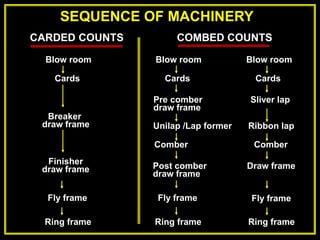

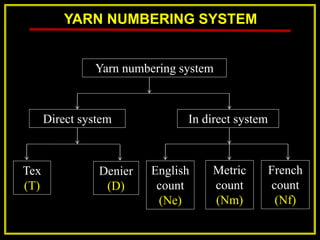

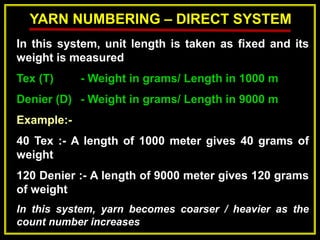

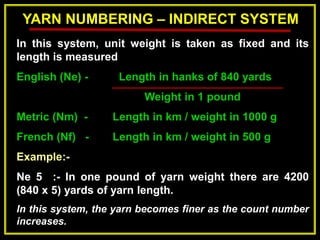

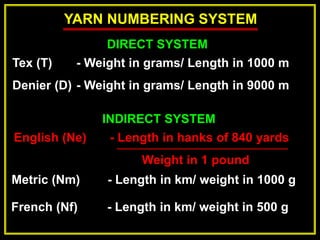

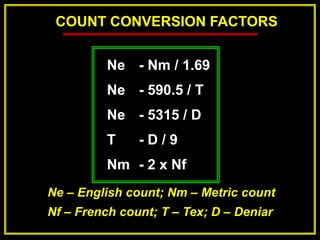

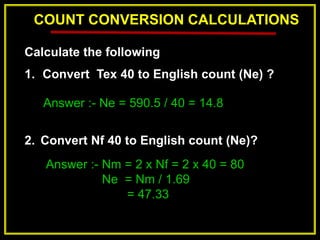

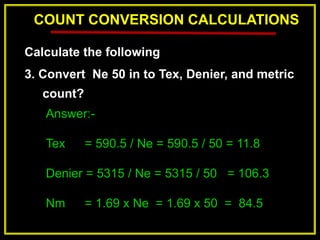

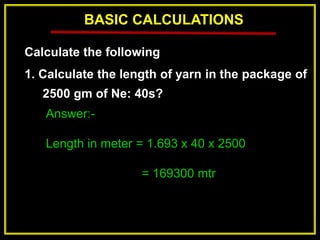

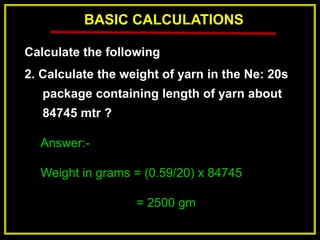

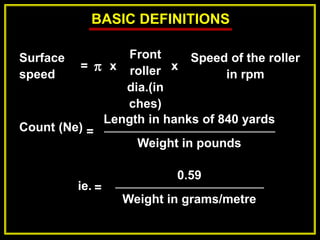

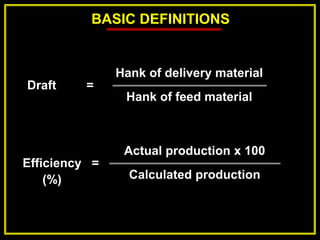

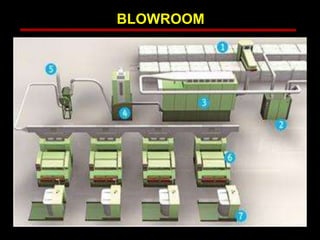

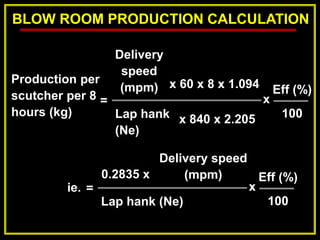

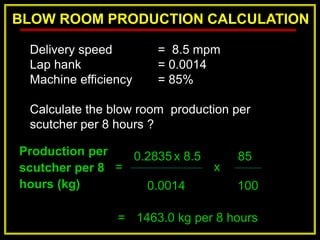

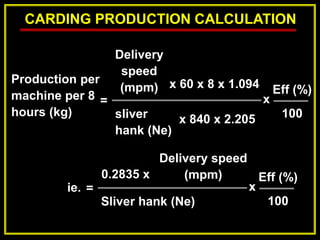

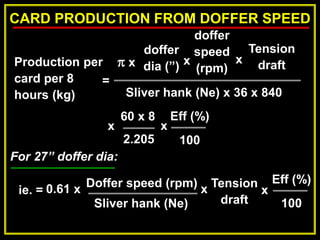

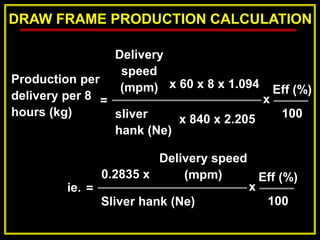

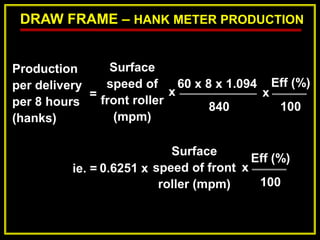

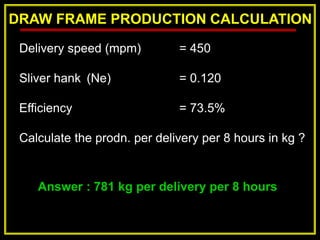

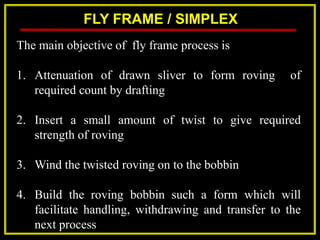

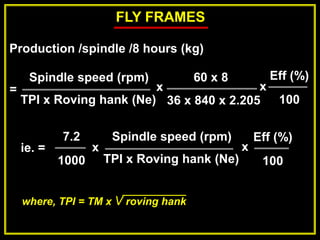

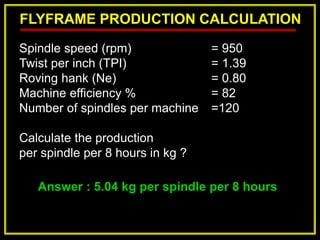

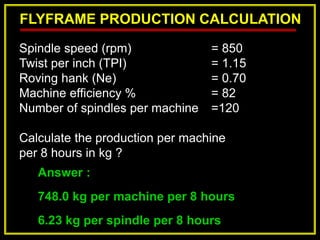

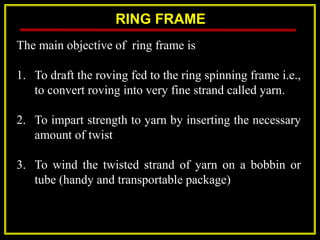

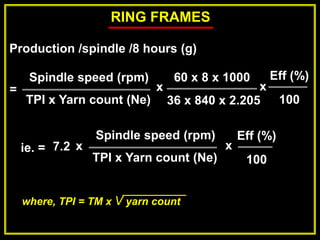

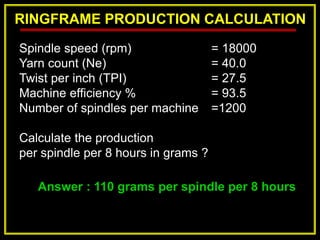

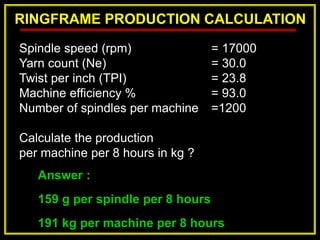

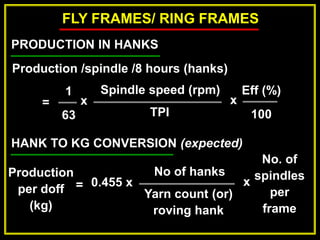

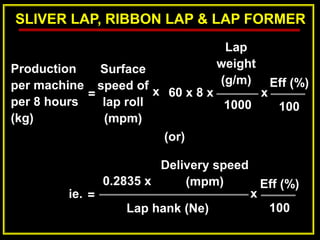

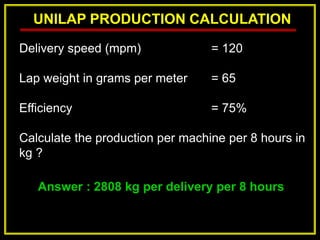

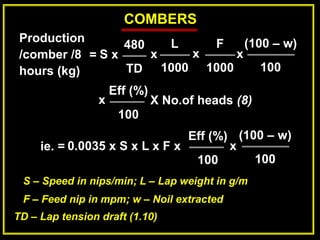

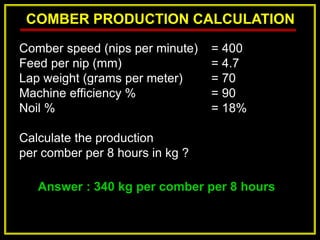

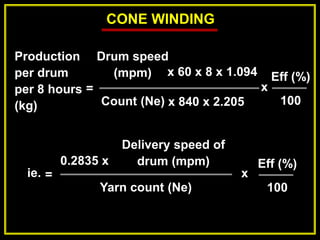

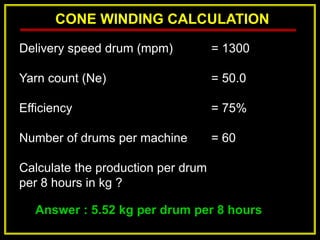

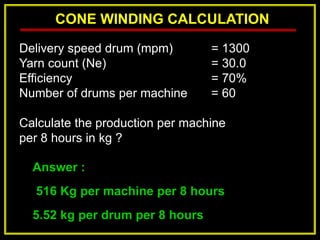

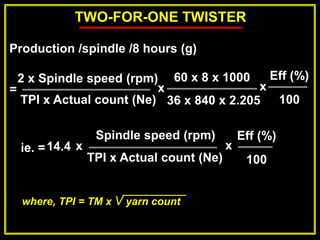

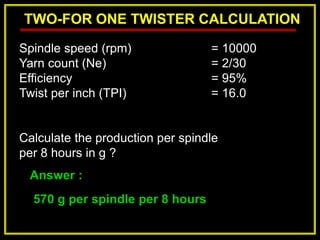

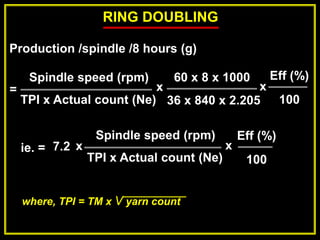

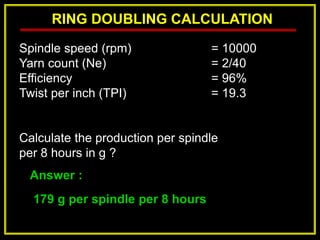

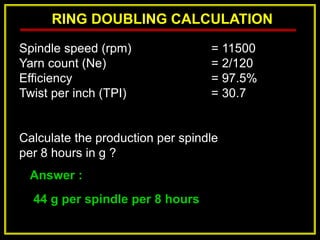

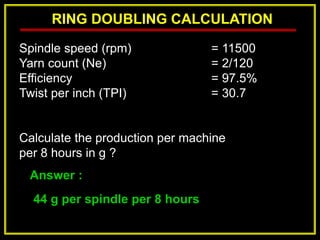

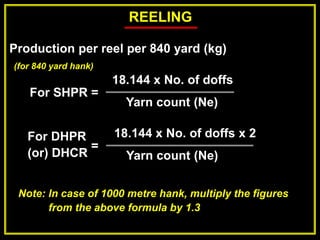

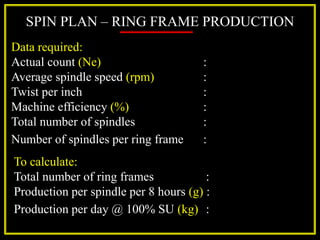

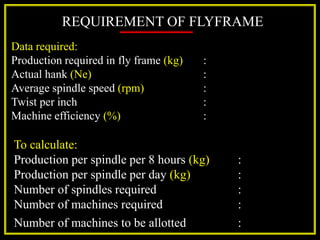

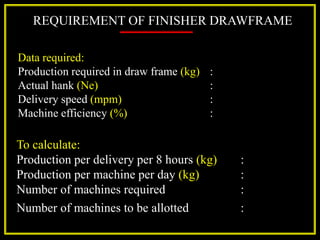

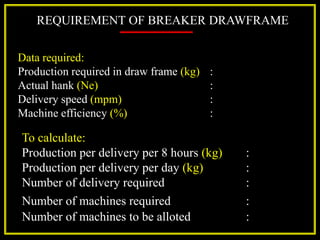

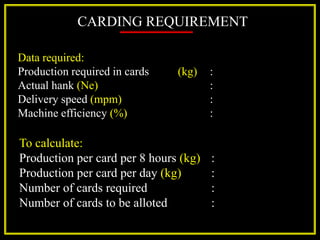

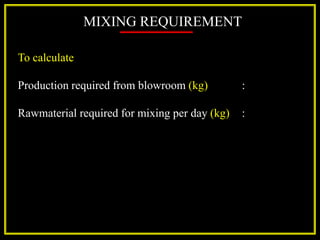

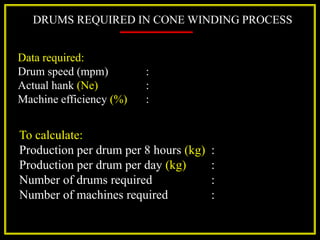

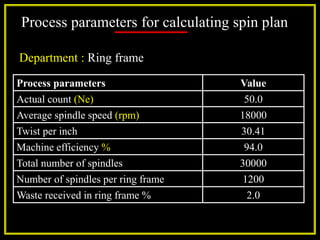

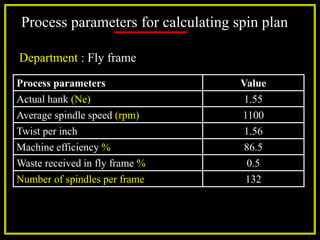

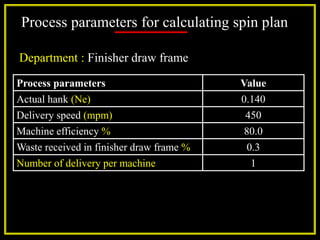

This document discusses standard production estimation in spinning mills. It begins by outlining the typical sequence of machinery used in carded and combed yarn production. It then explains yarn numbering systems including direct, indirect and count conversion factors. Formulas are provided for estimating production of various processes like blowroom, carding, draw frame, fly frame, ring frame, comber and cone winding. Key process objectives and variables that impact production calculations like efficiency, speed and count are defined.