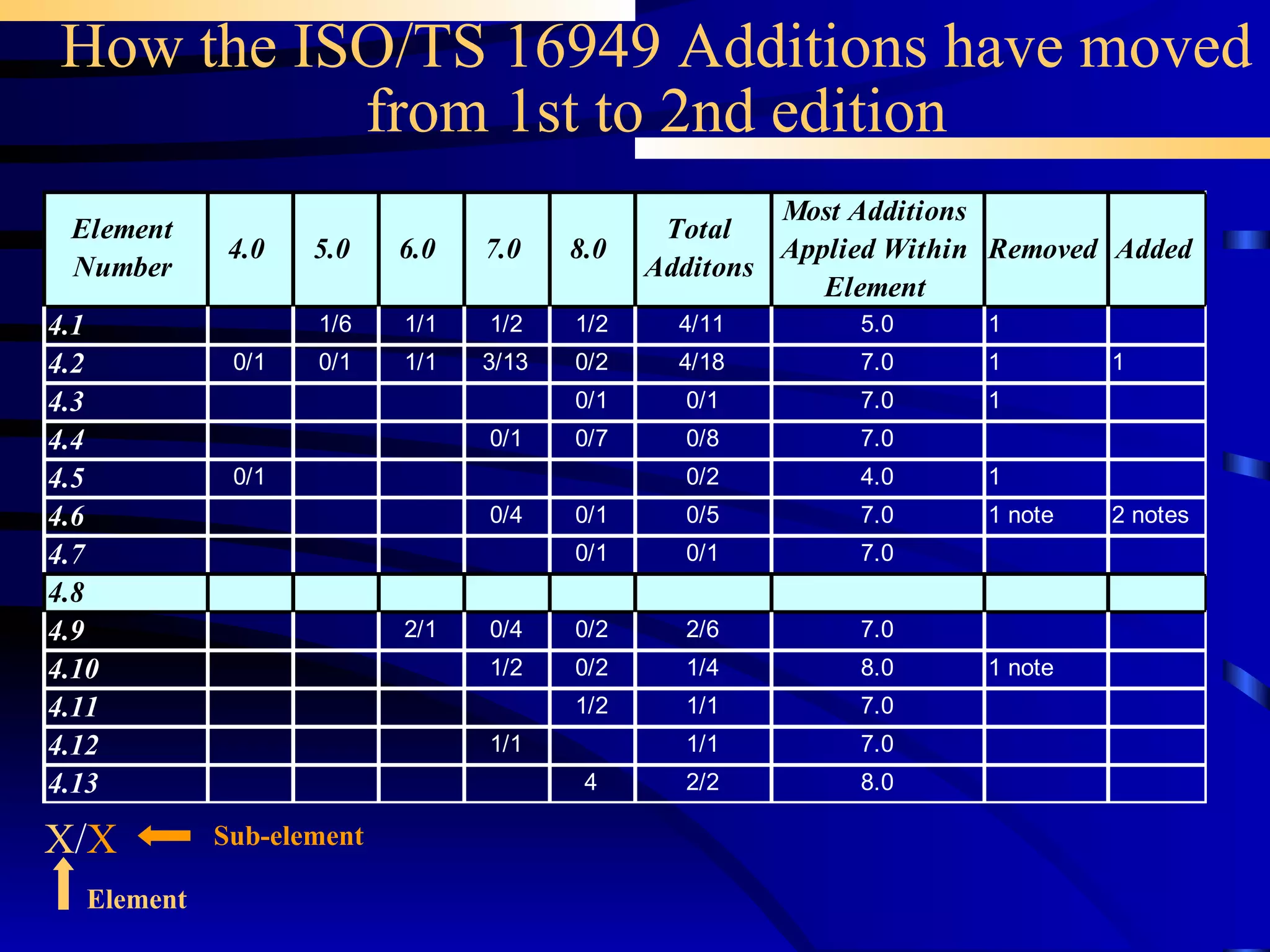

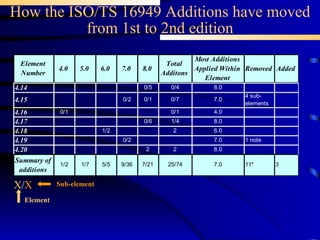

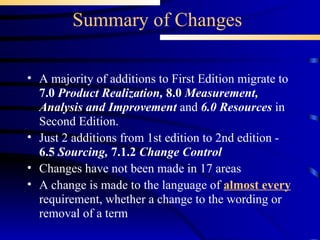

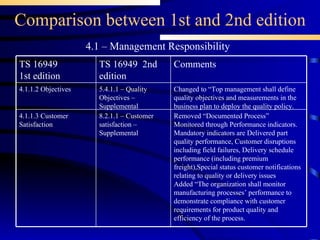

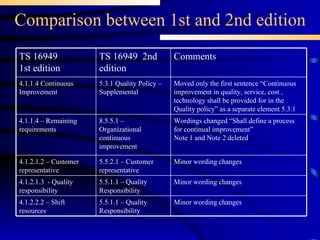

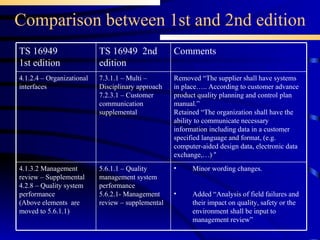

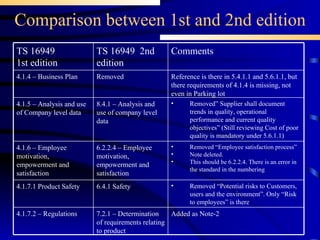

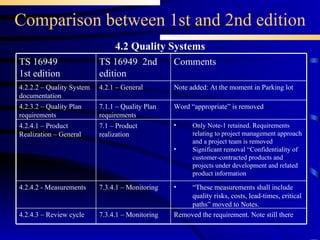

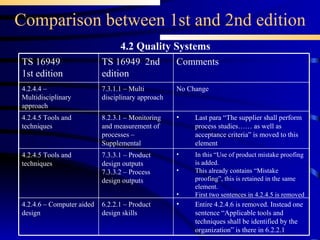

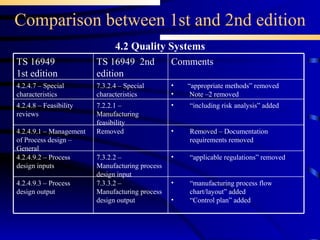

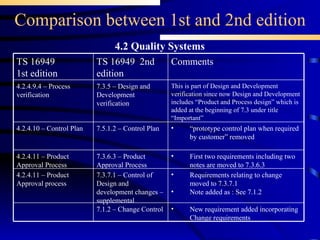

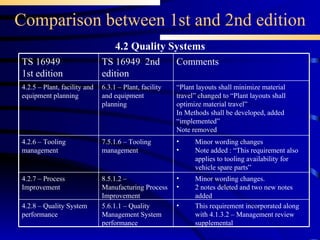

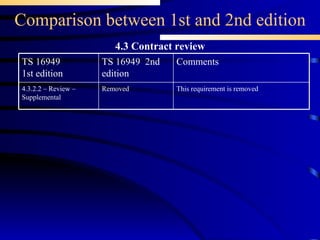

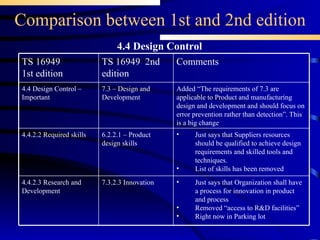

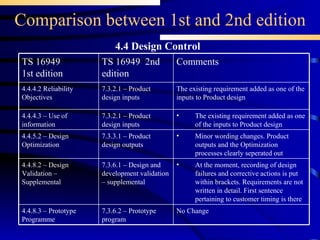

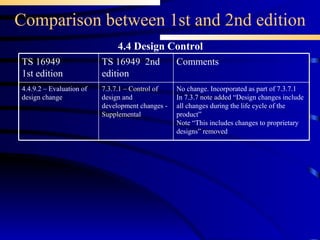

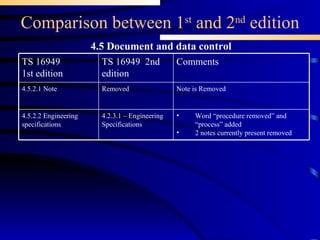

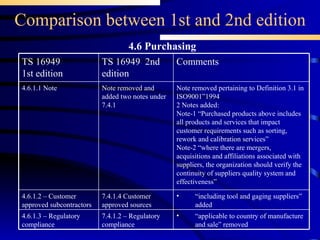

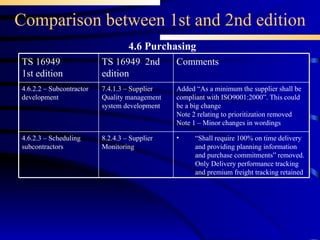

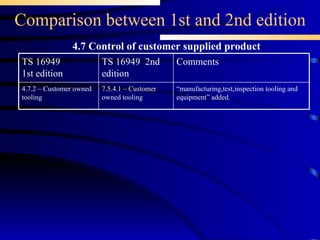

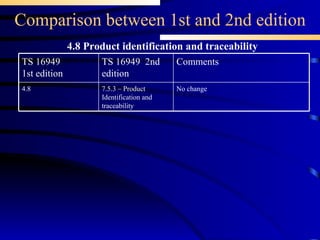

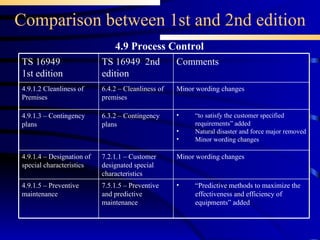

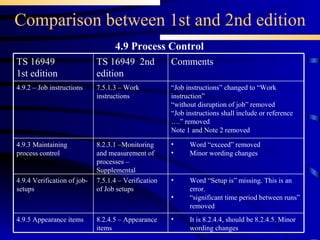

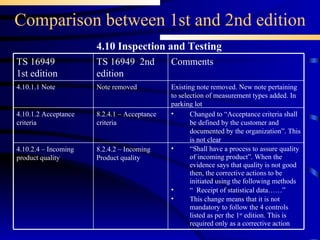

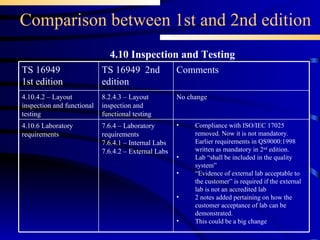

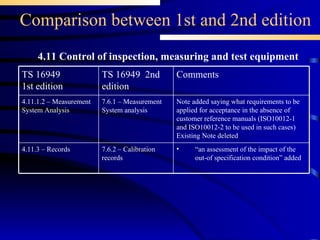

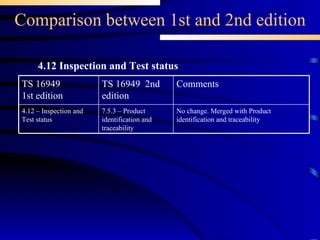

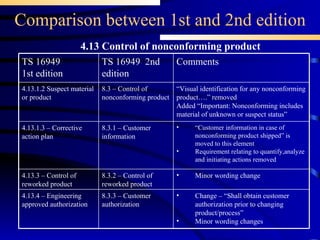

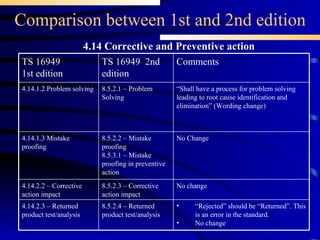

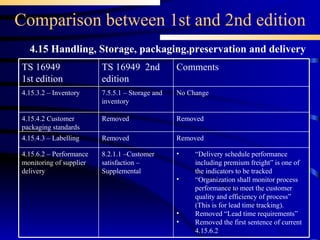

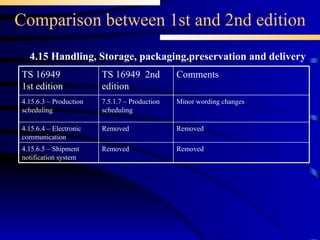

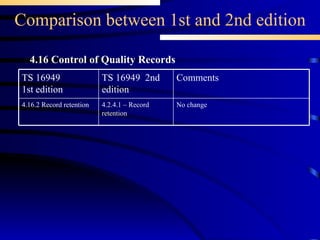

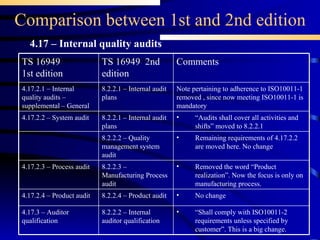

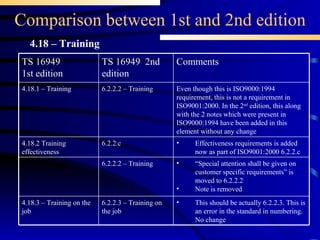

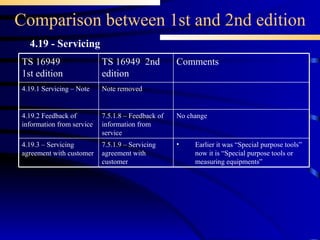

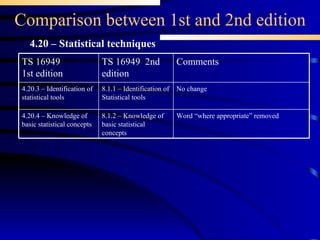

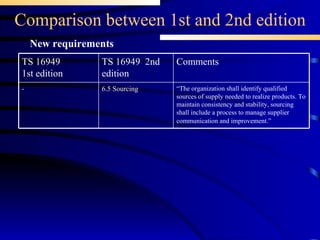

The document provides a comparison between the requirements in the 1st and 2nd editions of ISO/TS 16949. It summarizes the key changes made to the locations and wordings of various requirements. Major changes include requirements related to product and process design being included under design and development, removal of documented process, and changes to the wording of most requirements.