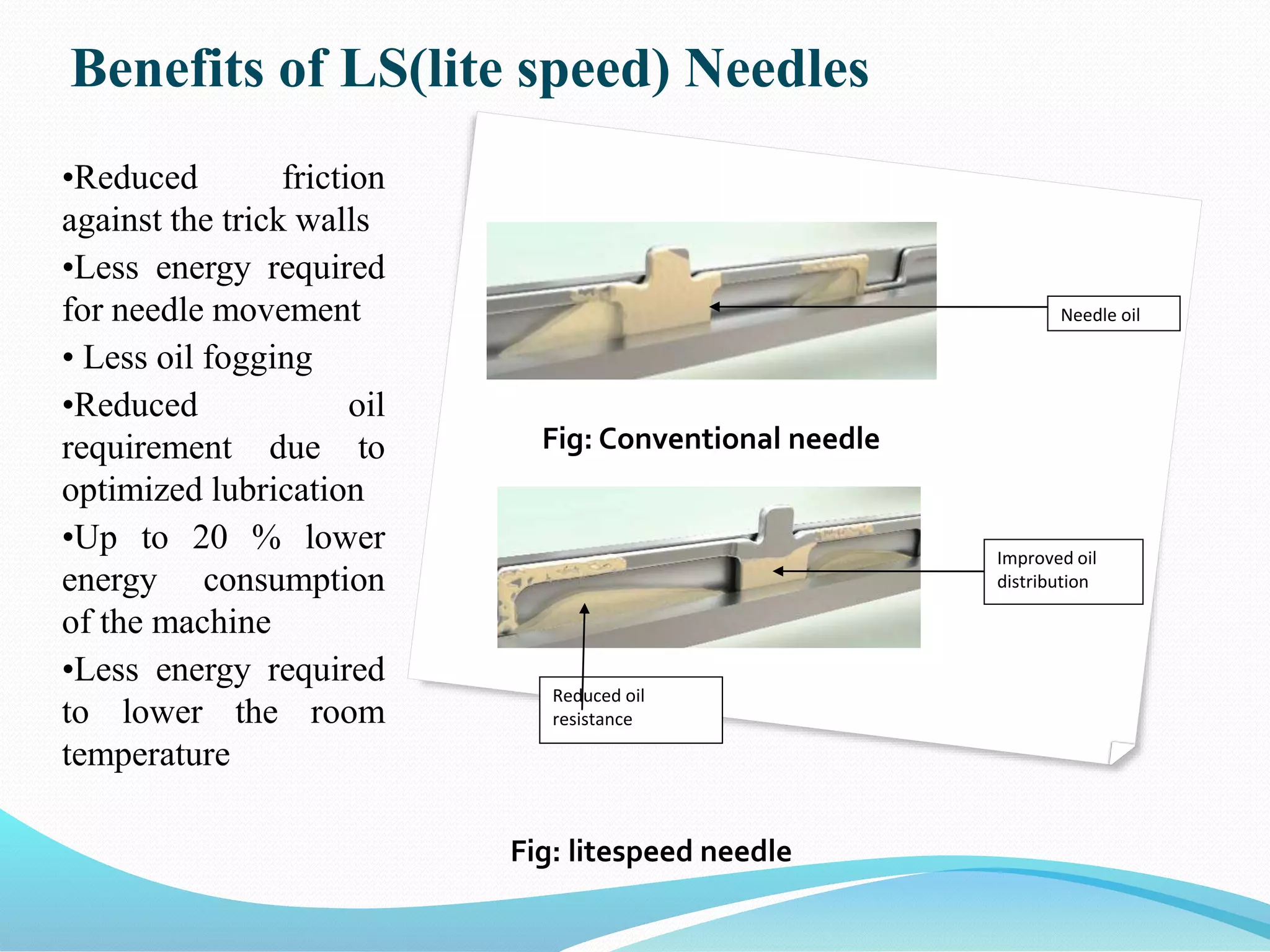

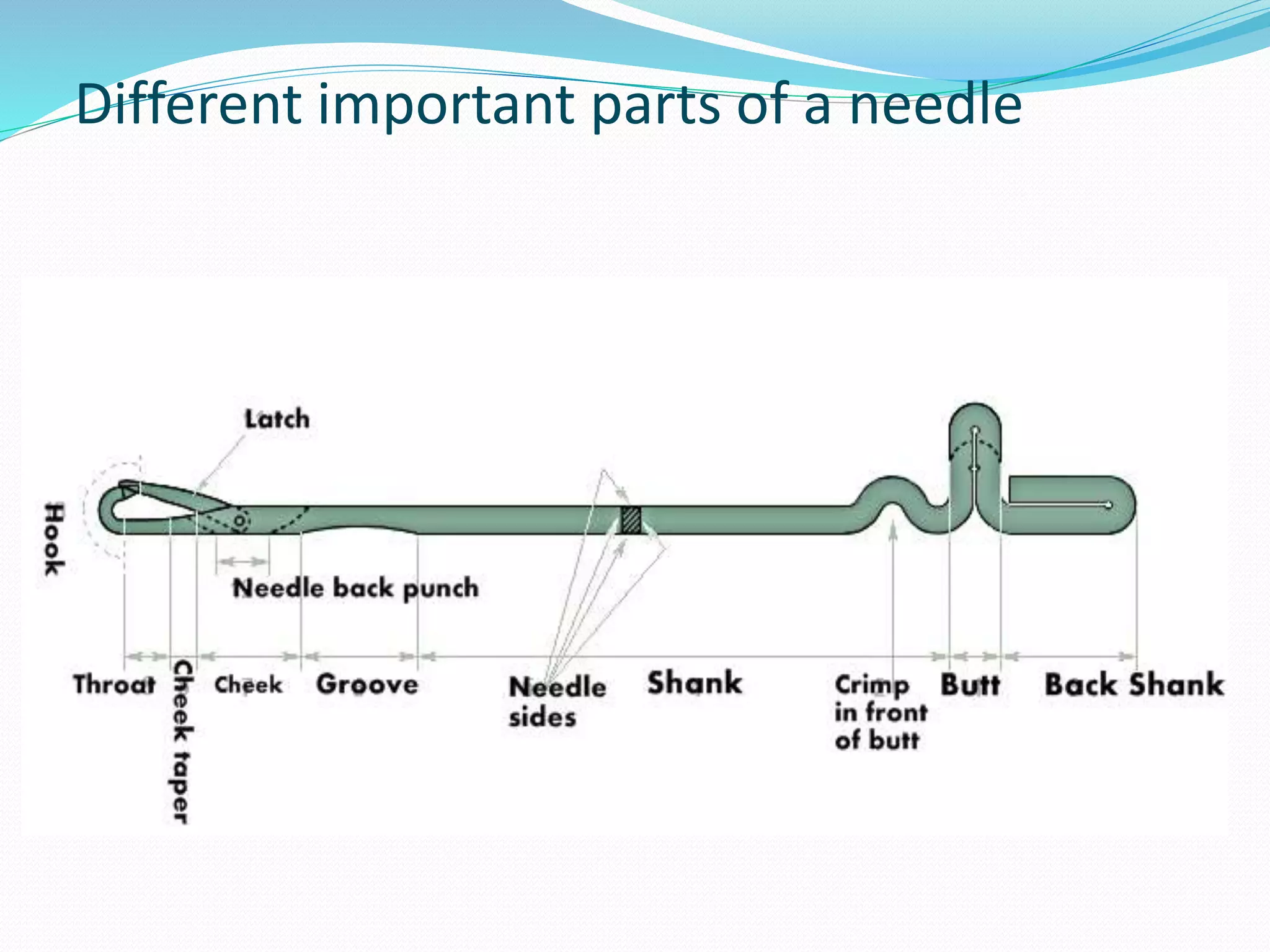

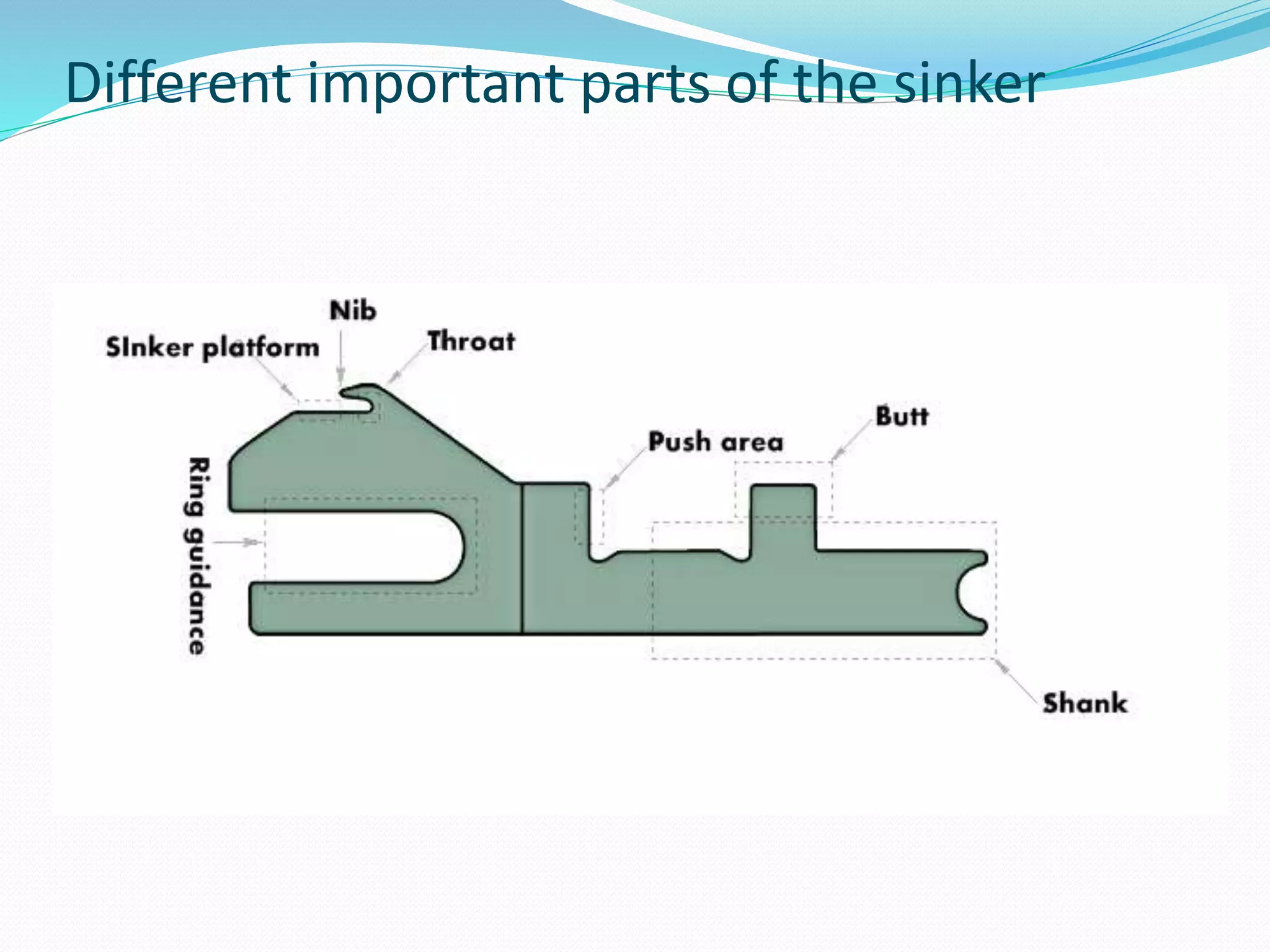

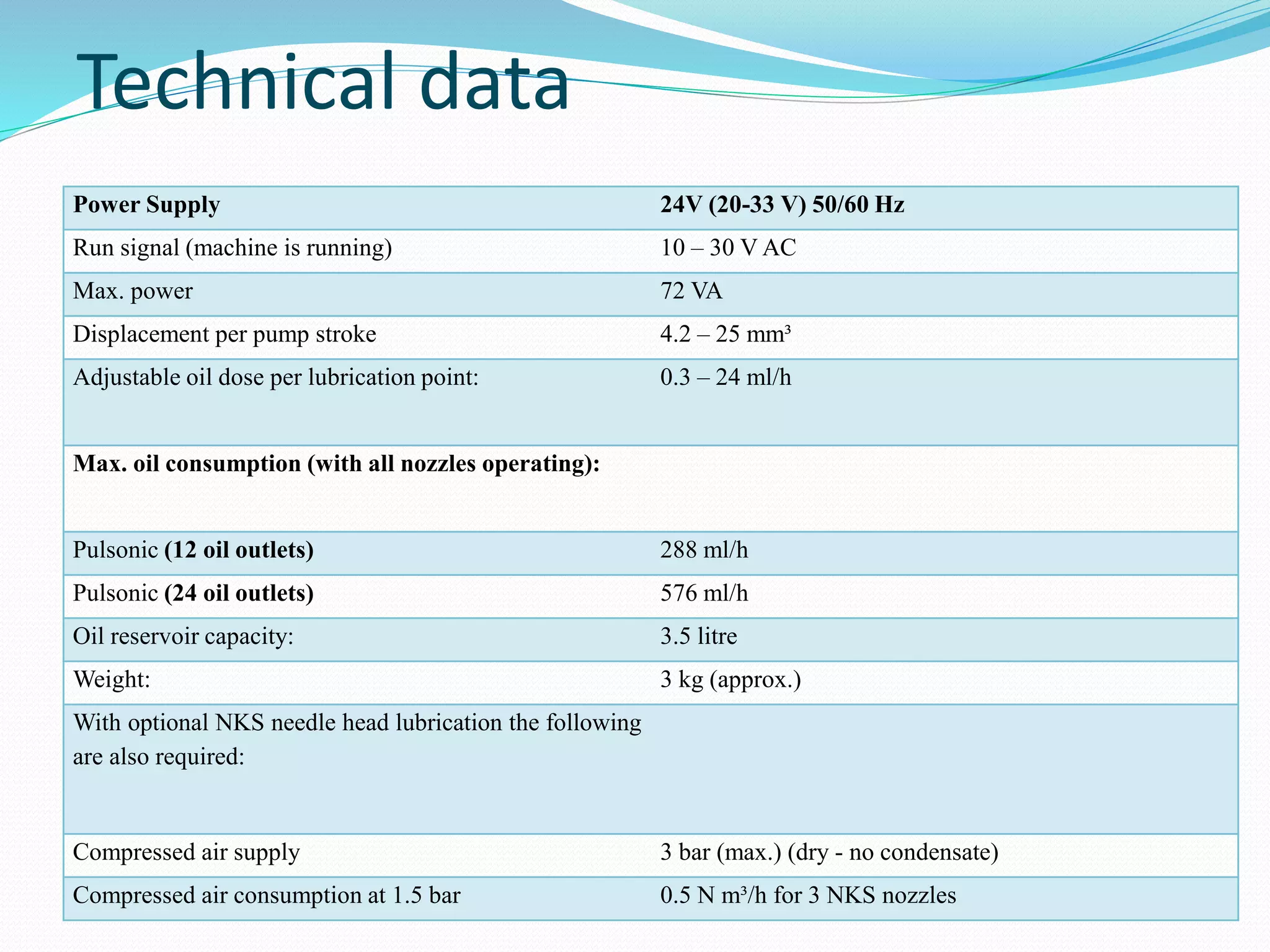

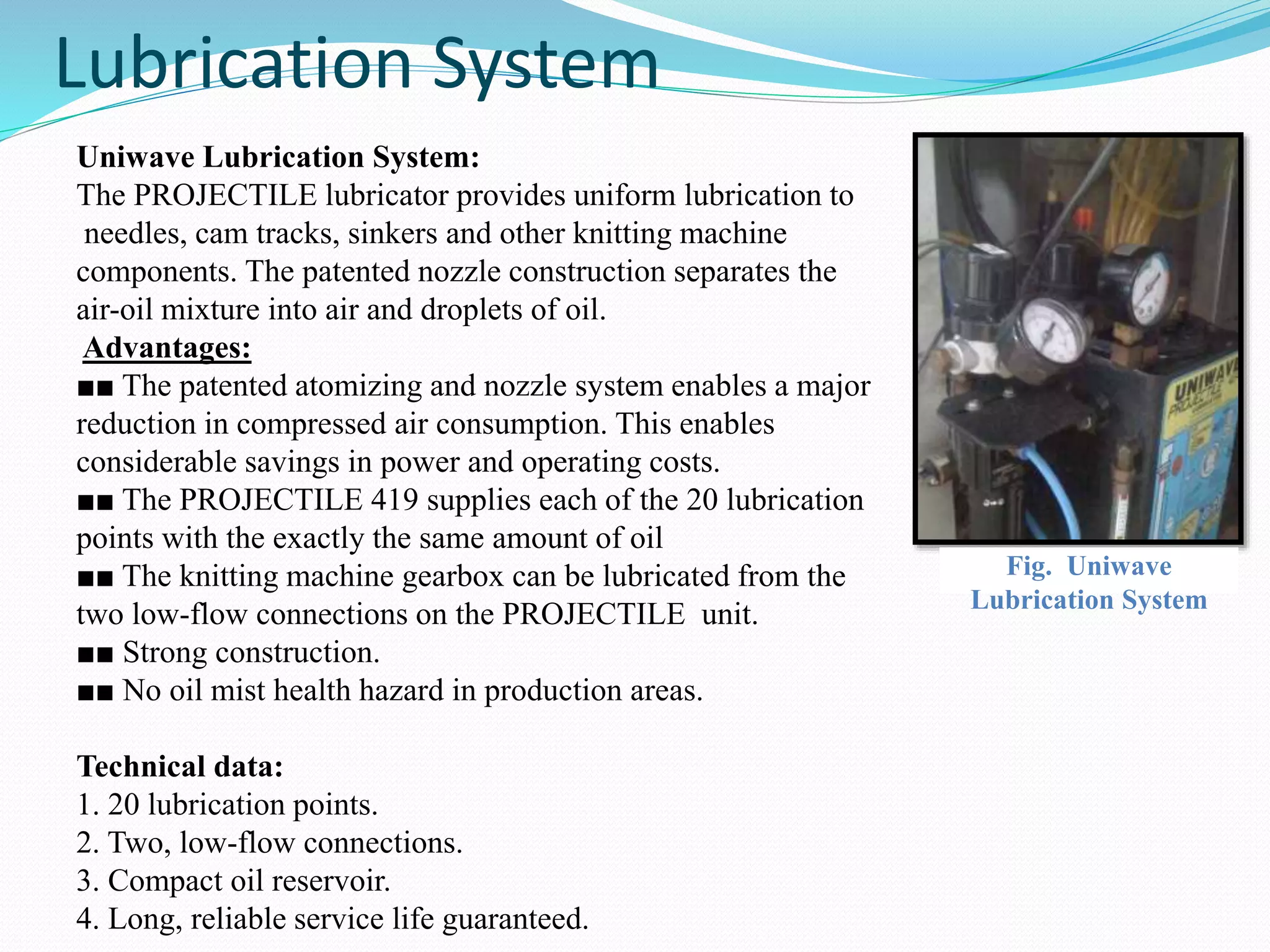

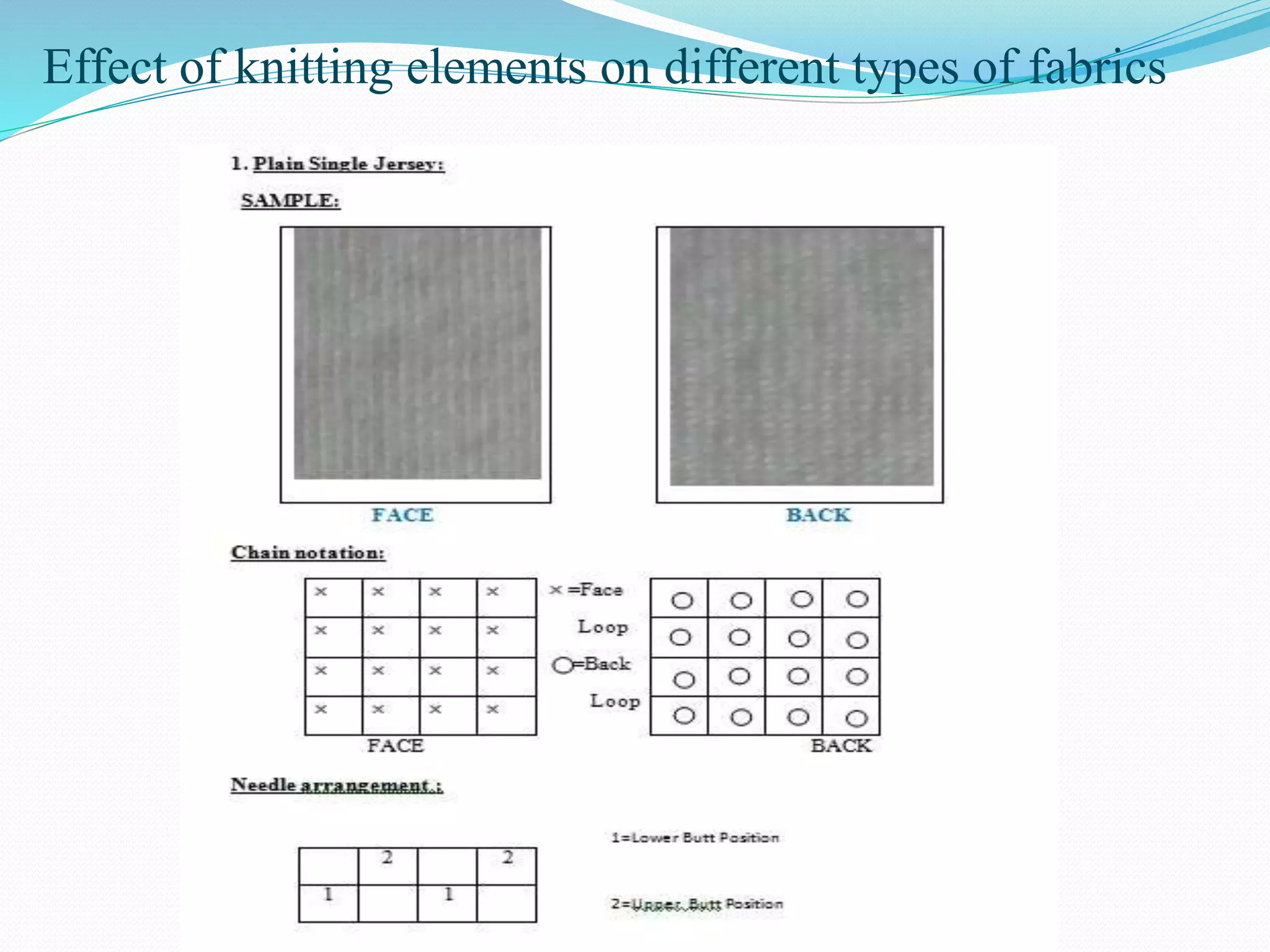

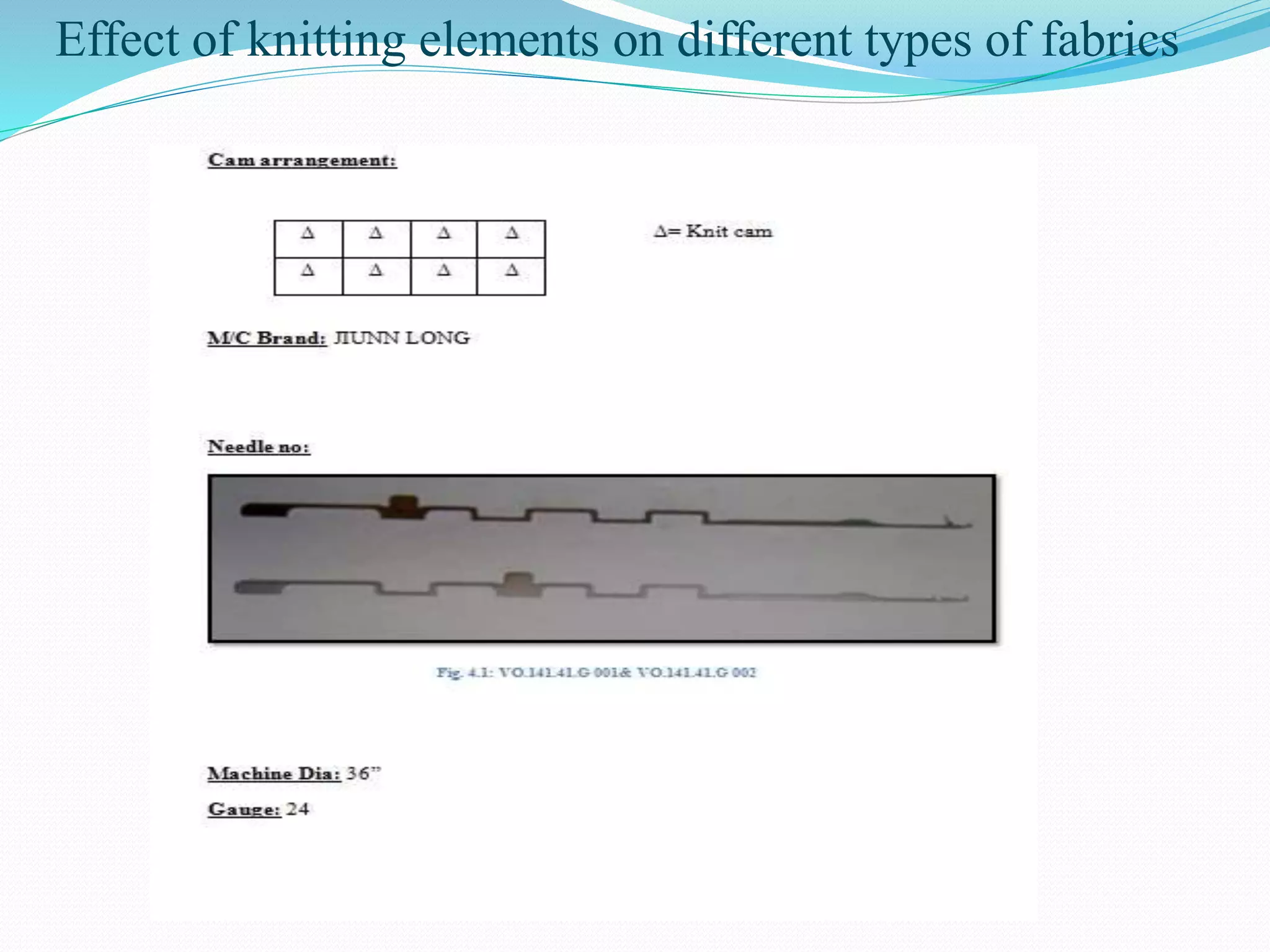

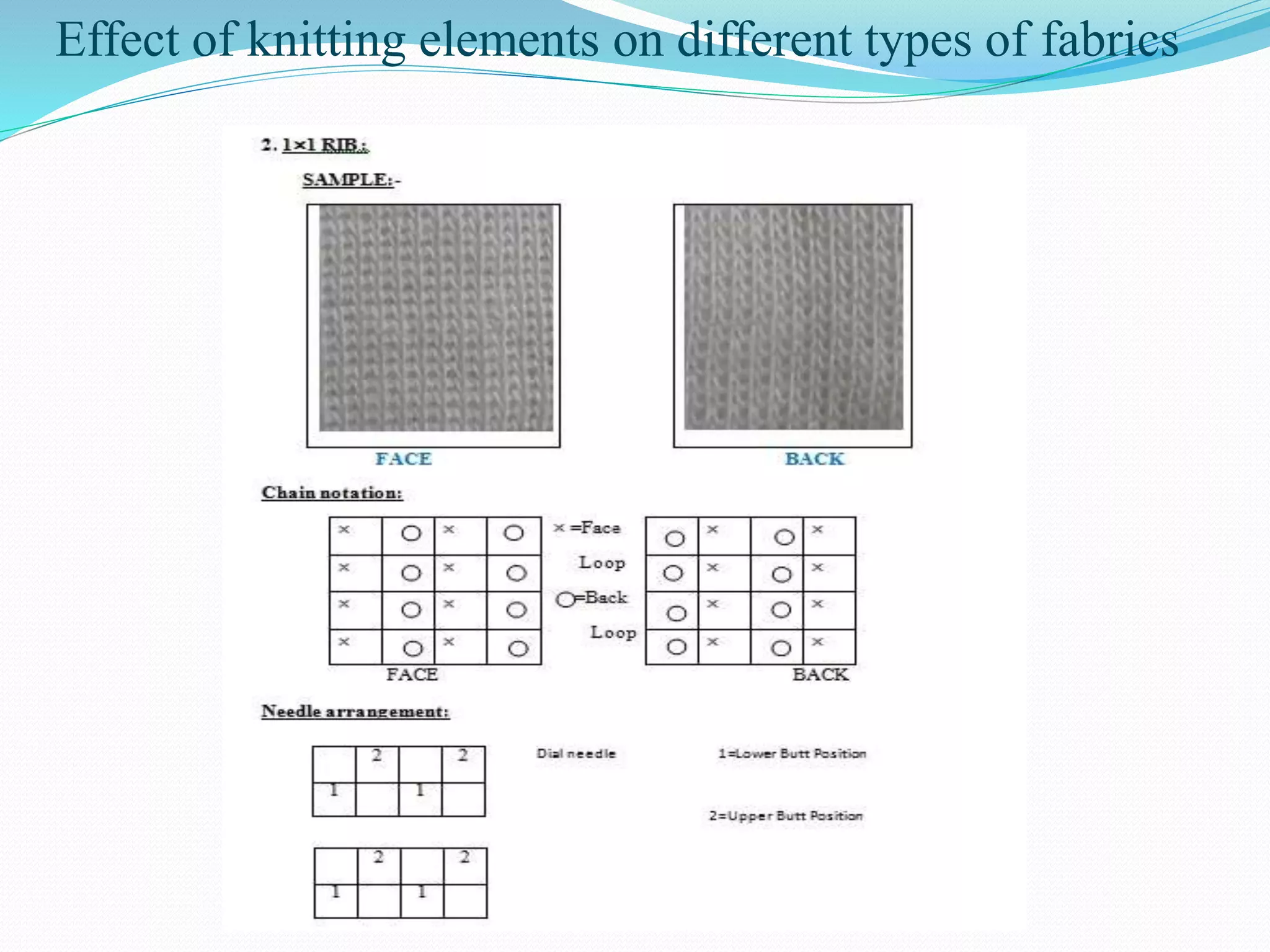

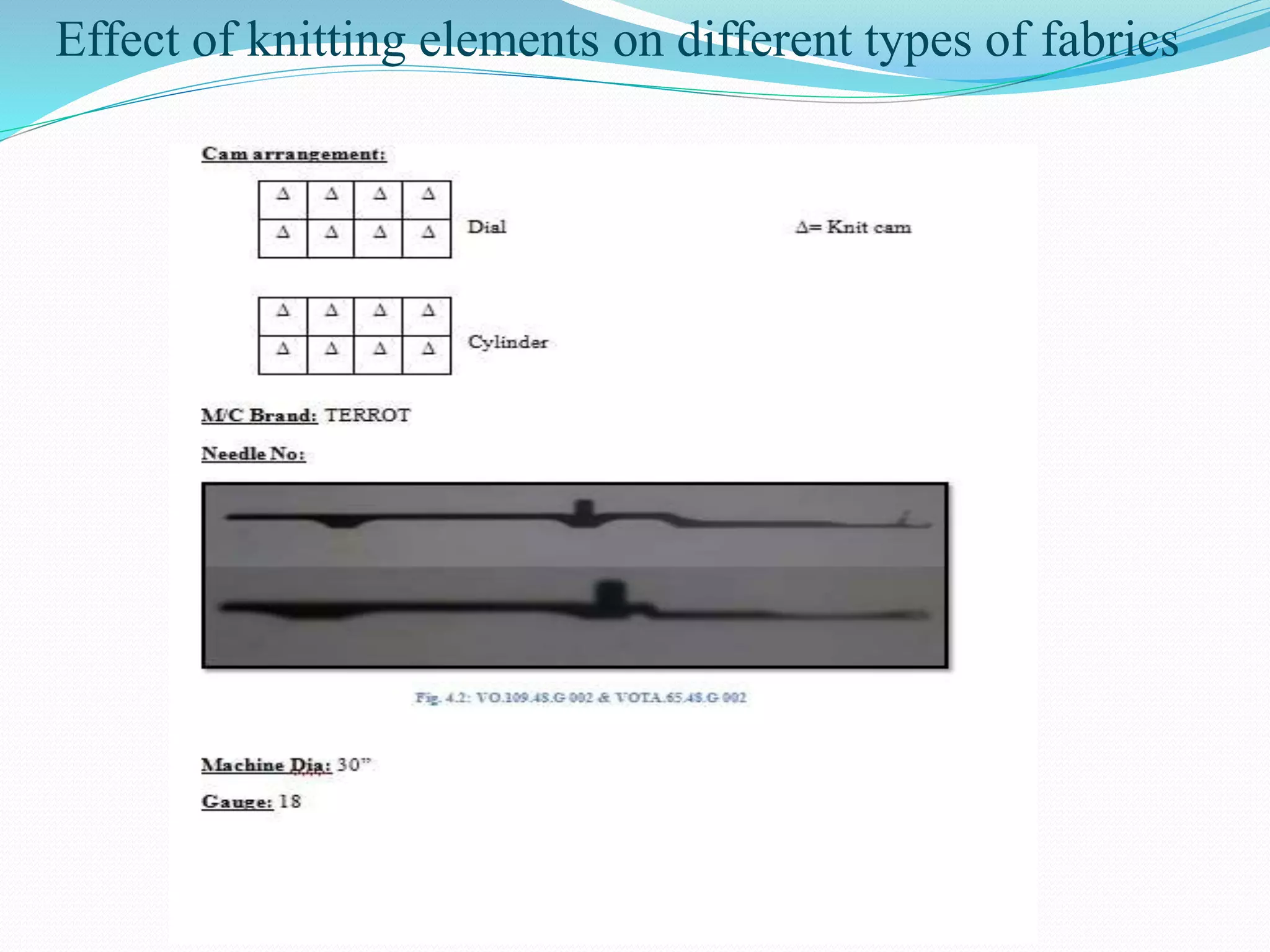

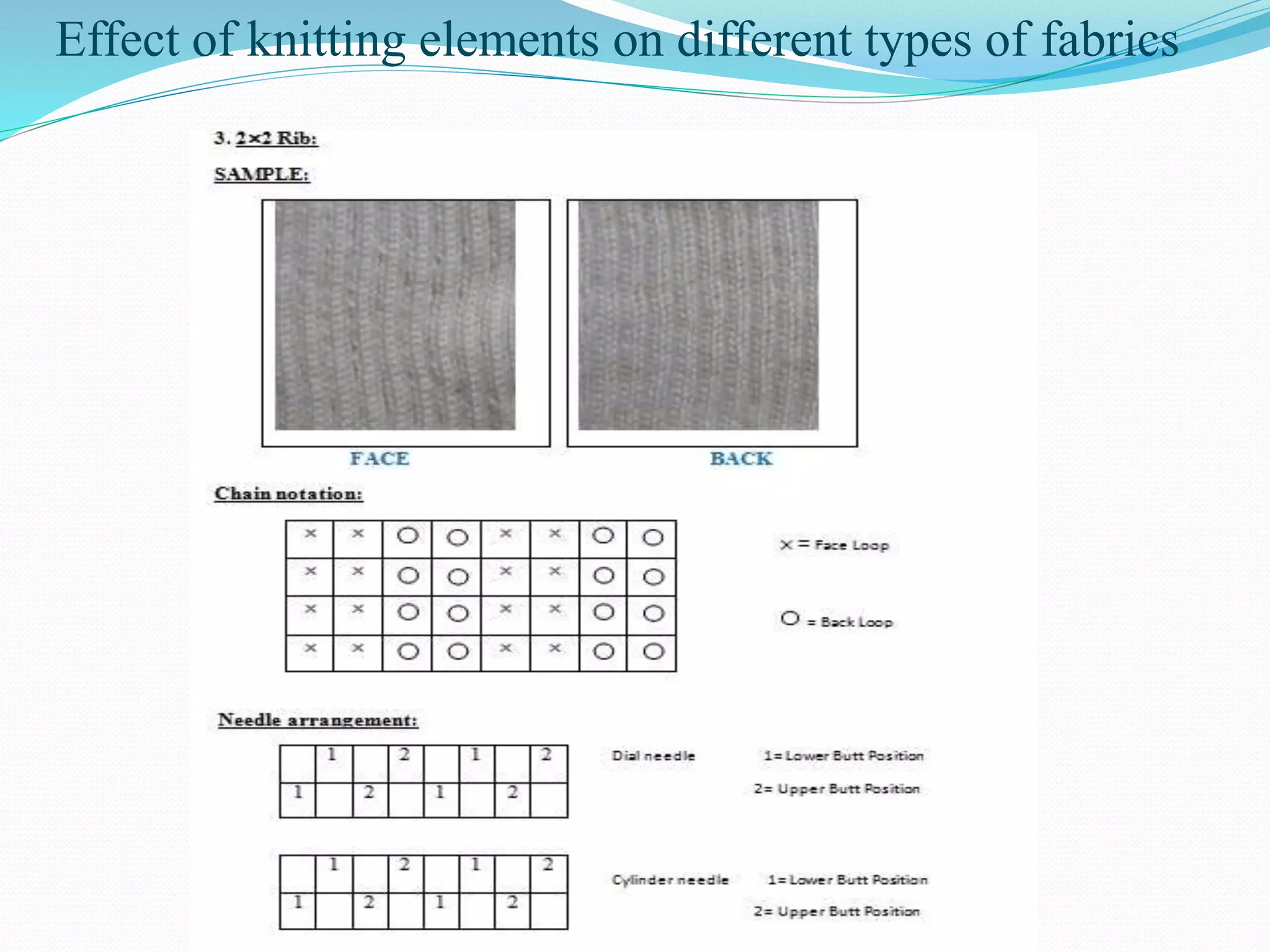

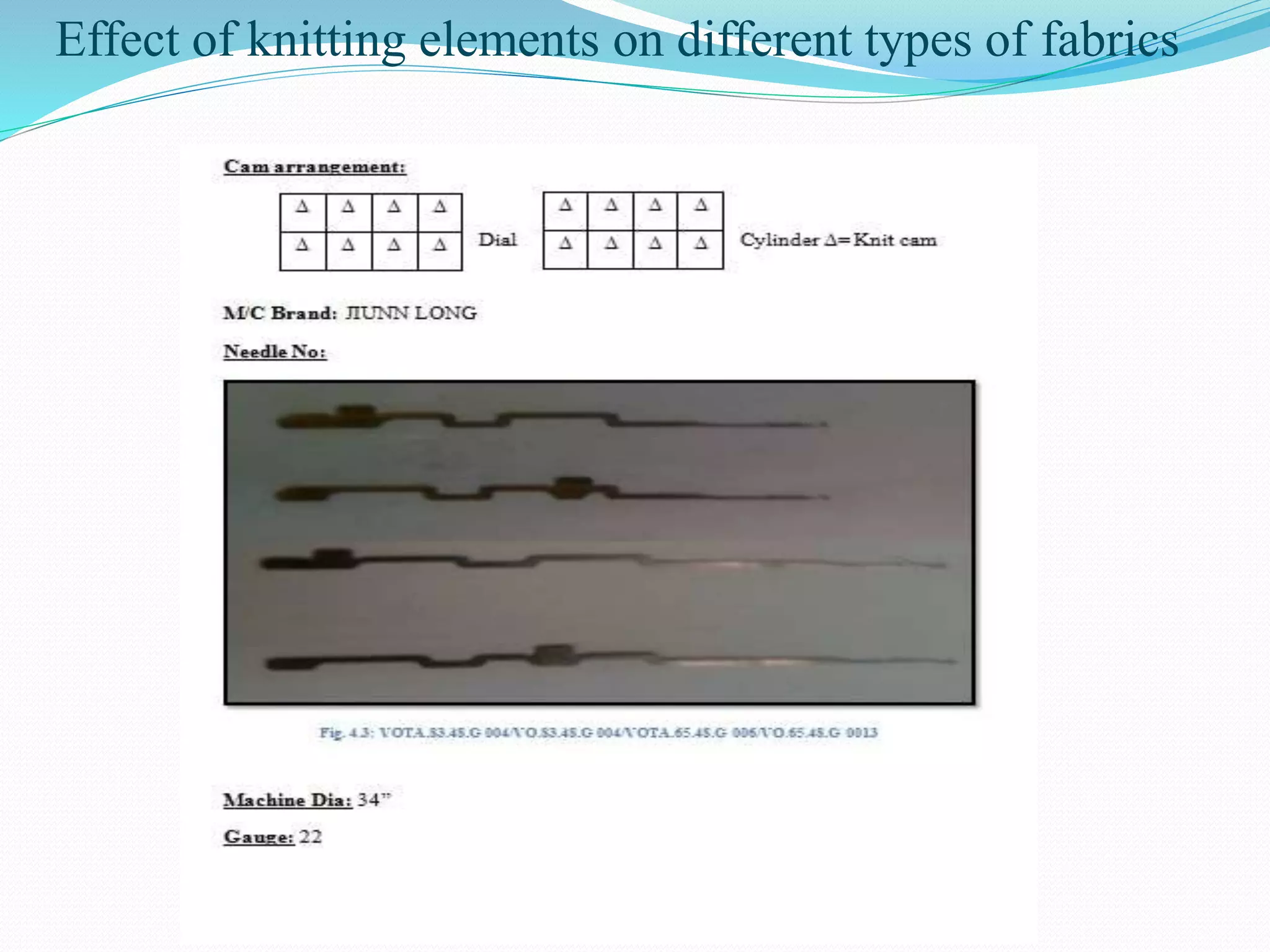

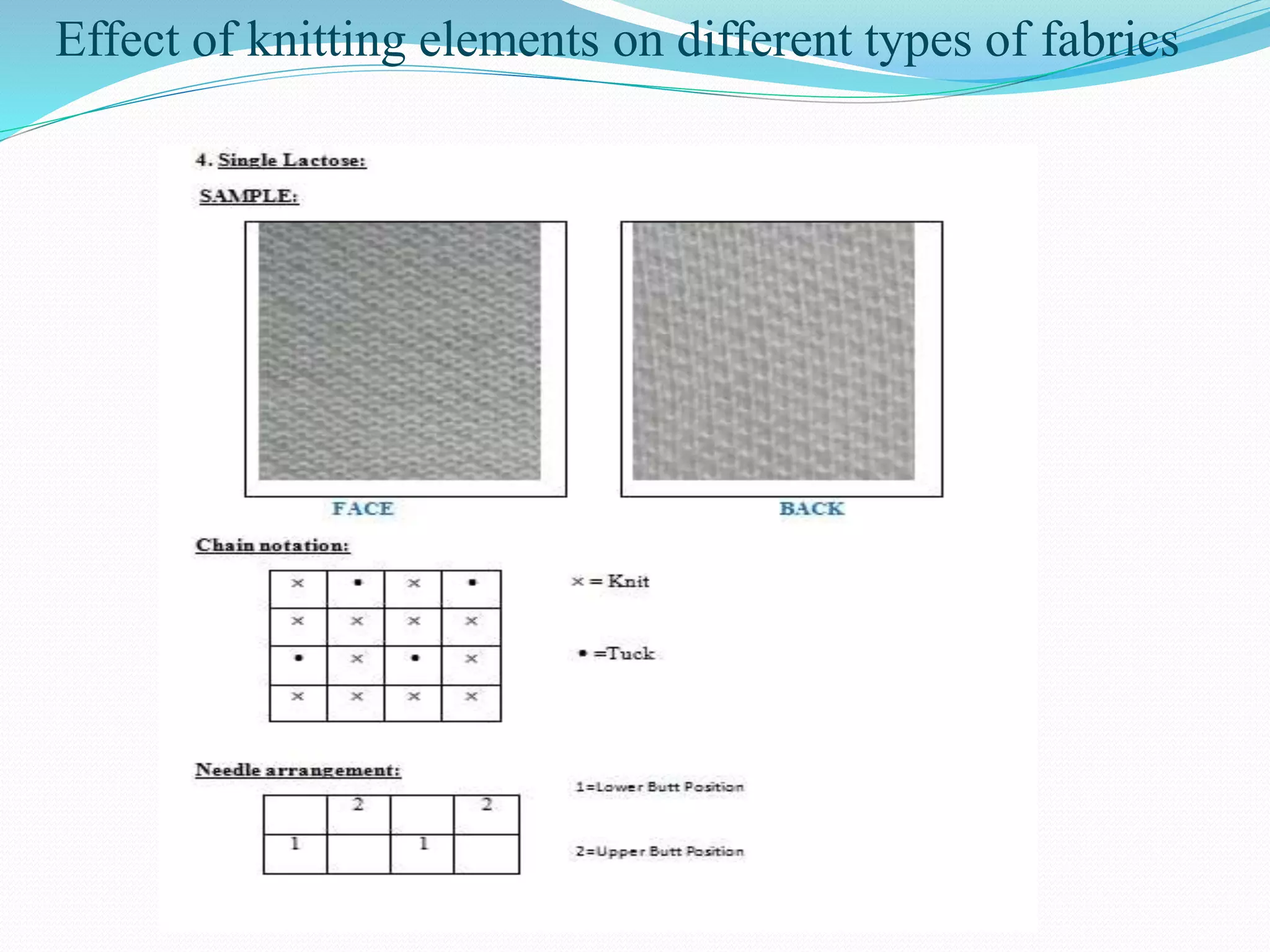

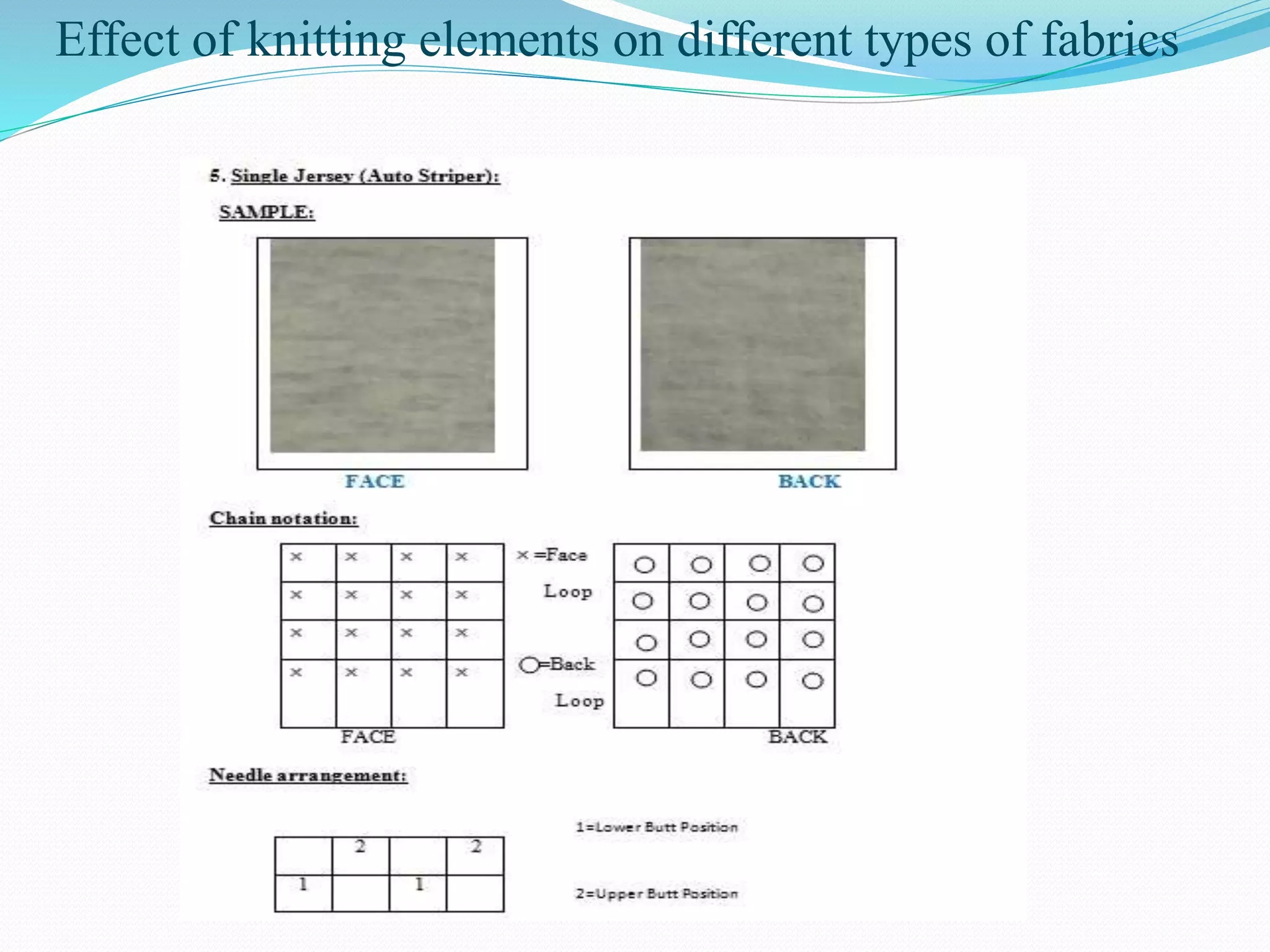

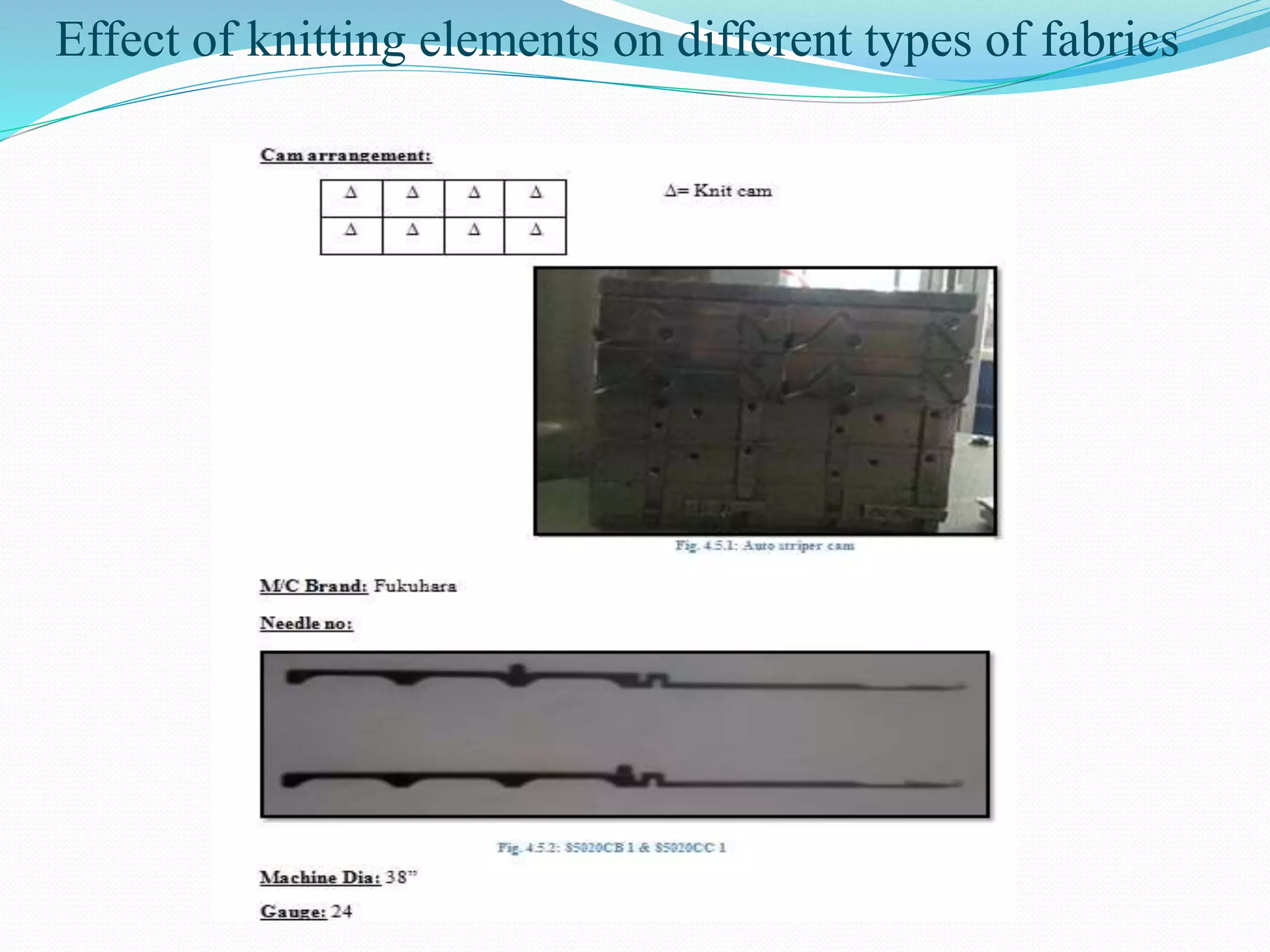

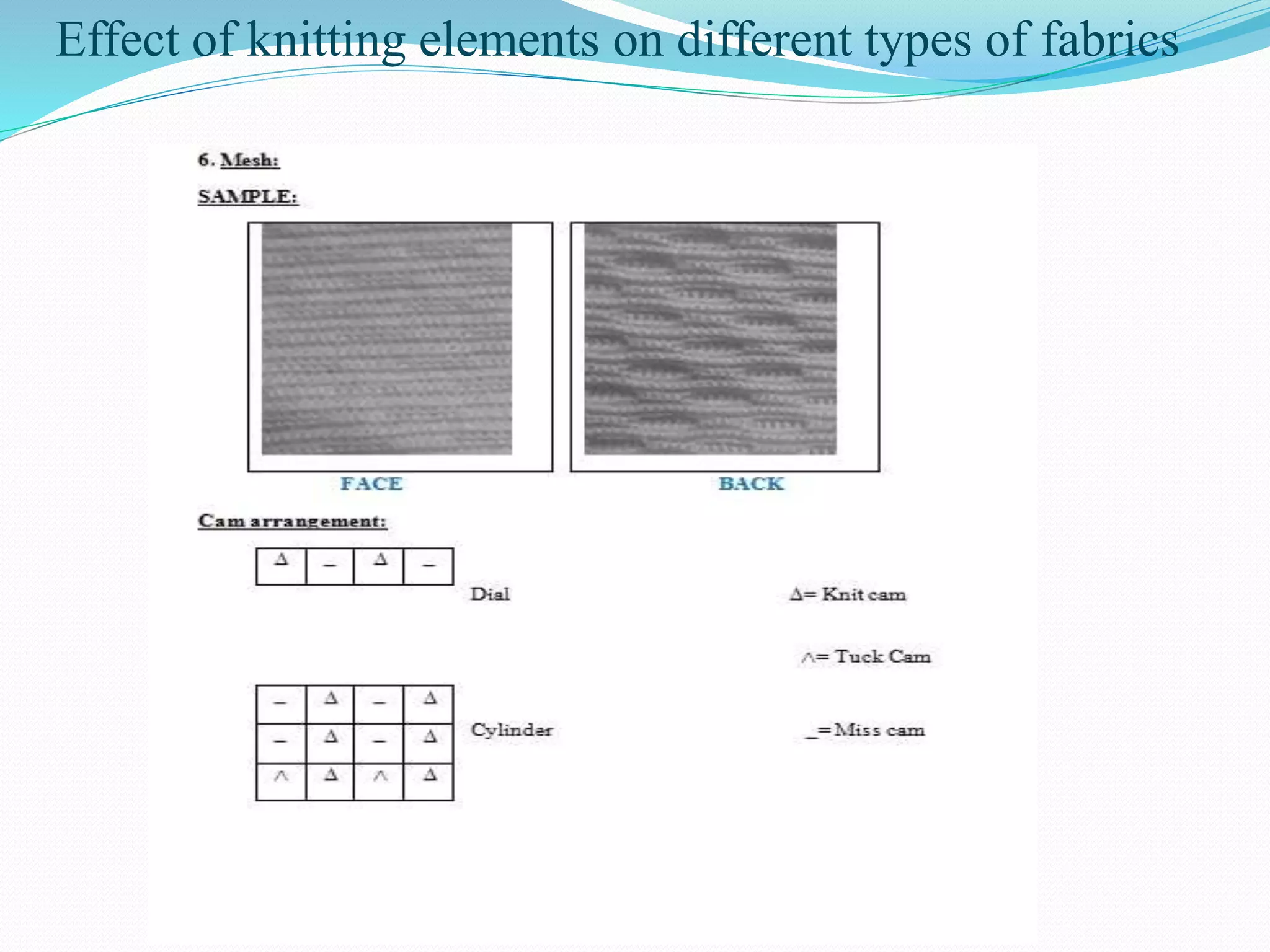

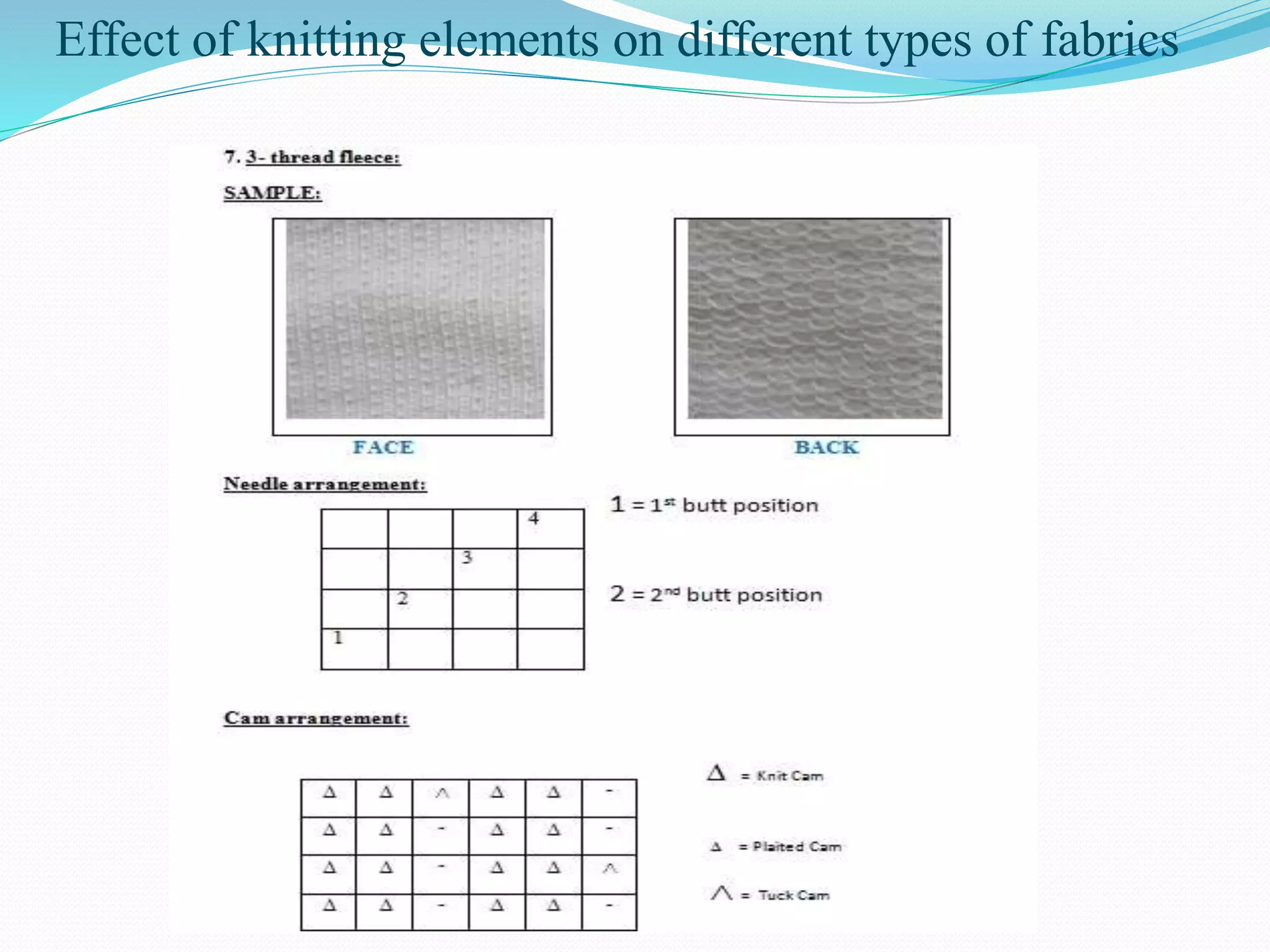

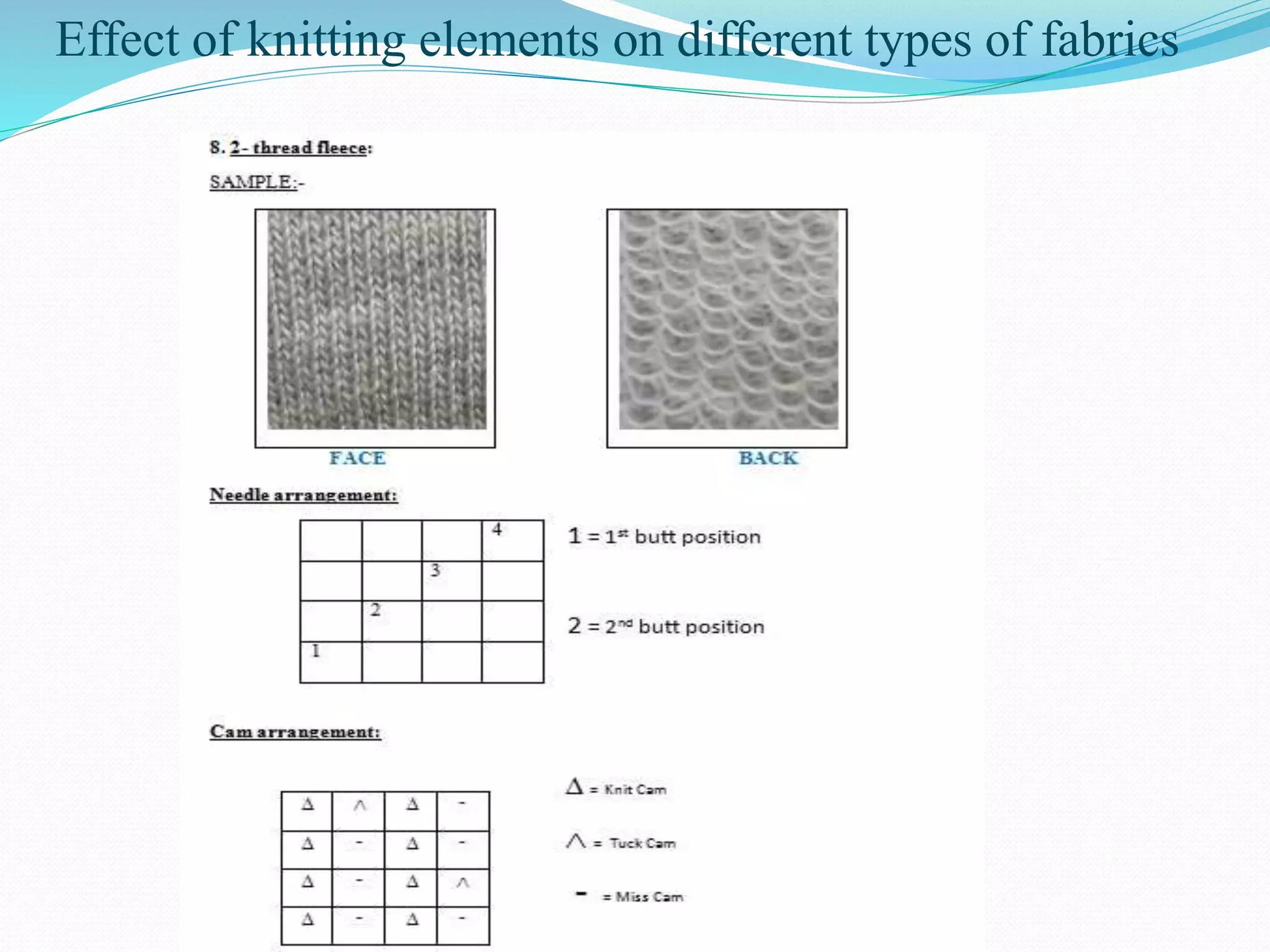

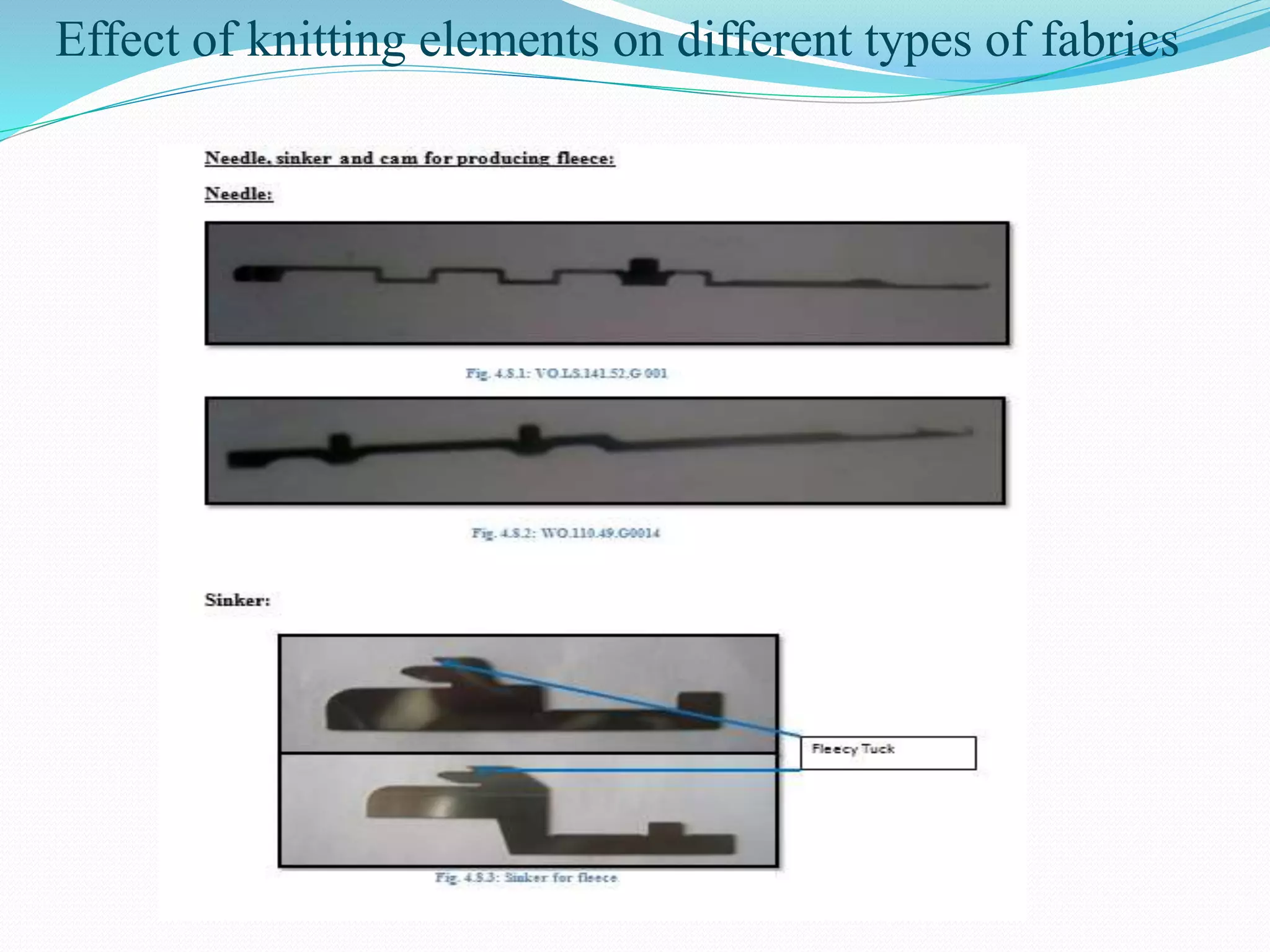

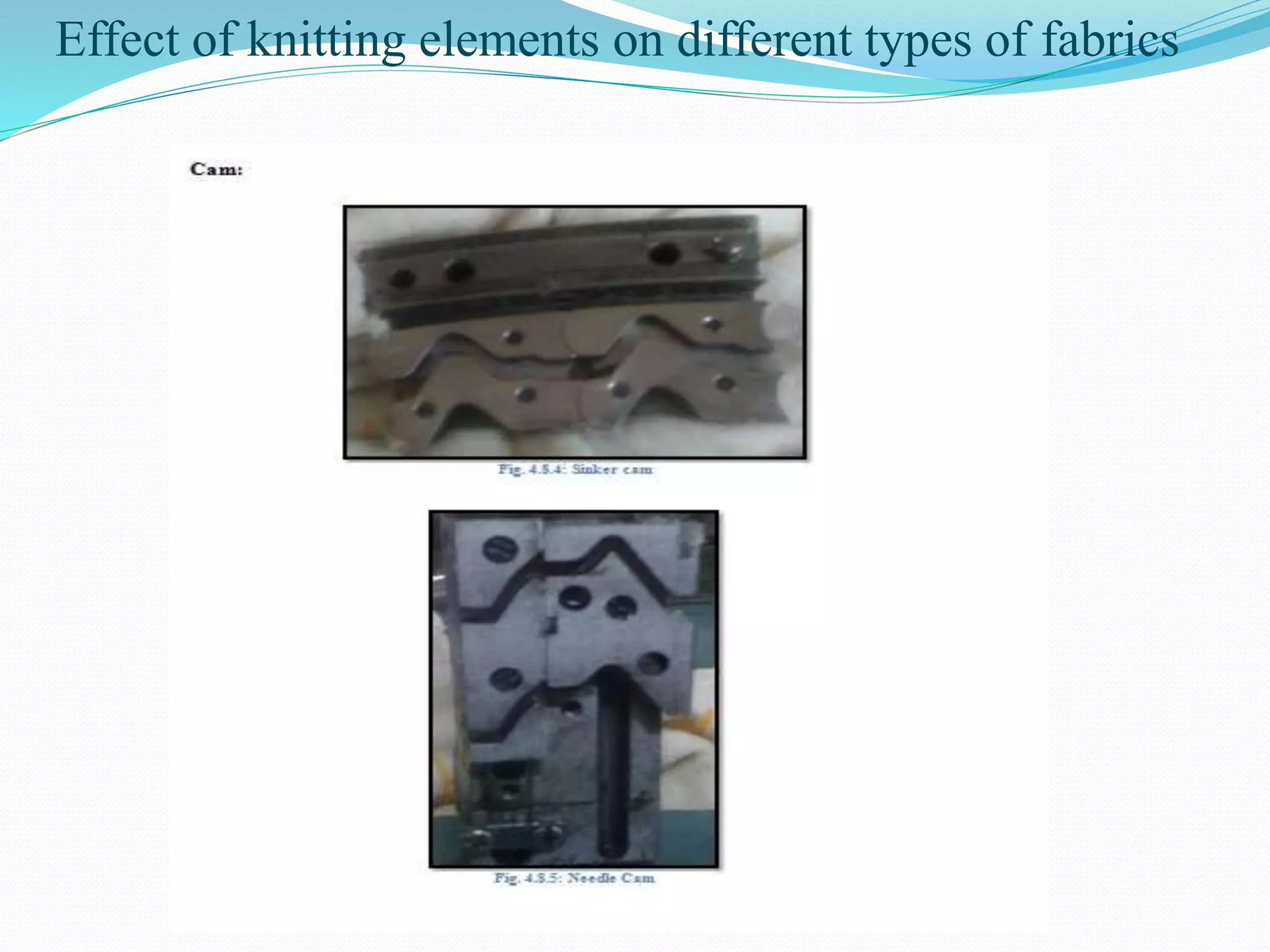

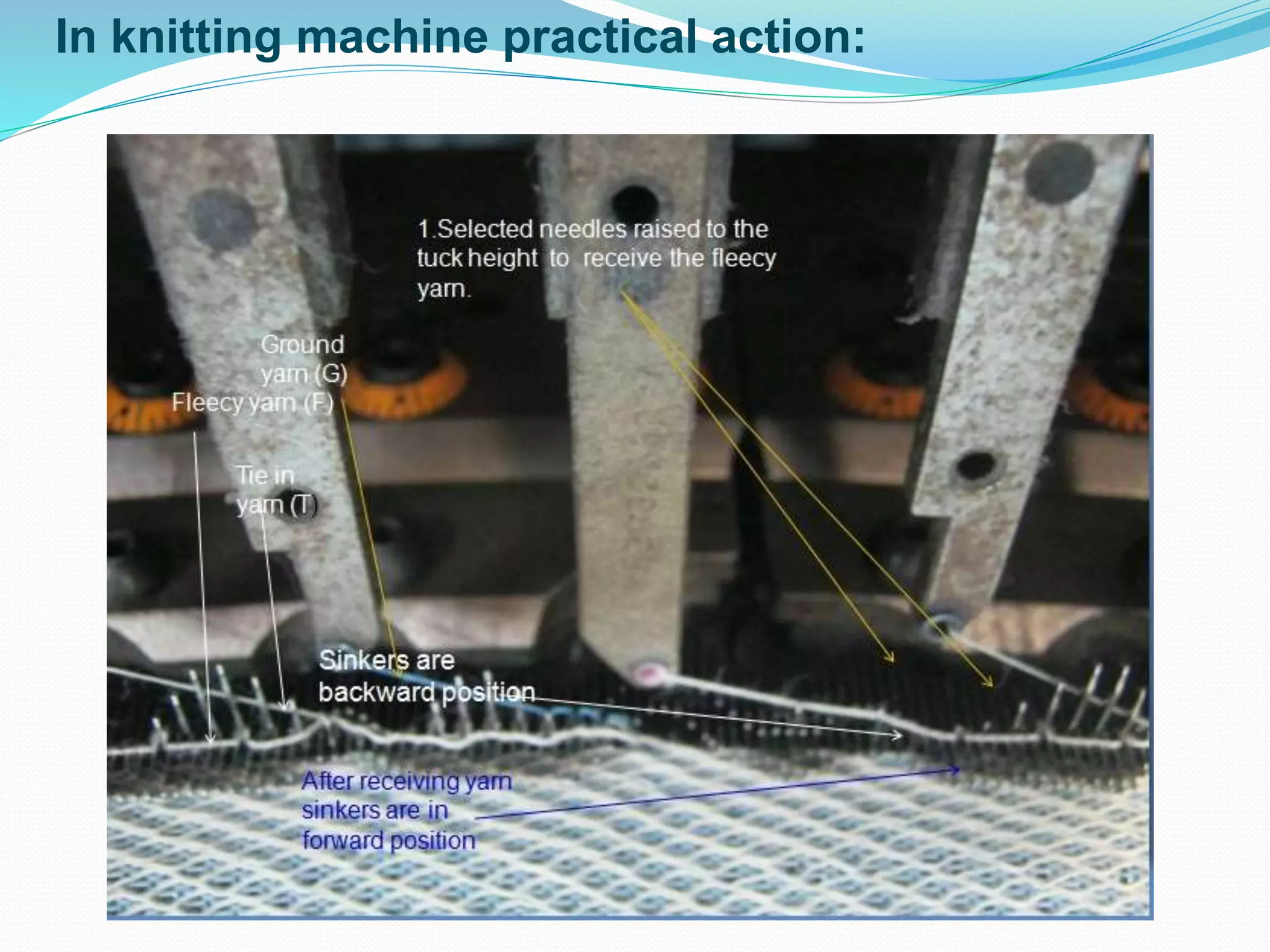

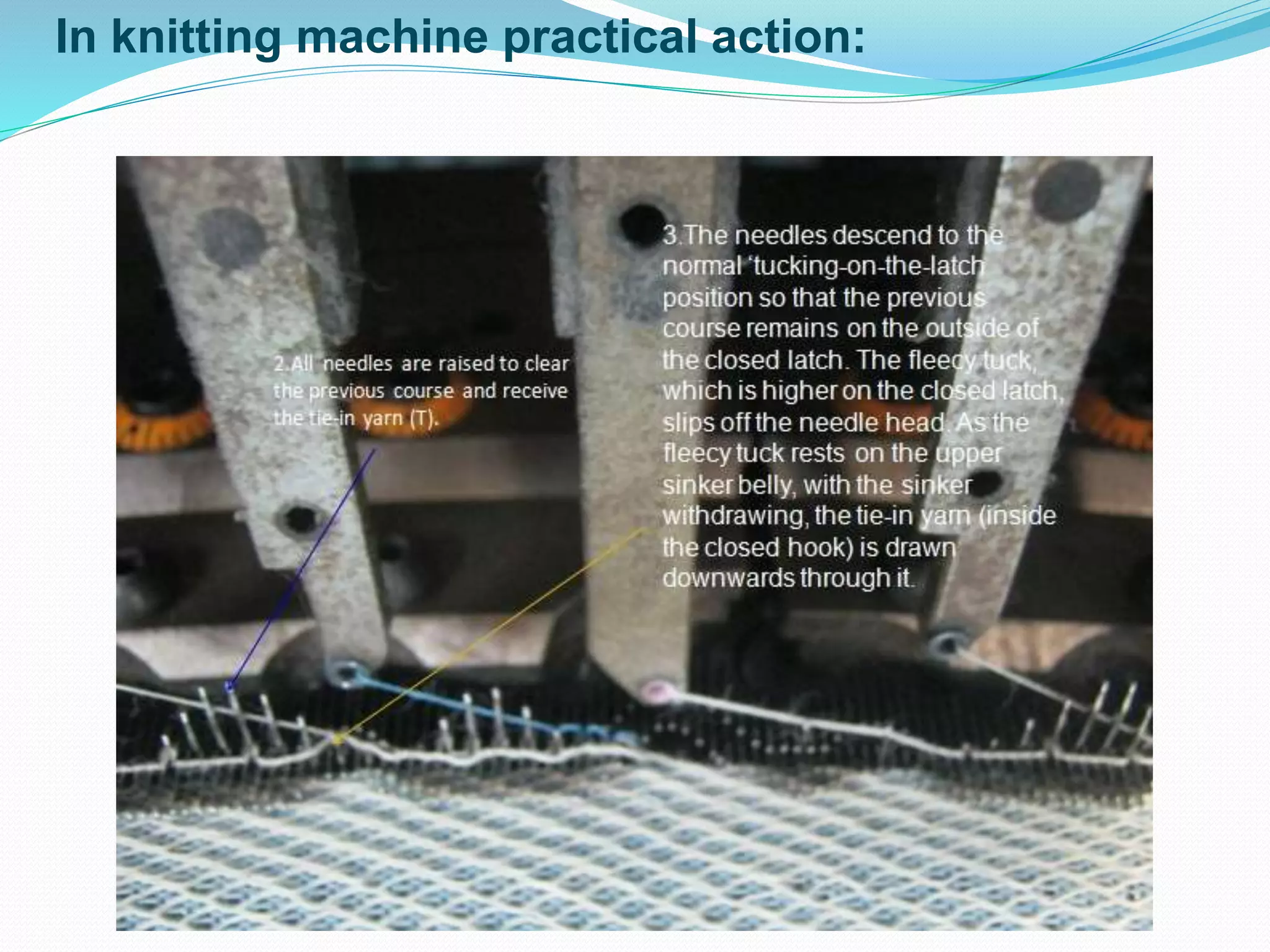

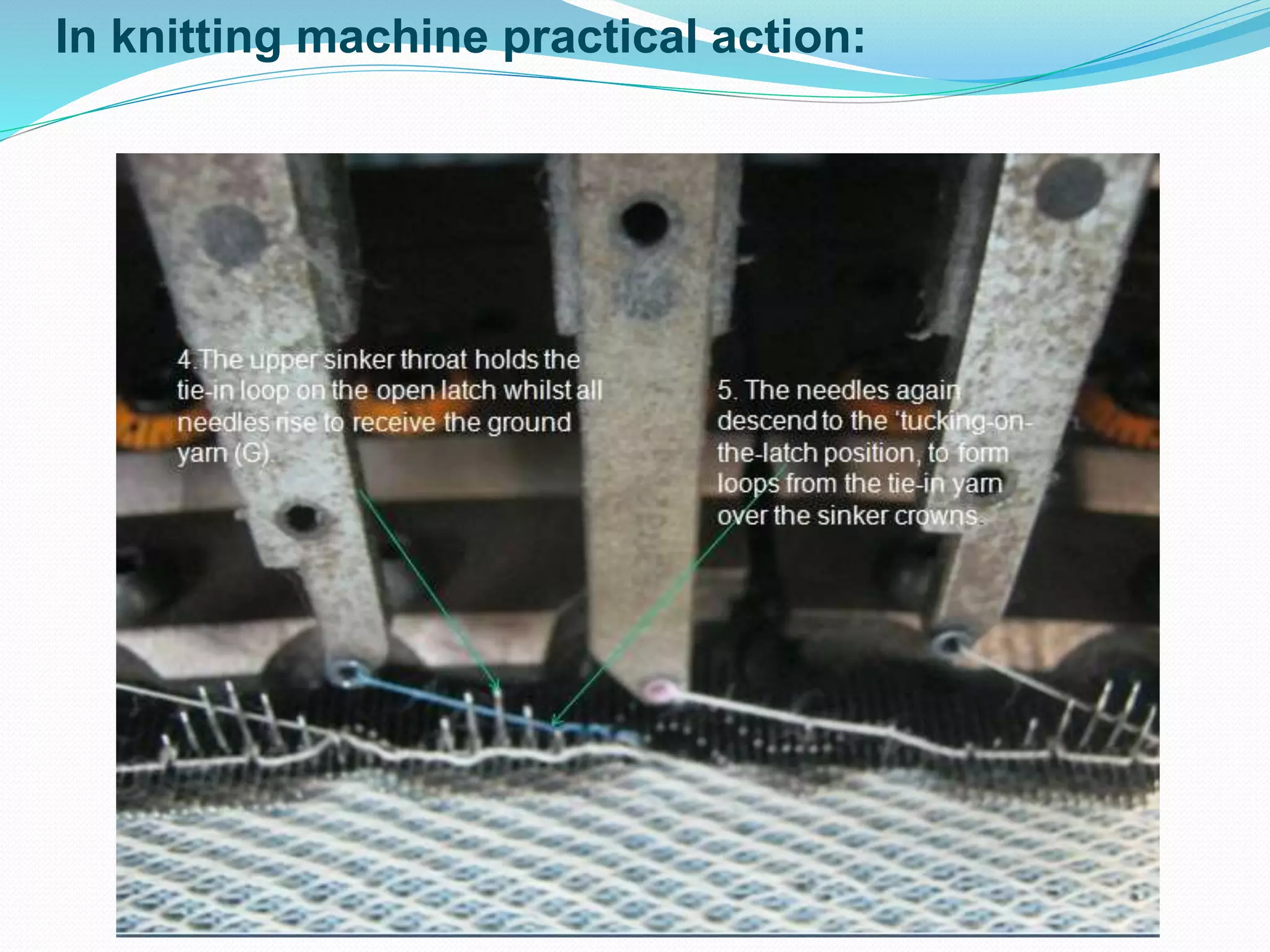

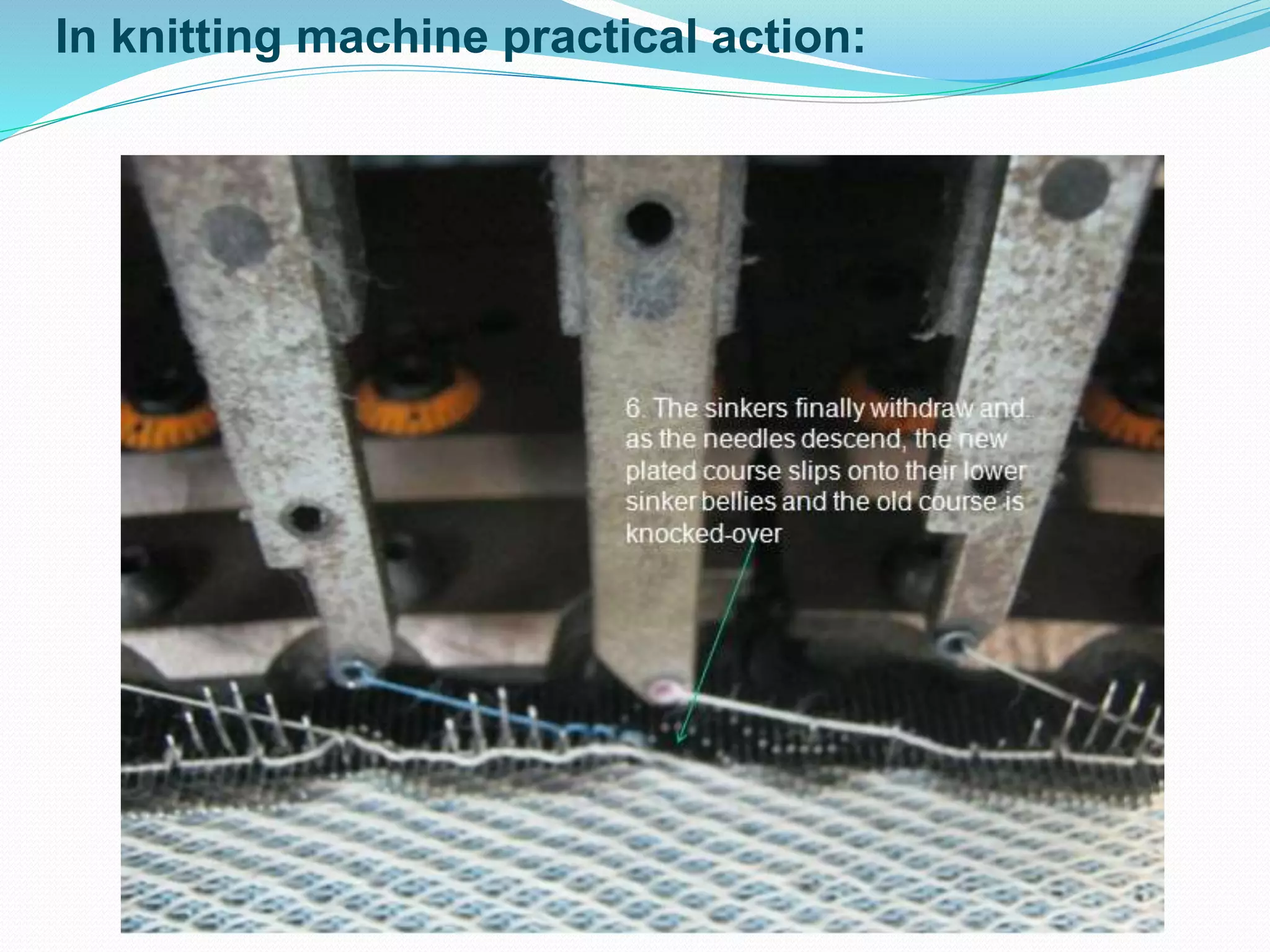

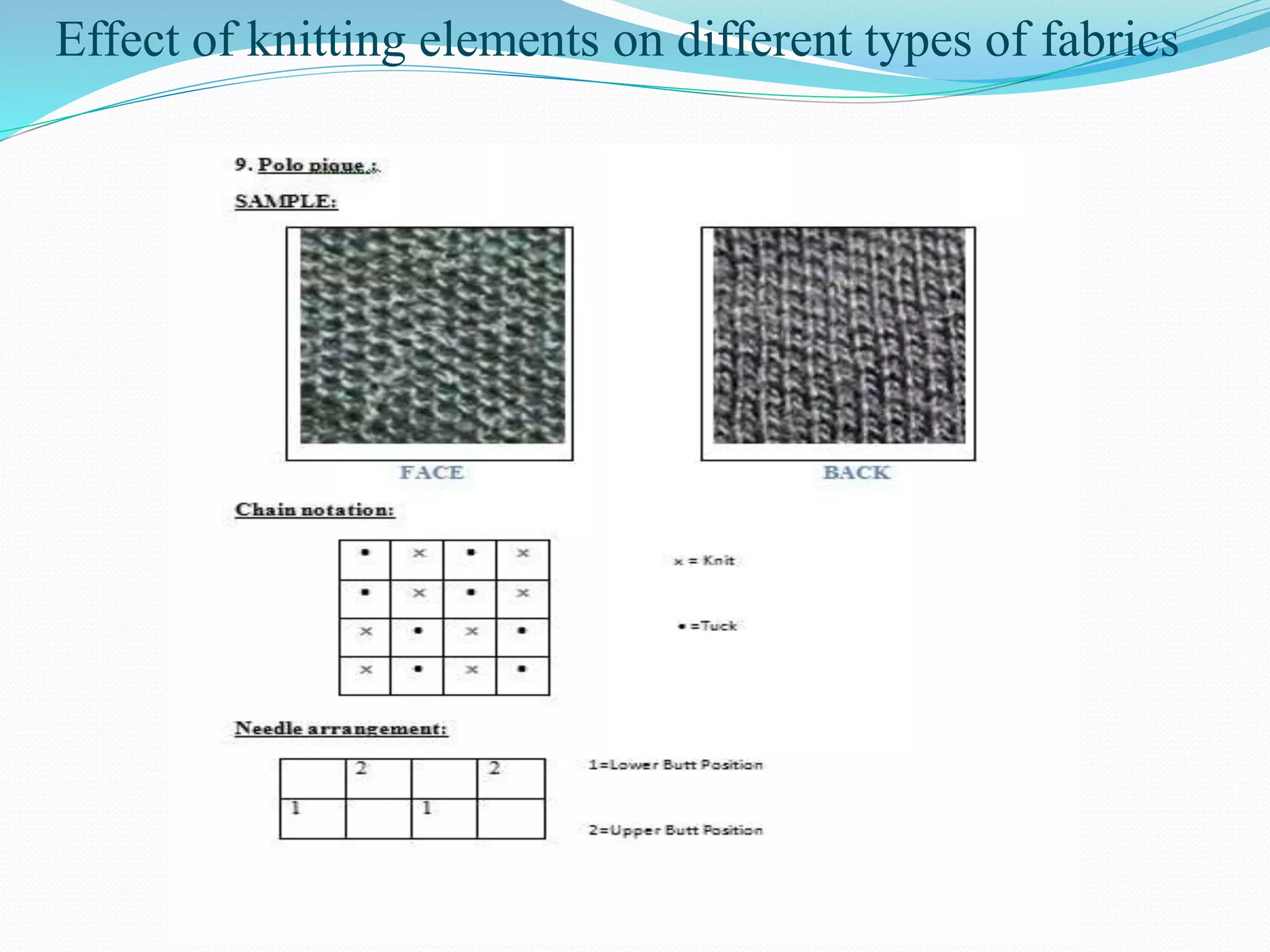

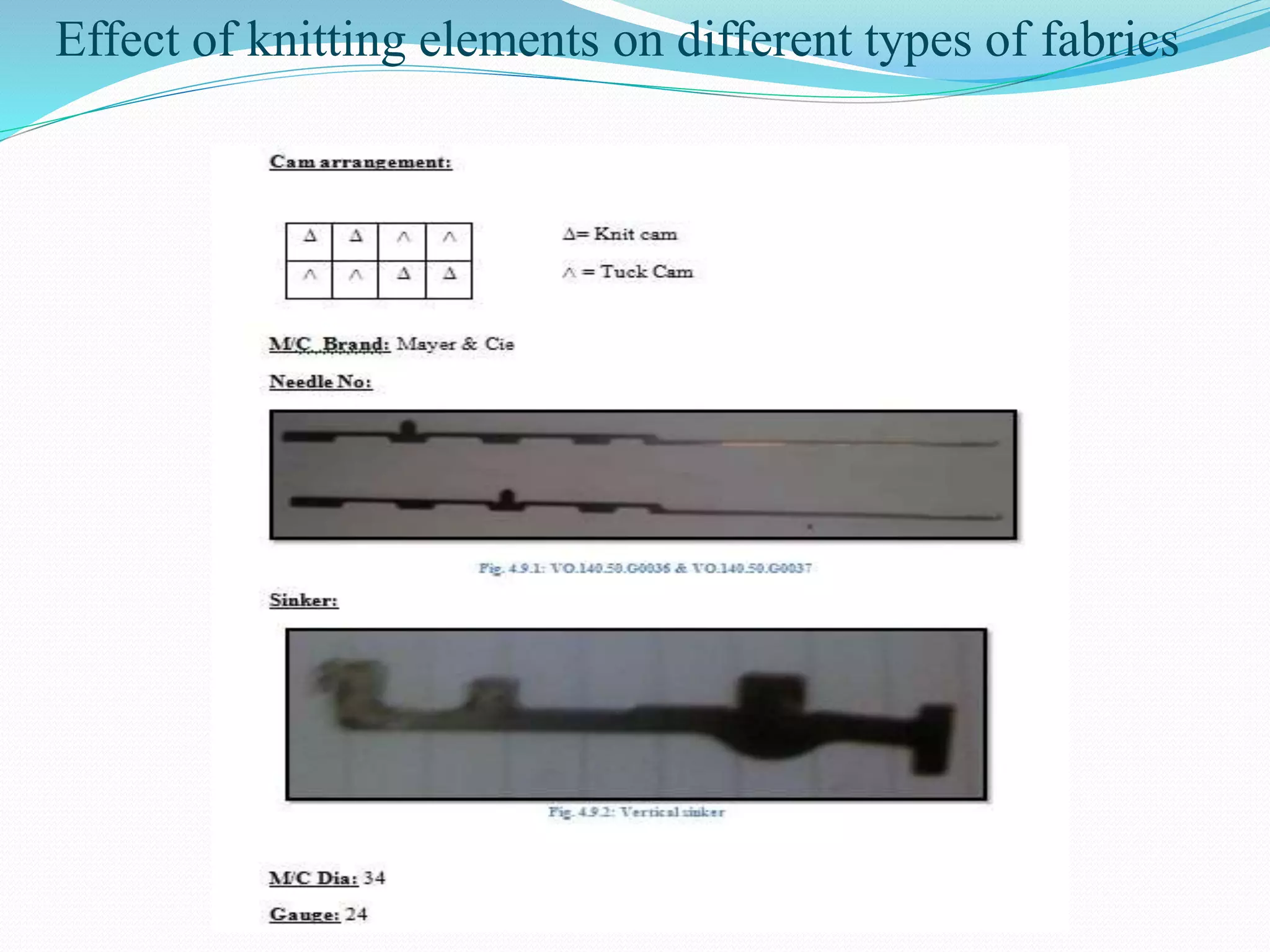

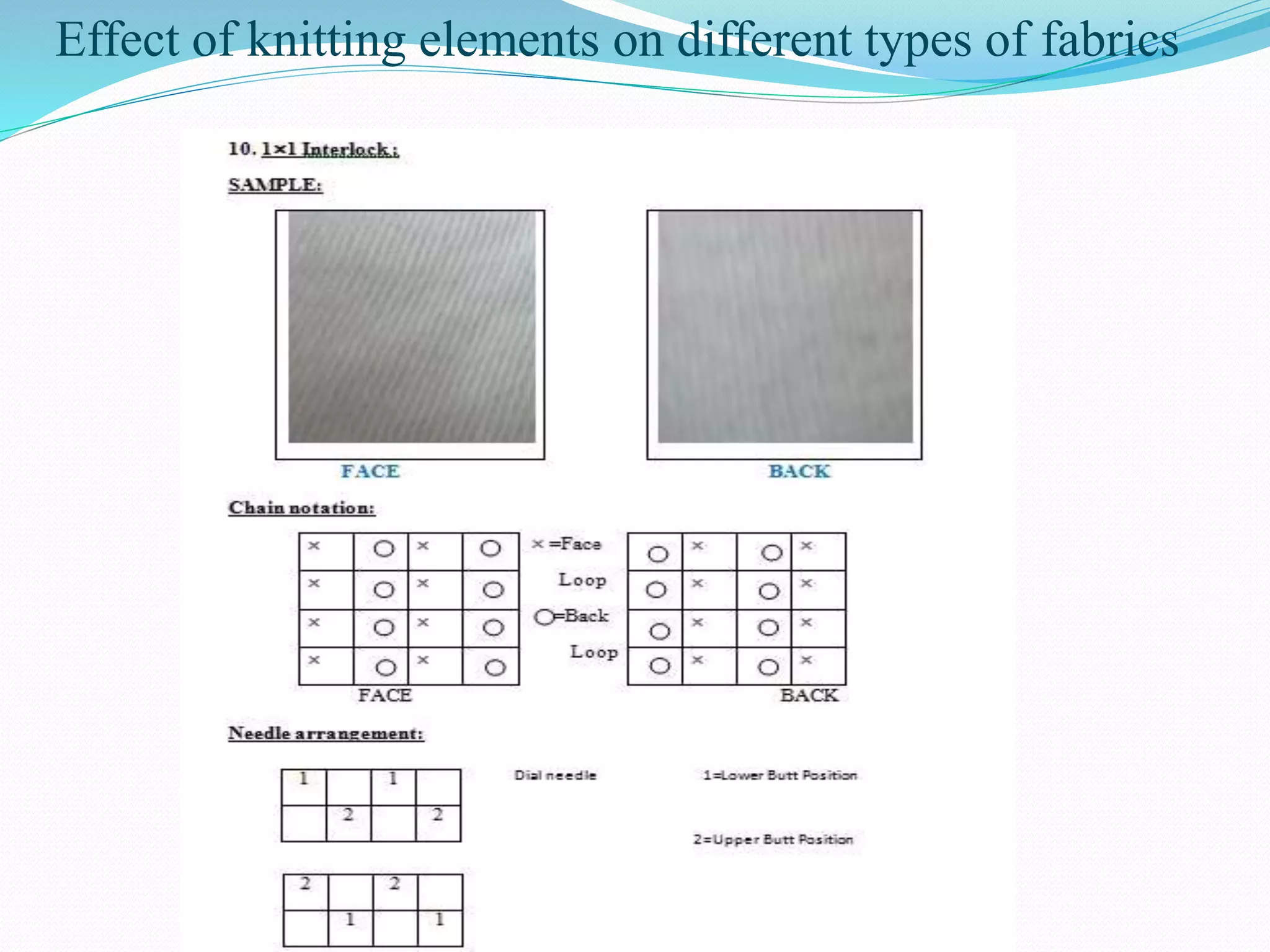

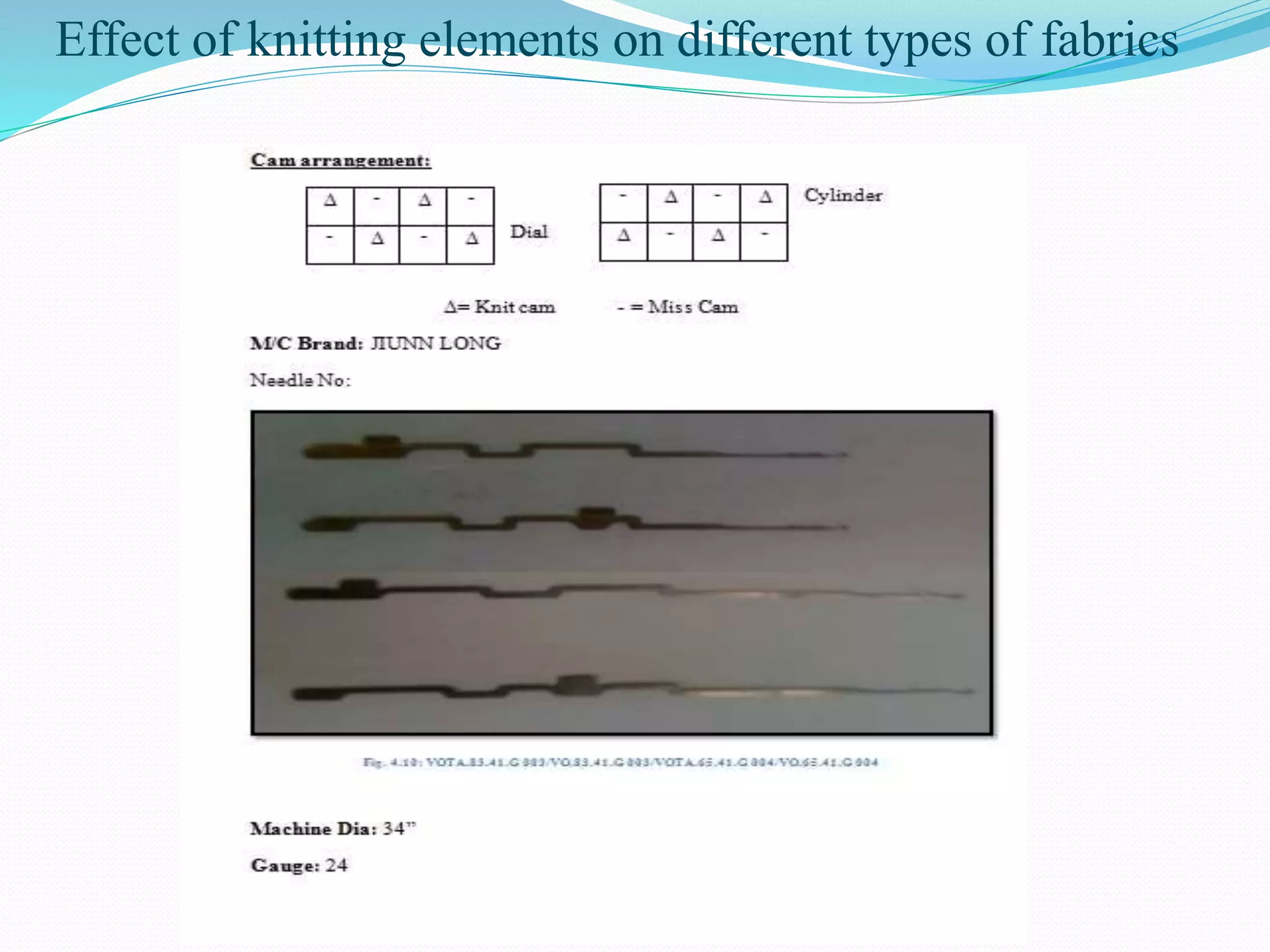

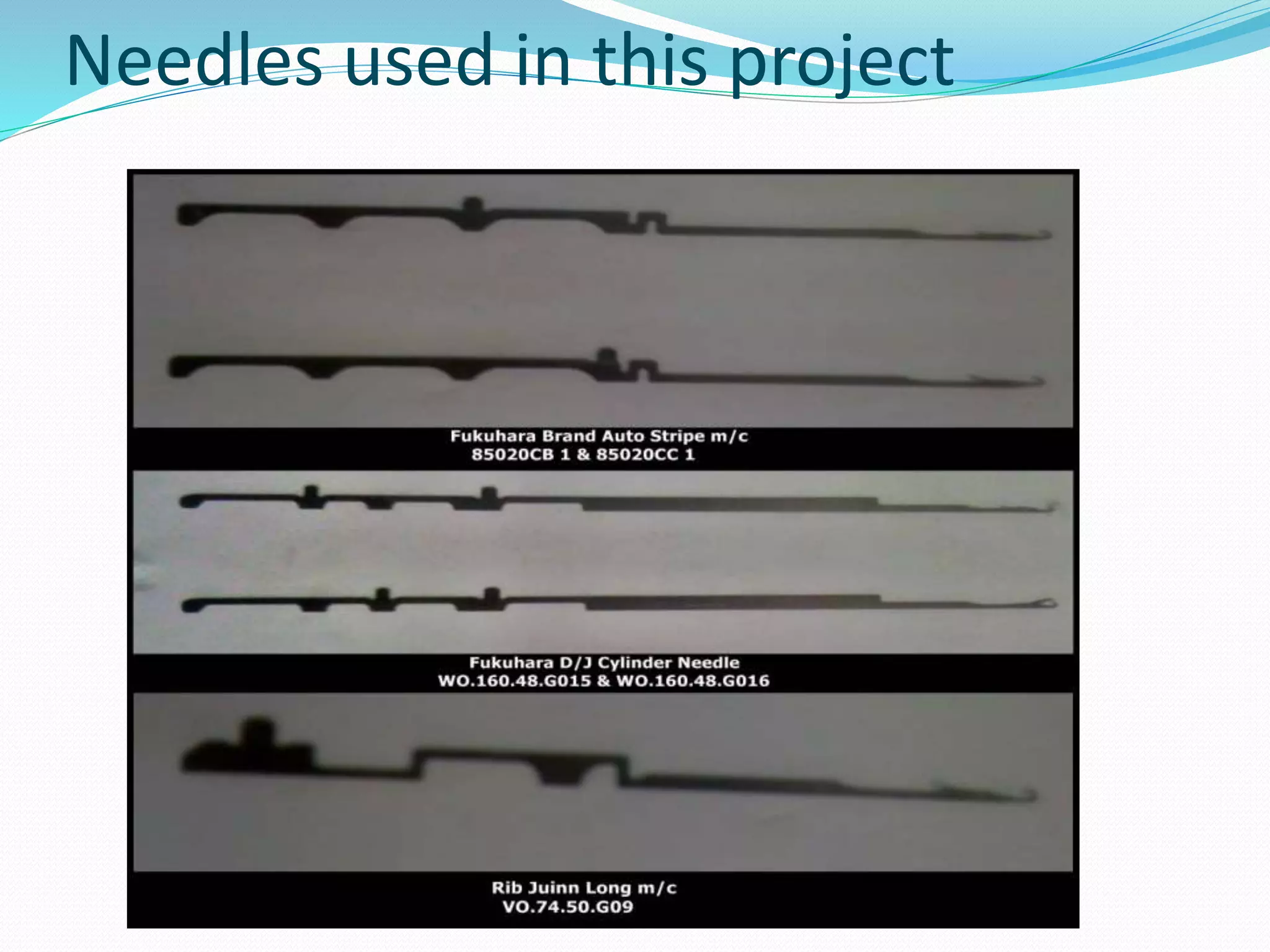

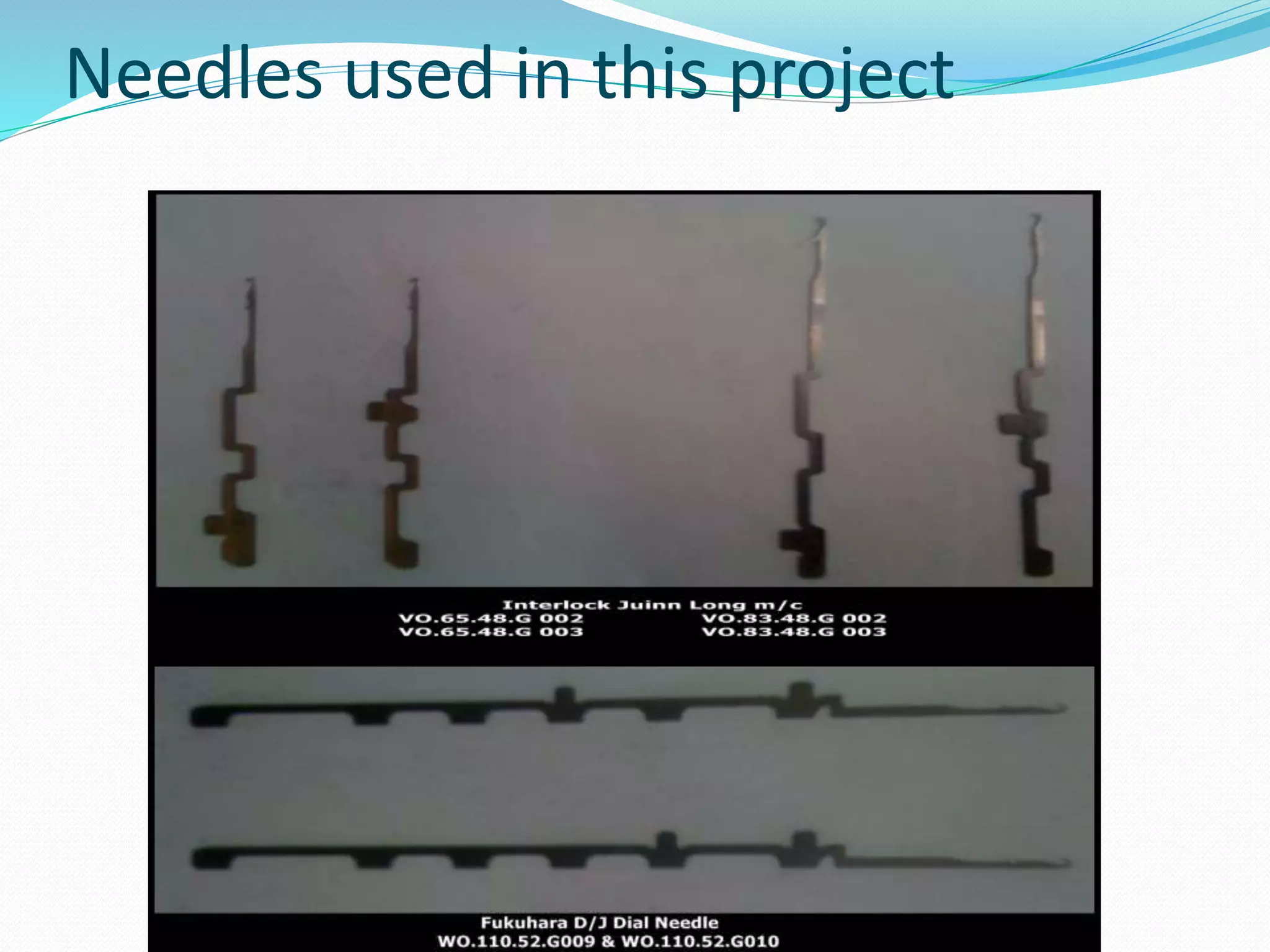

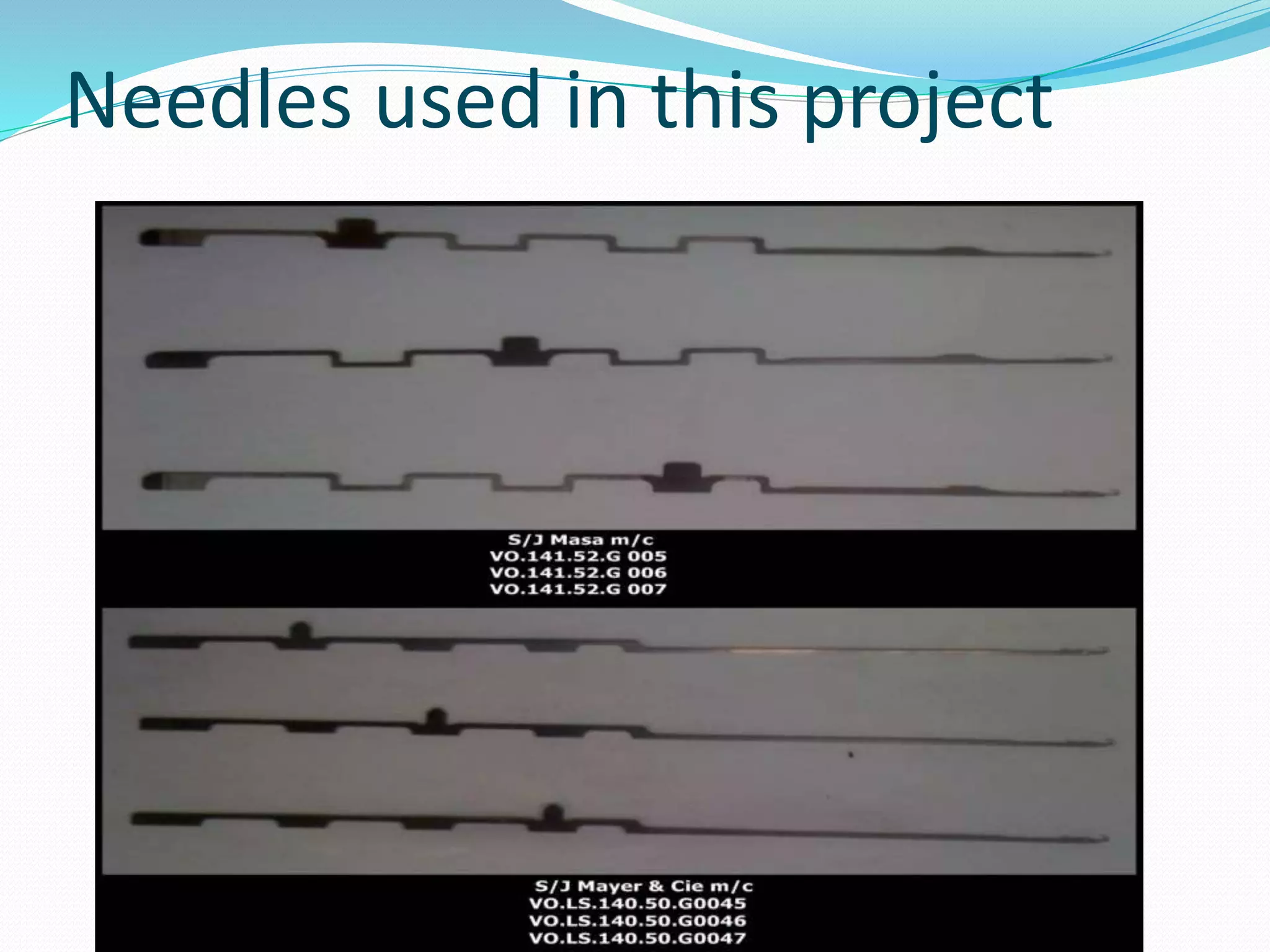

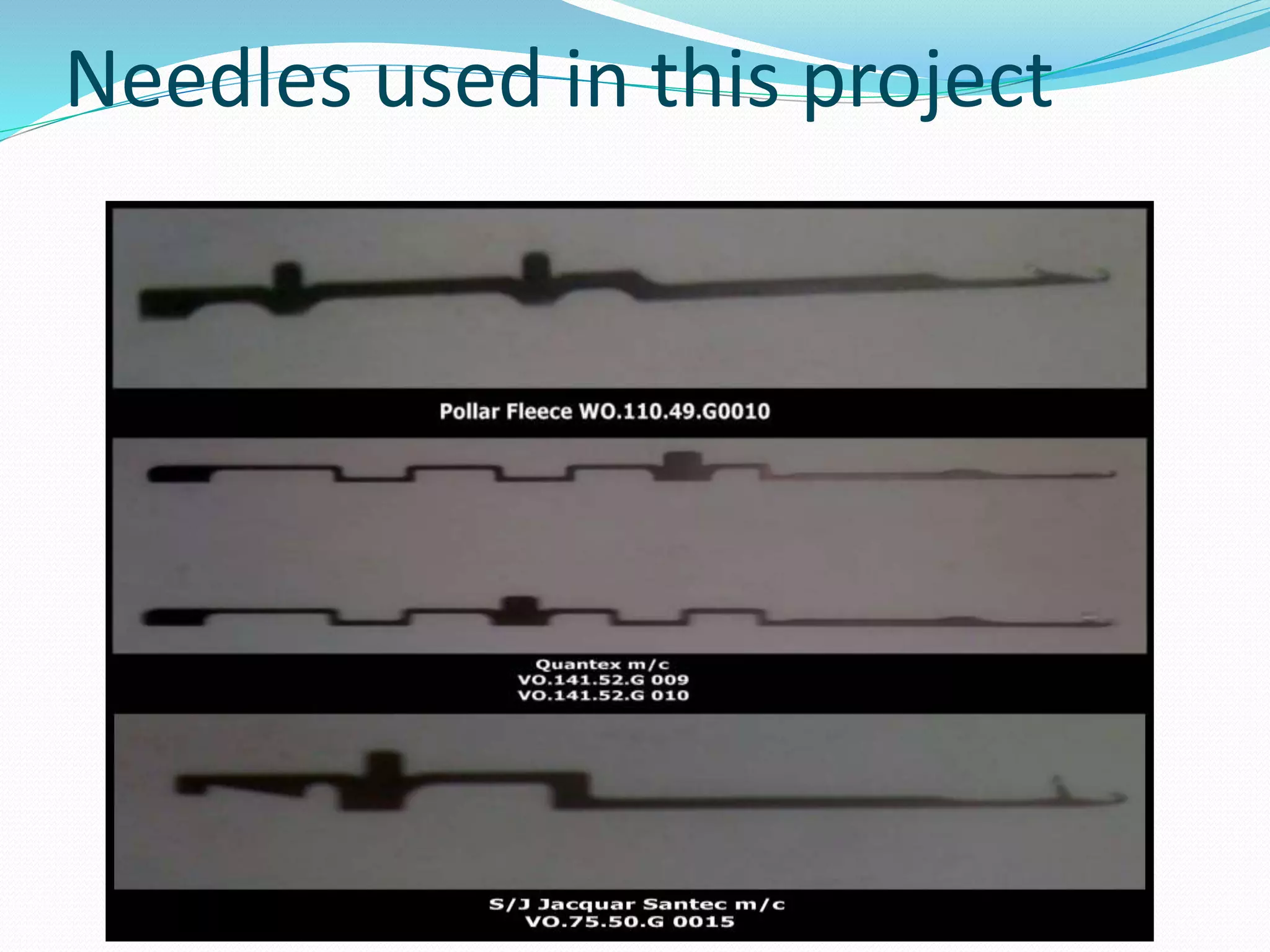

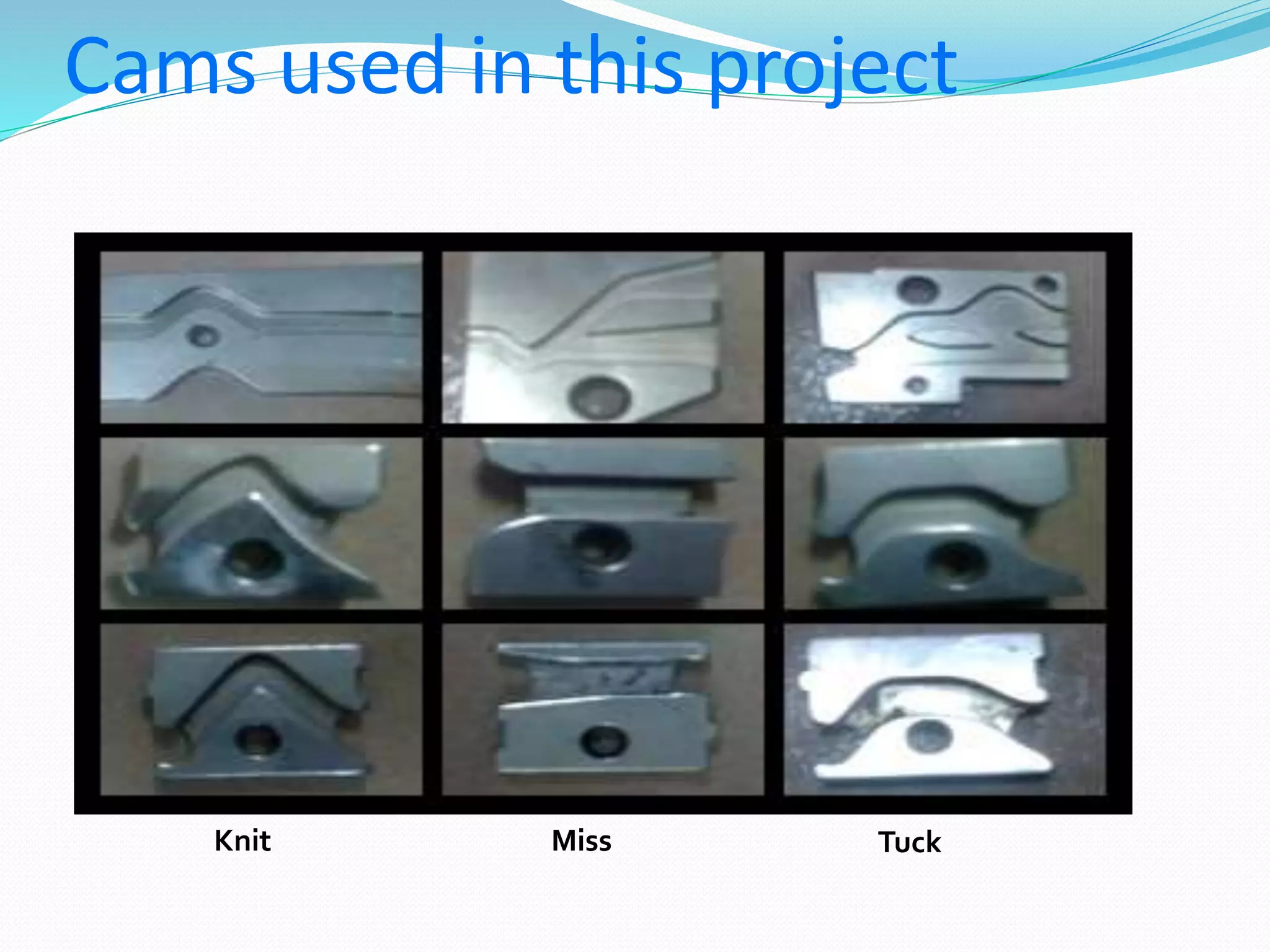

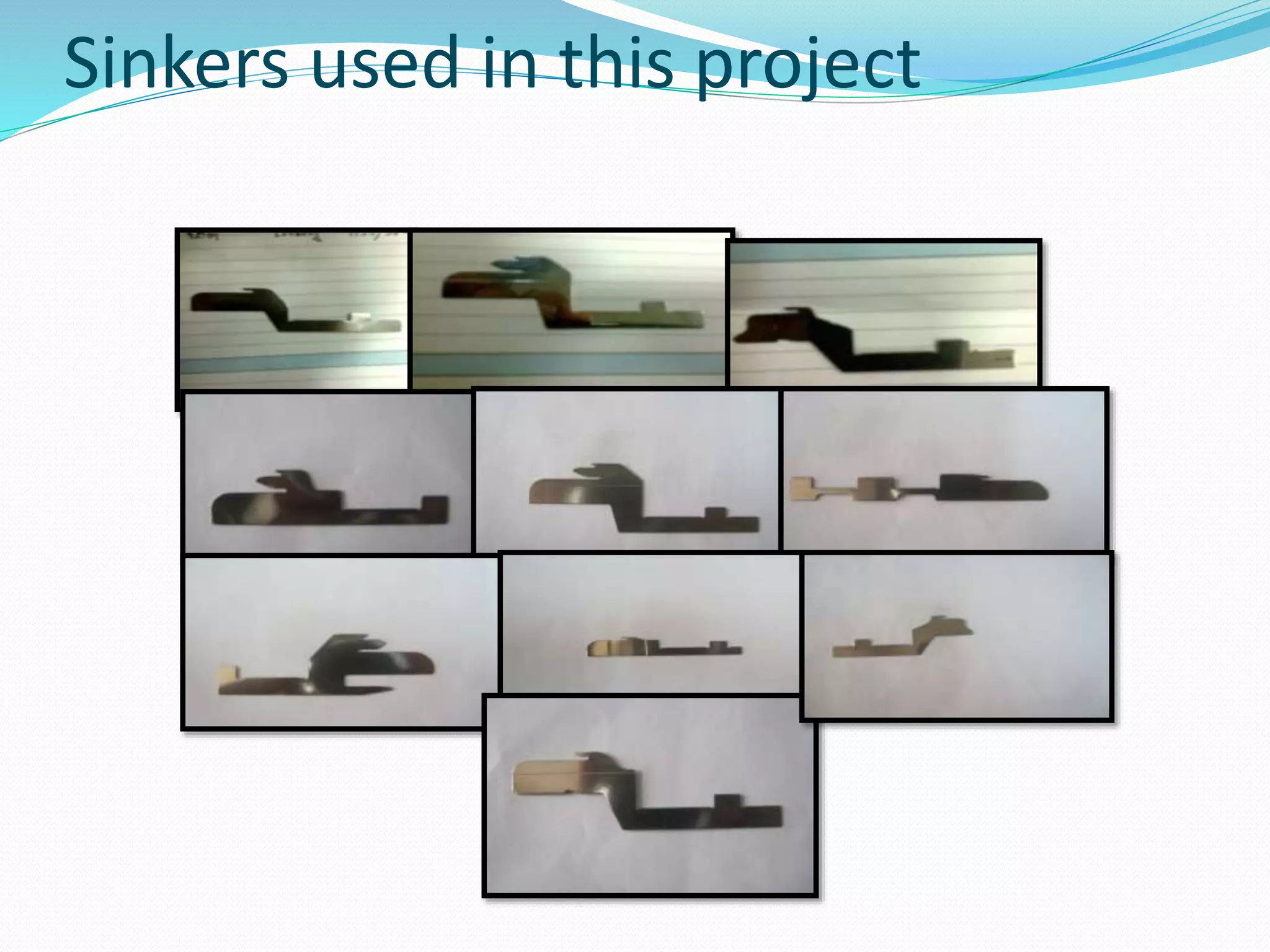

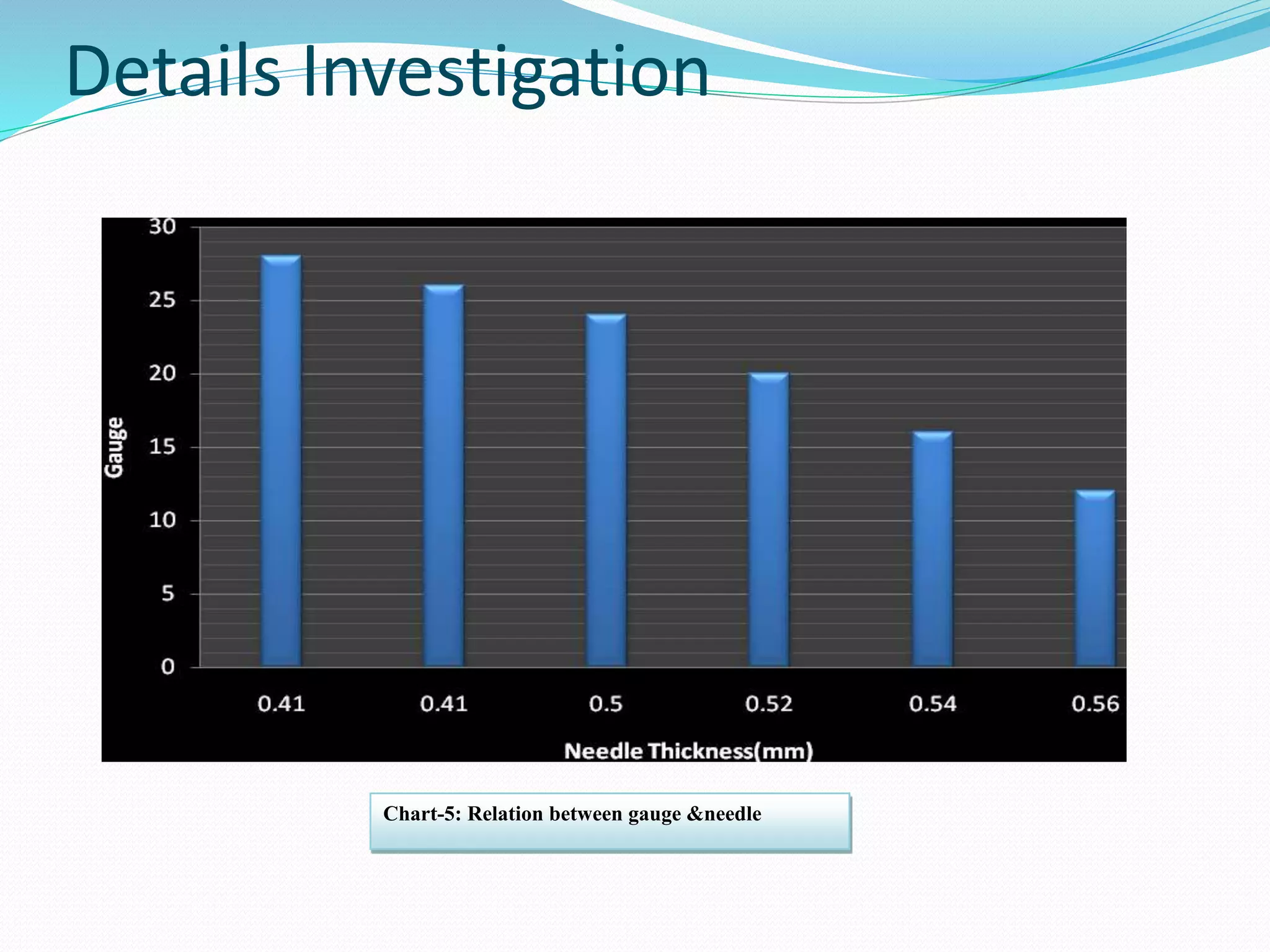

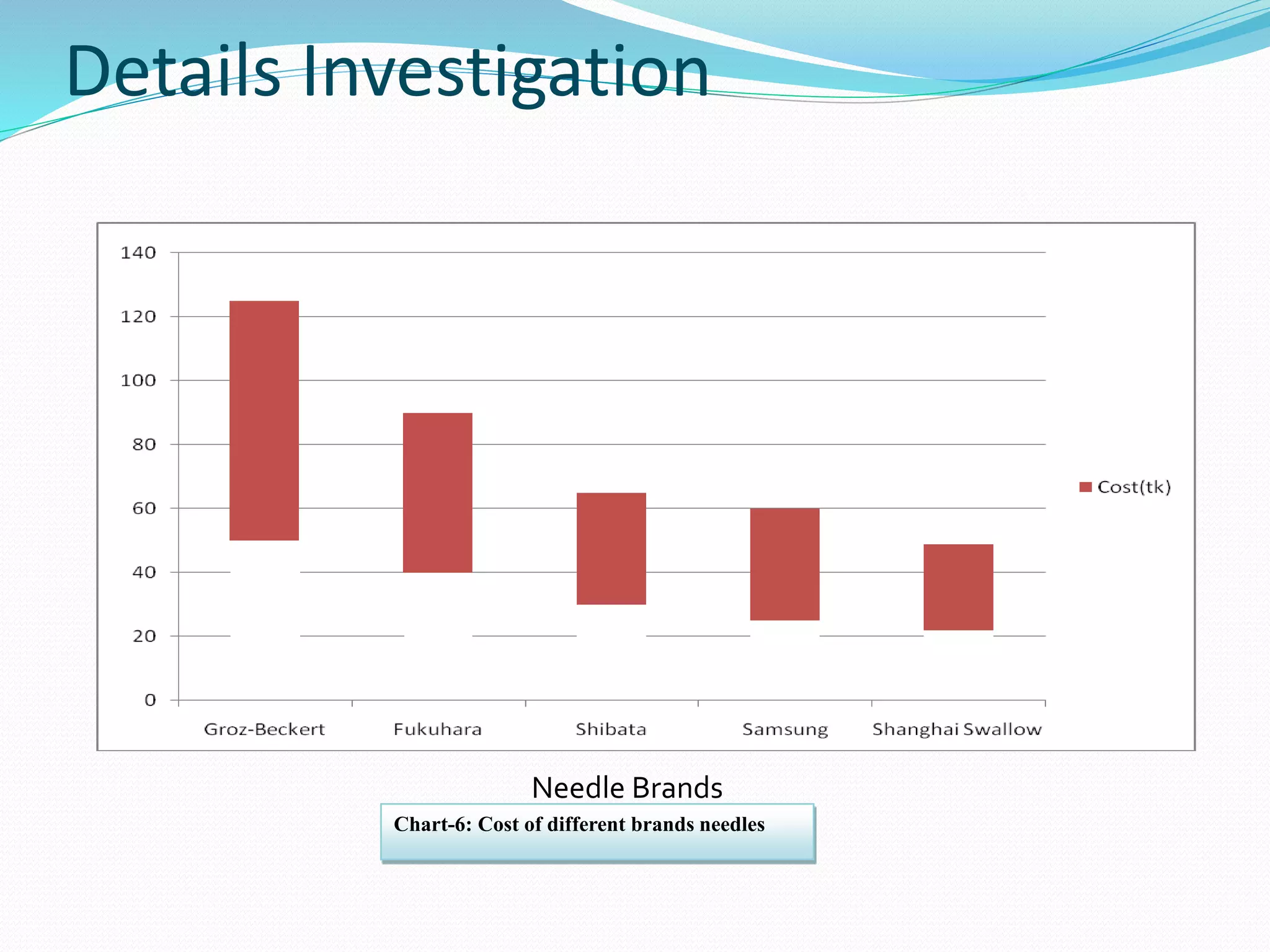

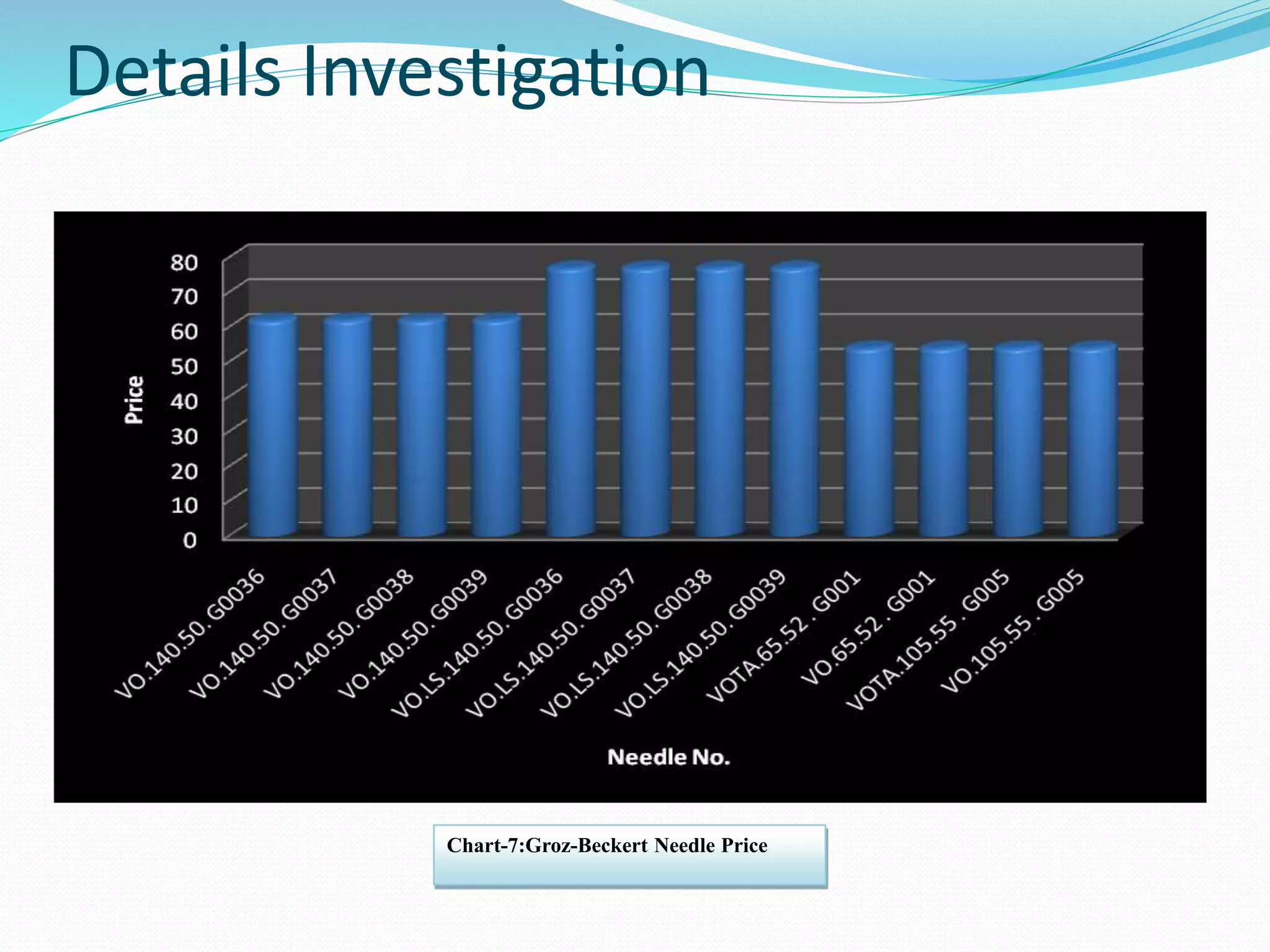

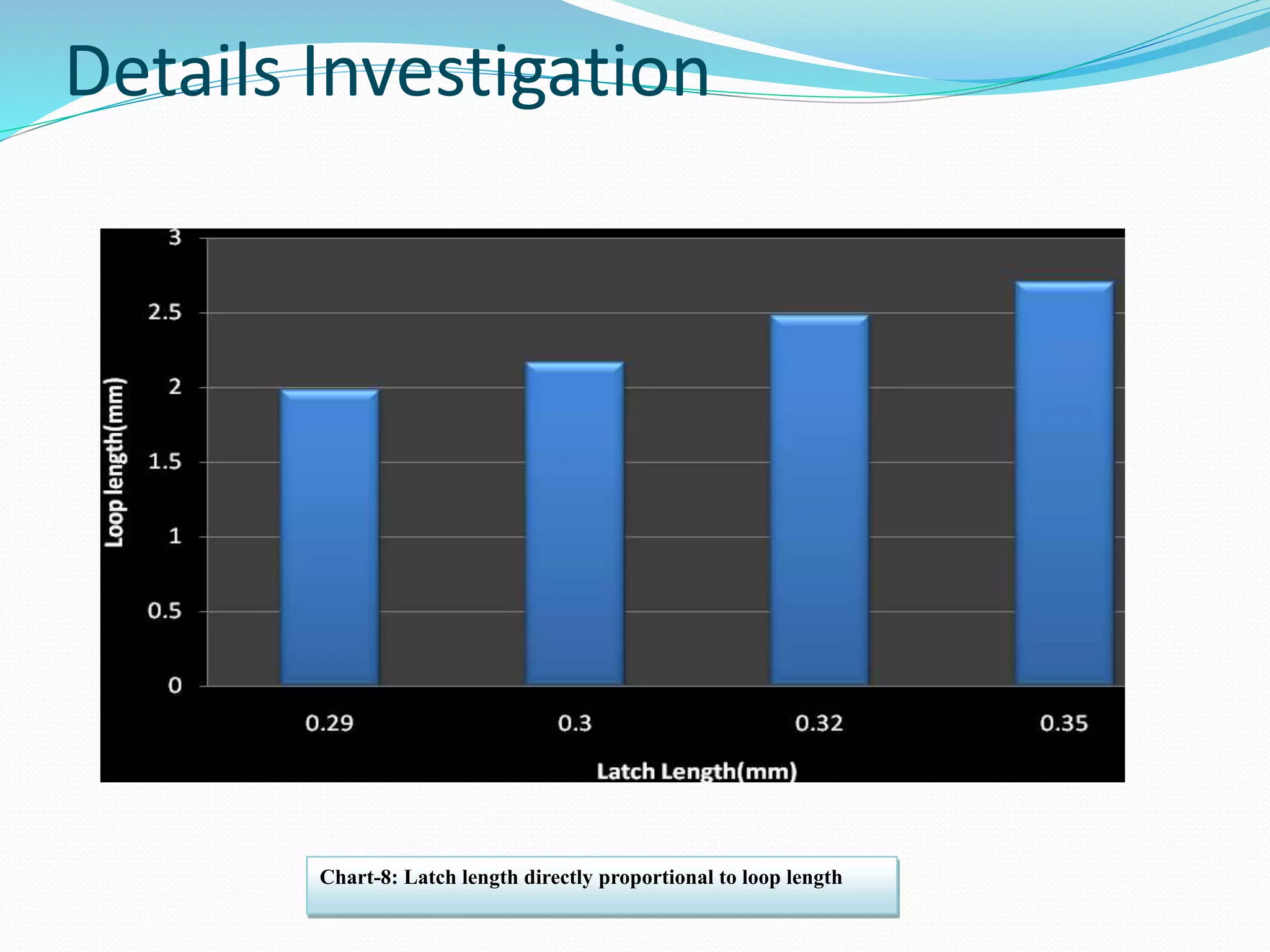

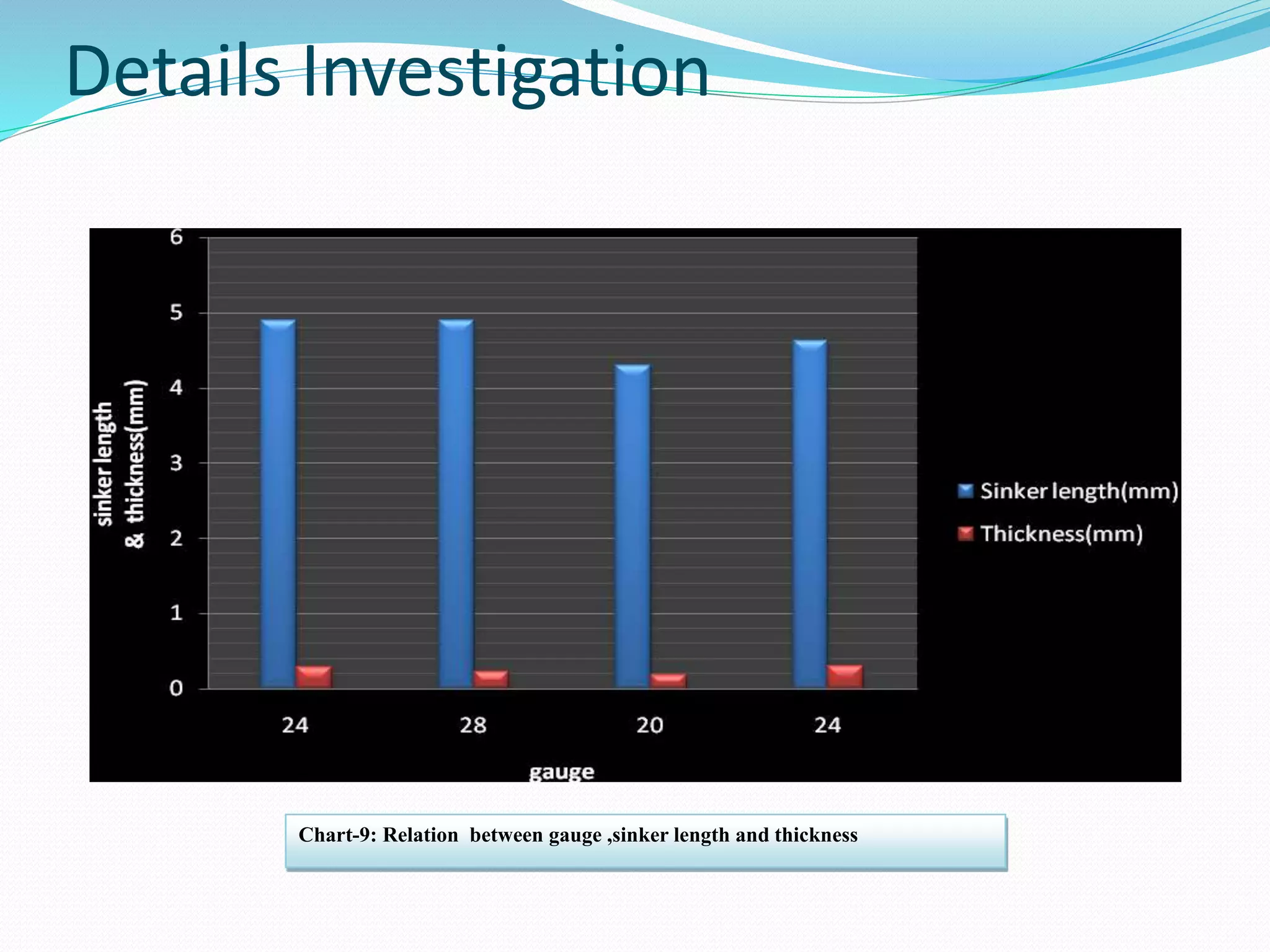

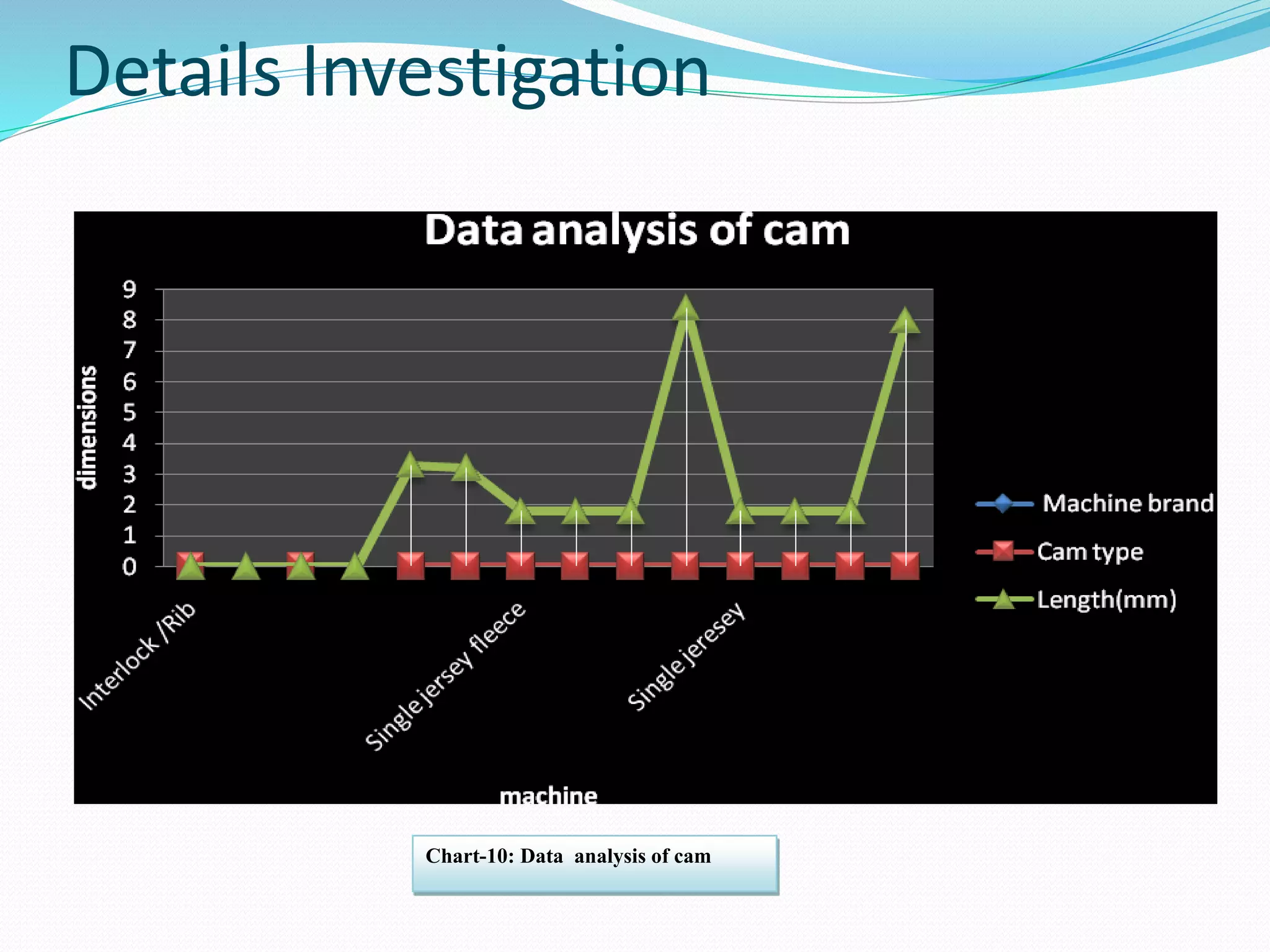

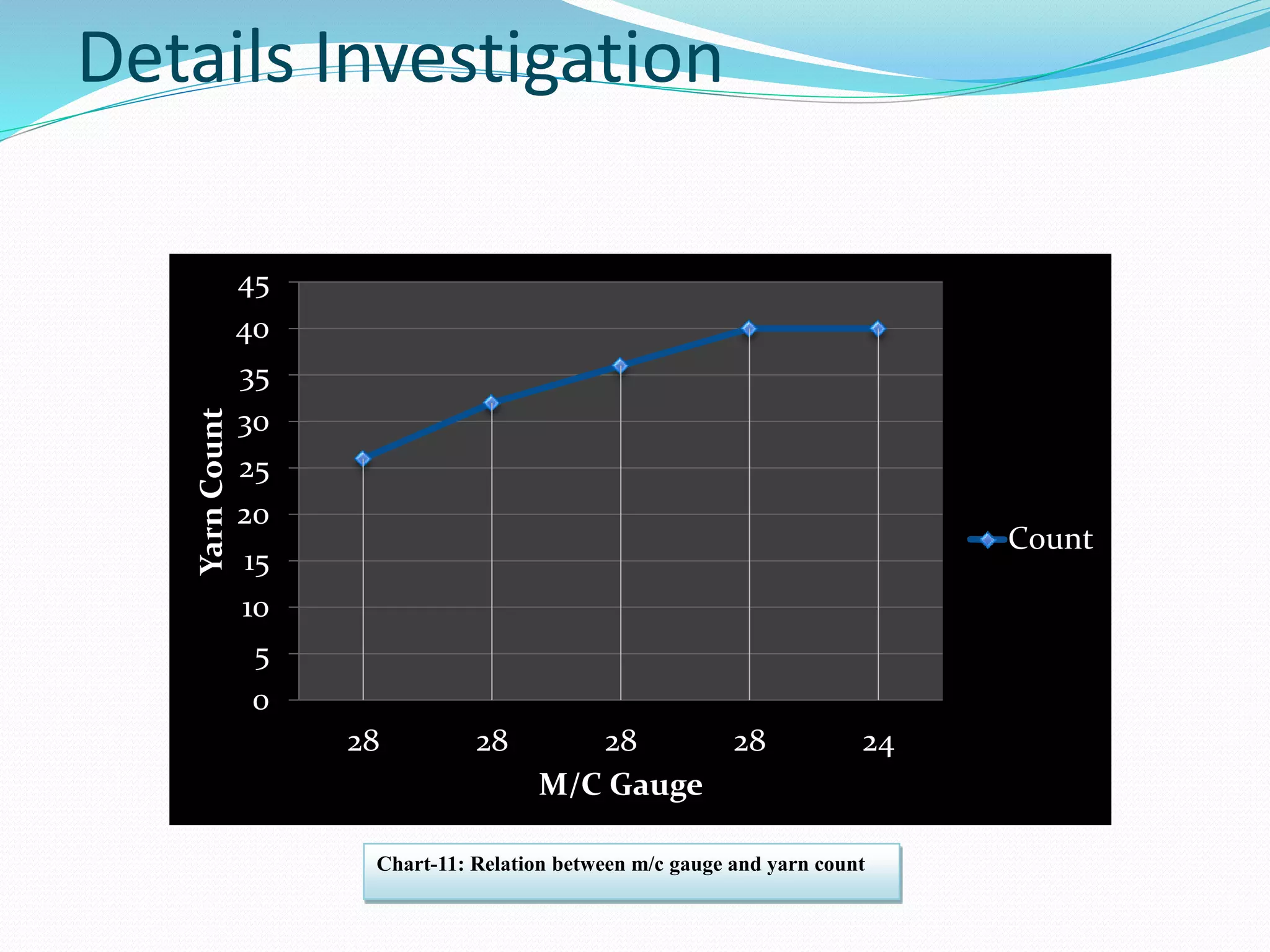

This presentation discusses knitting machine elements like needles, sinkers, cams, and lubrication systems. It describes different types of needles from manufacturers like Groz-Beckert, their specifications and benefits. Sinkers are thin metal plates that perform functions like loop formation and holding down. Cams are profiled to produce needle movements and include knit, tuck, and miss cams. Pulsonic and Uniwave are lubrication systems that precisely distribute oil to reduce consumption and mist. The effects of these elements on fabric properties are also examined.