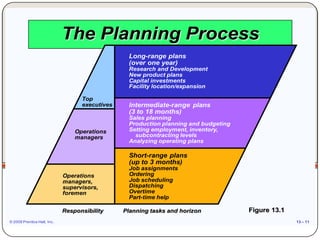

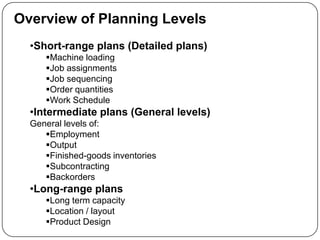

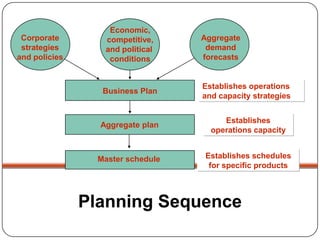

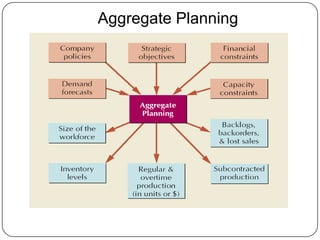

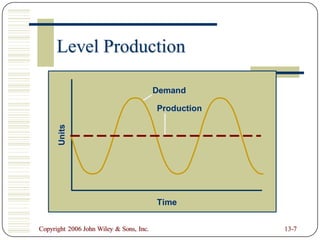

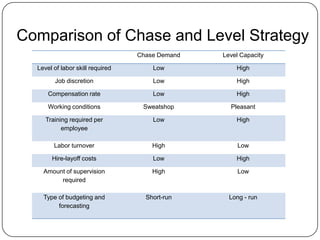

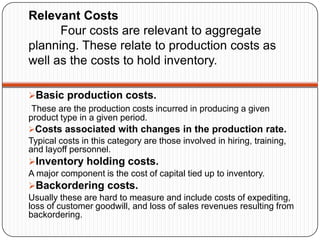

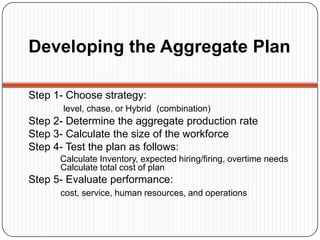

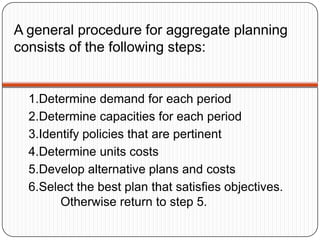

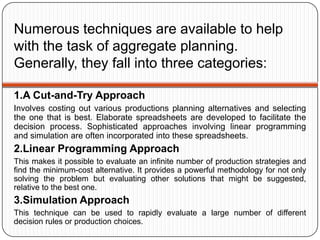

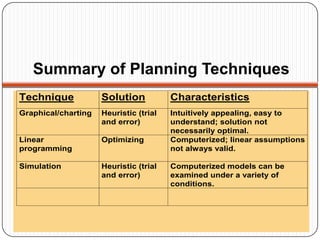

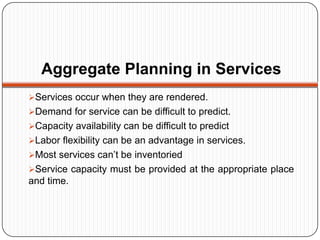

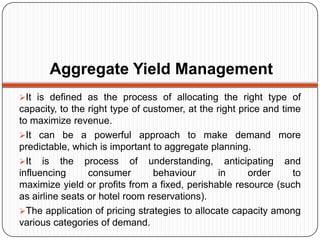

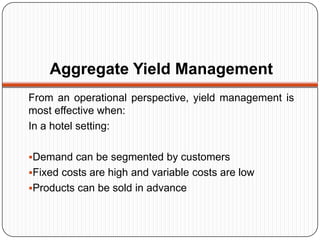

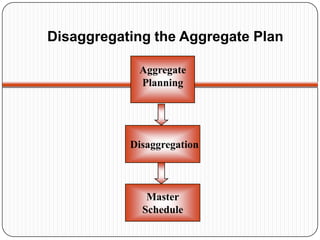

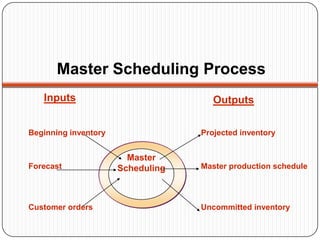

Aggregate planning involves matching supply and demand over a medium-term horizon of up to 18 months, focusing on overall output and resource utilization. It incorporates strategies such as proactive and reactive options to manage demand and capacity, utilizing techniques like linear programming and simulation. The planning process leads to disaggregation into a master schedule that indicates specific production requirements and timing.