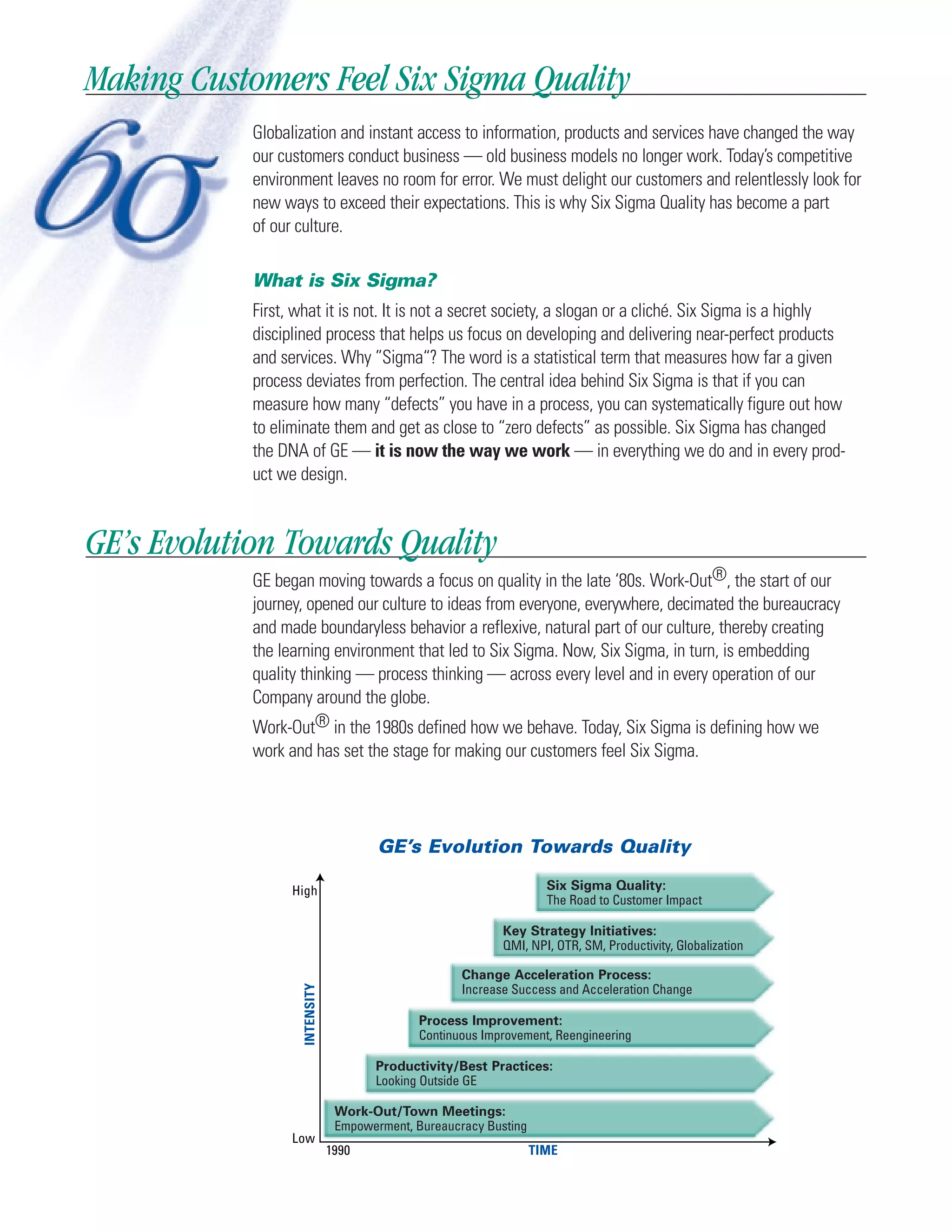

The document discusses Six Sigma, which is a highly disciplined process used by GE to develop and deliver near-perfect products and services. It aims to eliminate defects in processes and get as close to zero defects as possible. GE began focusing on quality in the 1980s with programs like Work-Out that broke down bureaucracy, and now Six Sigma is embedded in their culture and how they work. Key aspects of Six Sigma include focusing on critical quality attributes from the customer's perspective, reducing process variation, and training employees.