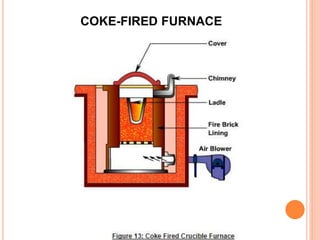

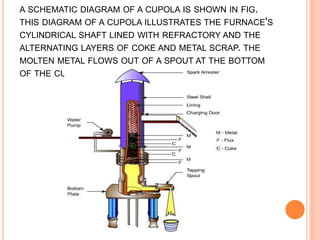

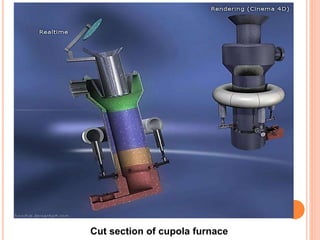

The document discusses different types of furnaces used for metal casting, including crucible furnaces, cupola furnaces, induction furnaces, and reverberatory furnaces. It focuses on crucible furnaces and cupola furnaces. Crucible furnaces melt metals indirectly using refractory crucibles and are used for non-ferrous metals. Cupola furnaces are tall cylinders that melt iron and alloys by alternately layering coke, metal scrap, and limestone and blasting air from below to produce combustion and melt the metal, which flows out the bottom.