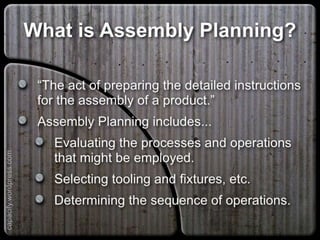

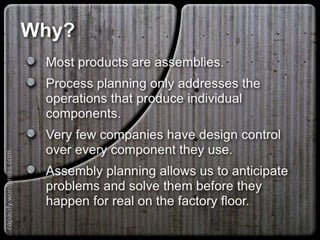

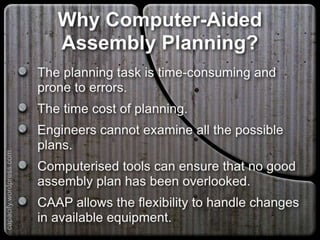

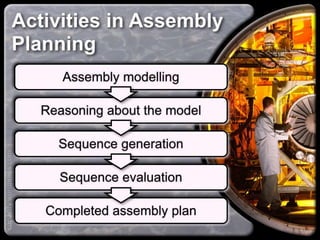

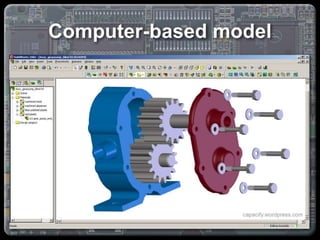

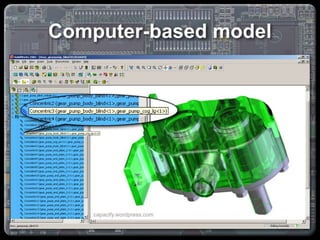

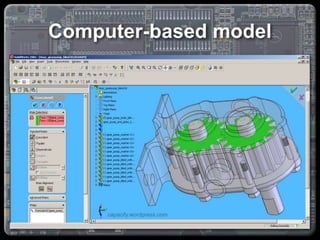

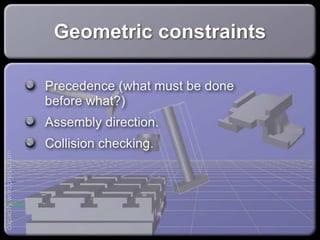

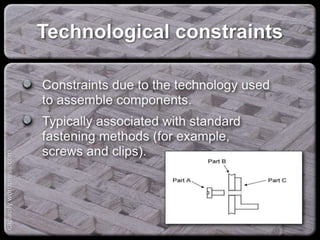

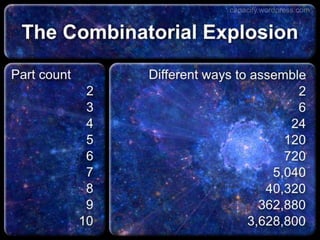

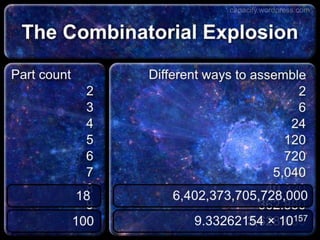

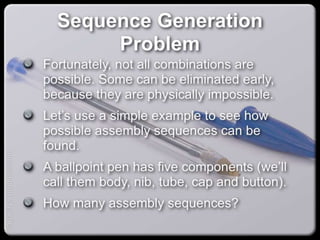

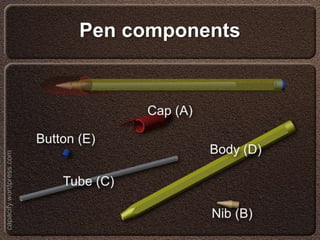

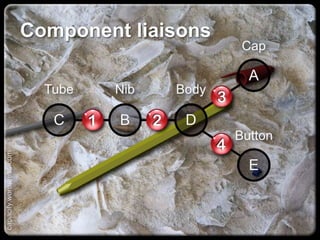

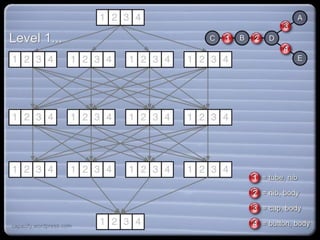

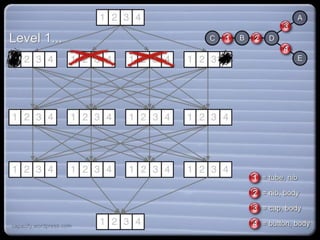

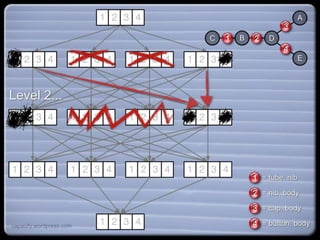

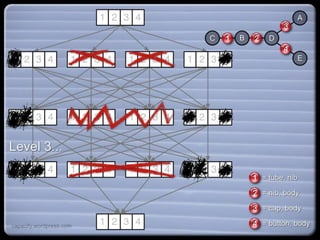

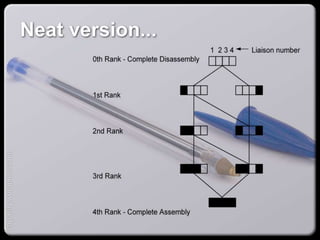

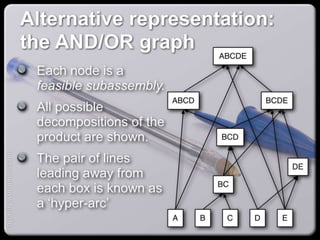

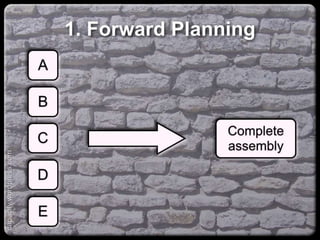

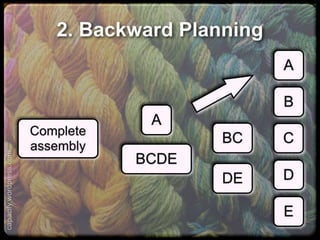

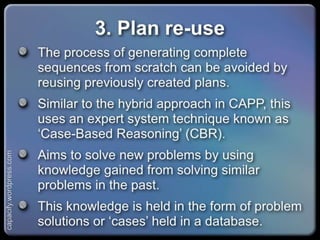

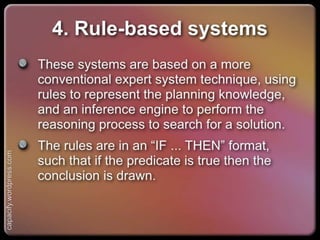

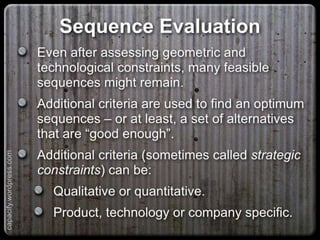

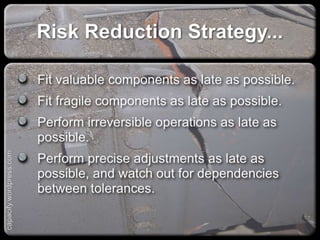

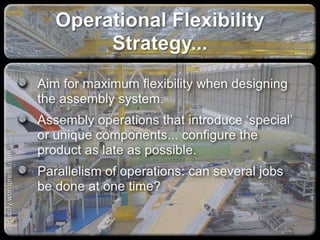

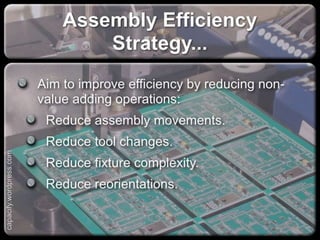

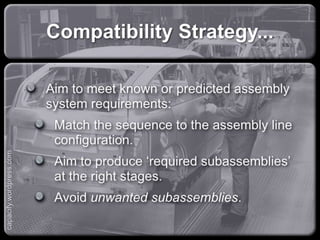

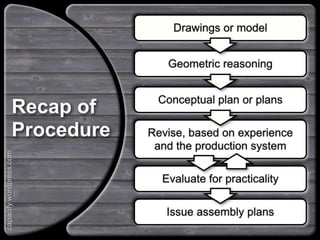

The document discusses the importance and methodology of computer-aided assembly planning (CAAP) in manufacturing, highlighting its role in efficiently organizing the assembly of products to reduce costs and time. It outlines the assembly planning task, including constraints and sequence generation techniques, while emphasizing the necessity of CAAP to manage complex assembly sequences. Additionally, it presents evaluation criteria for selecting optimal assembly sequences to enhance operational flexibility and efficiency.