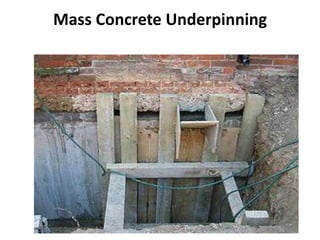

The document discusses underpinning, which is strengthening and stabilizing an existing building's foundation. Reasons for underpinning include an insufficient original foundation, changed building usage or soil properties, or nearby construction requiring soil excavation. Underpinning extends the foundation deeper or wider to bear on stronger soil or distribute load. Common methods are micropiles, jet grouting, and soil grouting. Types of underpinning include mass concrete, beam and base, and mini-piled underpinning. Mass concrete involves digging boxes and pouring concrete sequentially. Beam and base uses a reinforced concrete beam supported by mass concrete bases. Mini-piles are used for deep foundations on variable soils.

![Underpinning the foundations of a railway bridge using a

timber box crib to support the bridge. A completed

concrete pad underpinning can be seen at the bottom

right.]](https://image.slidesharecdn.com/underpinning-120412004141-phpapp02/85/Underpinning-10-320.jpg)