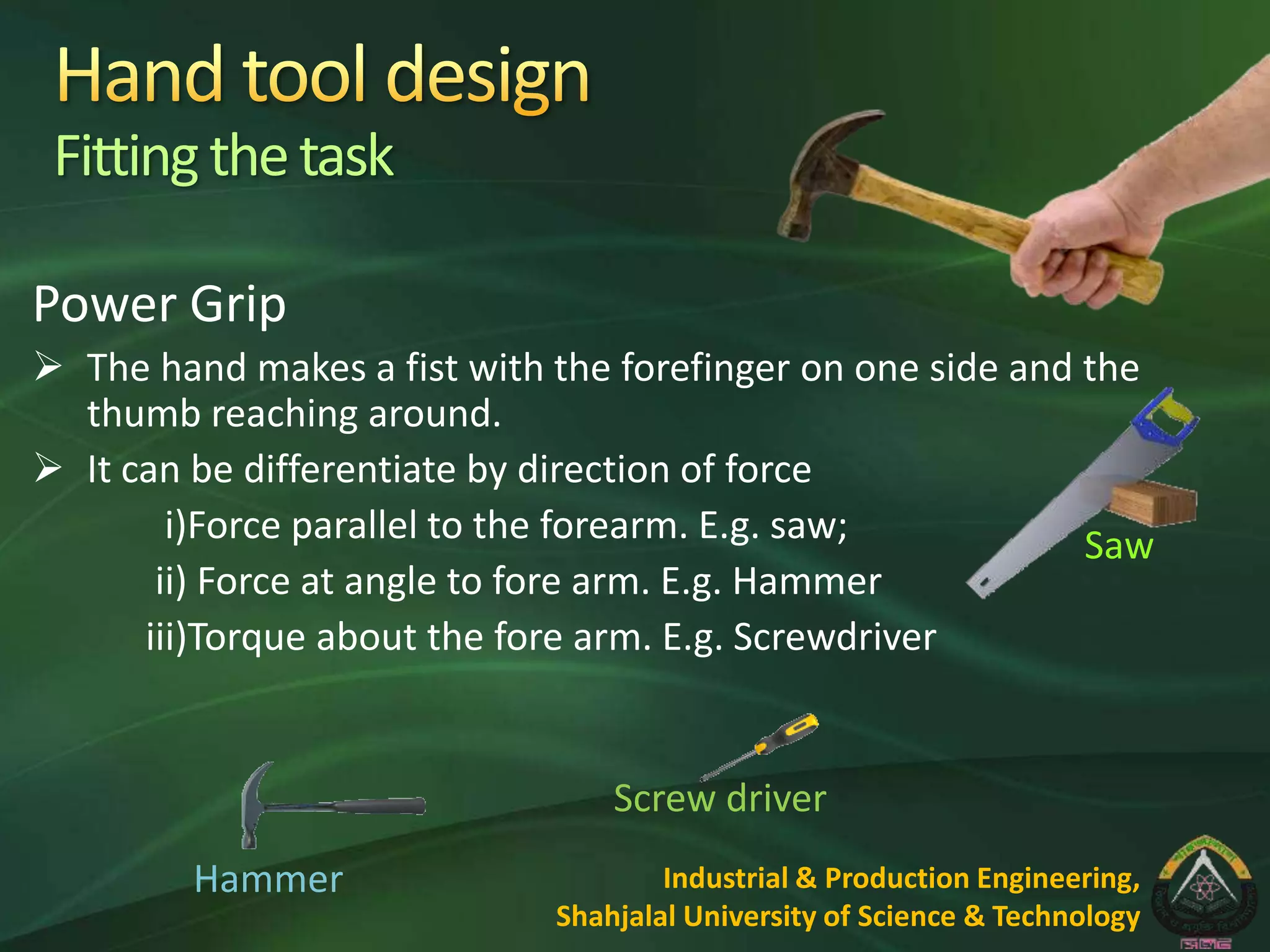

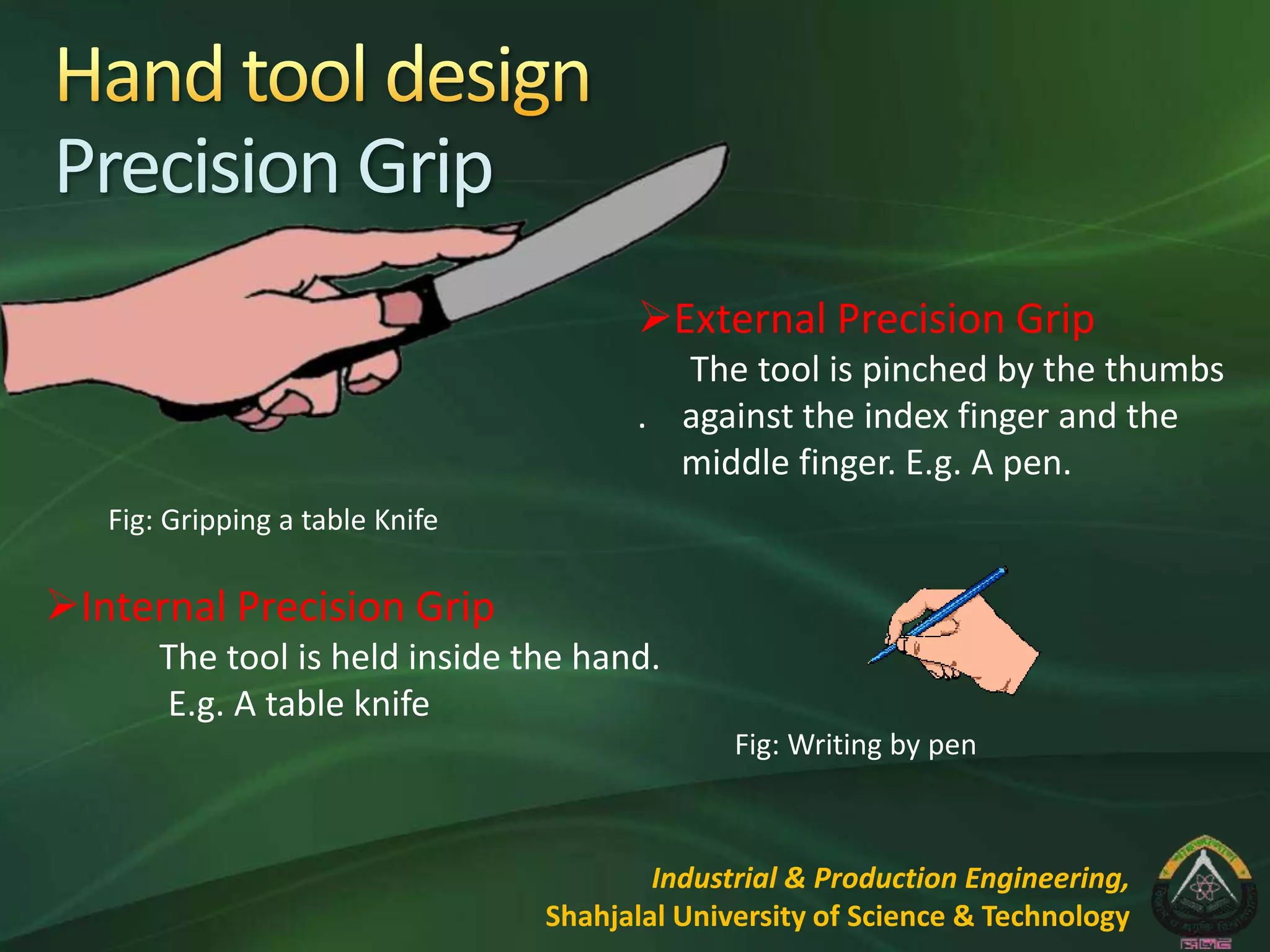

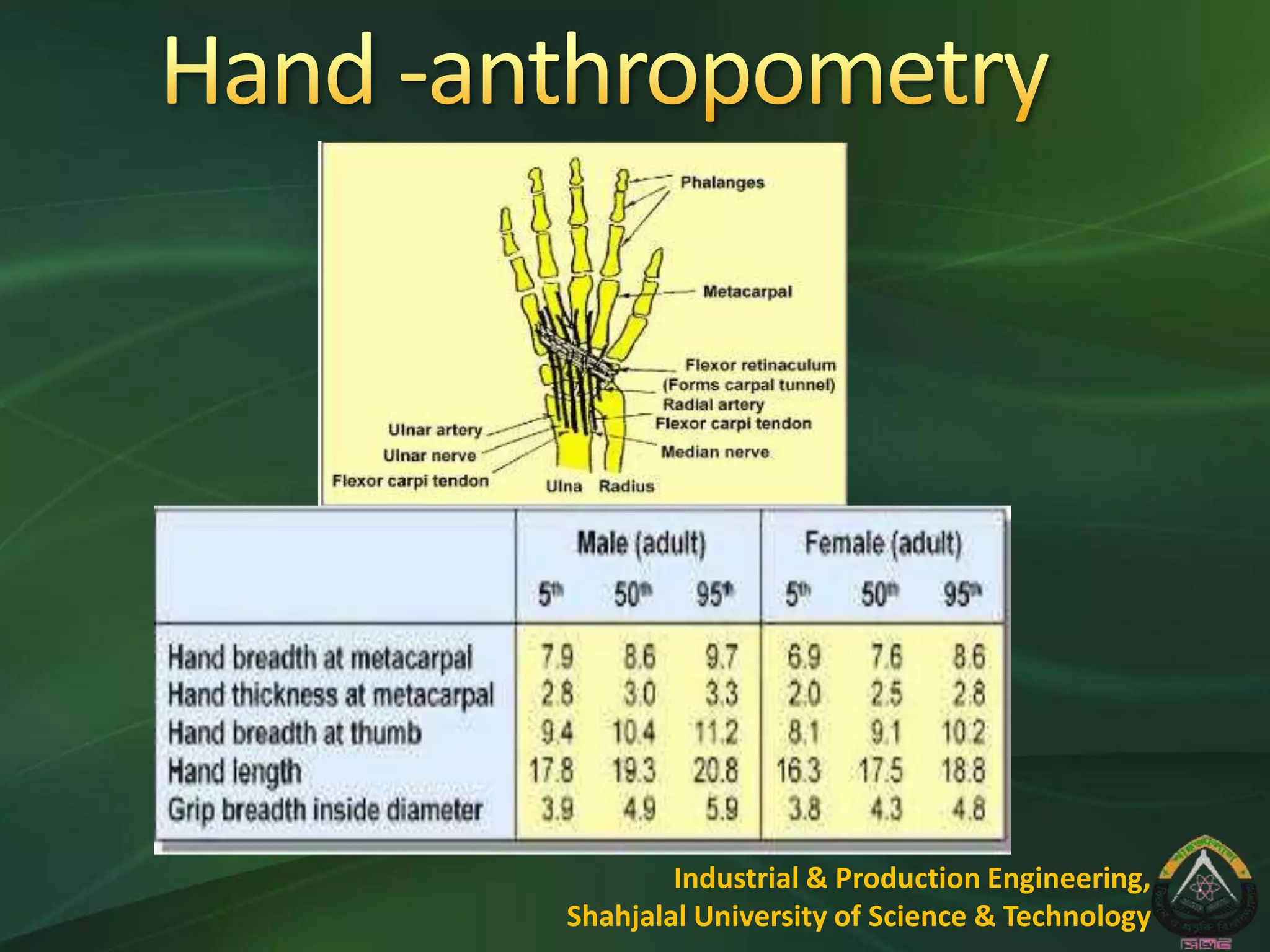

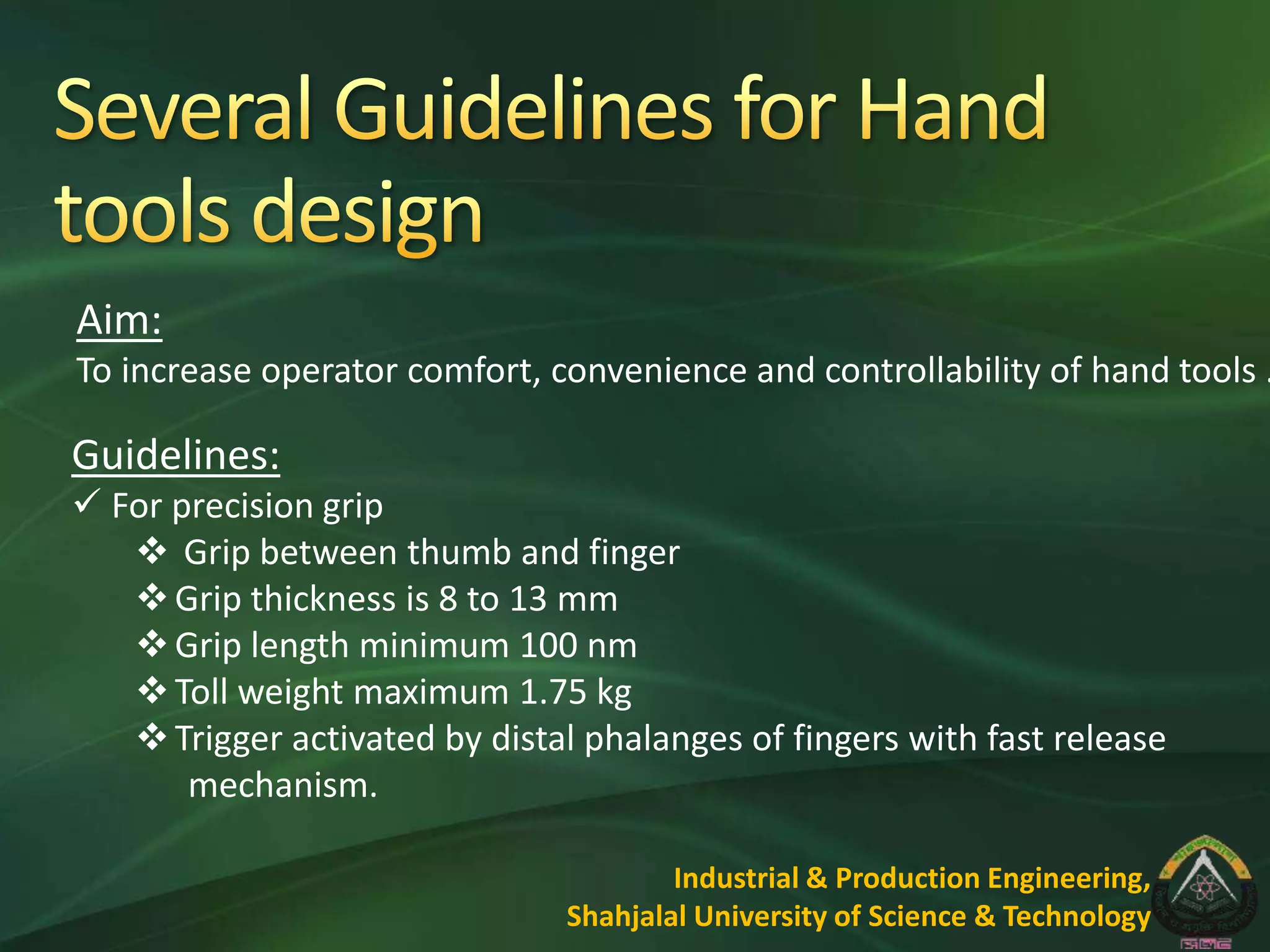

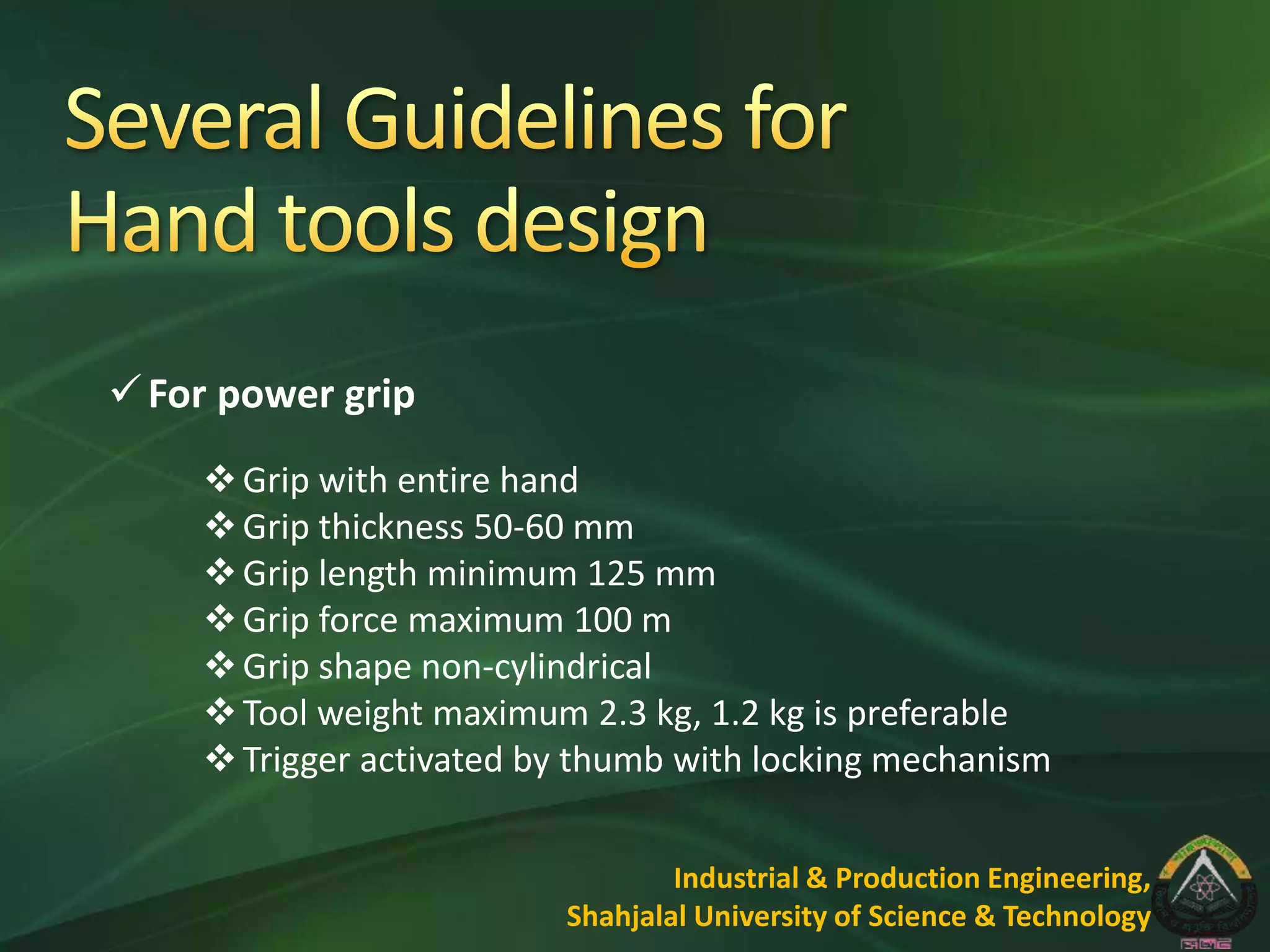

This document discusses hand tool design guidelines submitted by a group of students to their professor. It provides information on hand tools and power tools, ergonomic guidelines for hand tool design, and common injuries from hand tool use such as CTDs. The guidelines recommend designing tools for both right and left-handed users, with grips that are the proper size and shape to minimize vibration and maintain neutral wrist positions. The goal is to increase operator comfort, control, and prevent repetitive strain injuries when using hand tools.