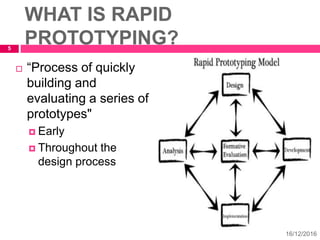

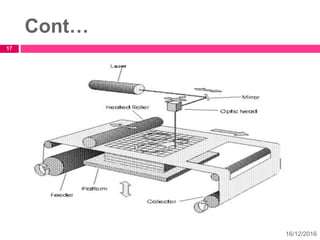

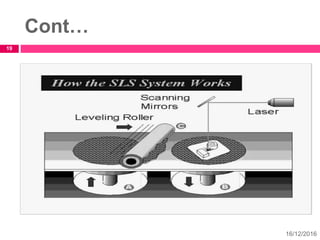

Rapid prototyping is a technology that enables quick creation and evaluation of prototypes from CAD data, primarily utilizing additive manufacturing techniques. It has applications in various industries such as aerospace, automotive, biomedical, and fashion, facilitating effective communication, reduced development time, and minimized costly mistakes. The process involves creating a digital model, slicing it into layers, and building the prototype layer by layer using different methods including stereo lithography and selective laser sintering.