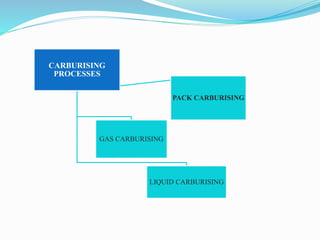

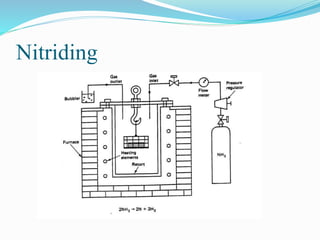

This document provides an overview of various surface hardening techniques including case hardening methods like carburizing, nitriding, and carbonitriding which involve diffusing carbon and/or nitrogen into the surface of steel. It also discusses selective surface hardening techniques like induction hardening where only the surface is heated and quenched to produce a hard martensitic case. Common components that undergo surface hardening are gears, bearings, valves, and machine tool components to improve properties like wear and fatigue resistance. Induction hardening involves inducing current in metal to quickly heat just the surface layer to about 750-850 degrees Celsius before quenching.