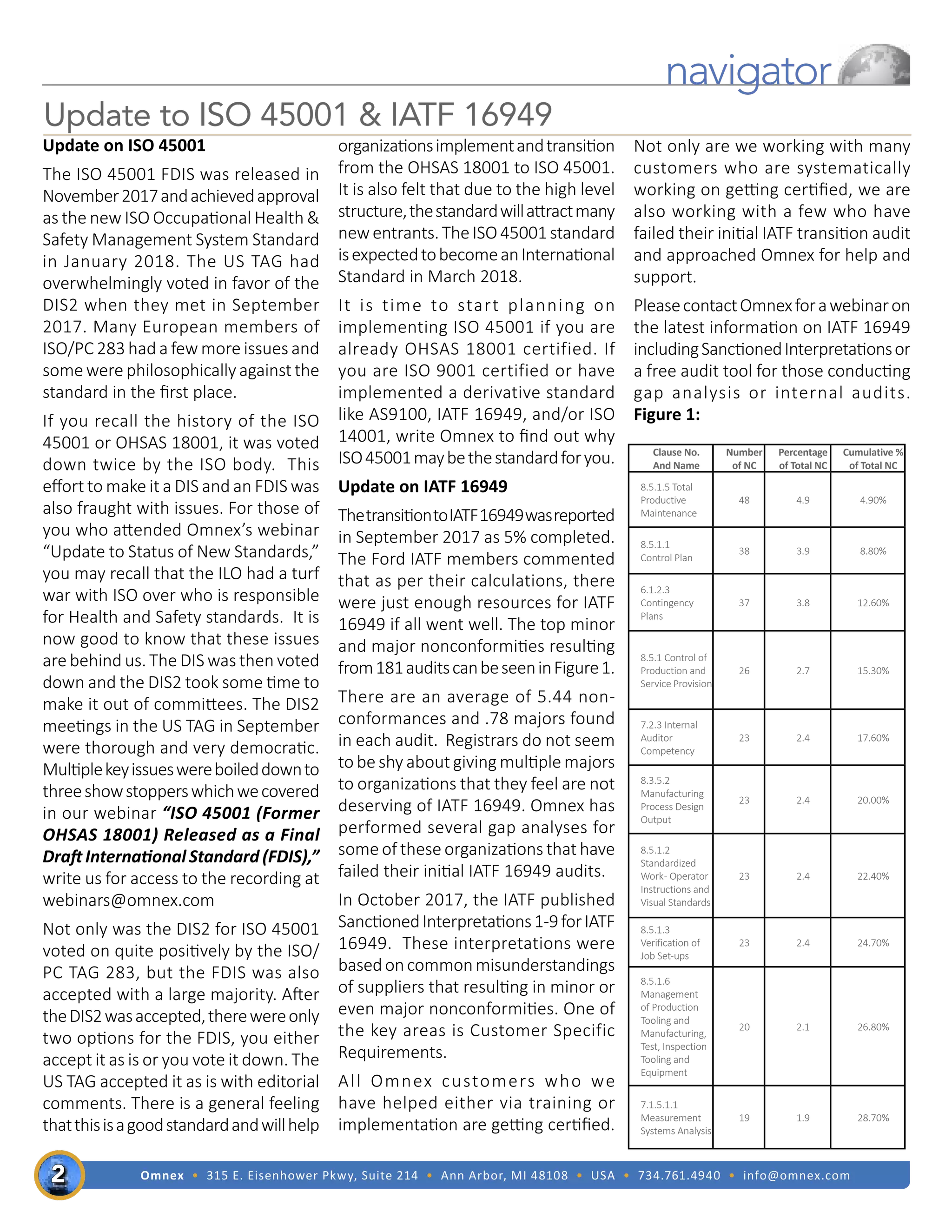

- 181 organizations that underwent transition audits from ISO/TS 16949 to IATF 16949 received an average of 5.3 nonconformities, with nearly one major nonconformity.

- The top nonconformity areas were total productive maintenance, control plans, contingency plans, control of production and service provision, and internal auditor competency.

- Major nonconformities were frequently issued for customer-specific requirements, internal auditor competency, quality management system audits, total productive maintenance, and management review inputs. This highlights key areas organizations need to focus on to pass IATF 16949 audits.