1. The document discusses assembly modeling in CAD, including defining assemblies as collections of independent parts with spatial and hierarchical relationships.

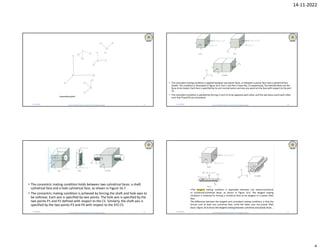

2. It describes how parts are modeled separately and then merged into an assembly, requiring specification of mating conditions that define how parts relate spatially. Common mating conditions include coincident, concentric, tangent, and coplanar.

3. Planning assembly creation involves identifying part and feature dependencies, determining the assembly order, and fully constraining parts with multiple mating conditions to prevent unwanted movement.