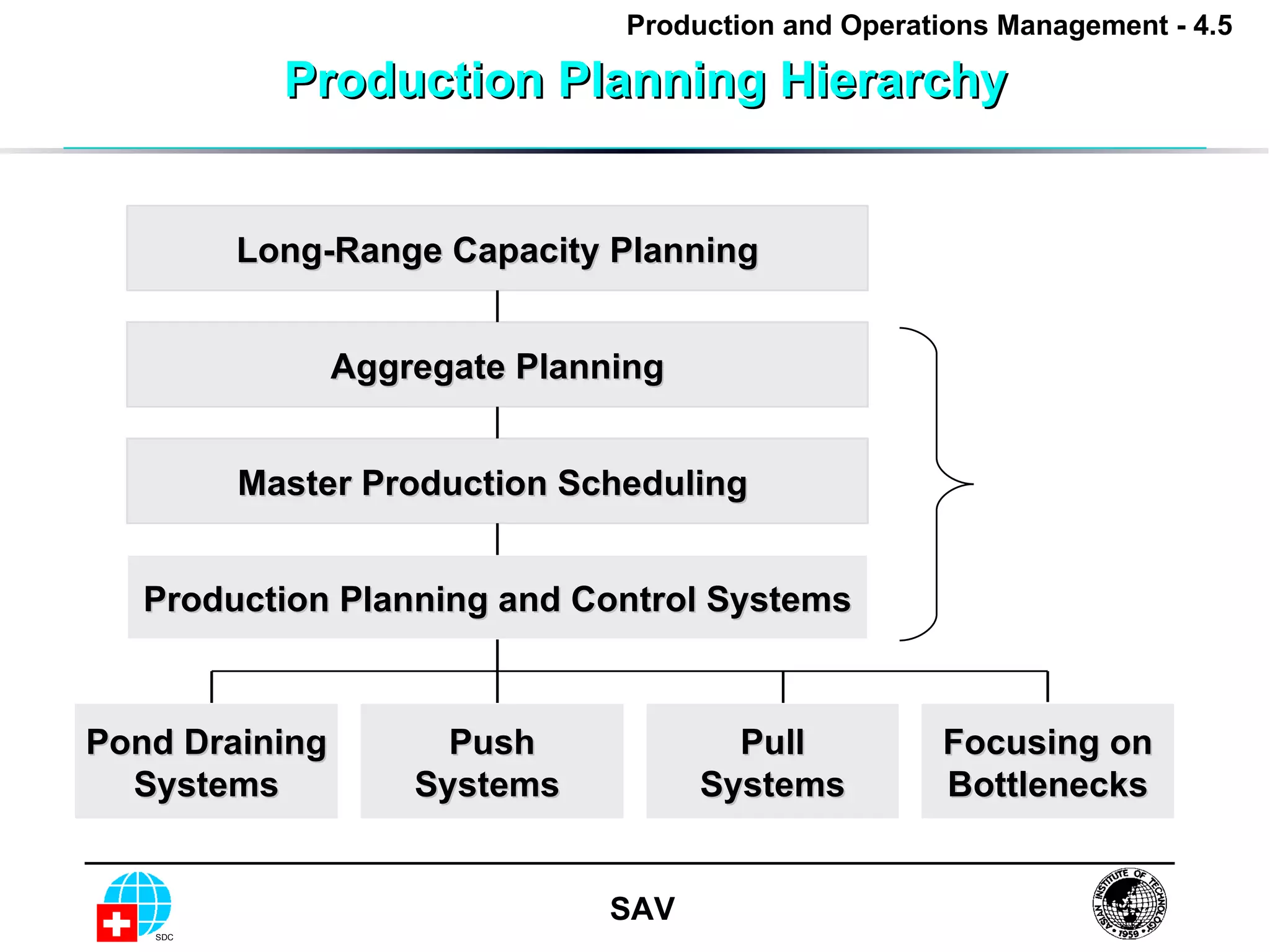

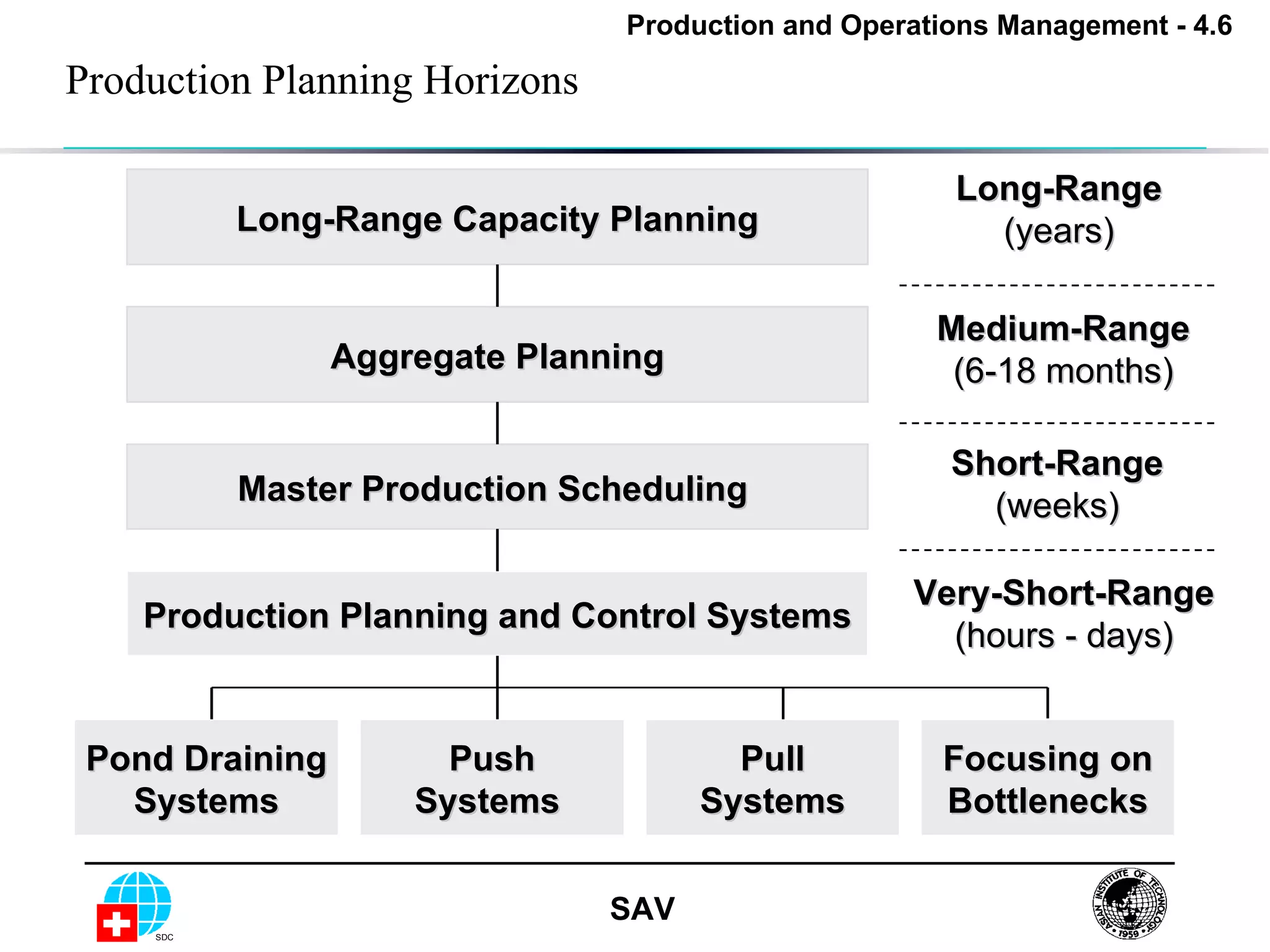

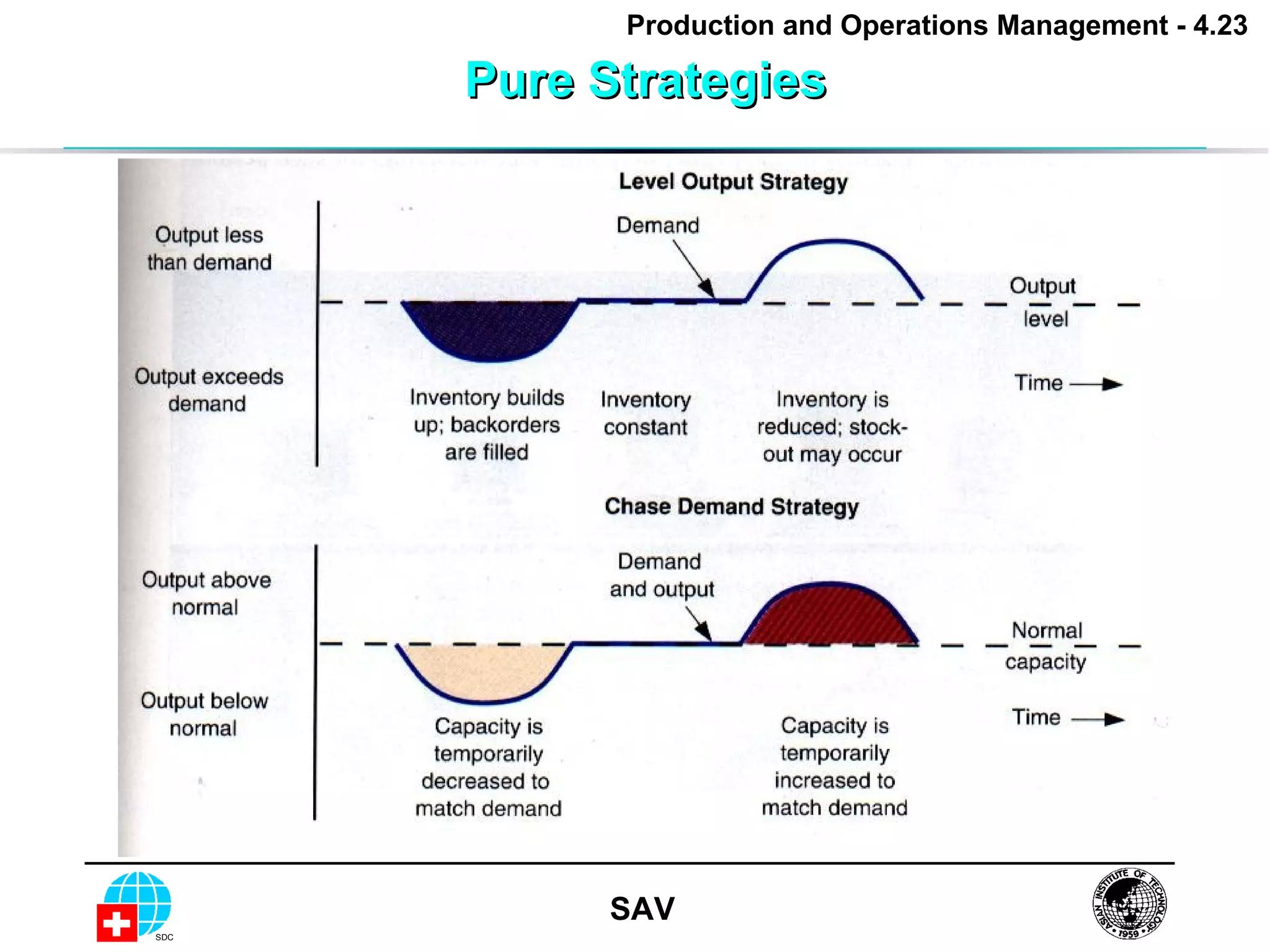

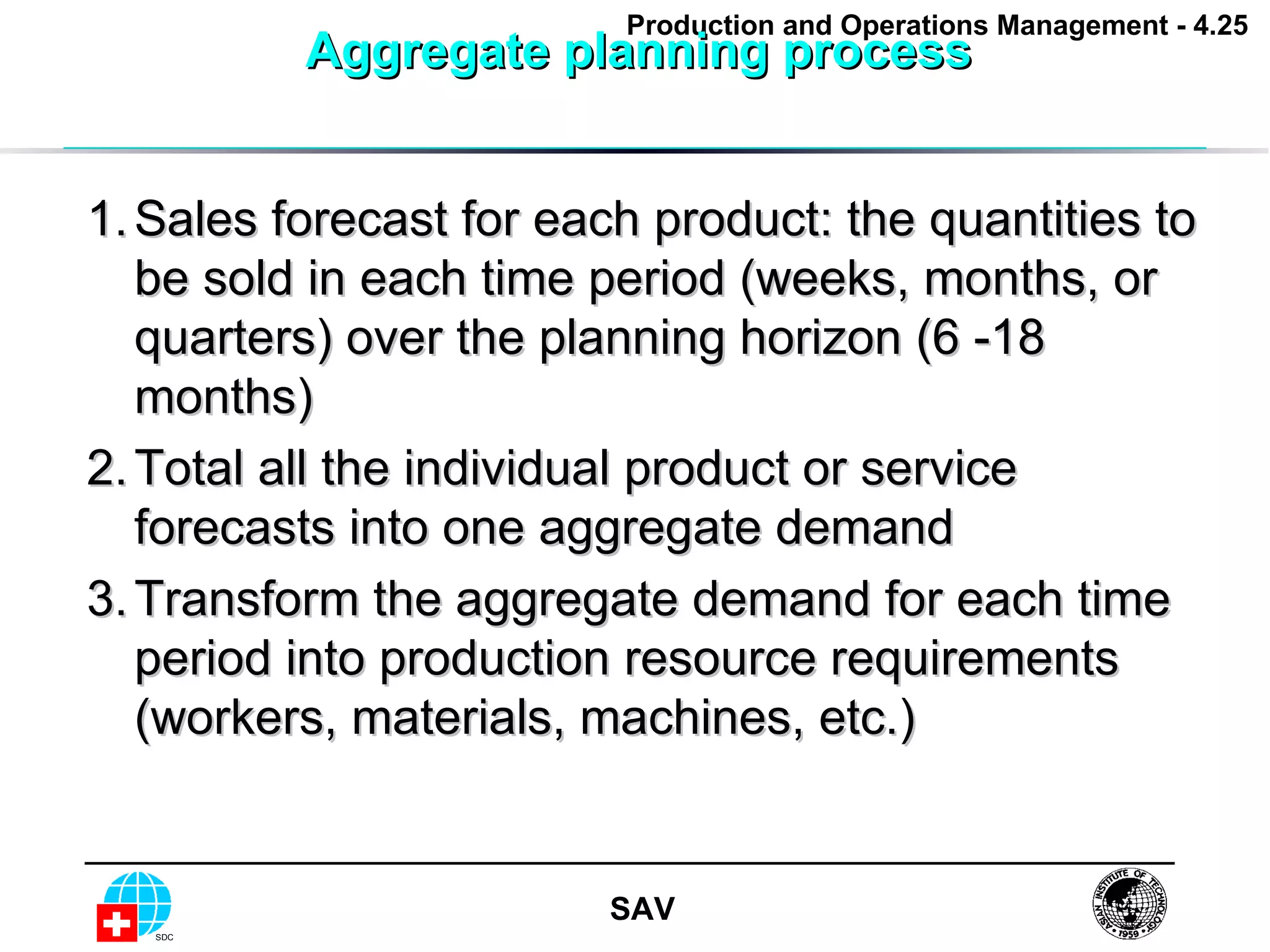

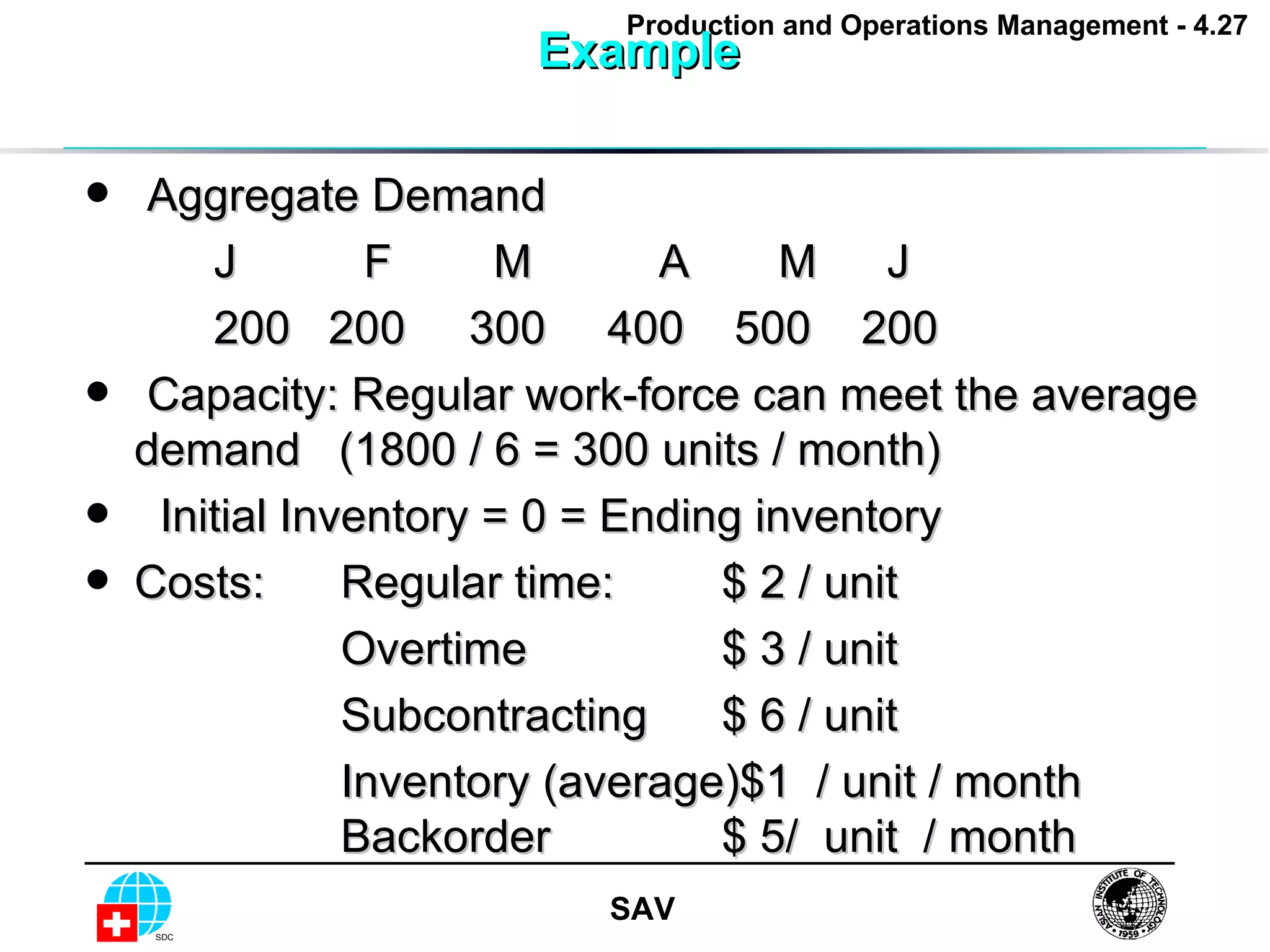

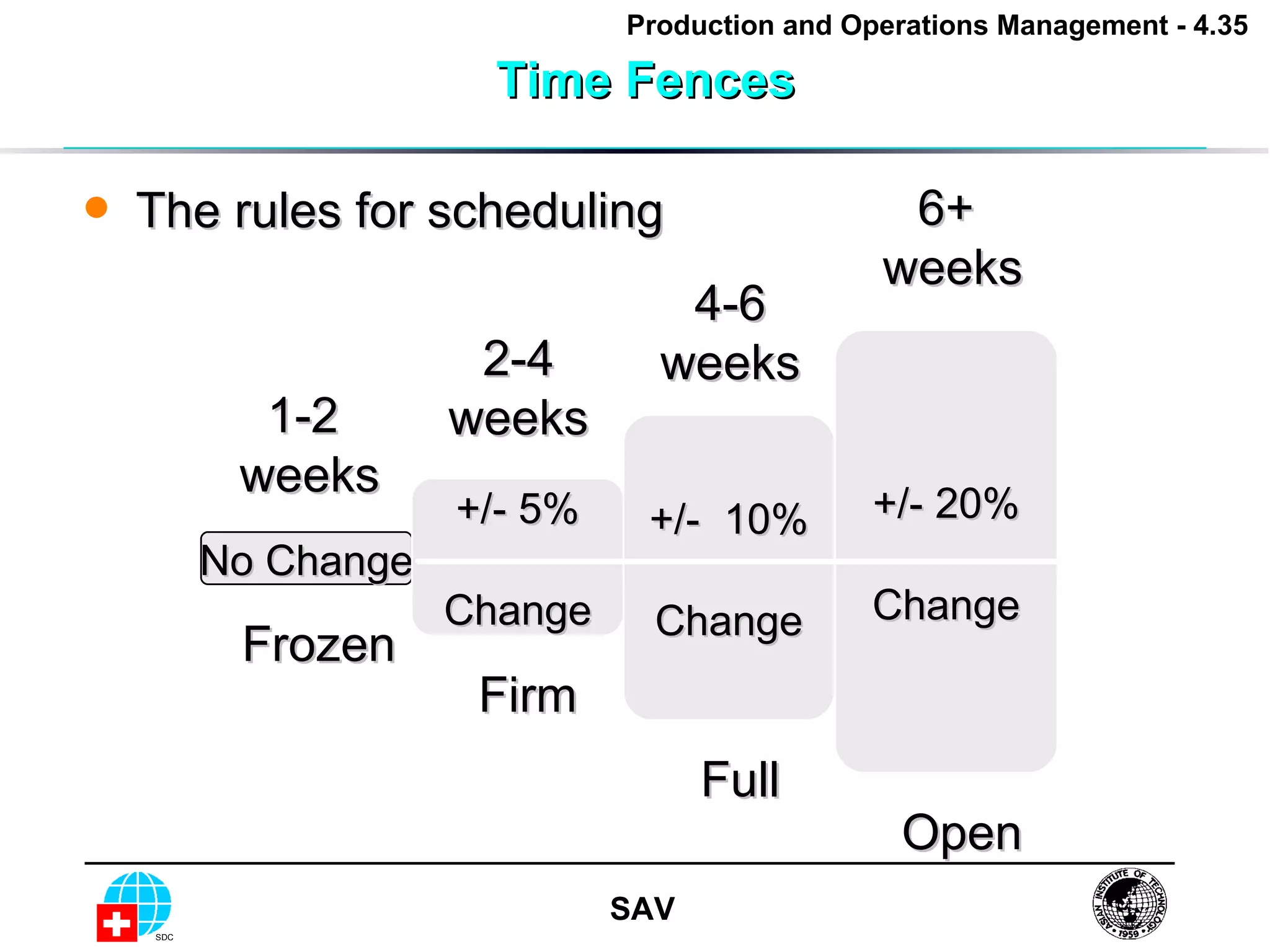

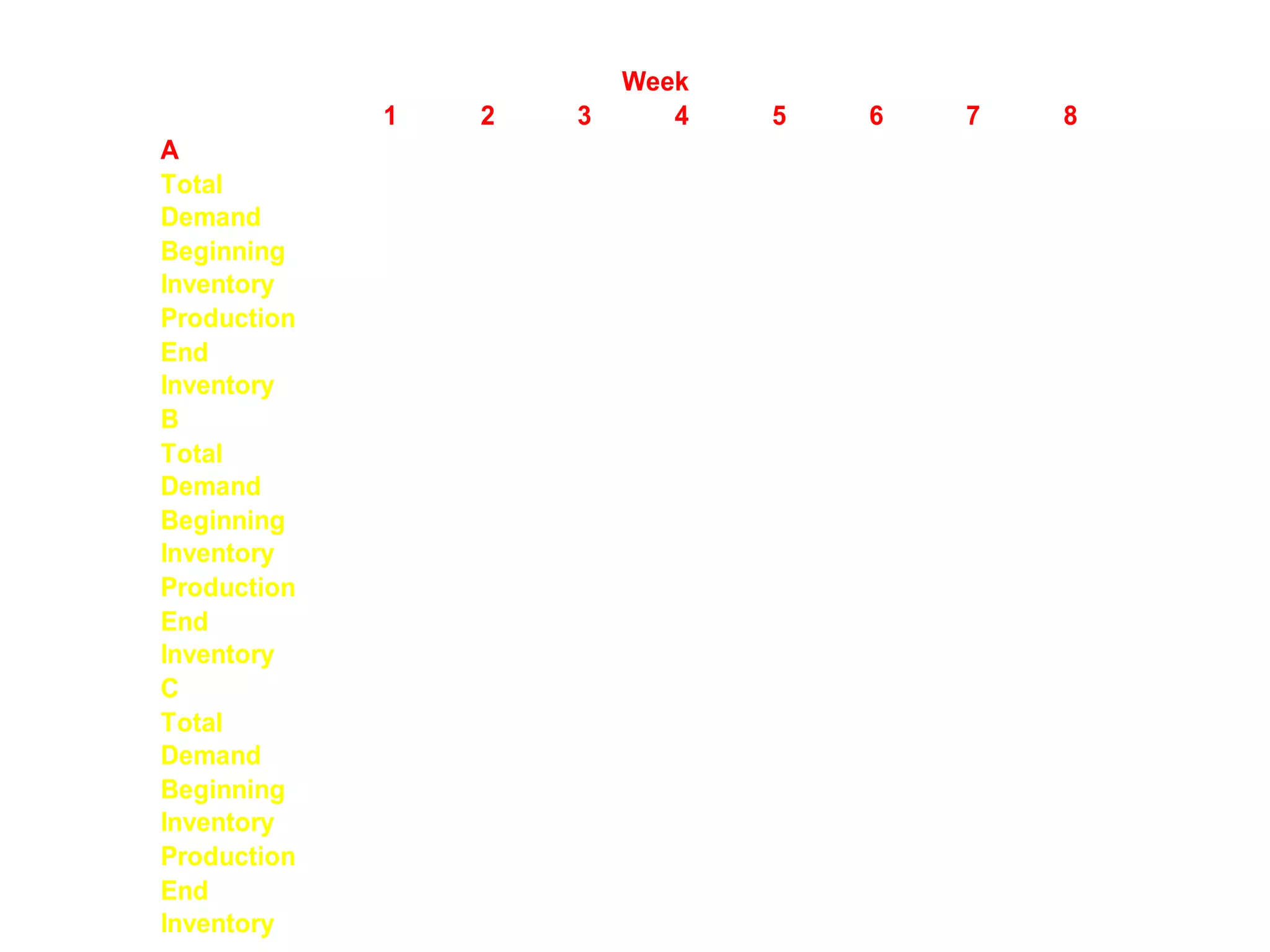

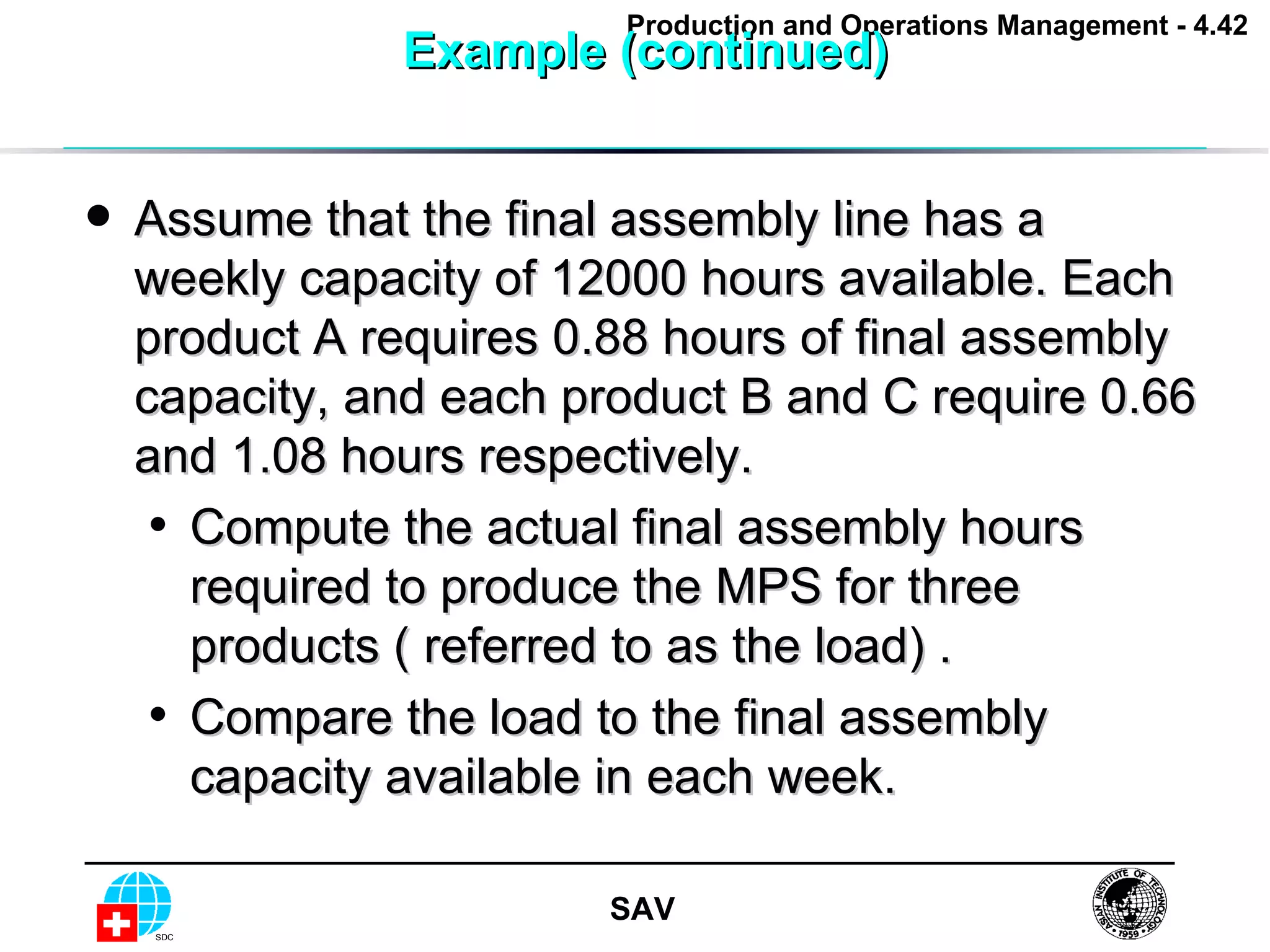

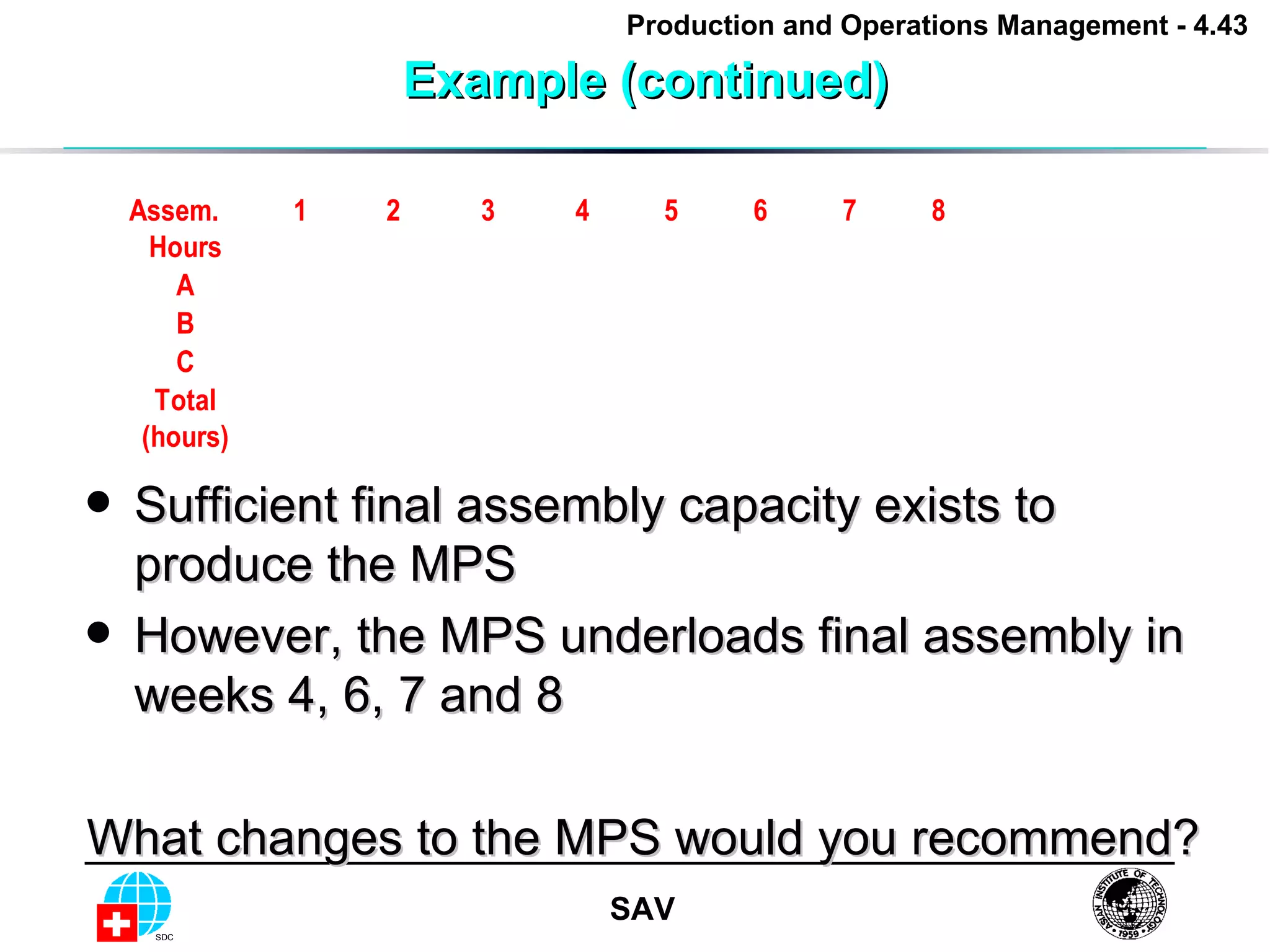

The document discusses production planning systems including aggregate planning and master production scheduling. It provides an overview of different planning horizons and techniques for aggregate and master production scheduling. An example is given demonstrating how to develop a master production schedule over an 8 week planning horizon for 3 products considering demand forecasts, safety stocks and production capacity.