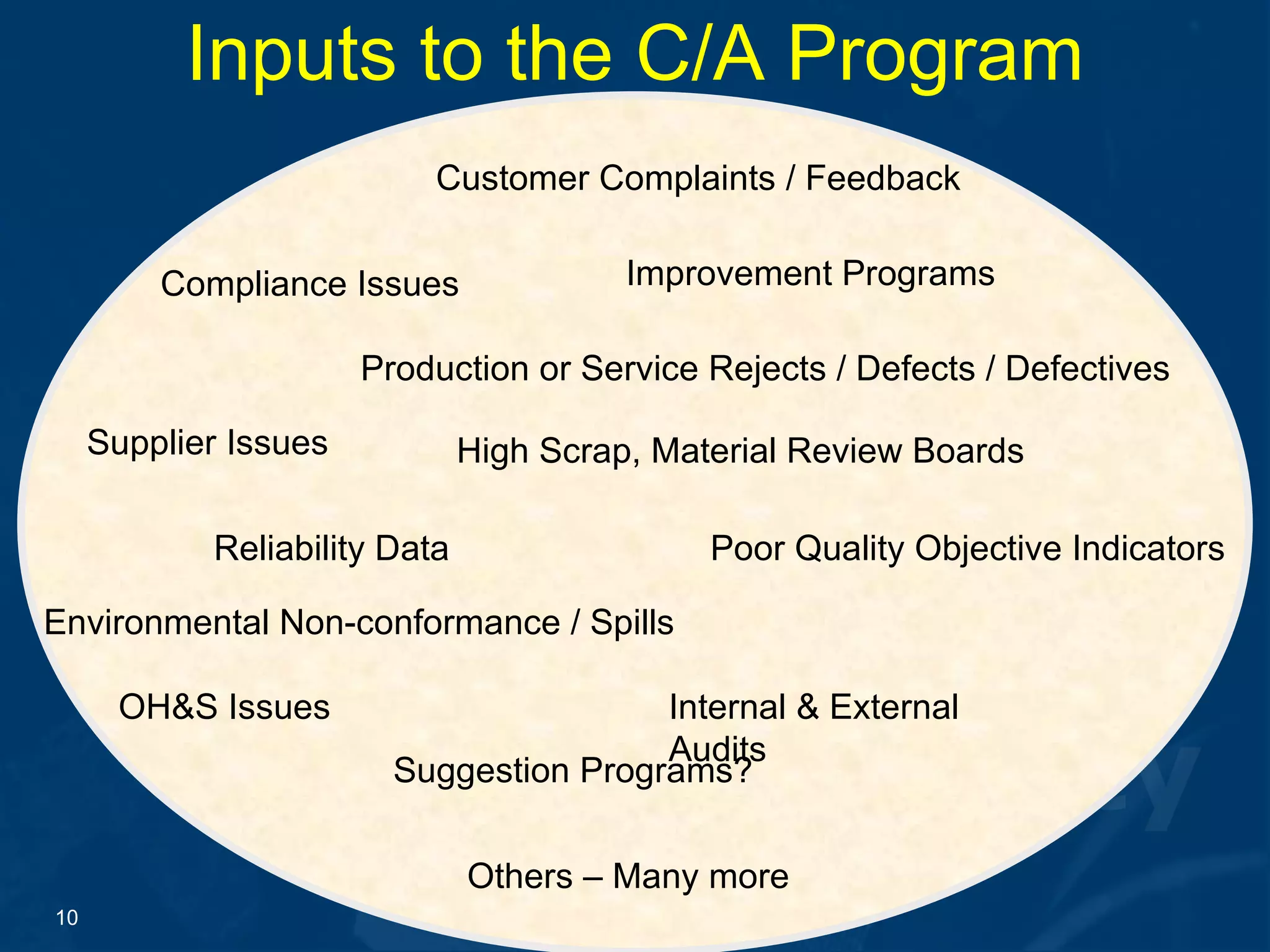

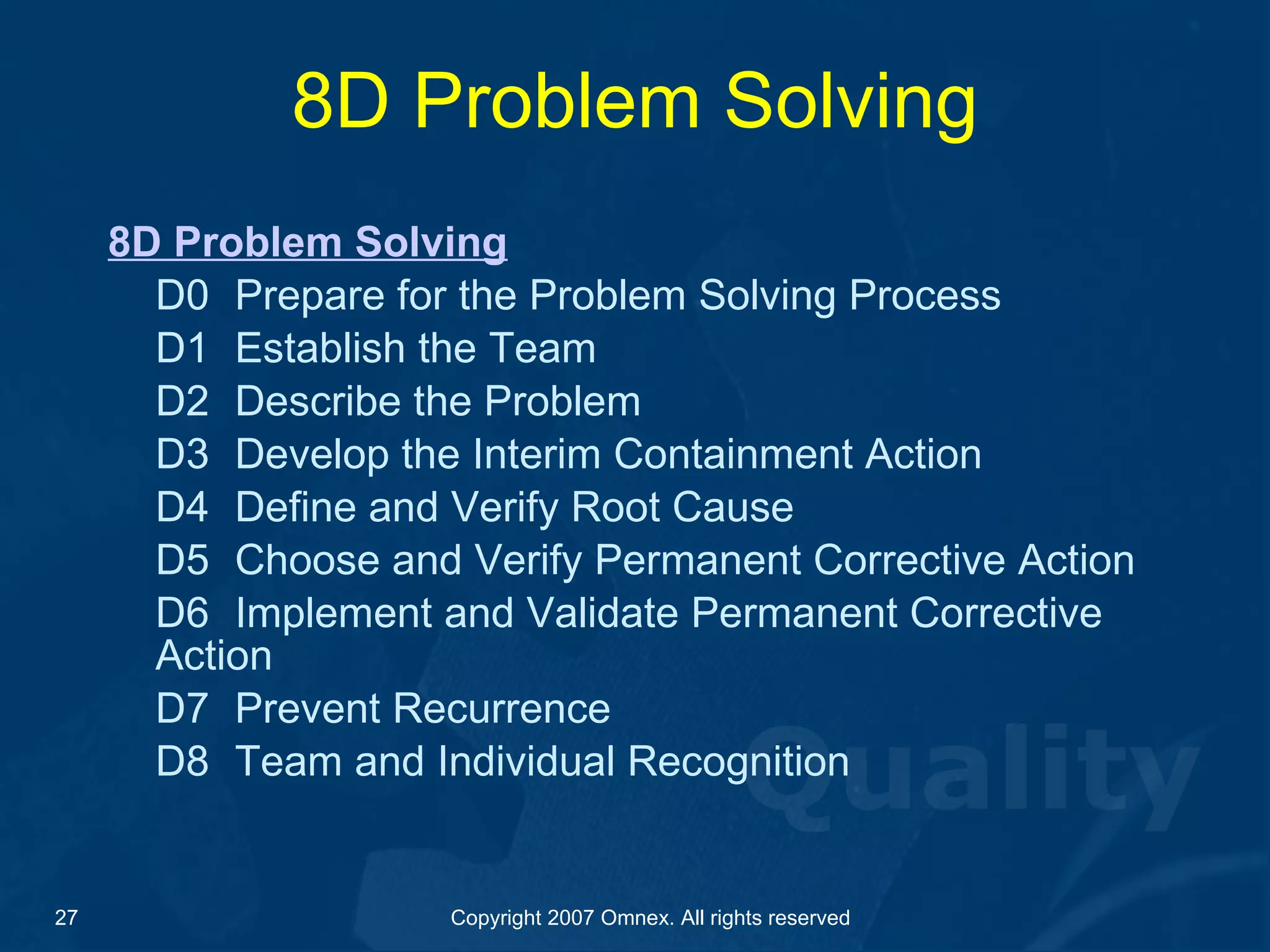

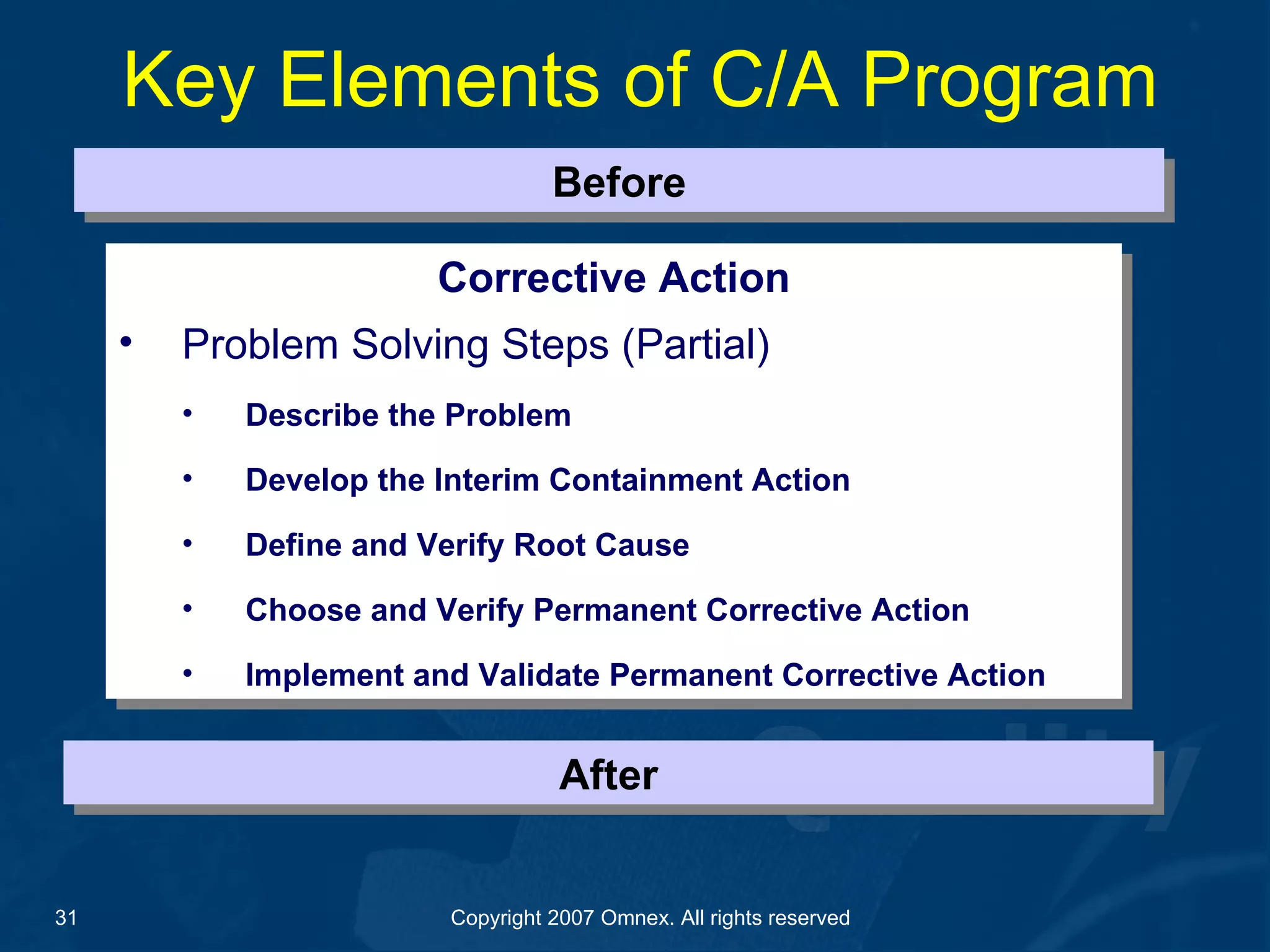

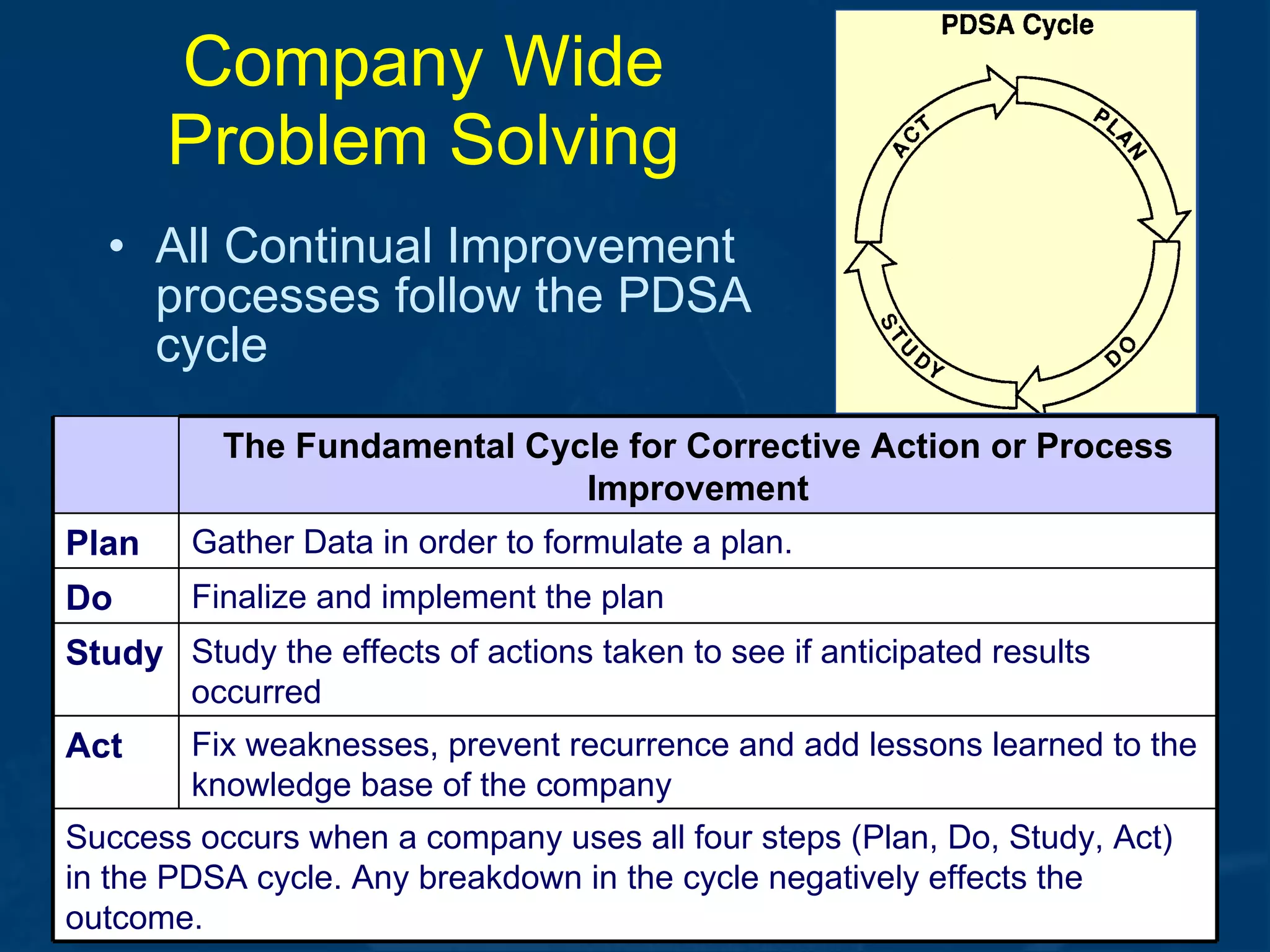

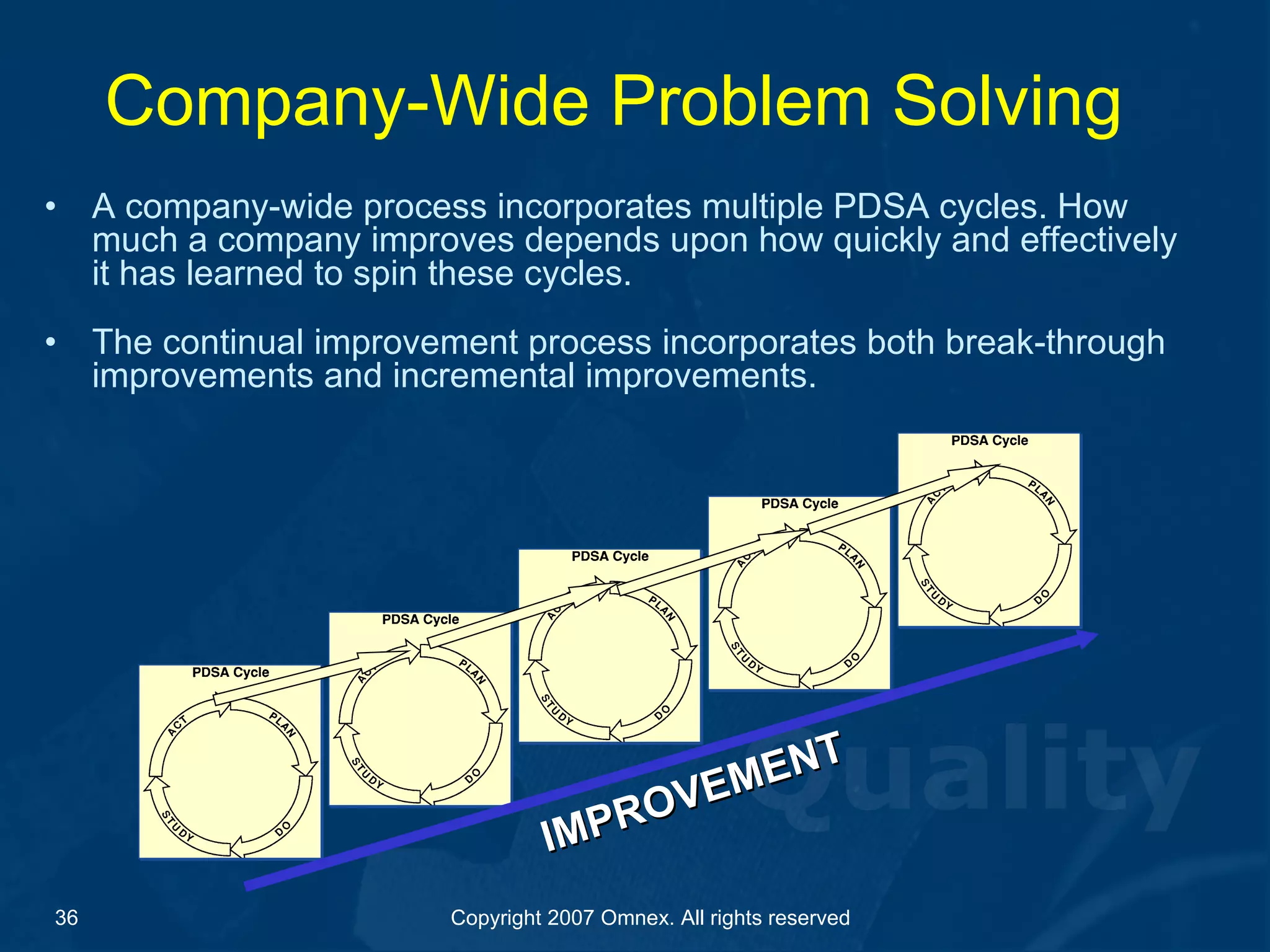

The document discusses effective corrective action programs. It defines a corrective action program as a process that manages various inputs like non-conformances, audits, and complaints. It also manages resources to provide training on techniques like team problem solving. The ideal program applies a problem solving method like 8D across the organization and continuously improves by learning from results and implementing preventative actions.

![Omnex provides training, consulting and software to the international market with offices in the USA, Canada, Mexico, China (PRC), Germany, India, the Middle East and Thailand. Omnex offers over 55 training courses in business, quality, environmental, and health & safety management systems worldwide. Internet email: [email_address] Web: www.omnex.com](https://image.slidesharecdn.com/asqtoronto10jan2007effectcorraction-110715071230-phpapp02/75/Asq-toronto10-jan2007effectcorraction-2-2048.jpg)