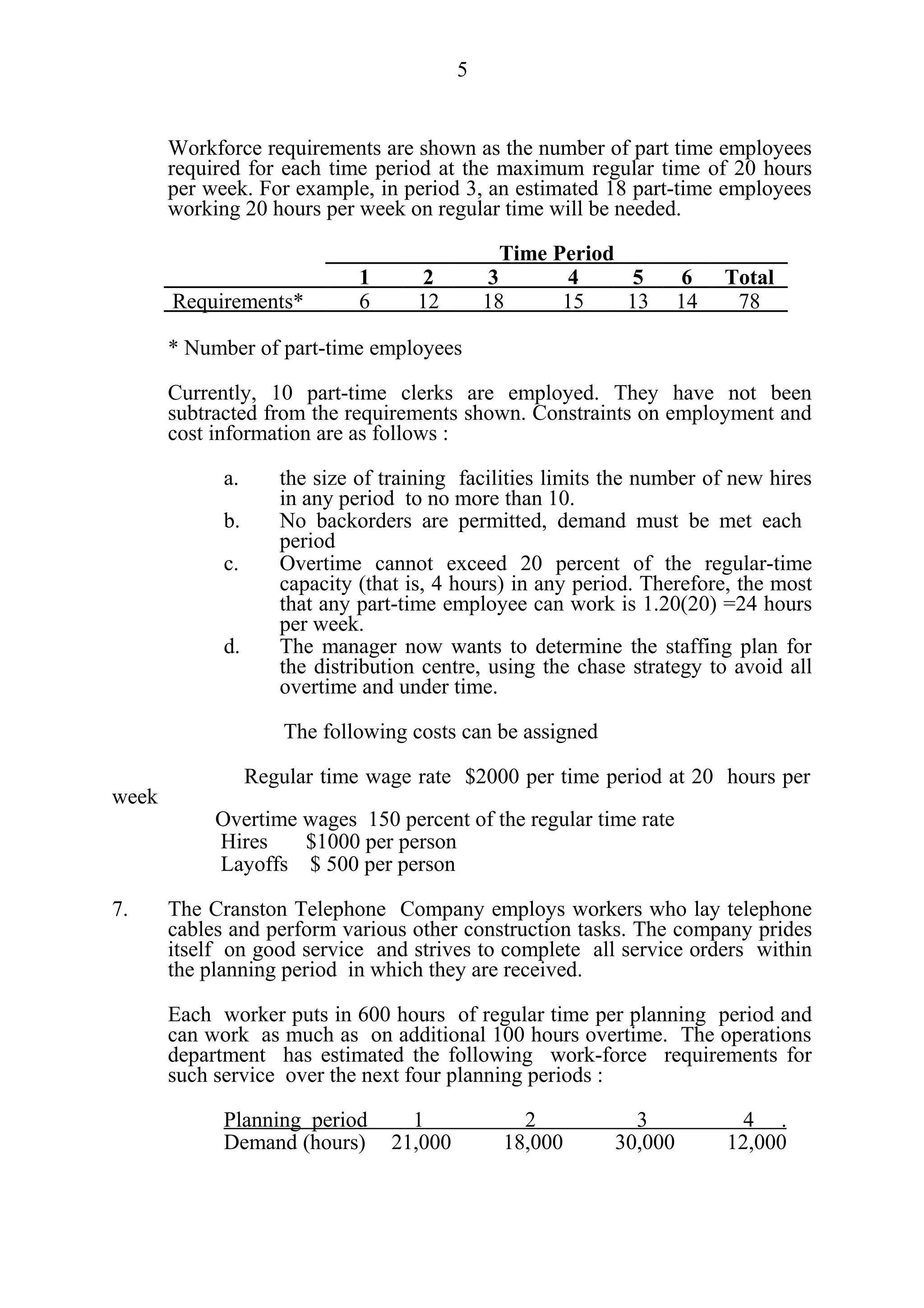

1. The document discusses aggregate planning, which involves balancing production capacity and inventory levels over an intermediate time horizon (3-12 months) to meet forecasted demand at minimal cost. Aggregate planning strategies include maintaining a constant workforce and varying inventory levels, adjusting workforce size, utilizing overtime, and subcontracting. The objective is to select the most cost-effective combination of these strategies.

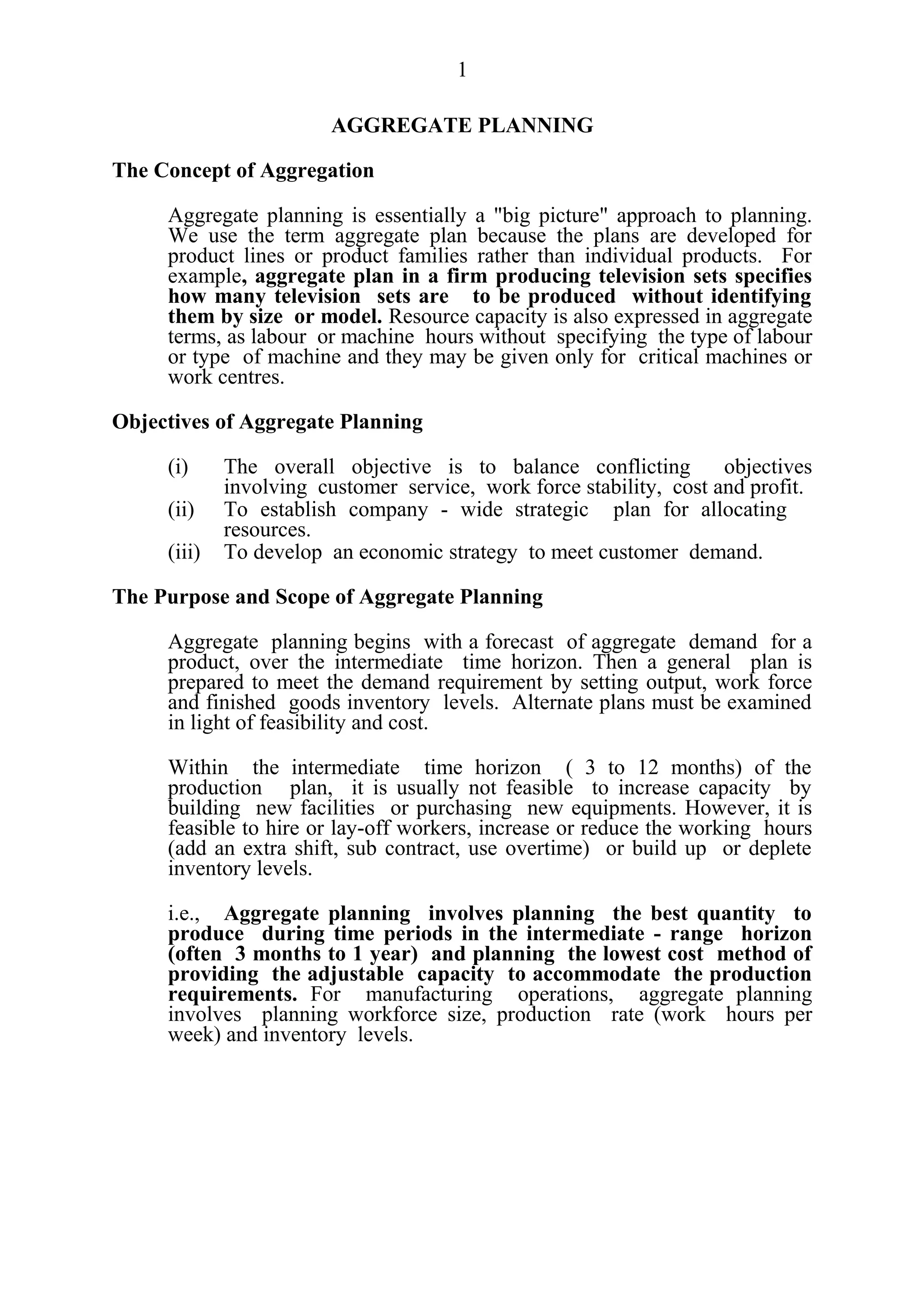

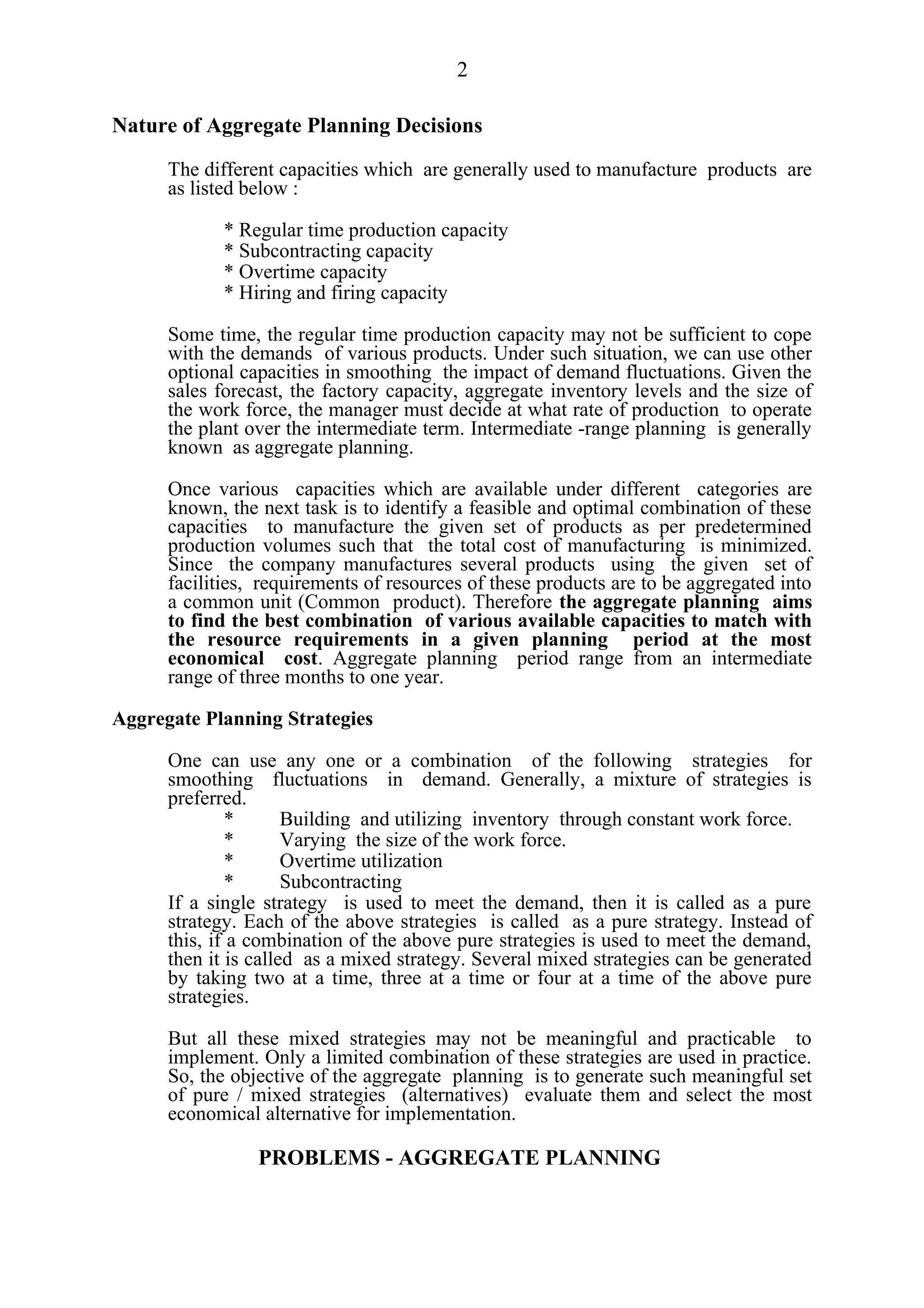

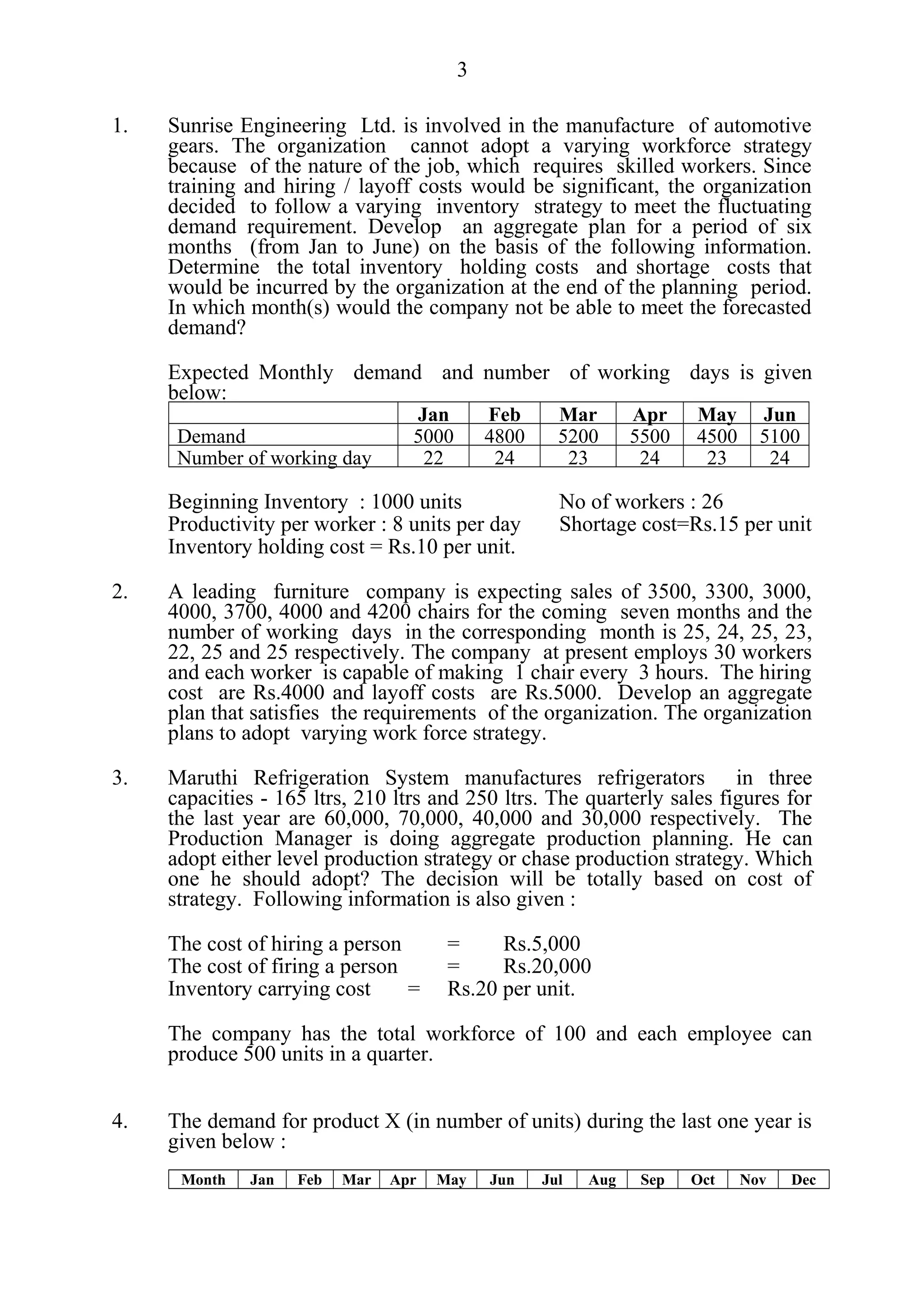

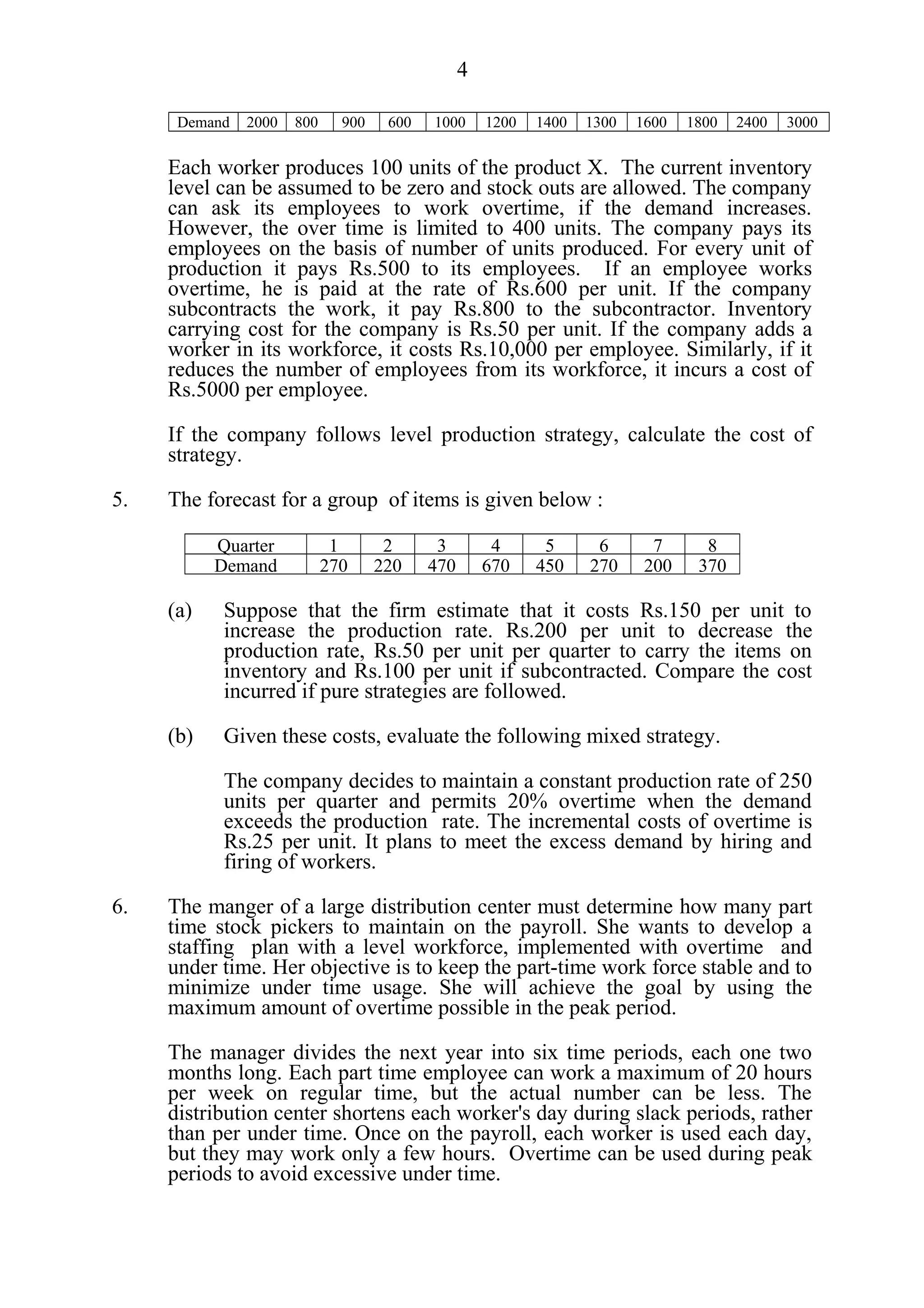

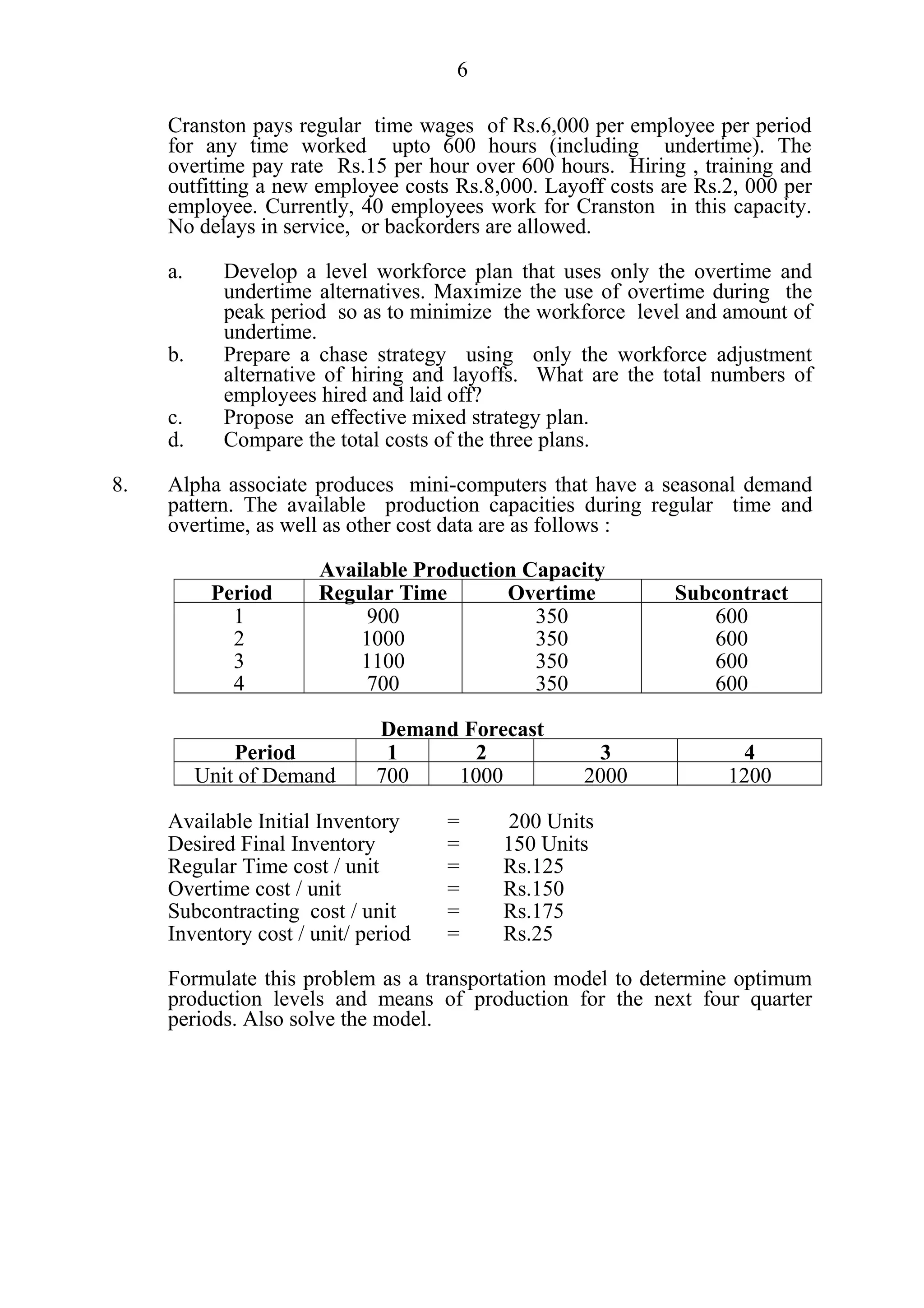

2. Several examples are provided to illustrate aggregate planning problems and solutions. Workers' productivity, hiring/firing costs, inventory holding and shortage costs are factors considered to develop aggregate plans that minimize total costs over the planning period. Different strategies like level production or chase production may be adopted depending on costs.

3. Aggregate