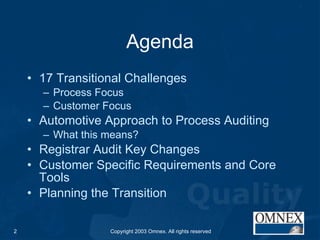

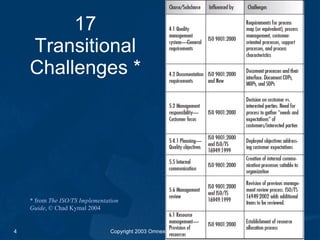

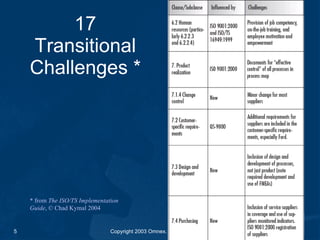

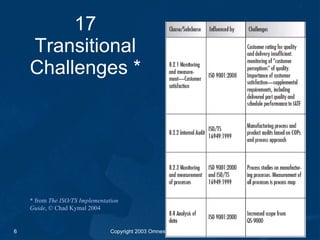

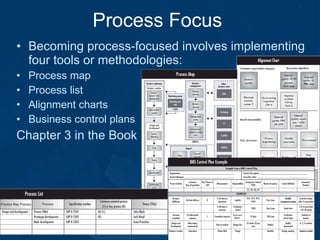

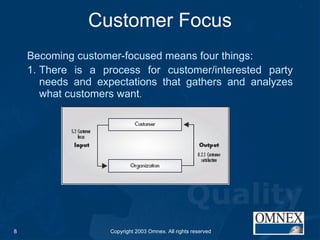

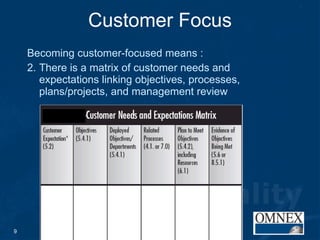

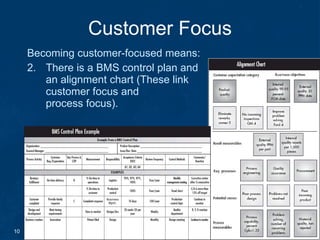

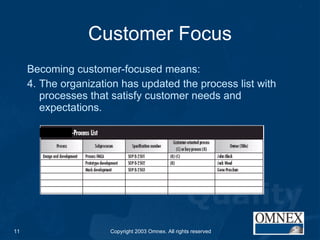

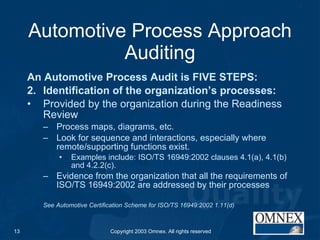

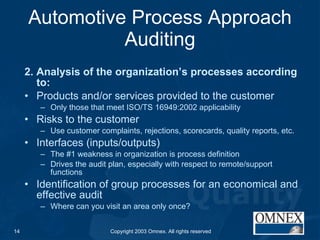

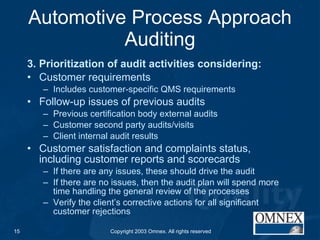

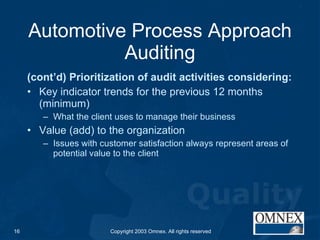

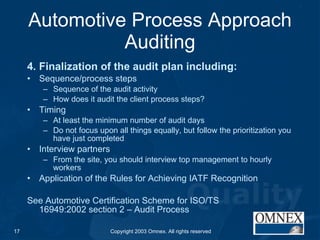

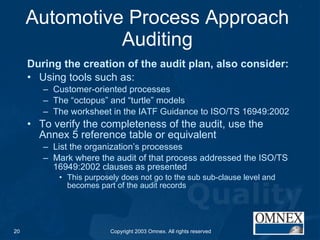

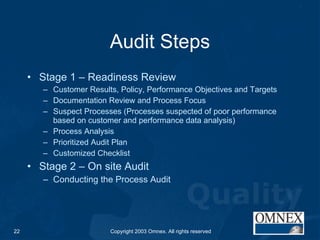

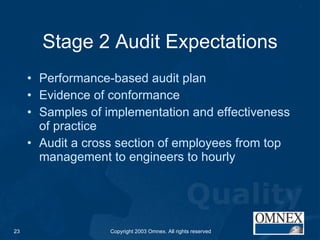

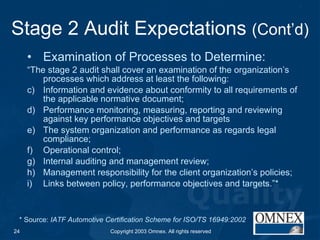

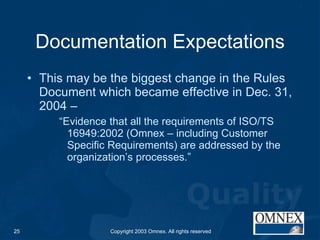

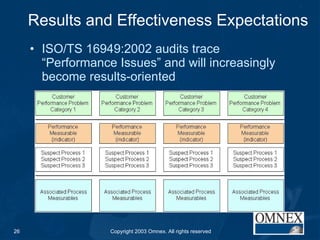

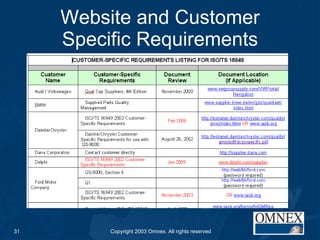

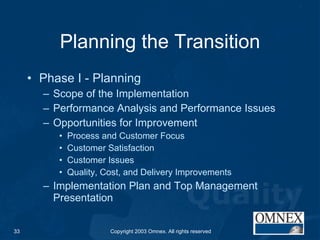

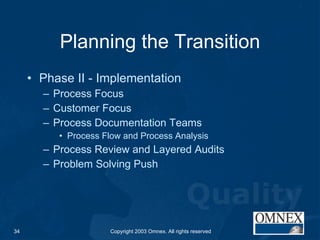

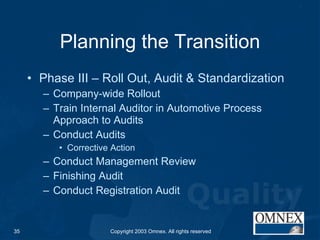

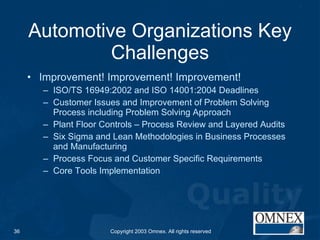

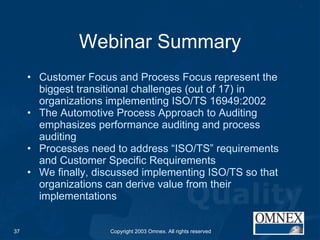

The document discusses key topics in implementing ISO/TS 16949:2002, including transitional challenges, process focus, customer focus, and the automotive approach to process auditing. It outlines a 5-step automotive process audit approach and emphasizes that processes must address both ISO/TS requirements and customer-specific requirements. The webinar agenda also reviews documentation expectations, results and effectiveness expectations, and planning the transition in three phases from planning to roll out and standardization.