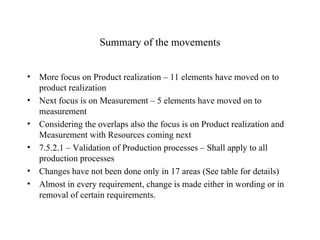

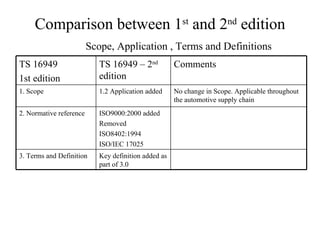

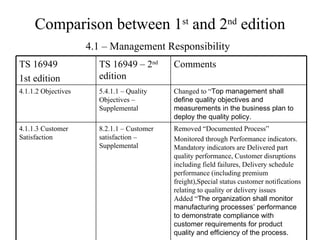

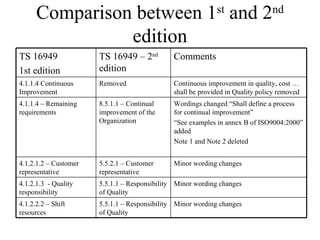

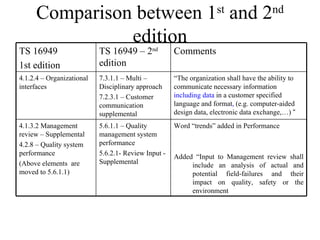

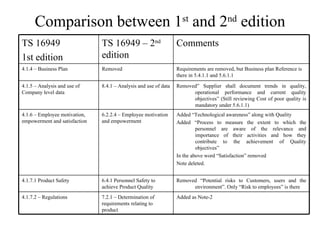

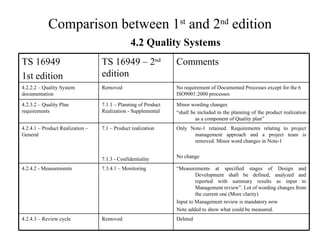

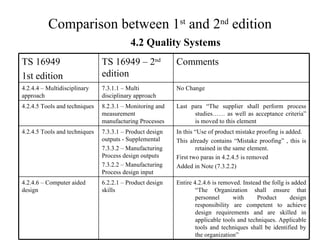

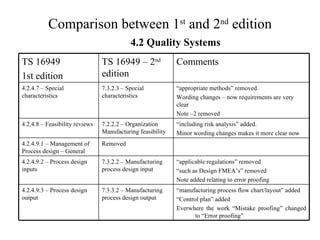

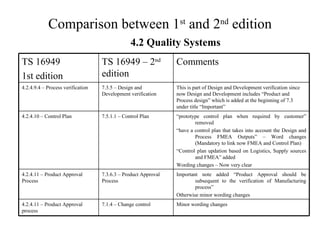

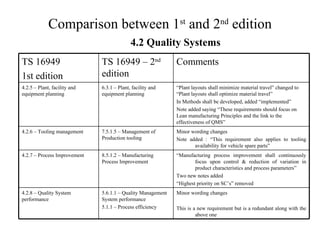

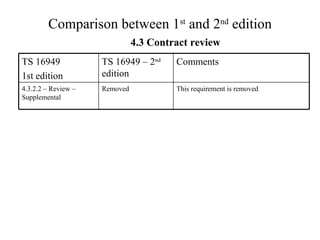

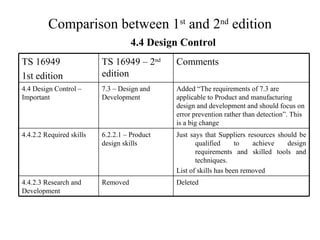

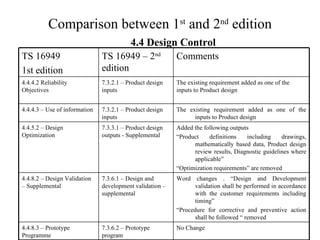

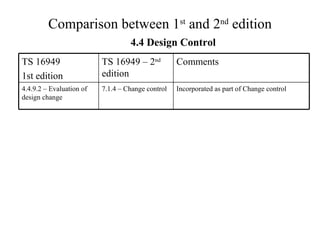

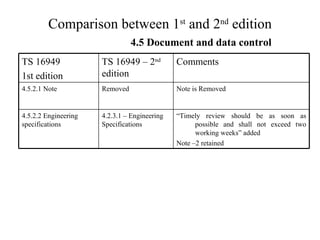

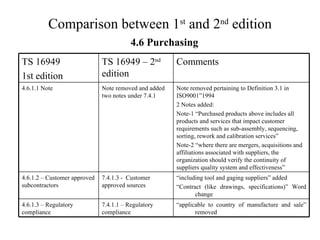

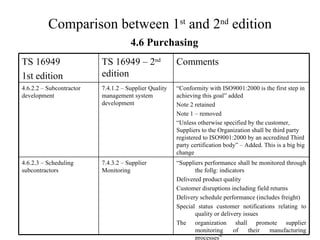

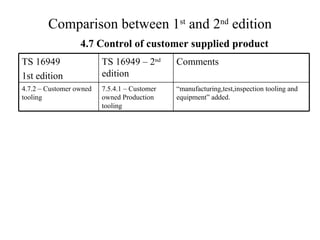

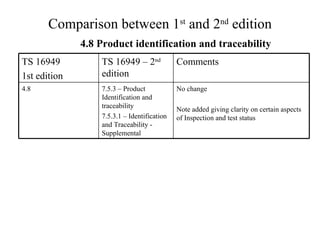

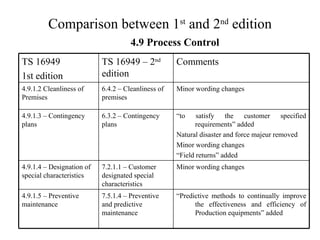

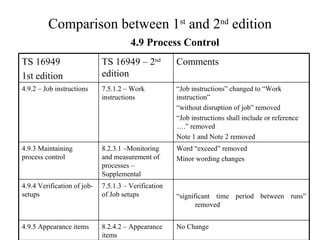

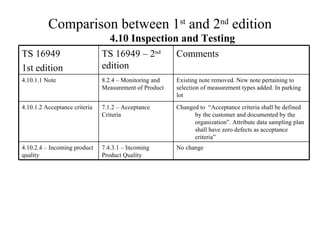

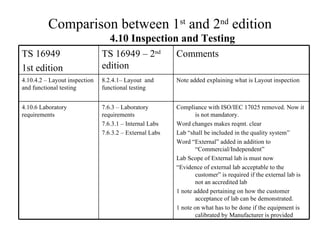

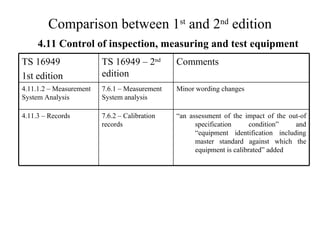

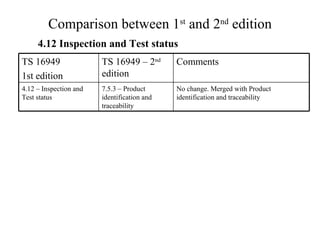

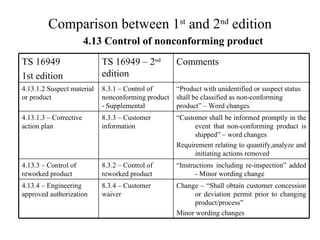

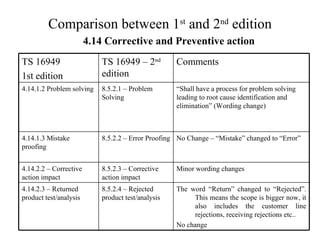

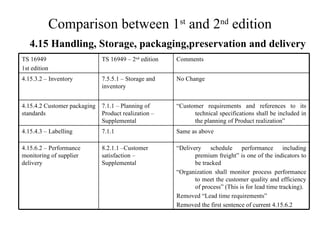

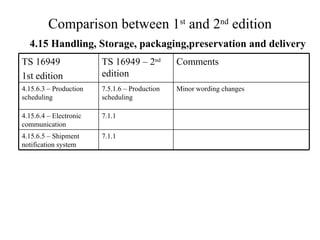

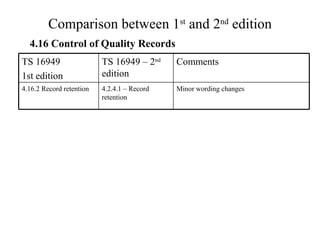

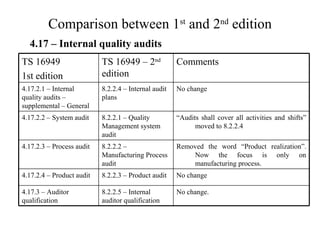

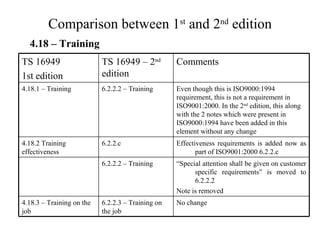

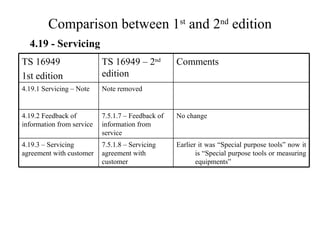

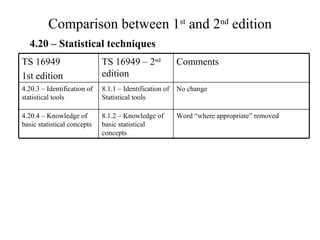

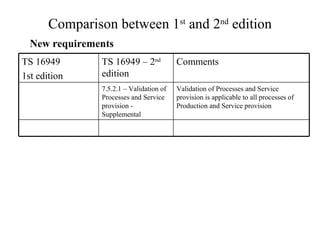

The document compares the quality management system requirements between the first and second editions of ISO/TS 16949. It provides a section-by-section analysis of changes made, including requirements that were removed, requirements that were moved to different sections, and changes in wording. The key changes include a stronger focus on product and process design as well as error prevention. Requirements related to supplier quality management were also strengthened, now requiring suppliers to be third-party registered to ISO 9001.