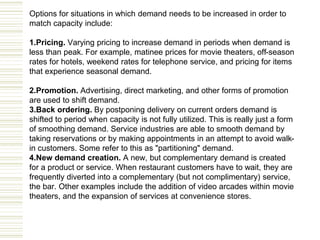

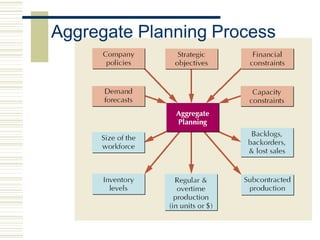

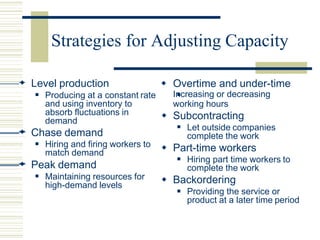

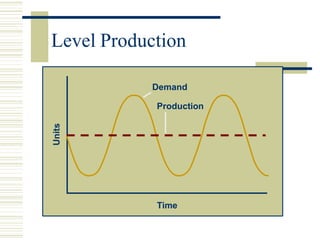

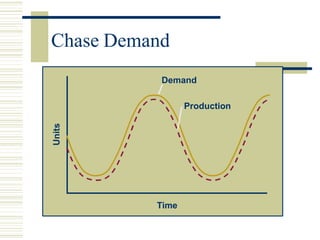

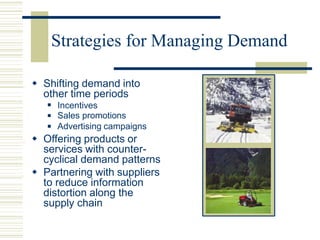

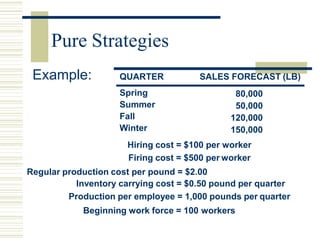

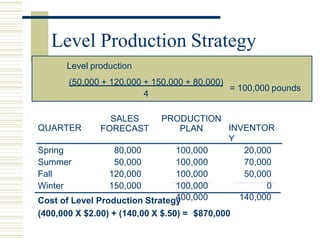

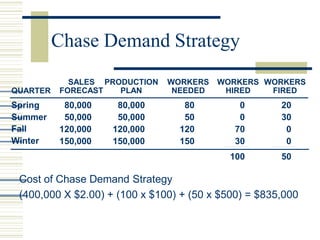

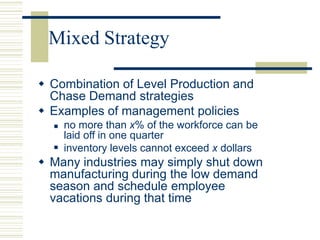

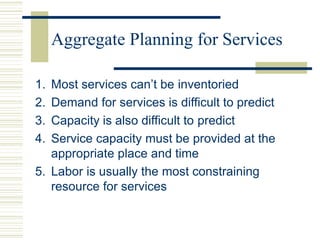

Aggregate planning is the process of developing, analyzing, and maintaining a preliminary schedule of overall operations over an intermediate time horizon. It matches the supply of resources to demand for products or services. The objectives are to establish a company-wide plan for allocating resources and develop an economic strategy to meet demand. Options for adjusting supply include varying workforce levels, overtime, inventory, and subcontracting. Options for managing demand include pricing, promotion, backordering, and creating new demand. Quantitative techniques can help evaluate strategies like level production, chasing demand, or mixed approaches.