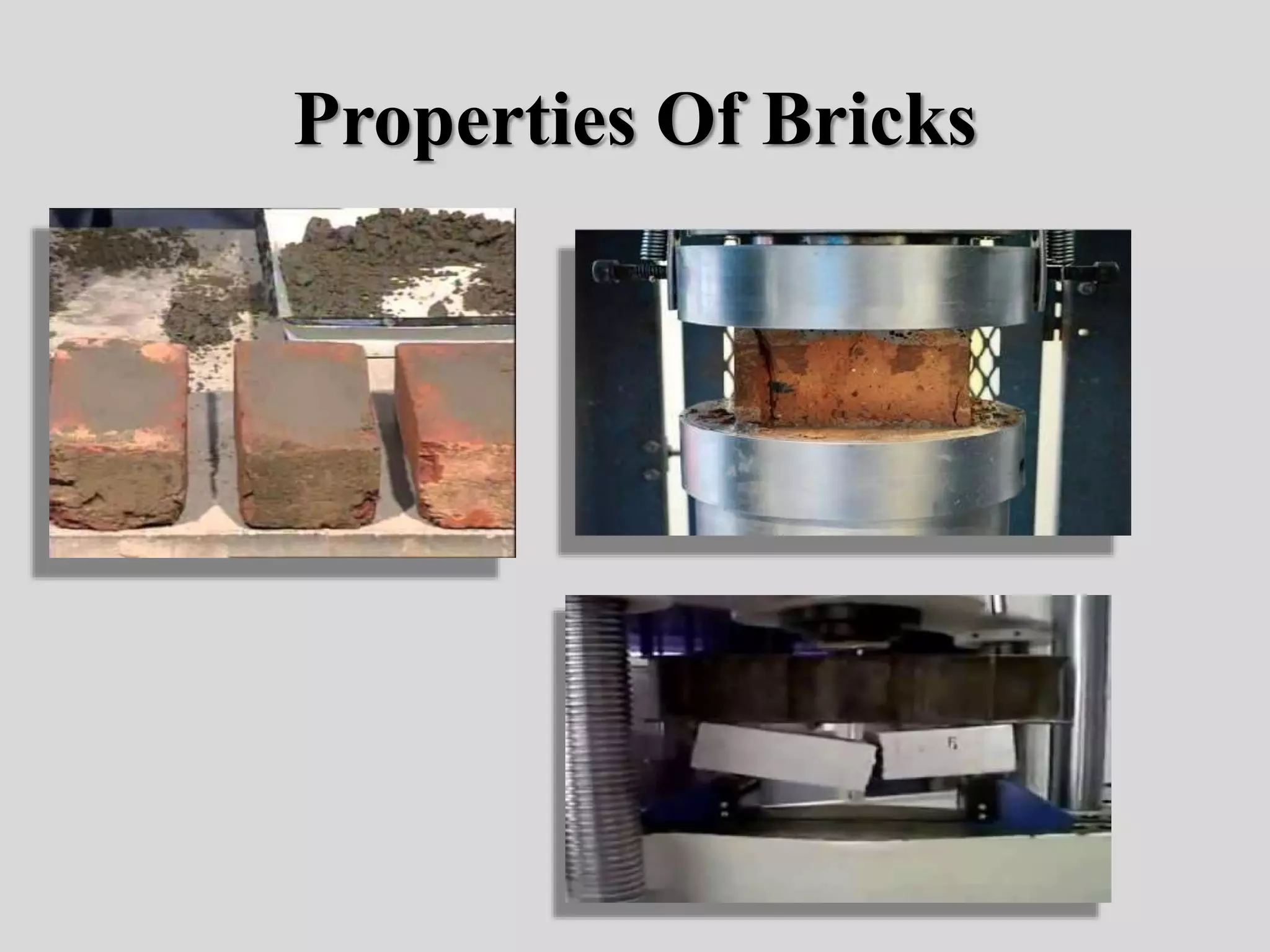

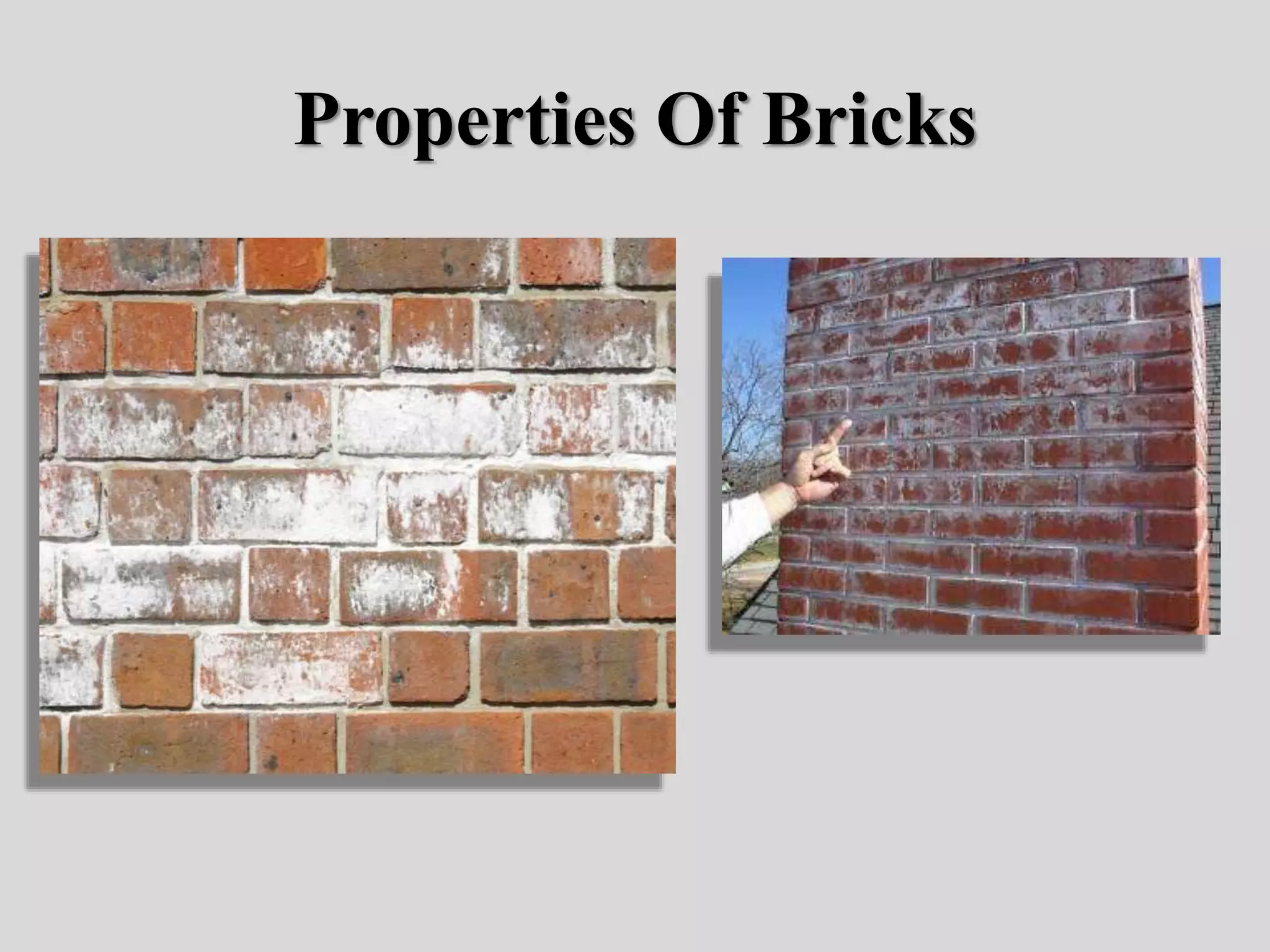

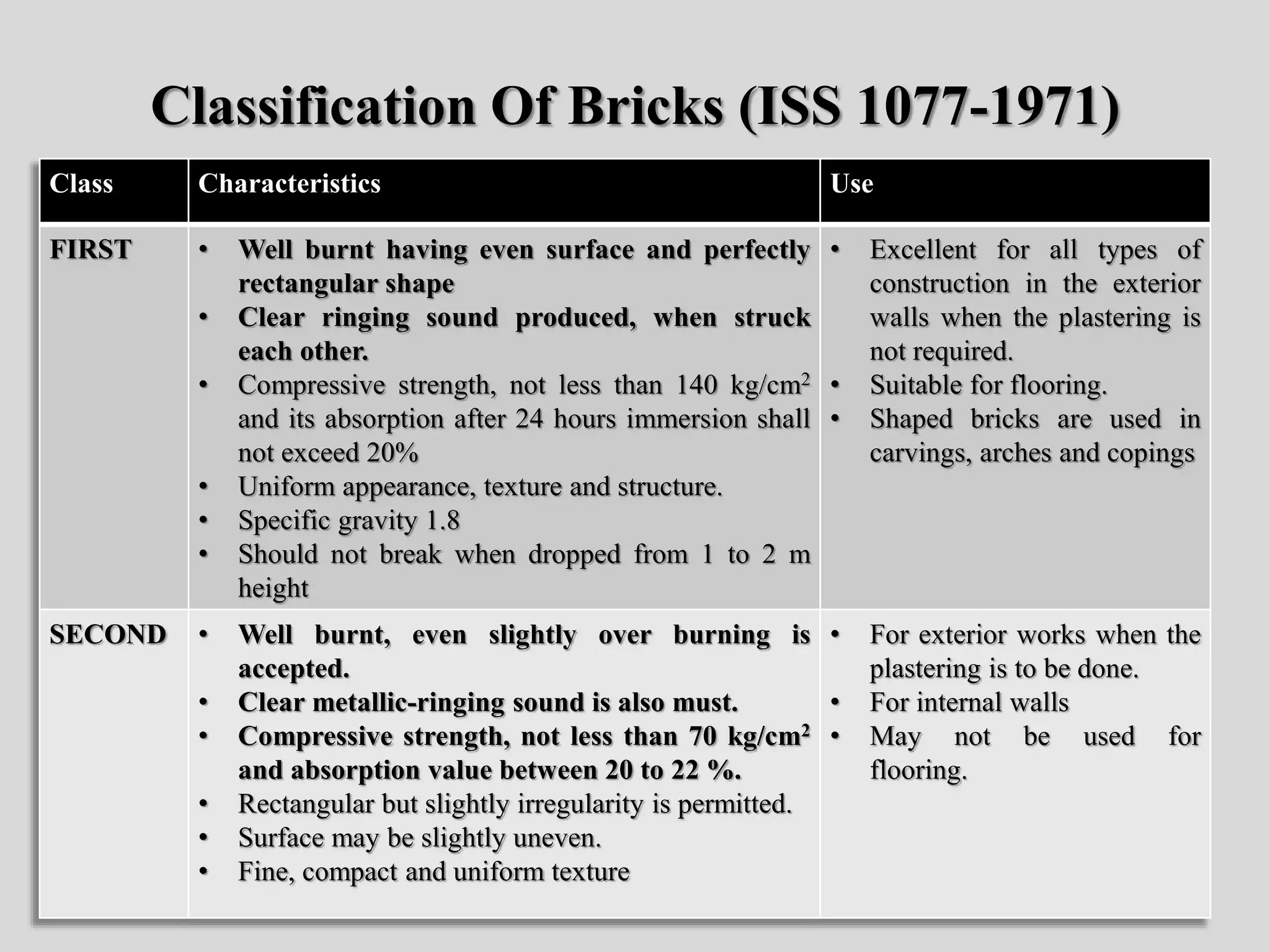

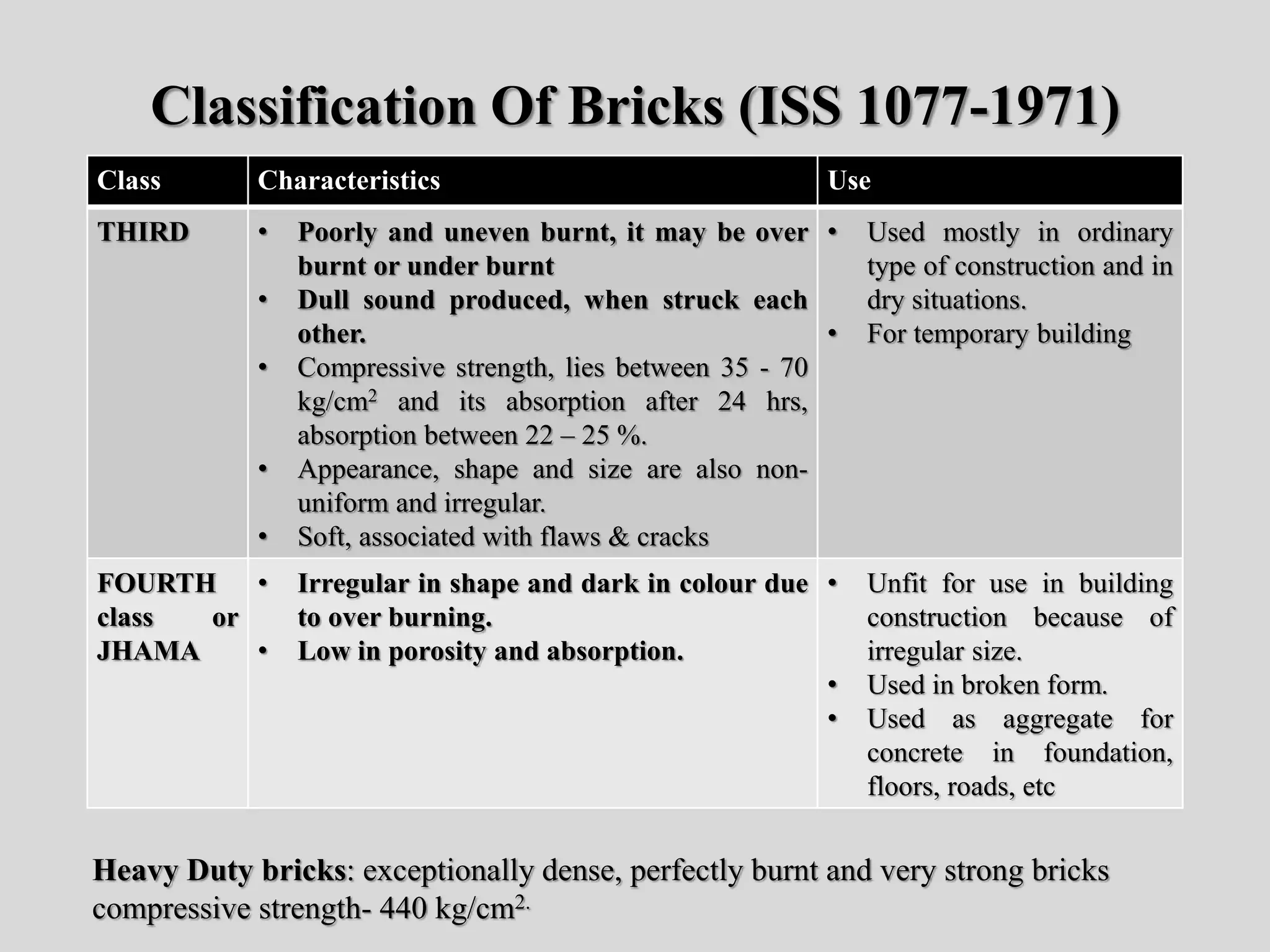

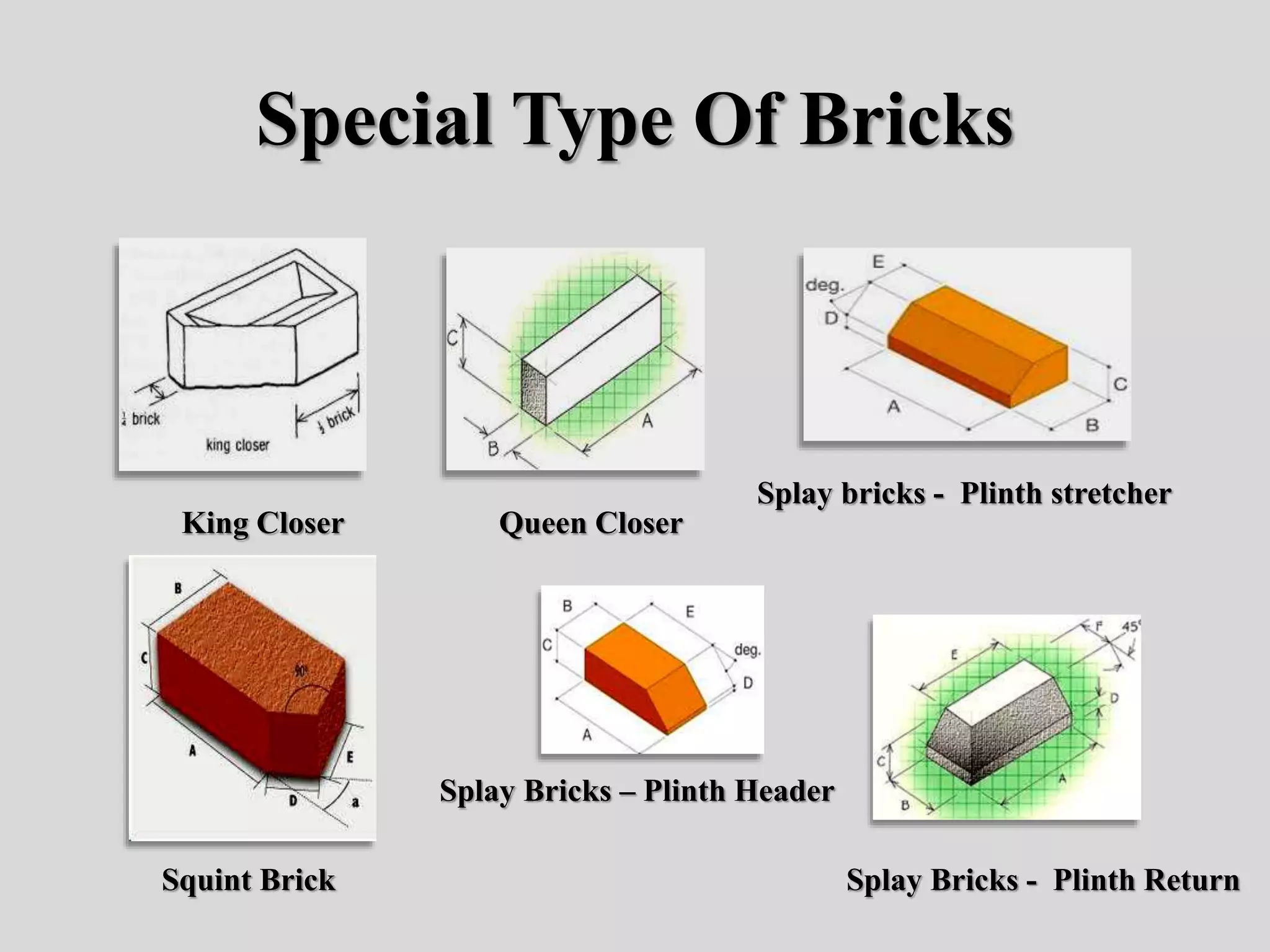

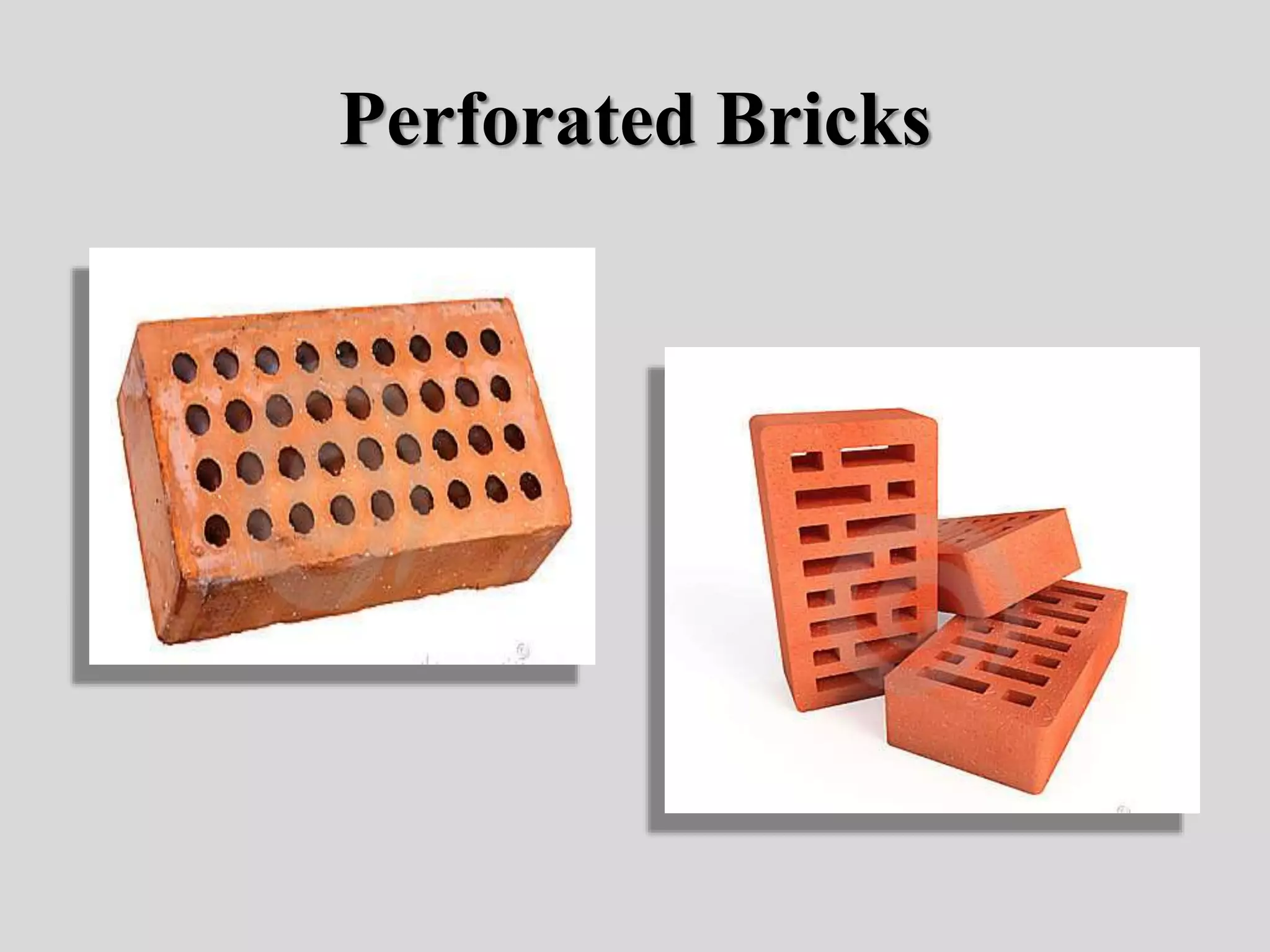

This document describes the properties of bricks, including their physical, mechanical, and thermal characteristics. It discusses the shape, size, color, density, compressive strength, insulation properties, durability, and frost resistance of standard bricks. It also outlines various tests conducted on bricks, such as those measuring compressive strength and water absorption. Additionally, it defines the qualities of good bricks and provides a classification system for bricks based on their characteristics and intended uses. Special types of bricks are also outlined, including those with modified shapes, perforations, and alternative compositions like sand lime bricks and refractory fire bricks.