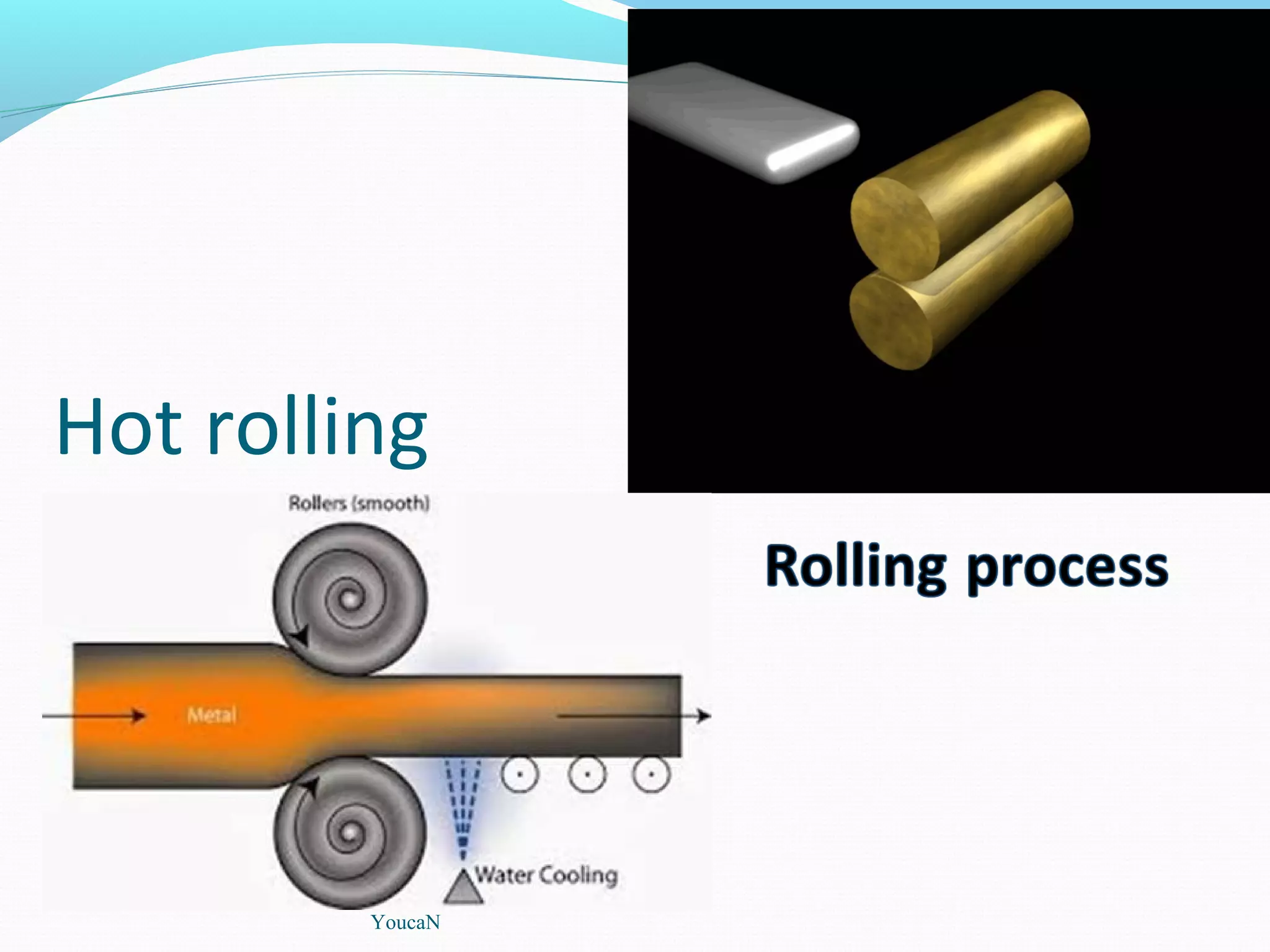

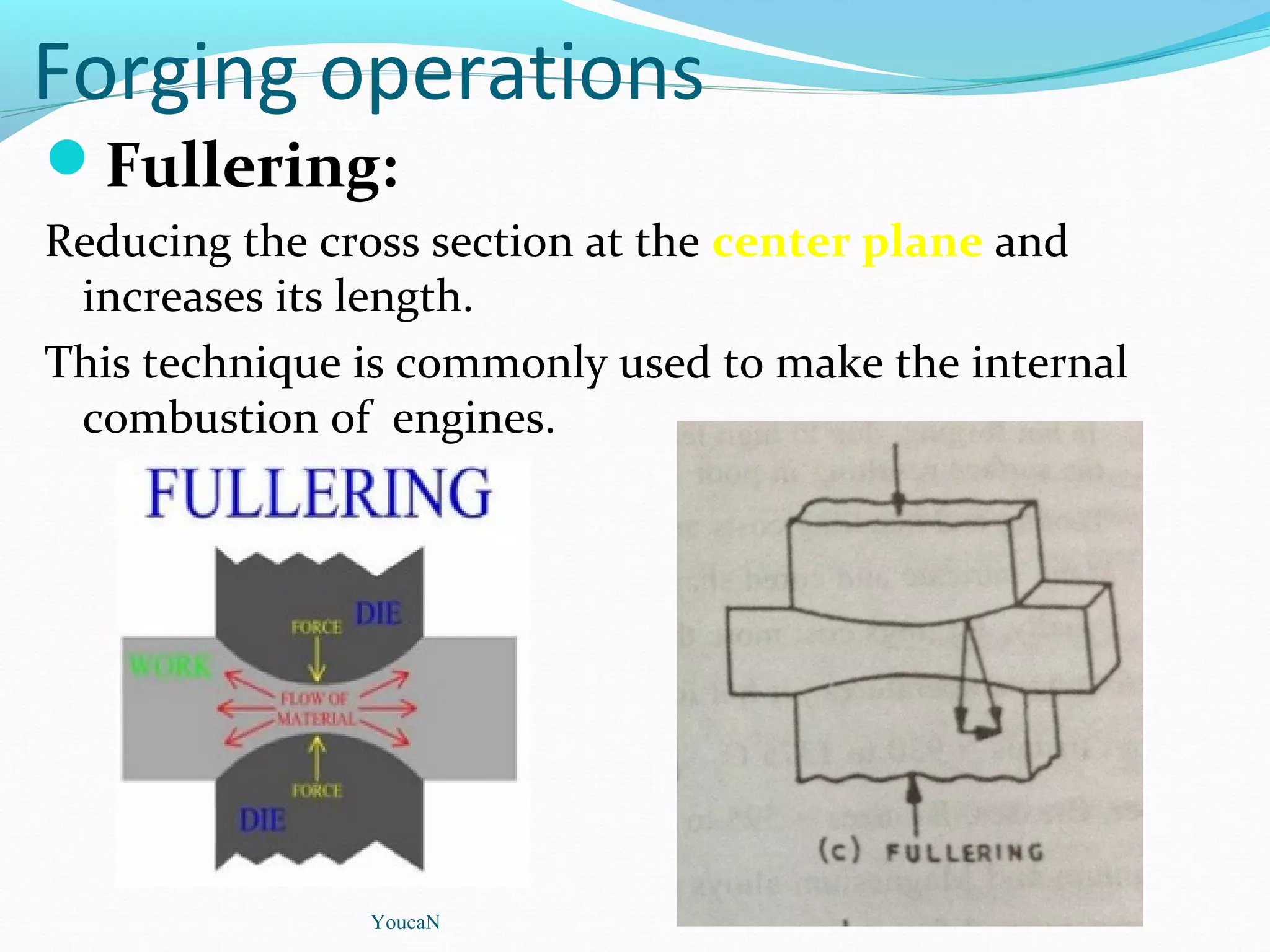

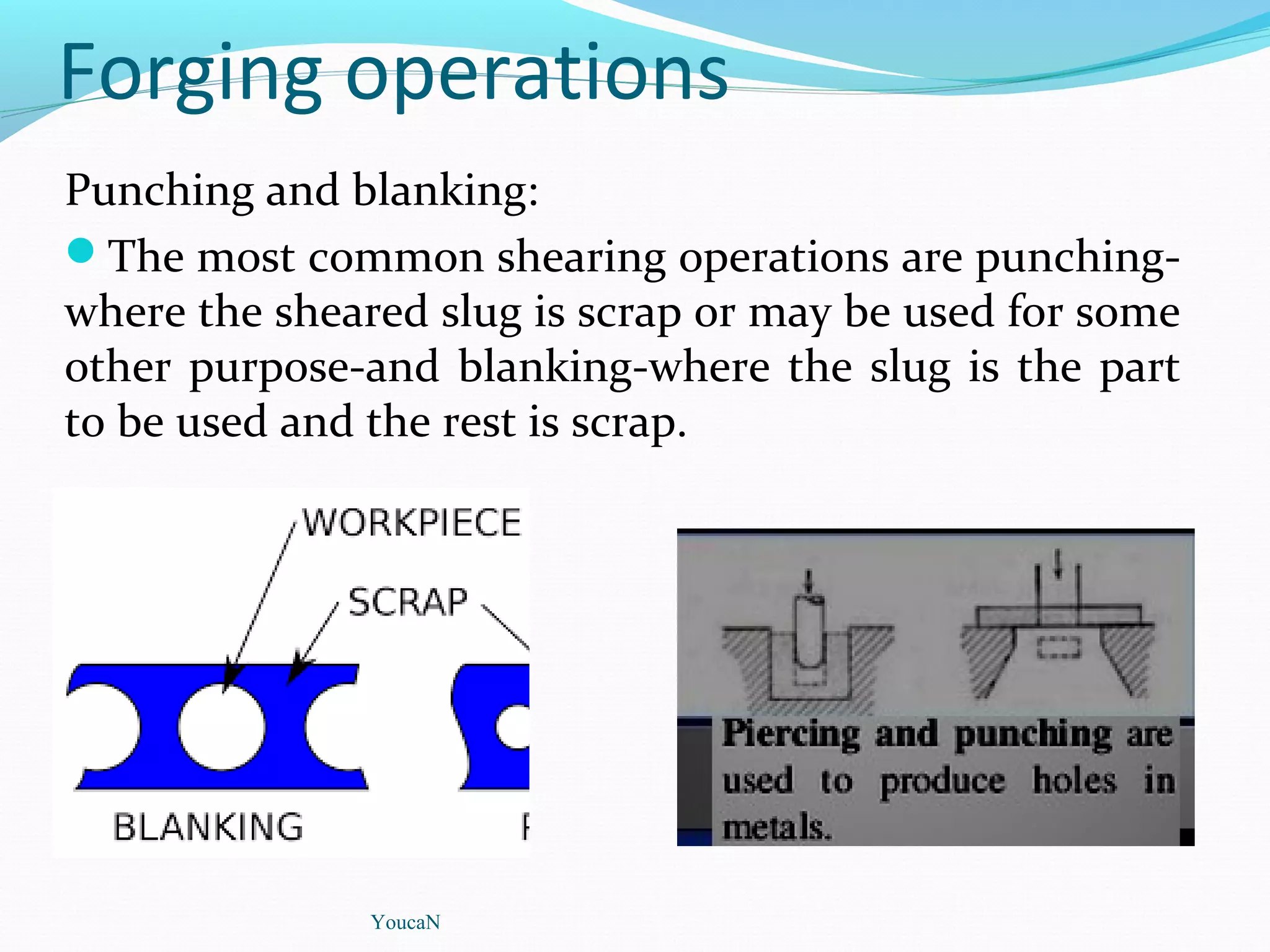

The document discusses various metal forming processes including hot working and cold working of metals. It describes processes like forging, rolling, extrusion, drawing, and spinning. Forging can be done through open die forging or closed die forging using various machines. It involves operations like upsetting, drawing down, punching, bending, and forging welding. Rolling involves processes like flat rolling and shape rolling. Extrusion can be done through hot or cold working. The document compares the characteristics and advantages and limitations of hot working versus cold working of metals.