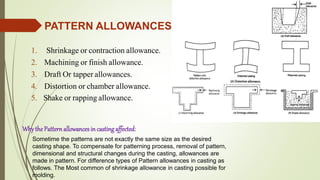

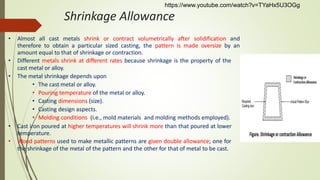

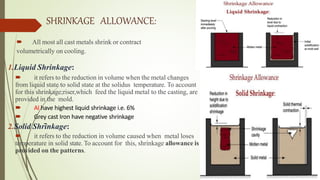

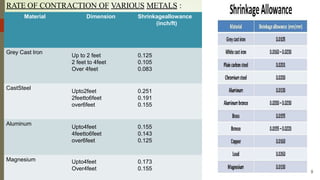

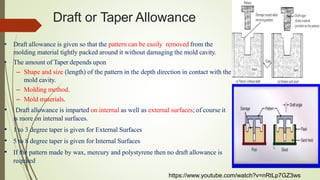

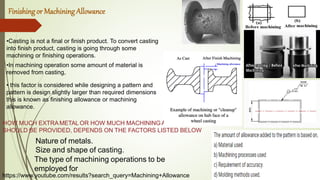

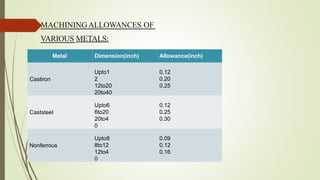

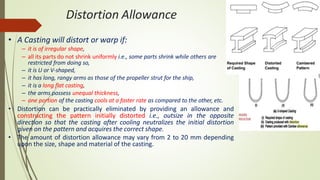

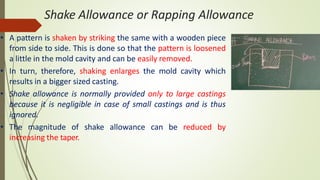

This document discusses pattern allowances in metal casting processes. It provides definitions of patterns and explains the need for various pattern allowances to account for shrinkage, machining, drafts or tapers, potential distortions, and shaking during casting removal. The key allowances discussed are shrinkage allowance, machining or finishing allowance, draft allowance, distortion allowance, and shake allowance. Specific percentages and dimensions for these allowances are provided for different metals like cast iron, cast steel, aluminum, and magnesium.