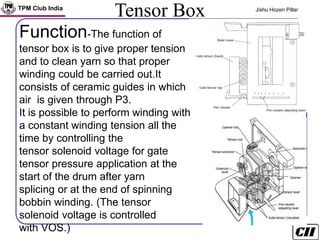

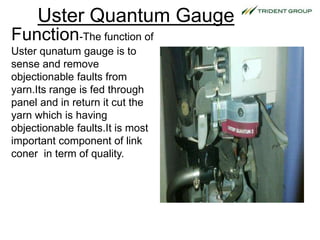

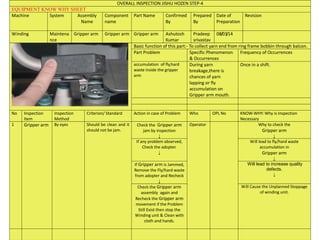

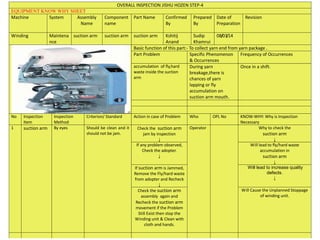

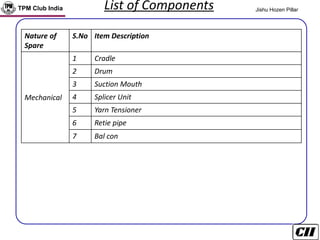

The document provides information about a winding machine called a link coner. It describes the main components of the link coner including the cradle, drum, suction mouth, retie pipe, tensor box, bal con, splicer and electrical components like the fan motor, main control panel, and Uster gauge. It also provides details on the functions, settings, and operations of these key parts that allow the link coner to wind yarn into cones and link the process between ring frames and winding.

![TPM Club India Jishu Hozen Pillar

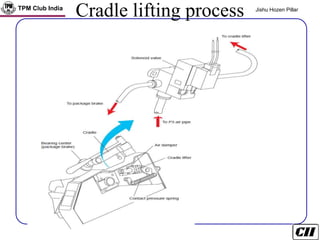

[1] The contact pressure is kept at a constant level by the balance between the air cylinder

and the spring.The P3 pressure is normally fixed at 0.45 MPa. This pressure presses the

cradle against the drum.

[2] The gradual contact pressure reduction spring generates reaction to the air cylinder. The

contact pressure curve and the contact pressure during pressure application are

determined by this spring and the eccentric pin.

Contact pressure during pressure application = P3 air pressure - gradual contact pressure

reduction spring force

[3] Contact pressure during winding-The contact pressure during winding can be set with the

P4 air pressure.

Contact pressure during winding = Contact pressure during pressure application - P4 air

pressure = P3 air pressure - Gradual contact pressure reduction spring - P4 air pressure.

[4] The contact pressure valve is a normally open (NO) type. Air flows under normal

conditions; however, it is stopped when the valve is energized, discharging the air from

the air cylinder.Use of this valve makes it possible to apply contact pressure at the start

of winding, after splicing, etc. The contact pressure application time can be set on the

VOS screen

Cradle lifting process](https://image.slidesharecdn.com/windingstep-4-230710153205-fc9e92b0/85/Winding-step-4-ppt-17-320.jpg)