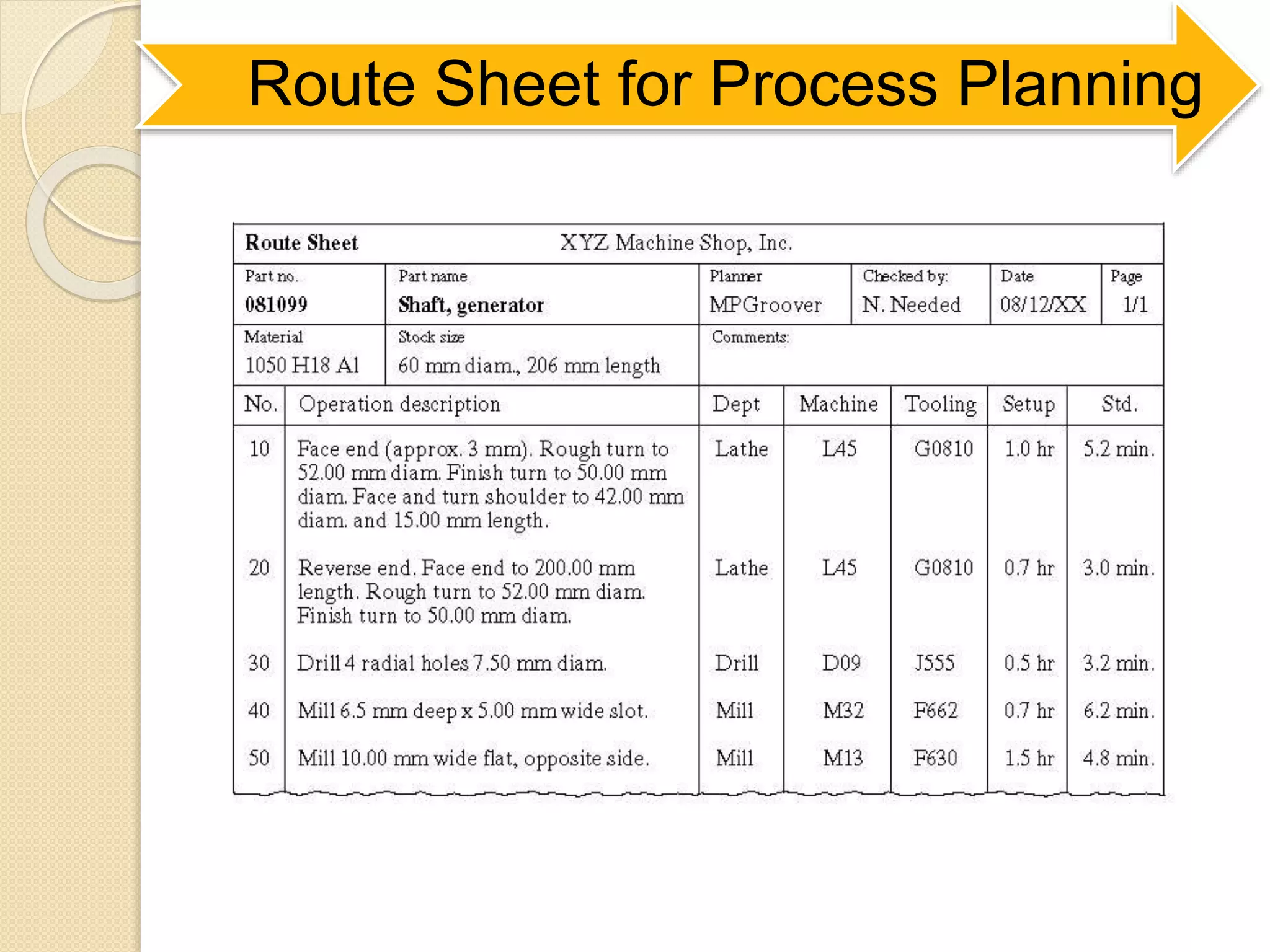

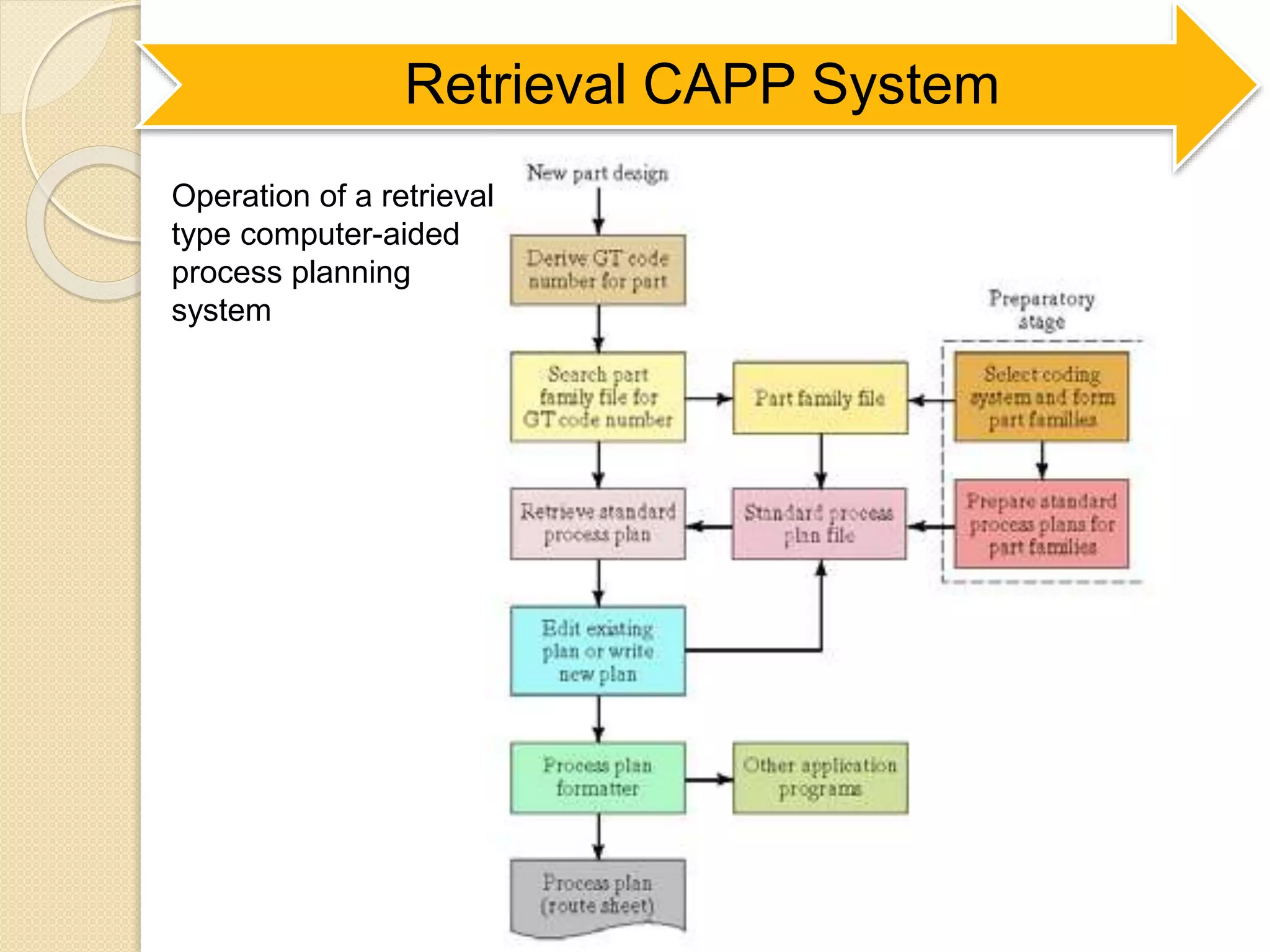

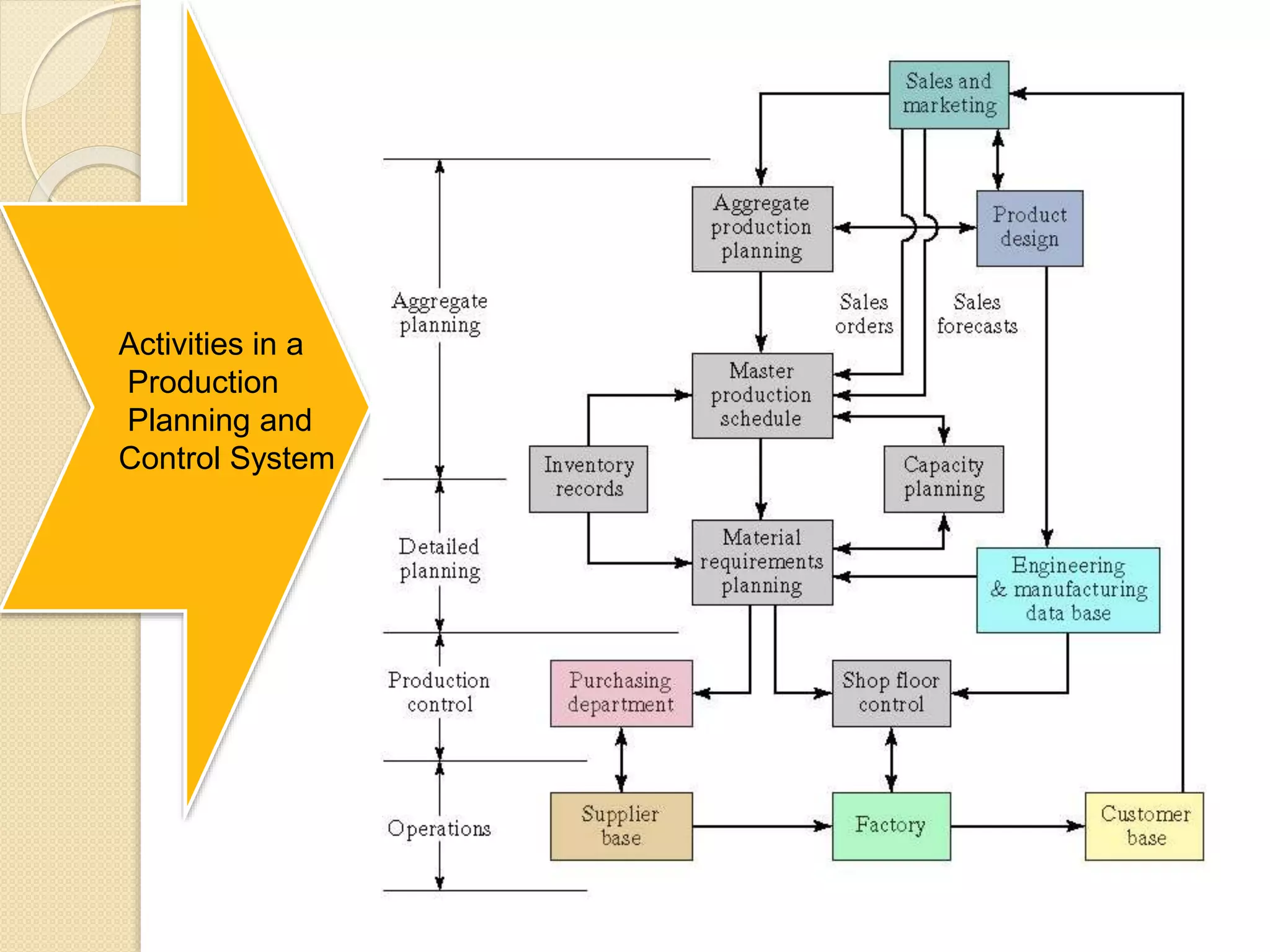

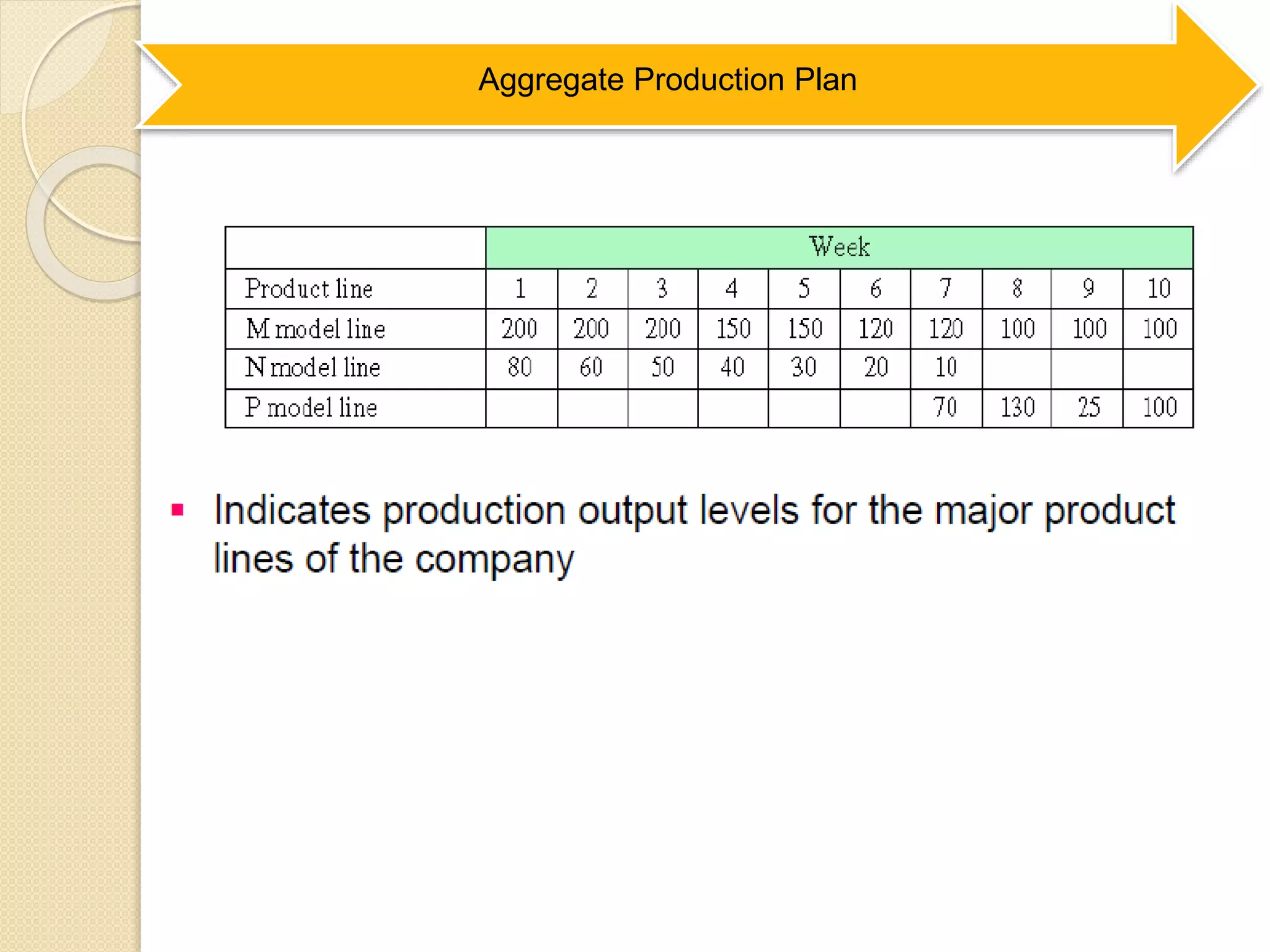

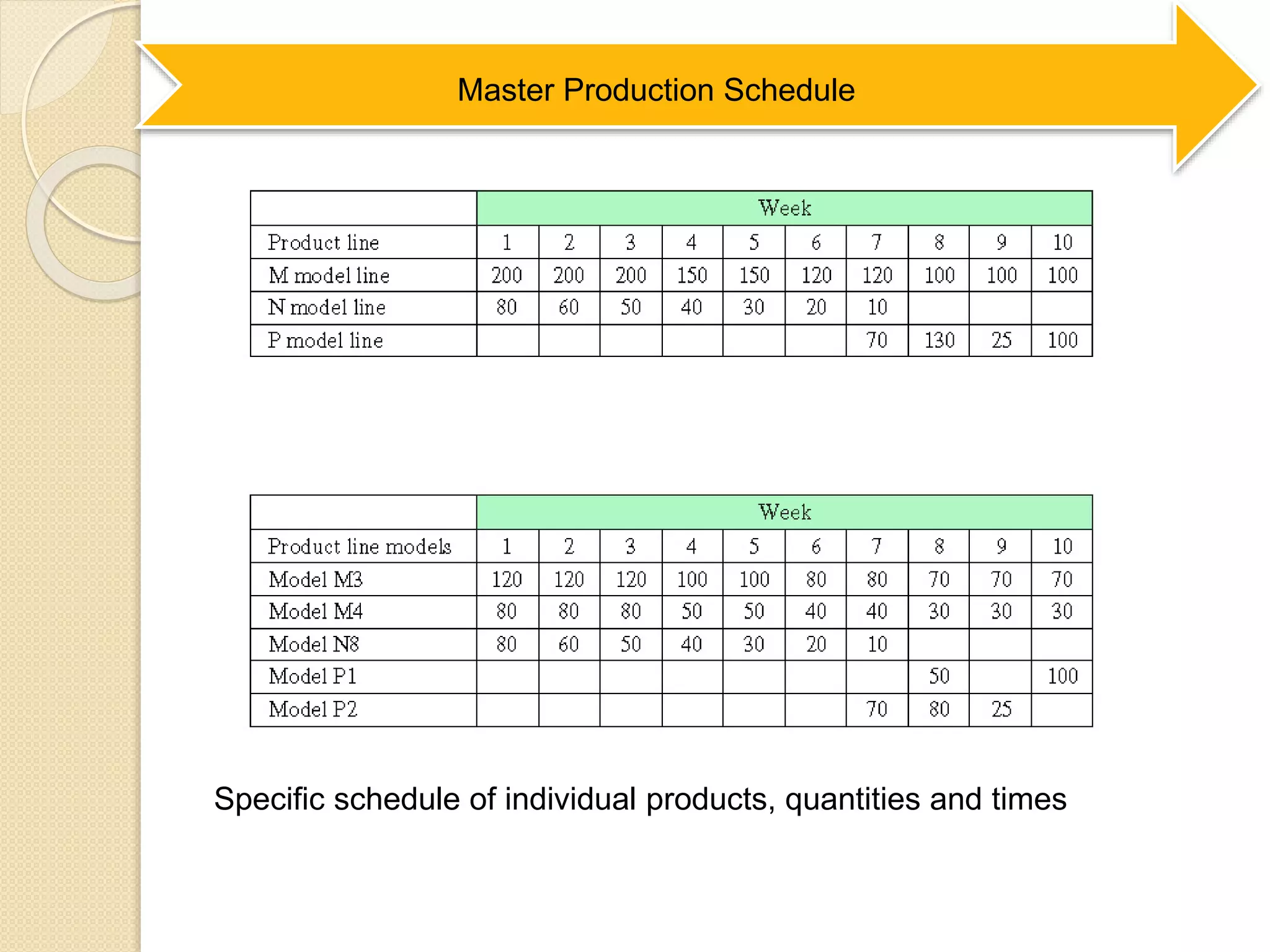

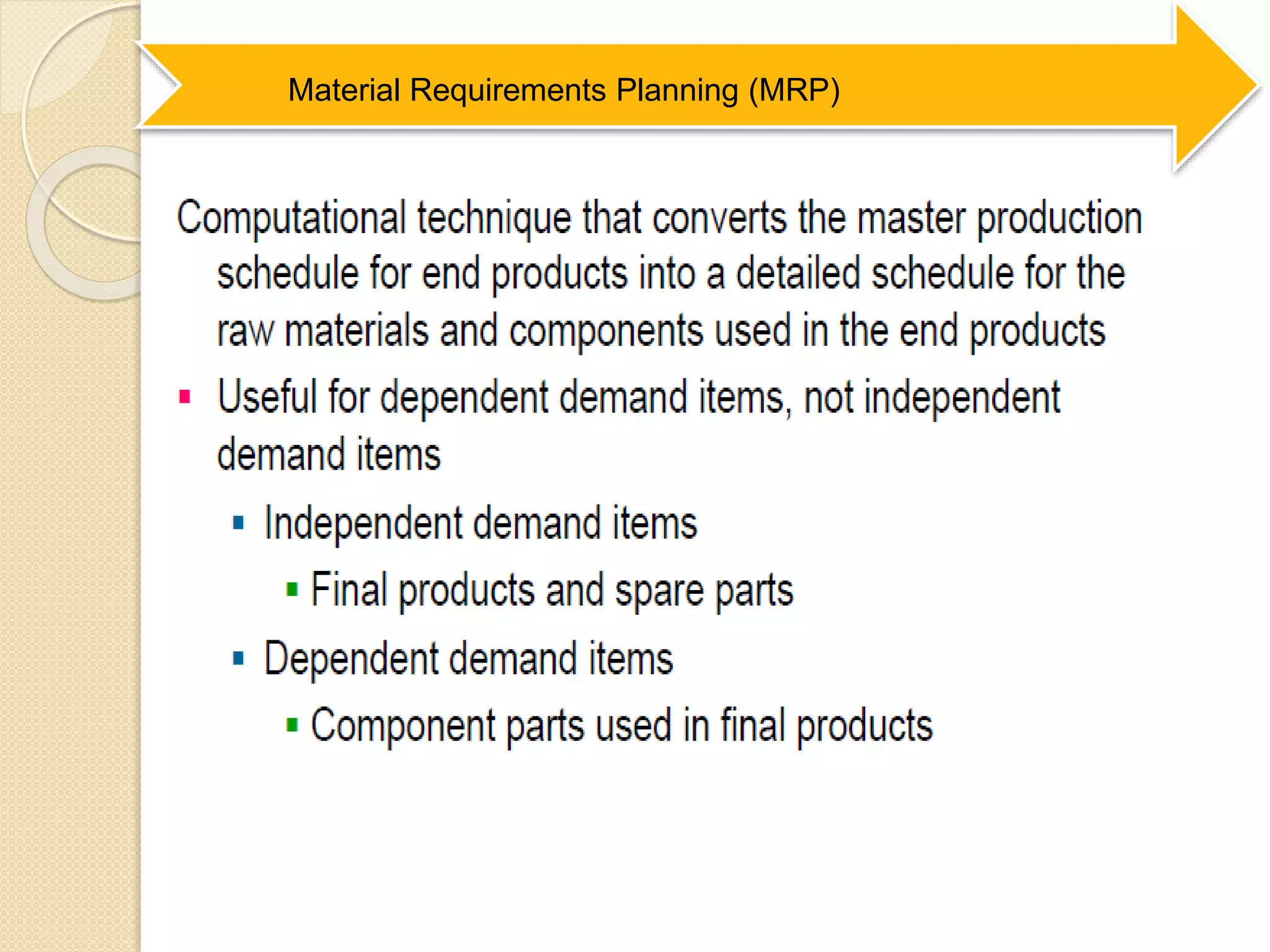

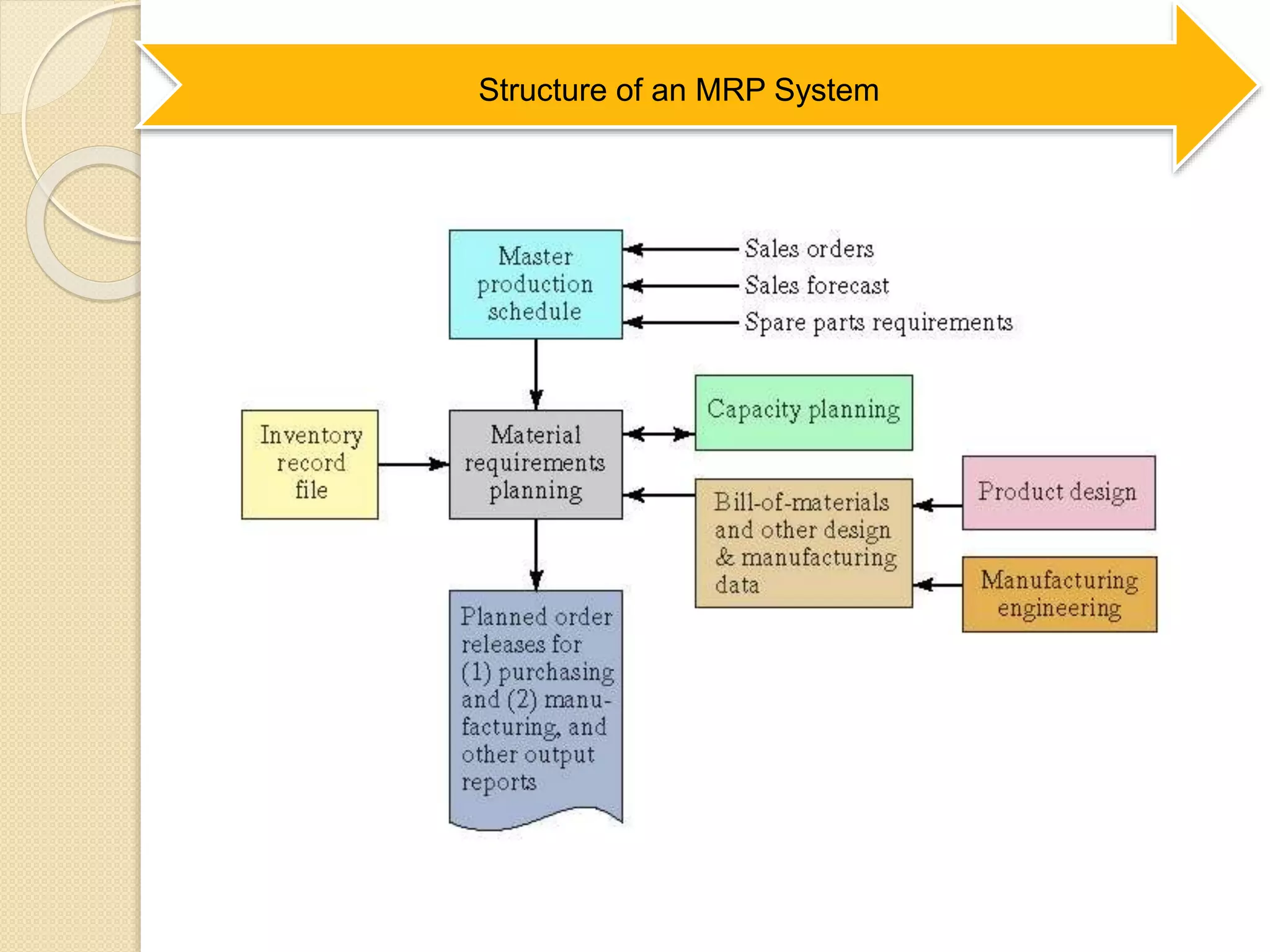

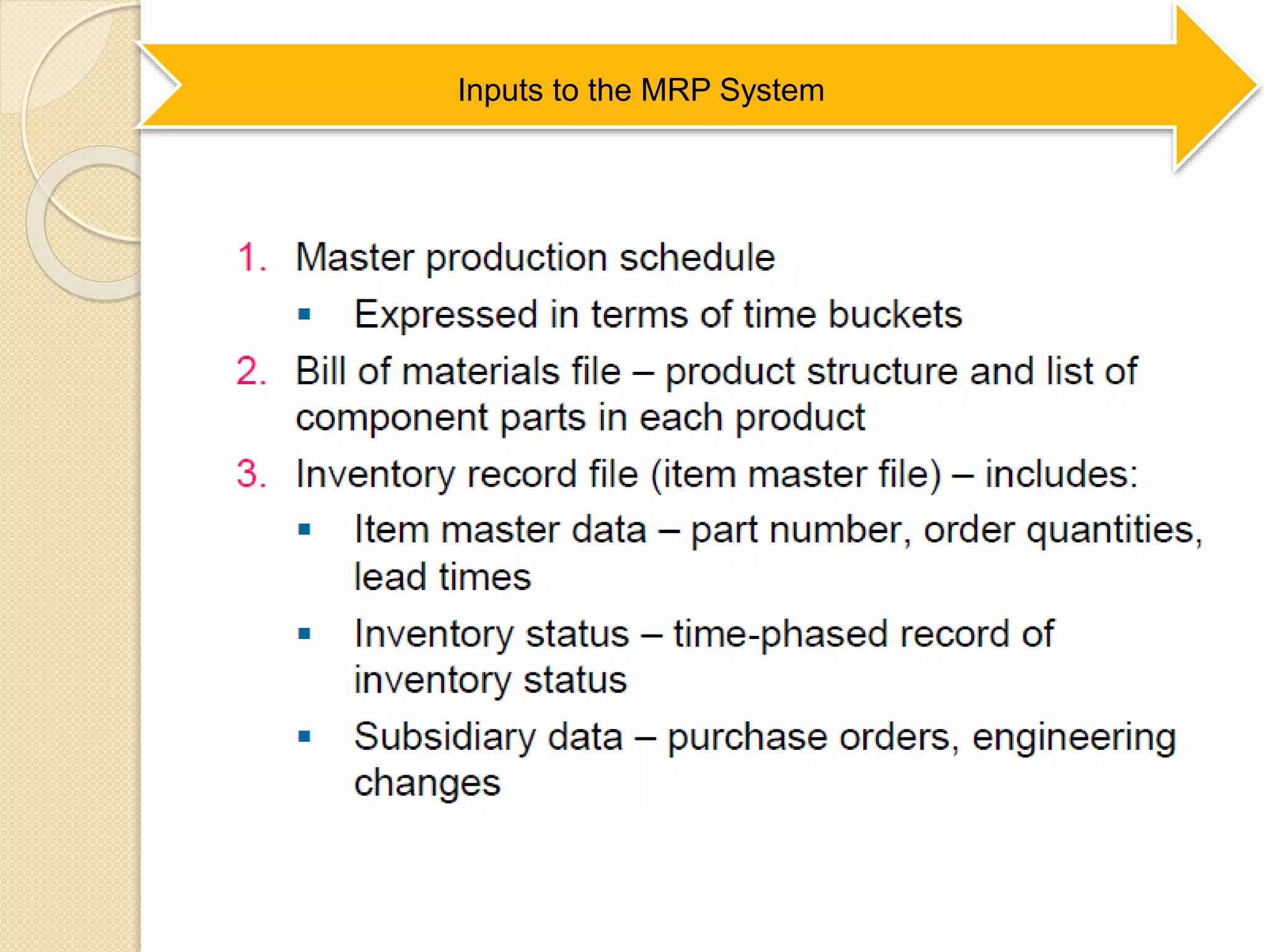

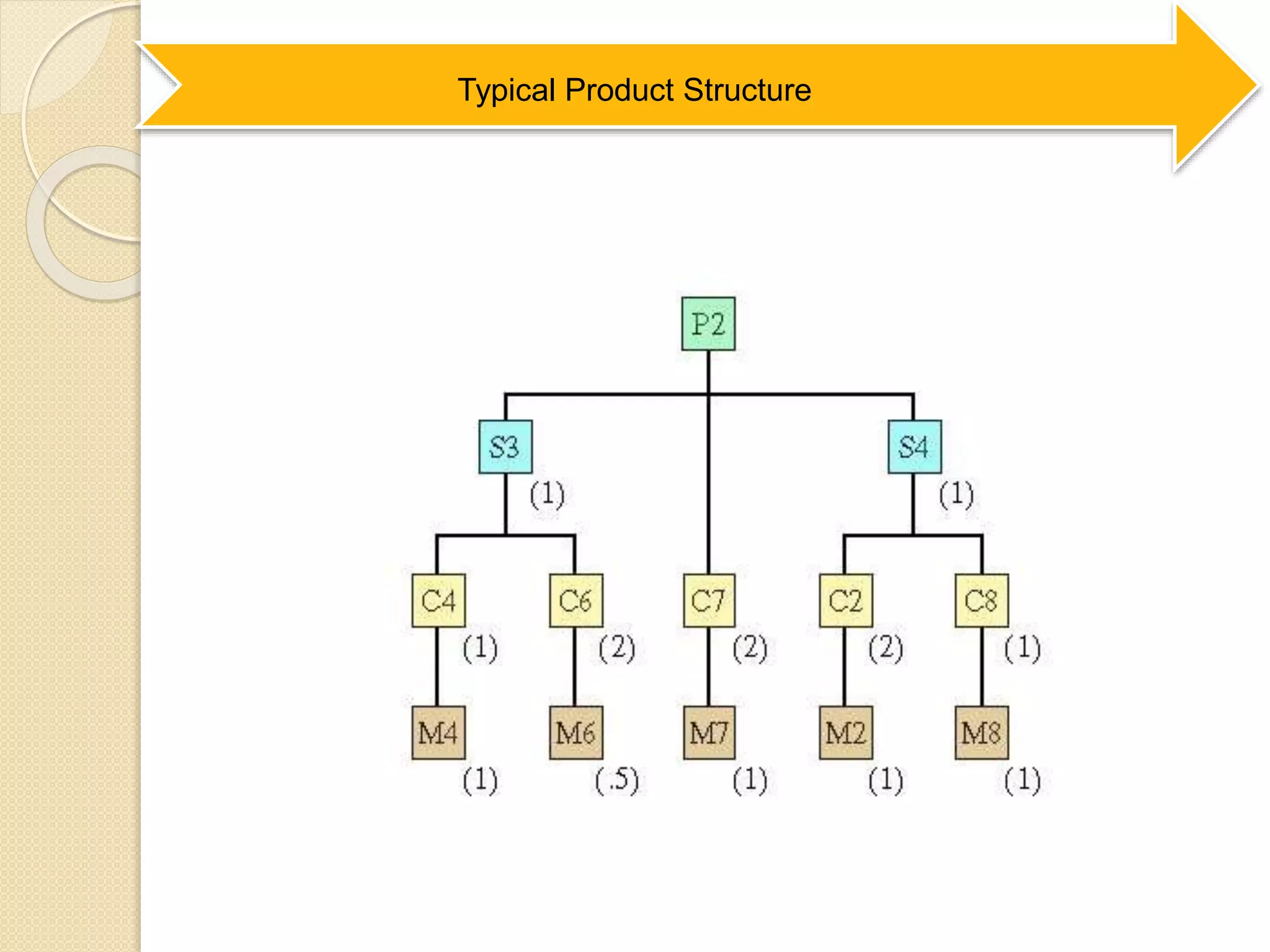

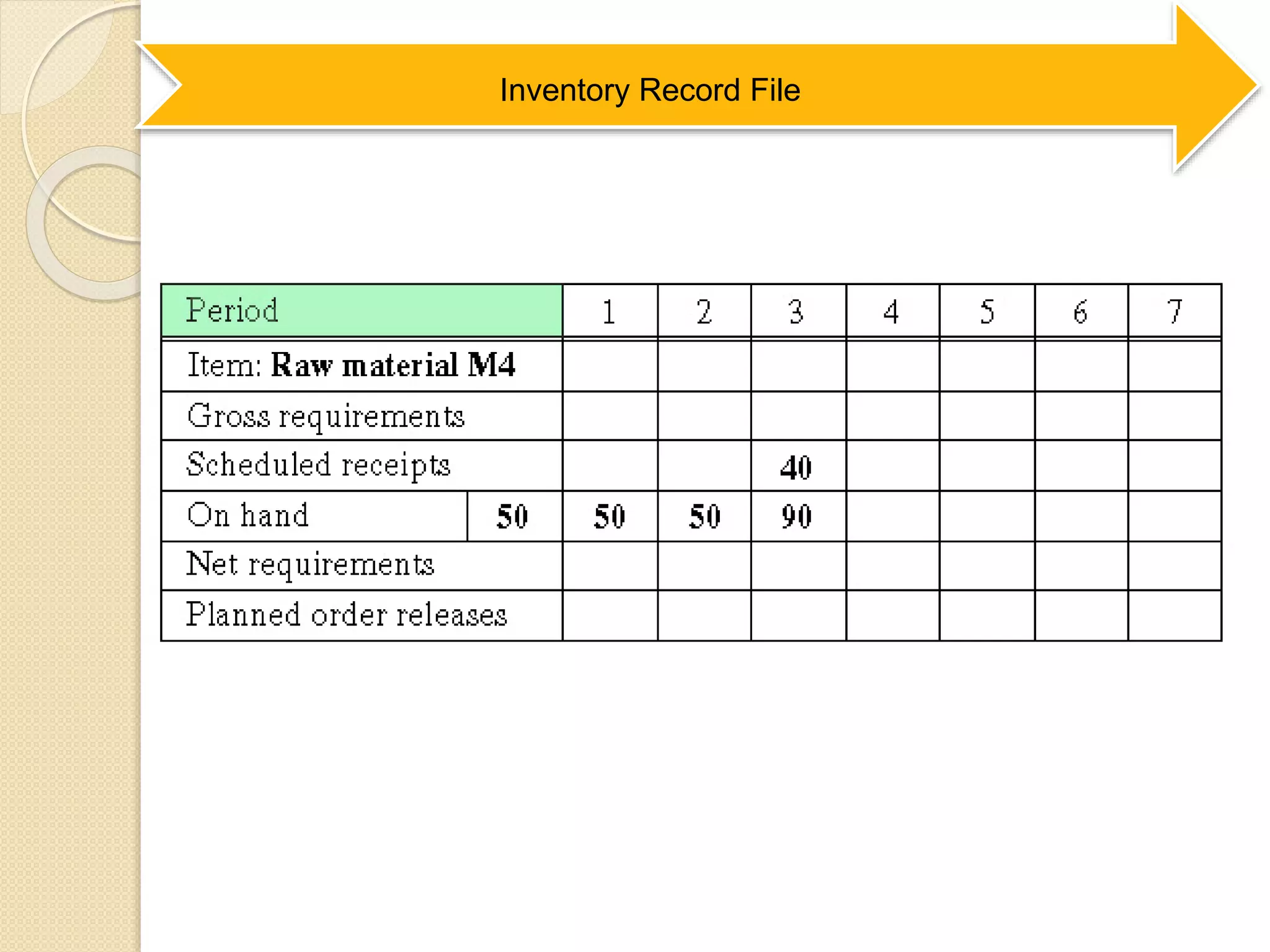

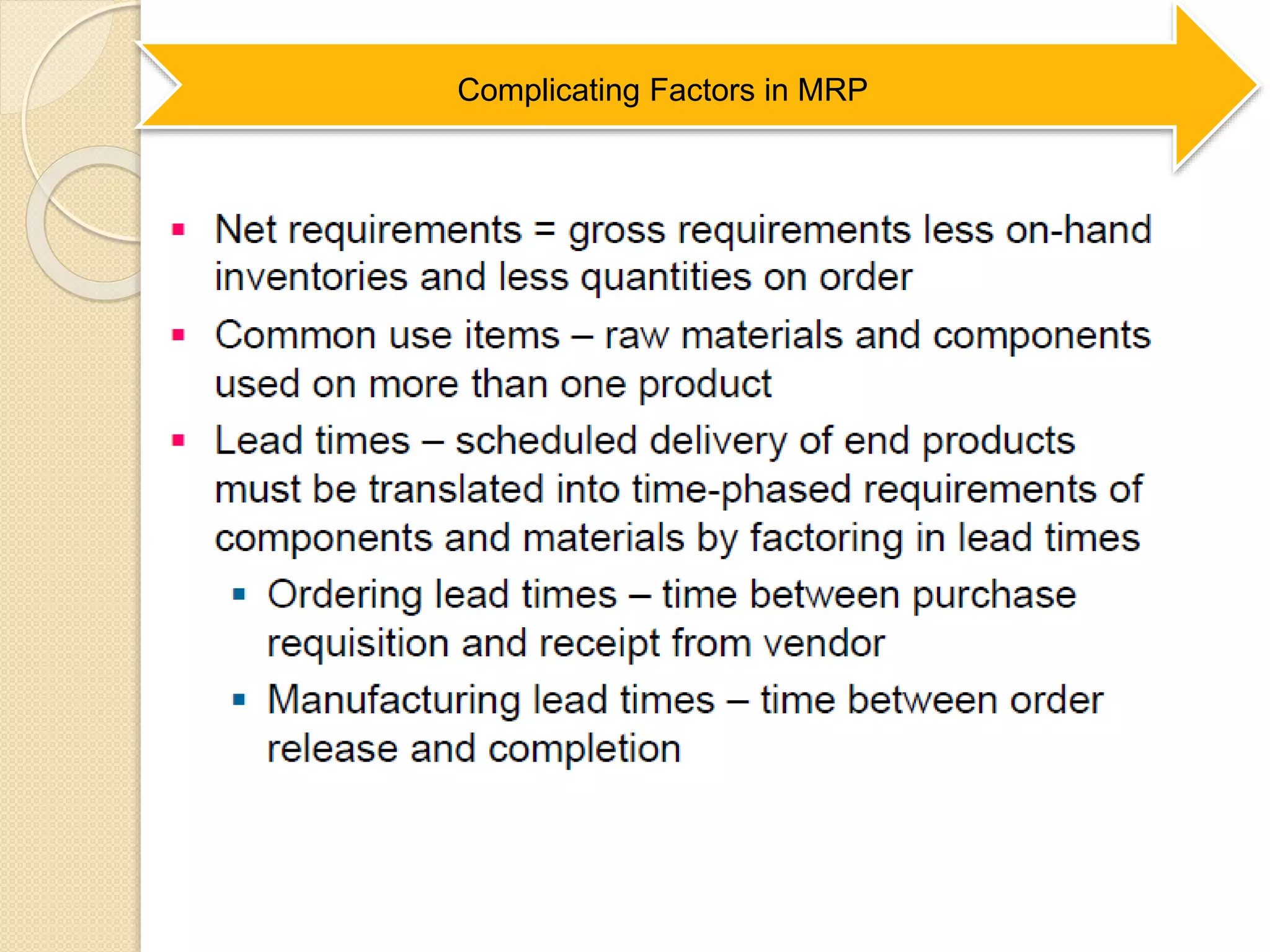

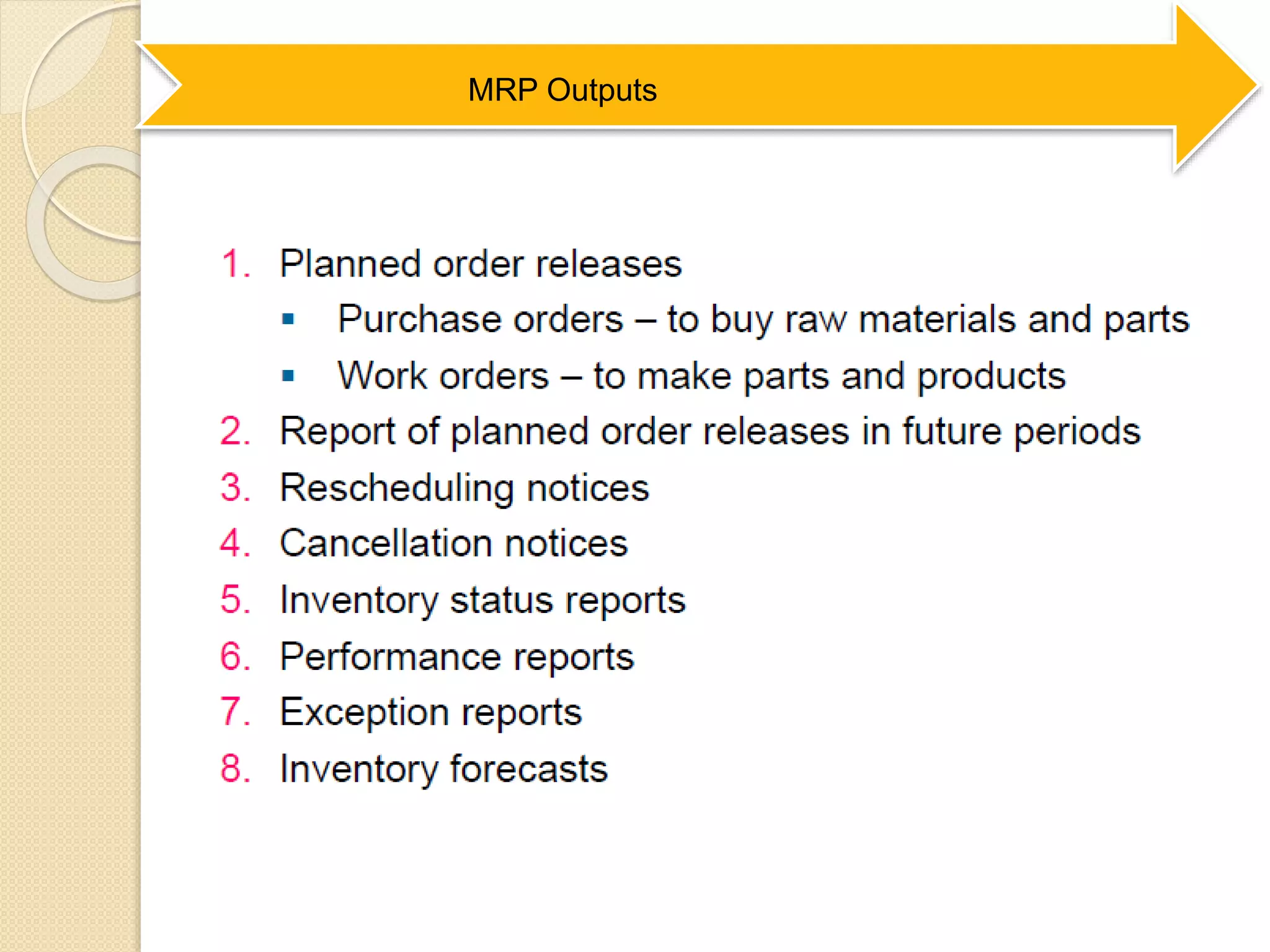

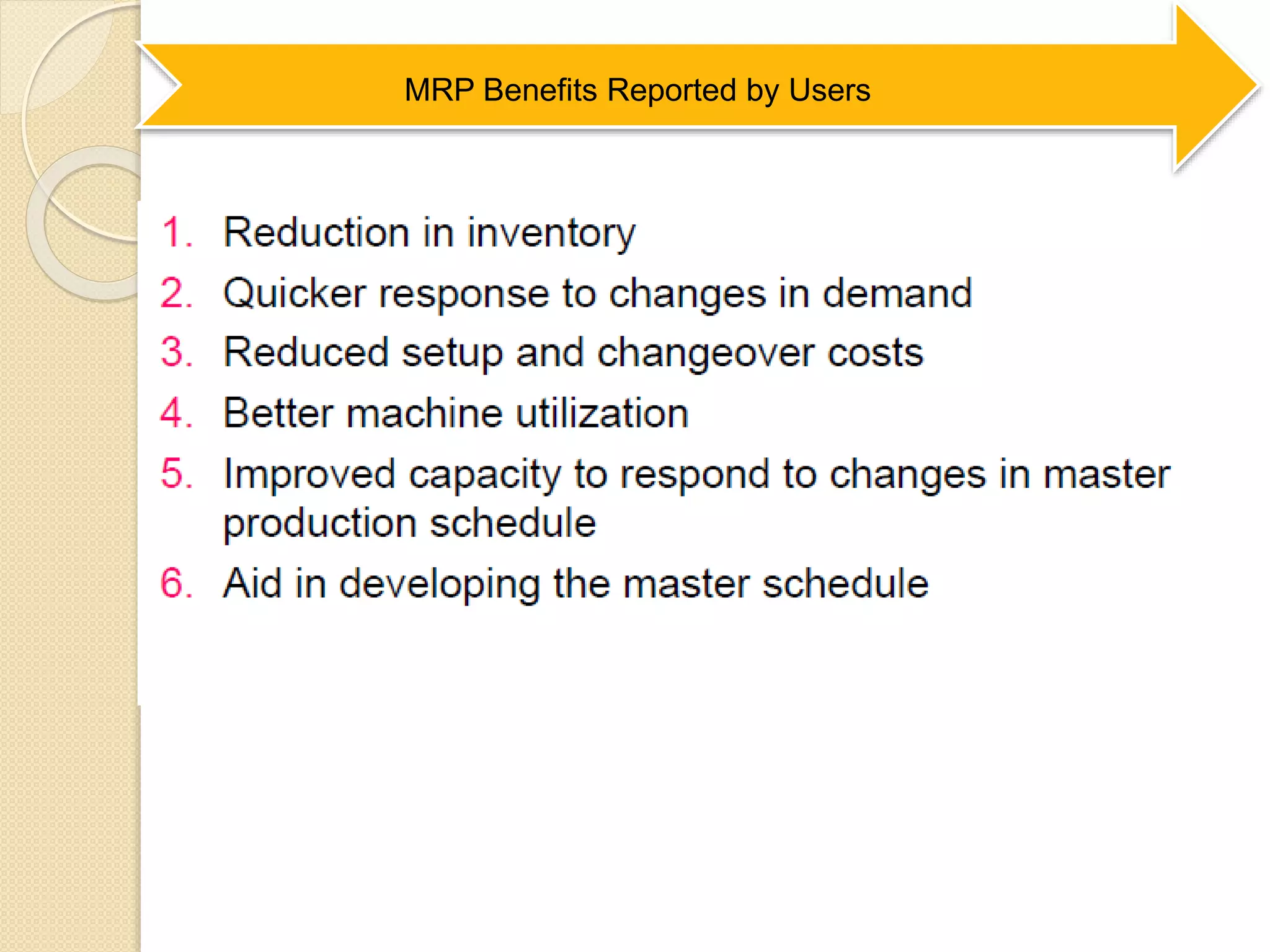

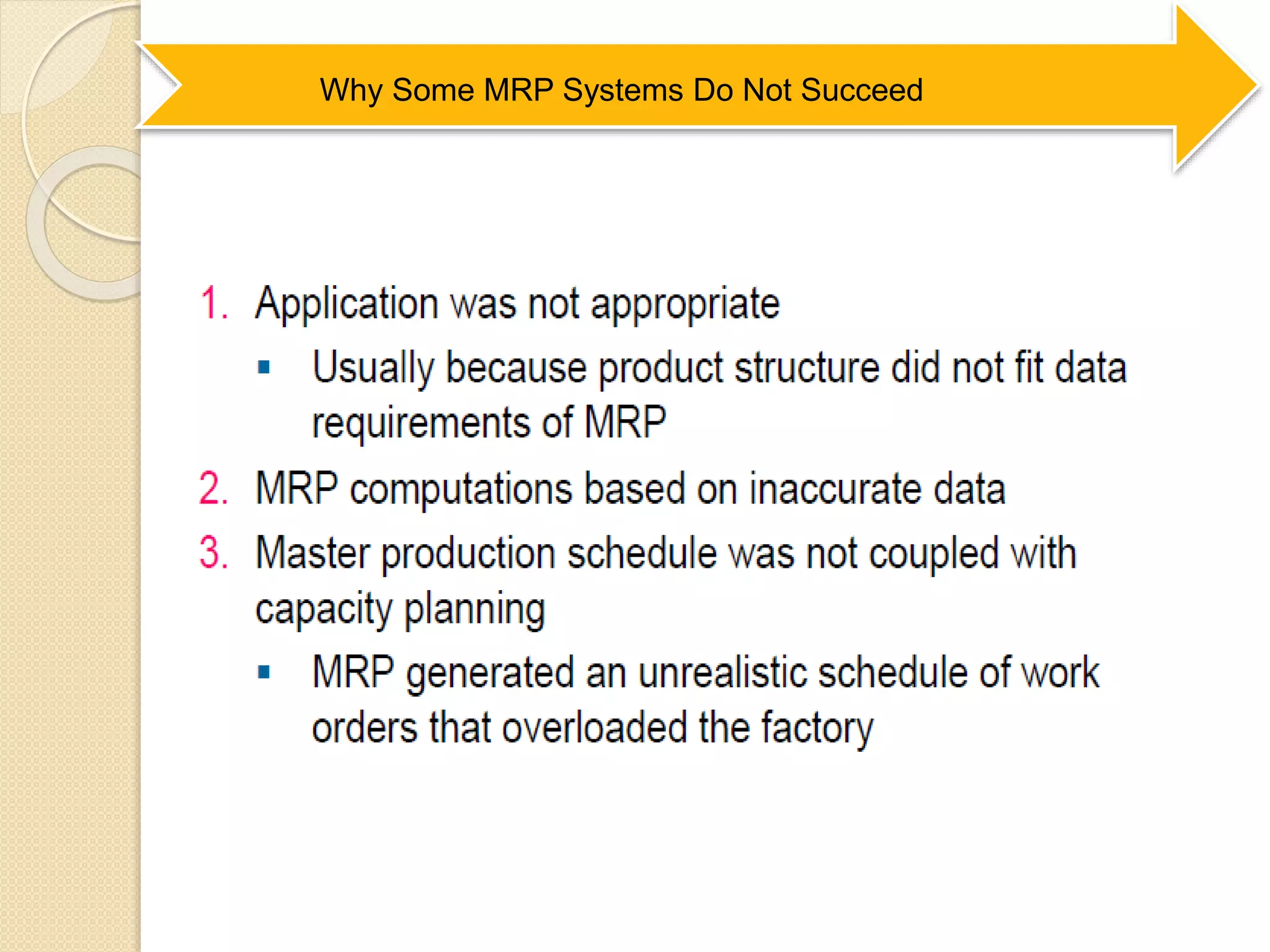

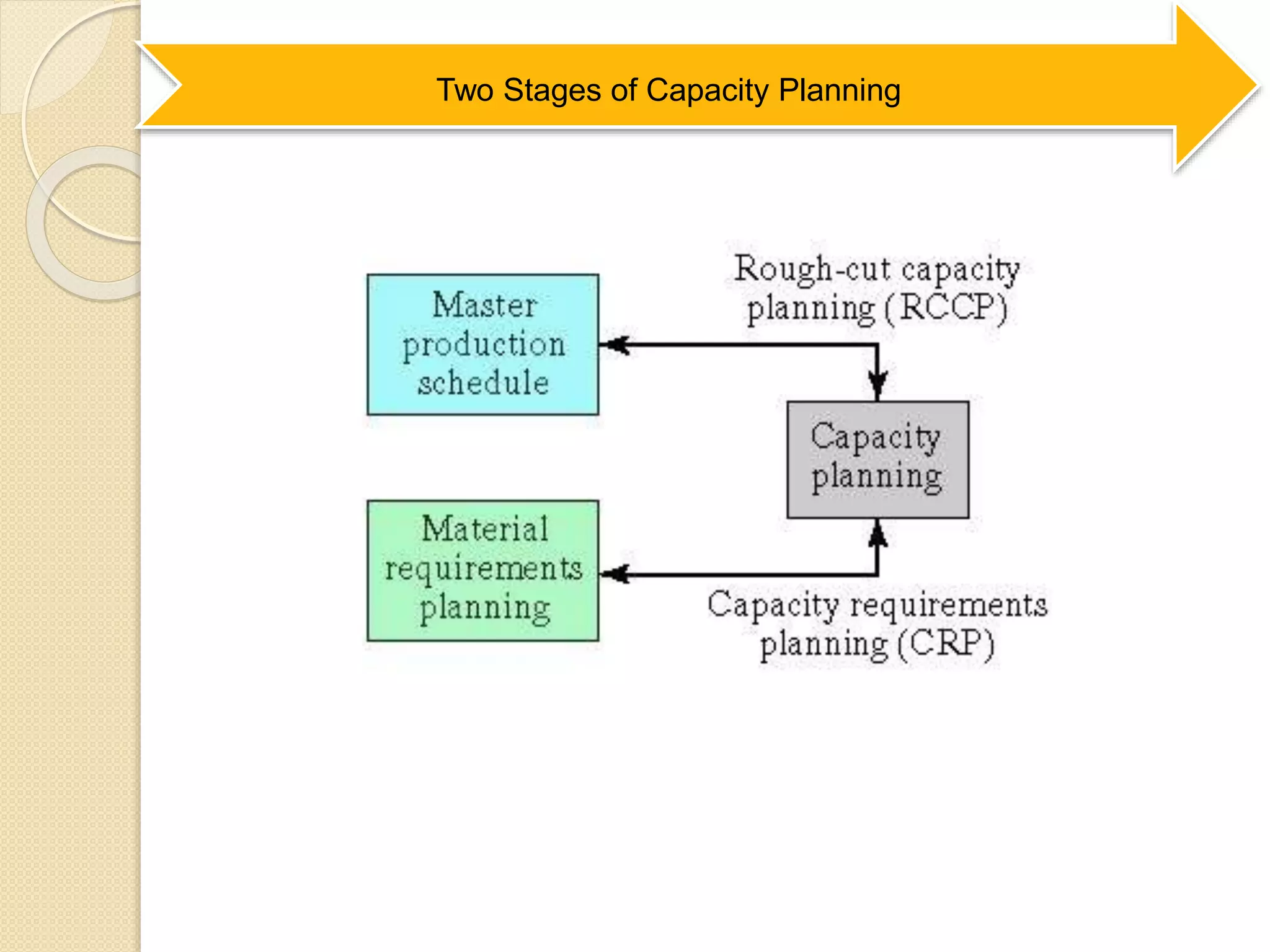

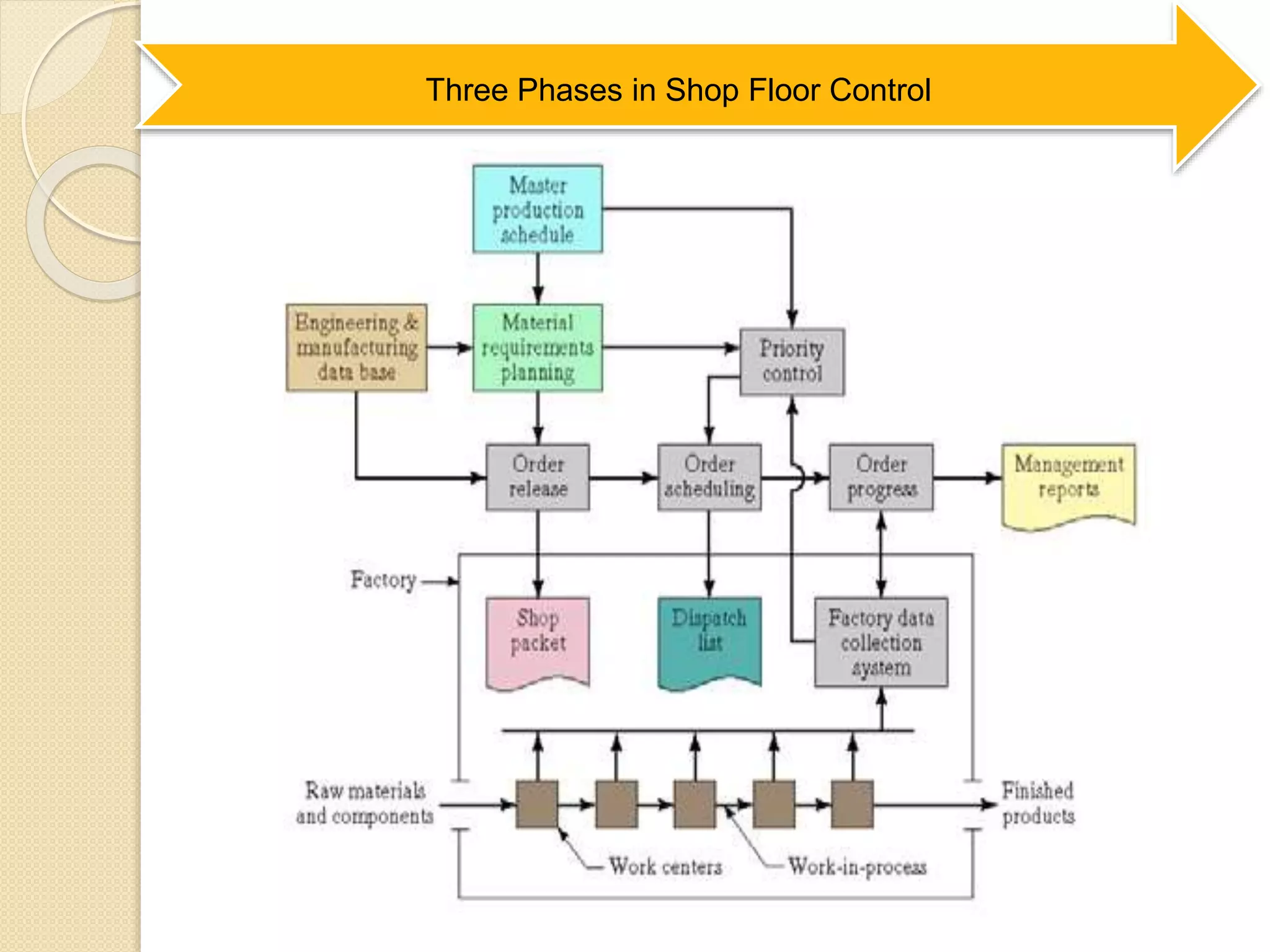

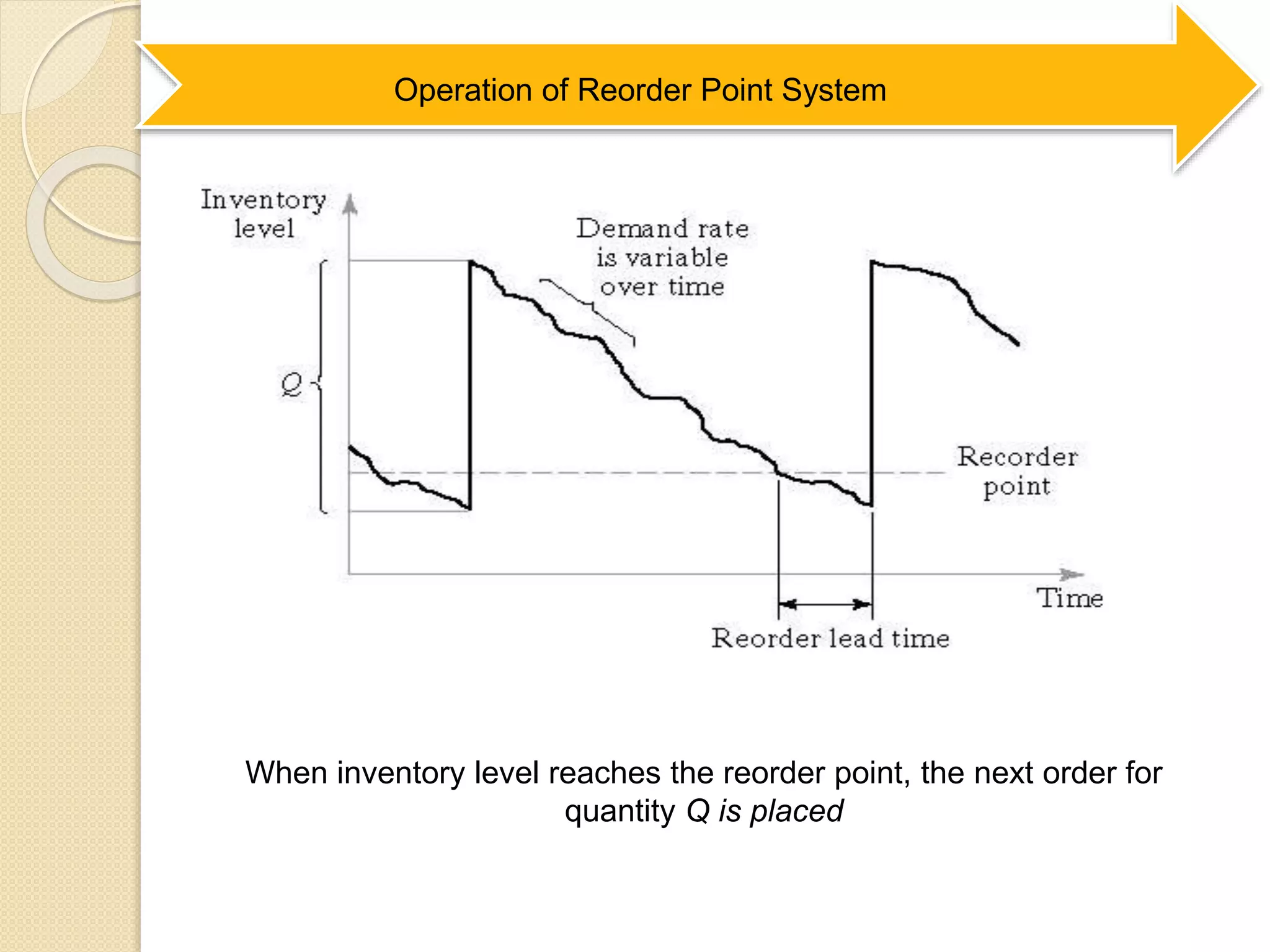

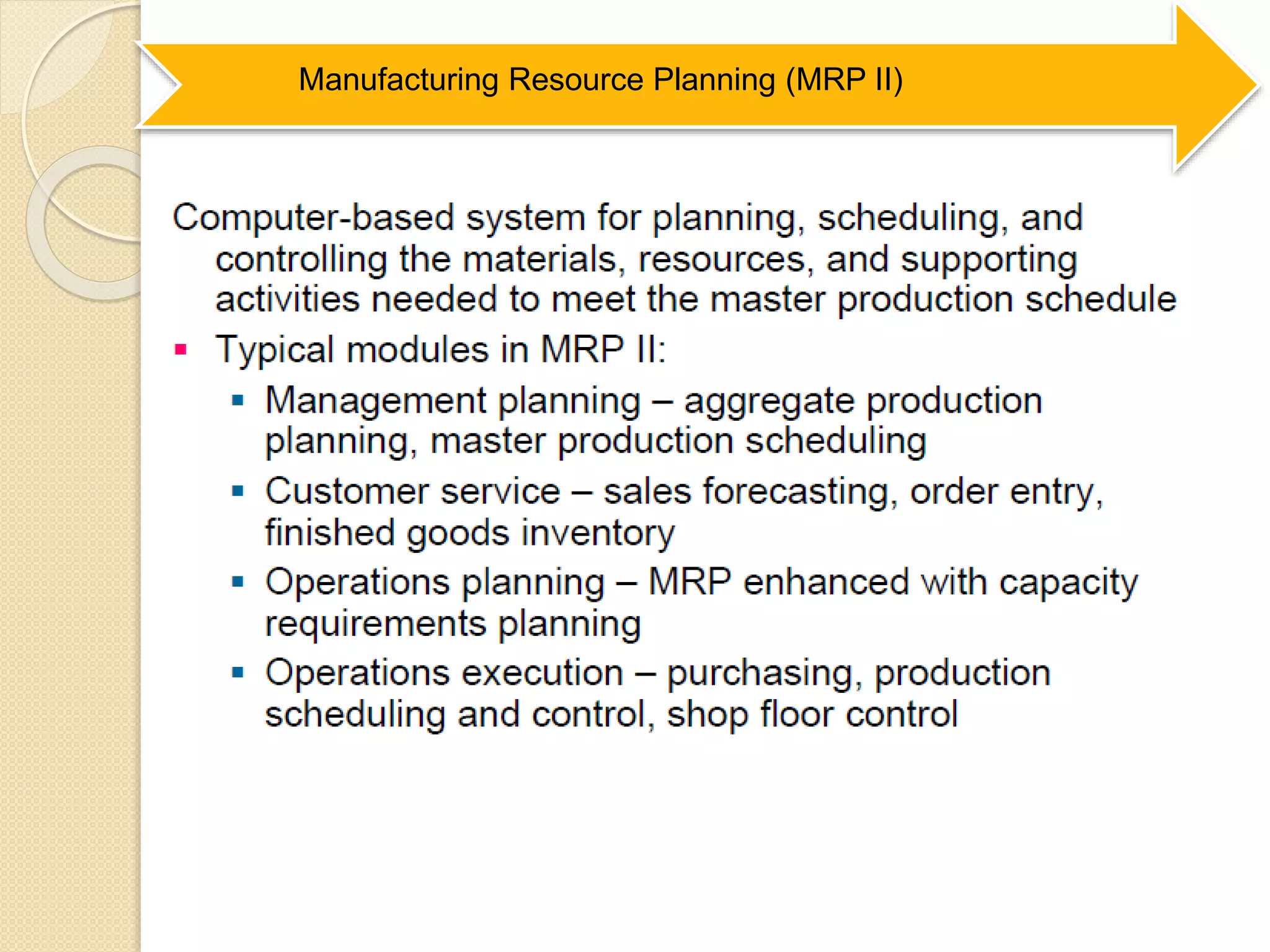

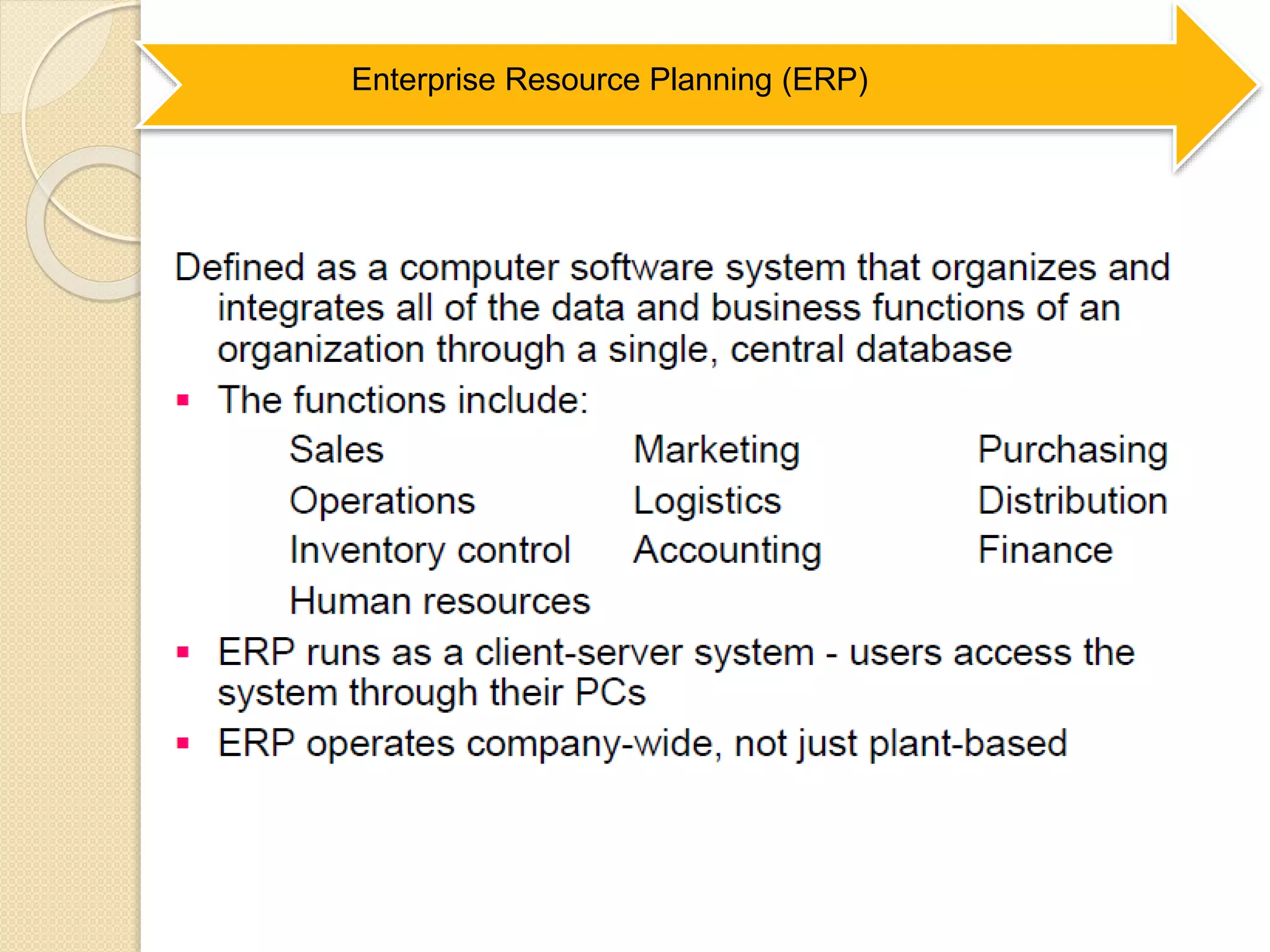

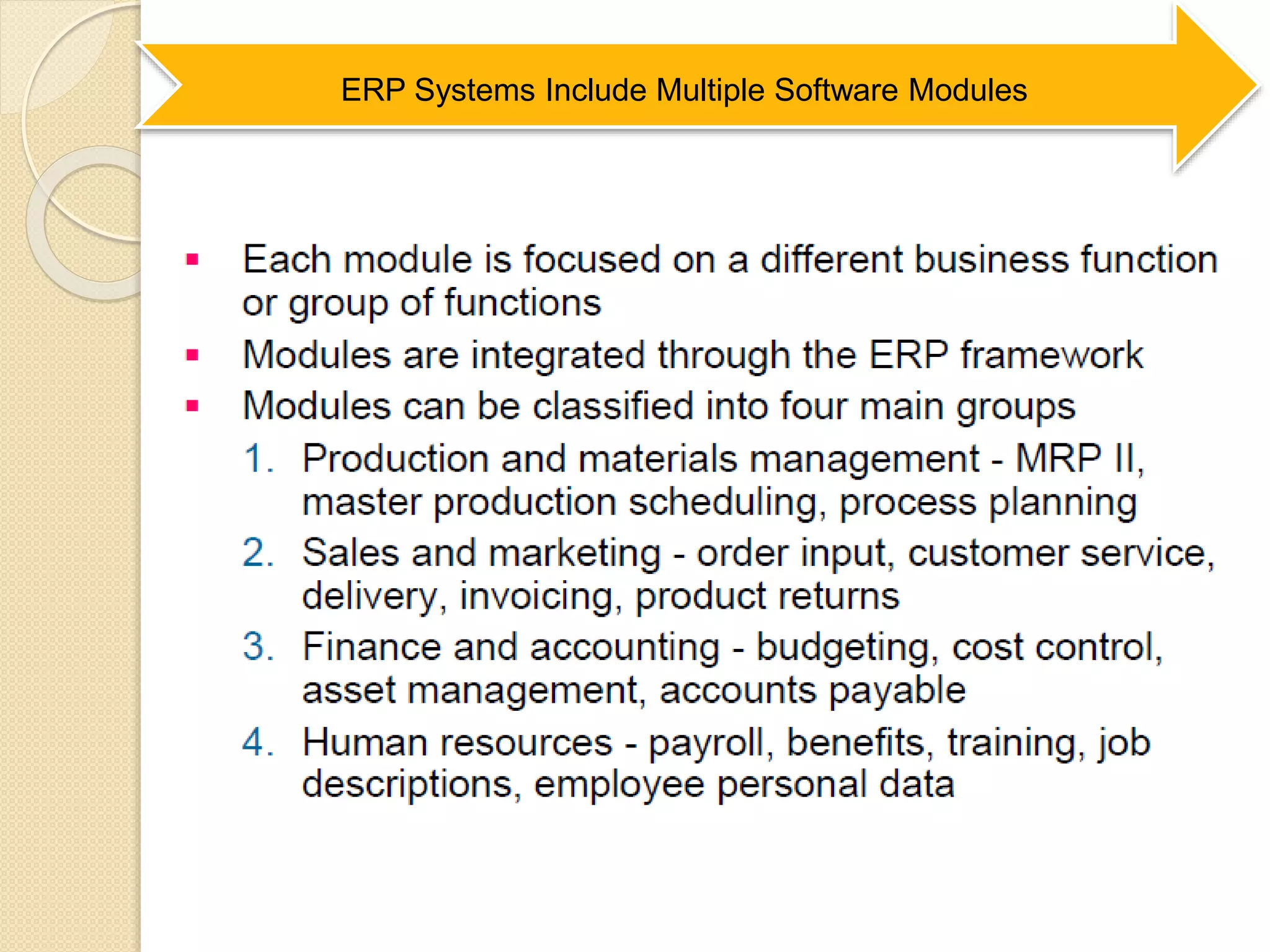

The document discusses various aspects of process planning and production management in manufacturing, including computer-aided process planning (CAPP), aggregate production planning, material requirements planning (MRP), capacity planning, shop floor control, inventory control, manufacturing resource planning (MRP II), and enterprise resource planning (ERP). It provides details on the logical steps, inputs, outputs, and operation of these different planning and control systems used to manage manufacturing production.