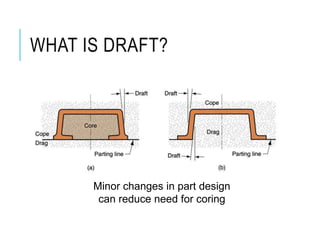

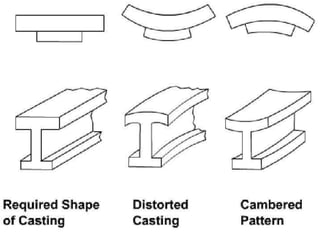

This document discusses various pattern allowances that must be accounted for when designing casting patterns. It describes shrinkage allowance, which accounts for the contraction of metals as they cool from liquid to solid. It also mentions machining allowance to allow for removal of surface imperfections during machining. Draft allowance tapers the pattern for easy removal from the mold. Distortion allowance accounts for uneven shrinking that can warp irregularly shaped castings. Finally, shake allowance enlarges the pattern to compensate for the mold cavity expanding slightly when the pattern is rapped to help removal.