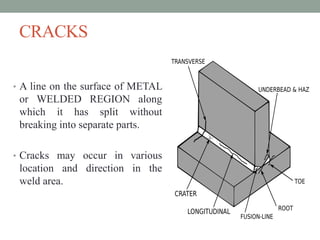

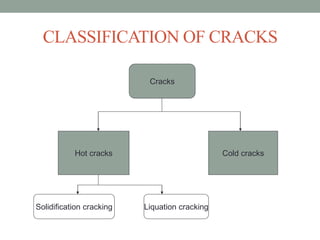

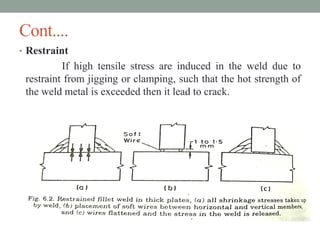

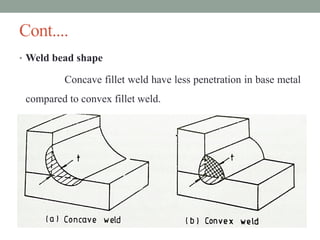

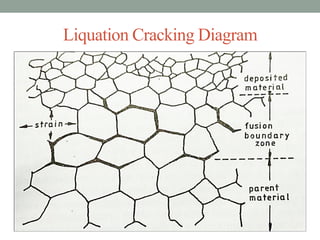

The document discusses various welding defects, particularly focusing on hot and cold cracks, their classifications, and the factors contributing to their formation. It explains solidification cracking, liquation cracking, and cold cracking, including their causes such as material composition, welding procedures, and hydrogen presence in weld metal. Prevention strategies, including preheating and hydrogen bake-out, are also highlighted to mitigate cracking issues in welding.