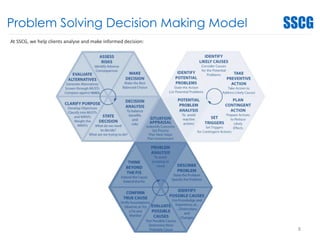

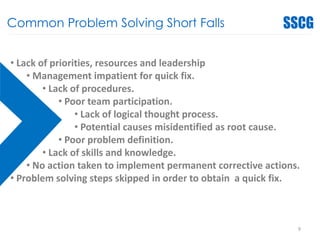

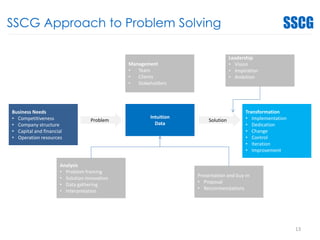

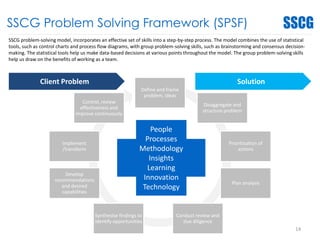

This document provides an overview of 8D problem solving methodology. It describes the 8D process as a systematic approach to solving critical problems in production. The 8 steps include forming a problem solving team, describing the problem, developing interim containment actions, determining the root cause, developing permanent corrective actions, implementing and verifying the actions, preventing recurrences, and closing out the project. Benefits of 8D include improved team problem solving skills and understanding of root cause analysis. The document also discusses common shortfalls in problem solving and how a consulting firm can help clients apply the 8D methodology.