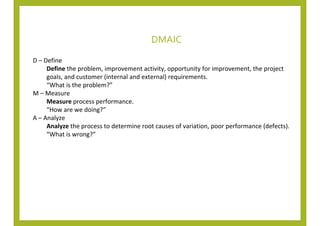

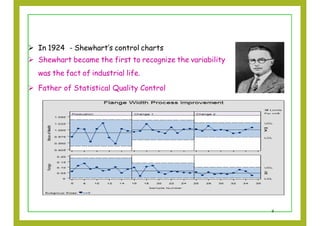

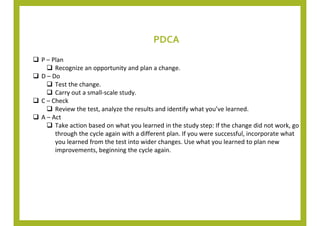

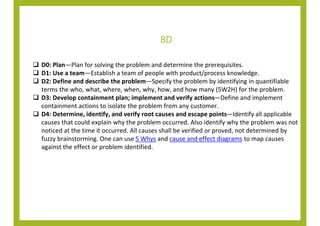

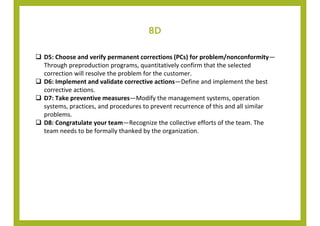

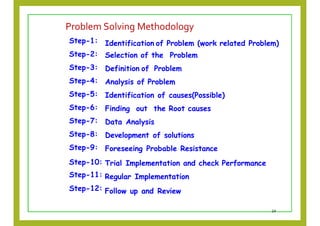

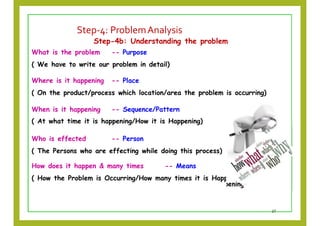

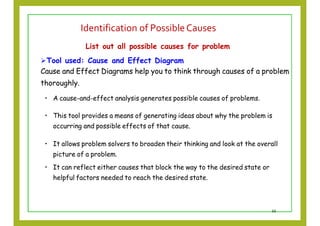

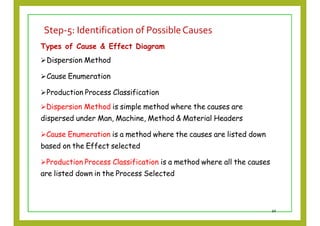

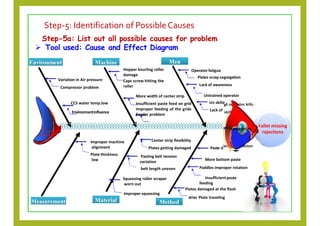

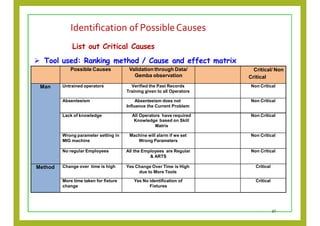

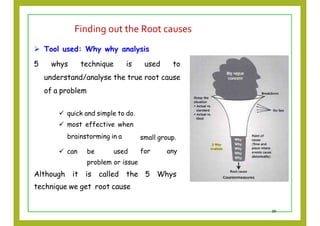

The document provides information about total quality management (TQM) and quality improvement tools. It defines TQM as integrating all functions and processes to continuously improve quality of goods and services. Key aspects of TQM include customer satisfaction, meeting standards and expectations. Tools covered include DMAIC (define, measure, analyze, improve, control), 8D (eight disciplines of problem solving), PDCA (plan, do, check, act) and basic quality tools like histograms, Pareto charts, flowcharts and control charts. The document discusses how these tools are applied in the problem solving methodology of identifying problems, analyzing causes, finding root causes, developing and testing solutions.