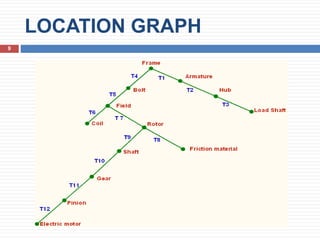

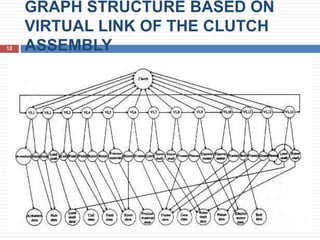

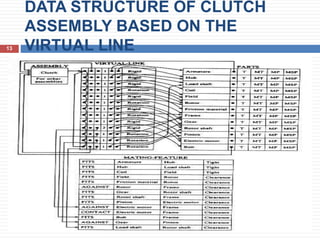

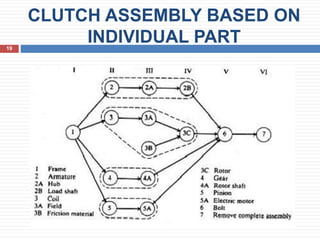

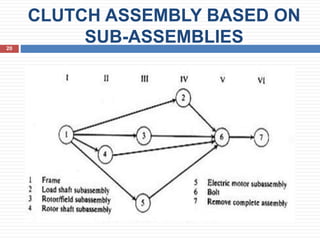

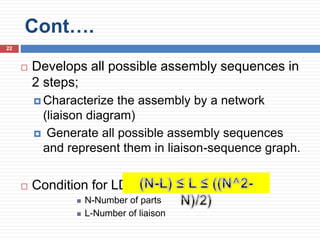

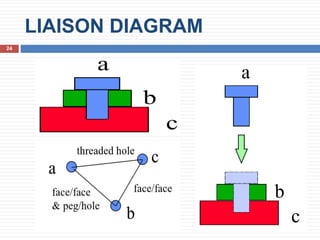

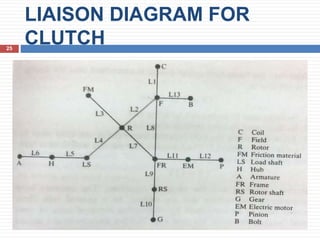

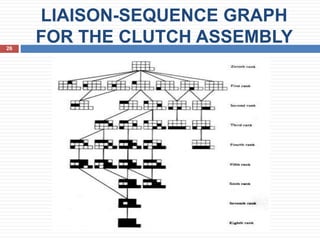

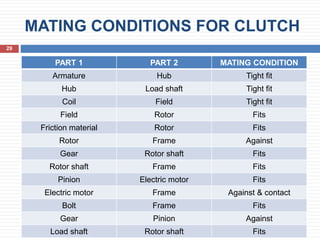

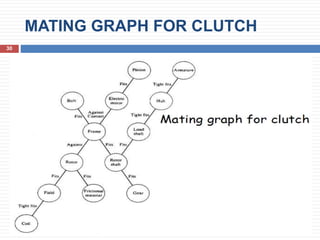

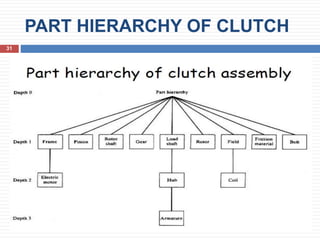

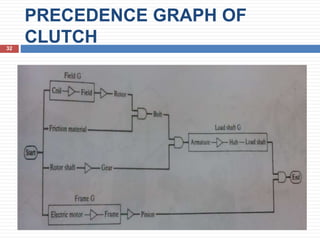

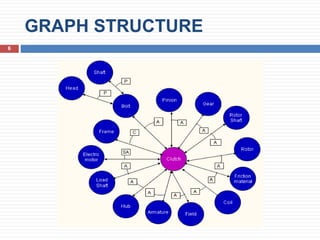

The document discusses the representation and assembly of parts using various graph structures, including a location graph and virtual links, to define relationships and constraints between components. It outlines the importance of assembly sequences in terms of efficiency and potential challenges, with methods for generating these sequences such as precedence diagrams and liaison-sequence analysis. Additionally, it describes the significance of mating conditions in the assembly process, which aids in the determination of optimal assembly methods.

![LOCATION GRAPH

7

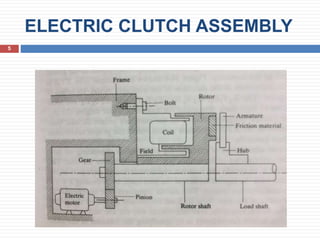

Coordinate system is the means used to specify

location of one part relative to other.

A chain of locations can be defined such that

each location is defined in terms of [T] another

part’s coordinate system.

A set of these chains results in a location graph.

Part to part is related by the transformation

matrix[T].](https://image.slidesharecdn.com/assemblyrepresentationscheme-180529091144/85/Assembly-representation-scheme-7-320.jpg)