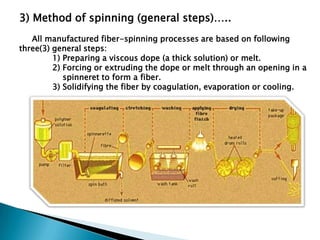

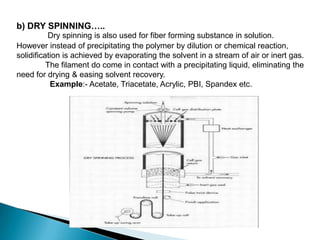

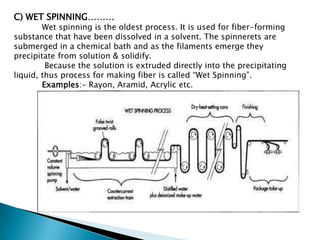

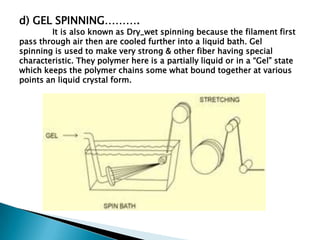

This document provides an overview of different spinning methods used to produce synthetic filaments and yarns. It defines spinning as the process of converting fibers into yarn. The key spinning methods discussed are melt spinning, dry spinning, wet spinning, and gel spinning. Melt spinning extrudes and solidifies molten polymers. Dry spinning evaporates the solvent without a coagulation bath. Wet spinning submerges the spinneret in a chemical bath for solidification. Gel spinning passes filaments first through air and then a liquid bath for cooling.