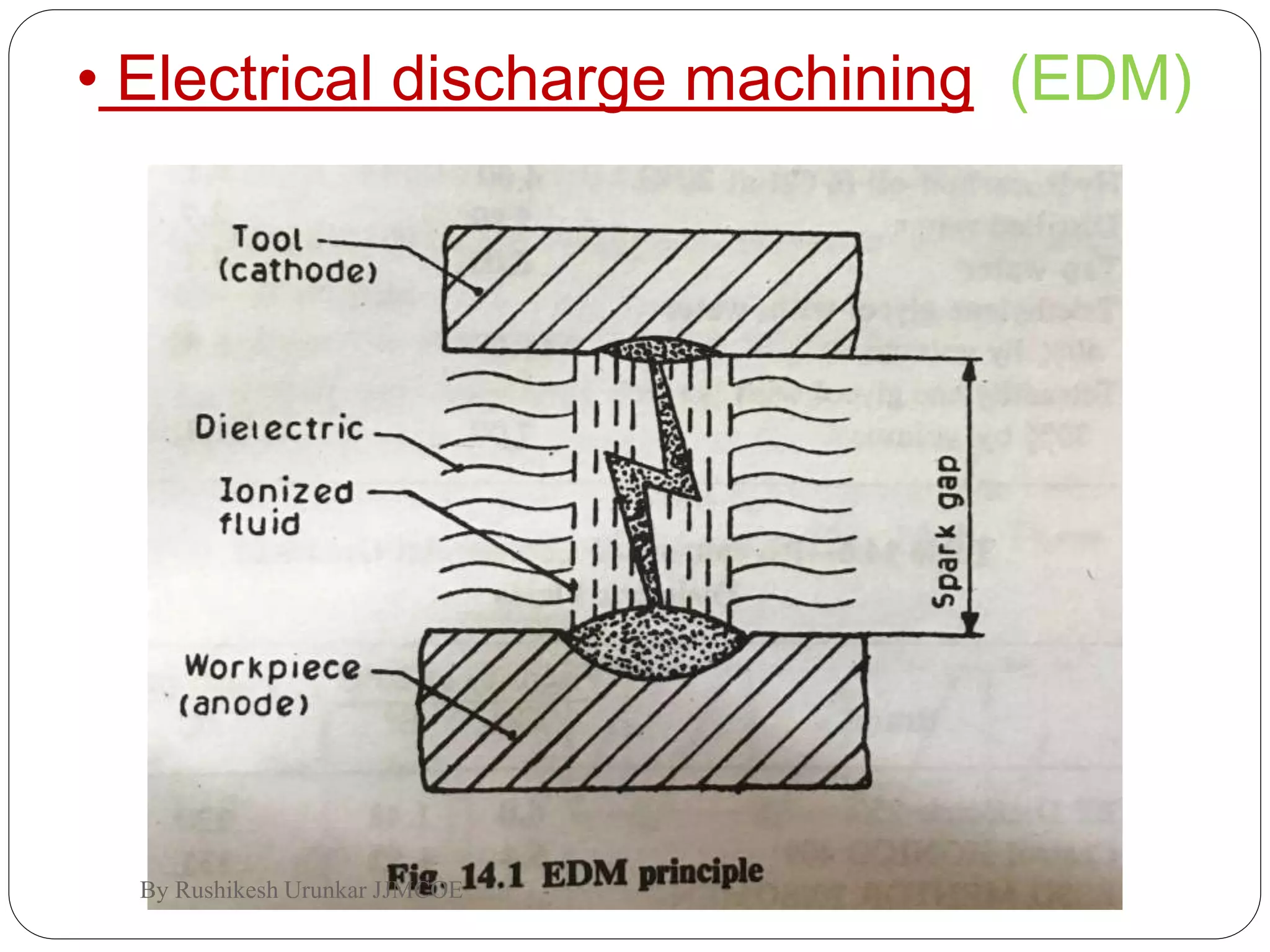

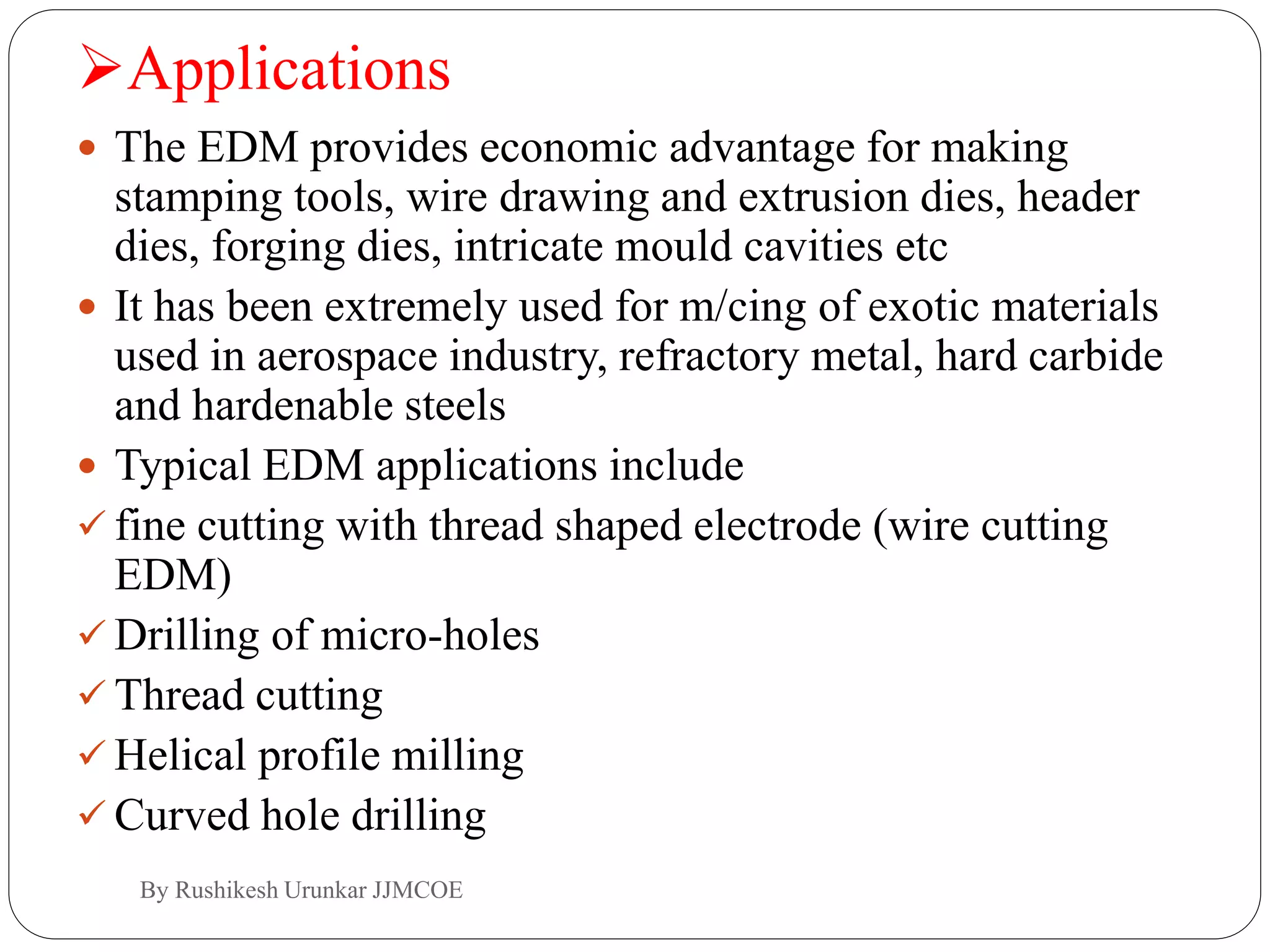

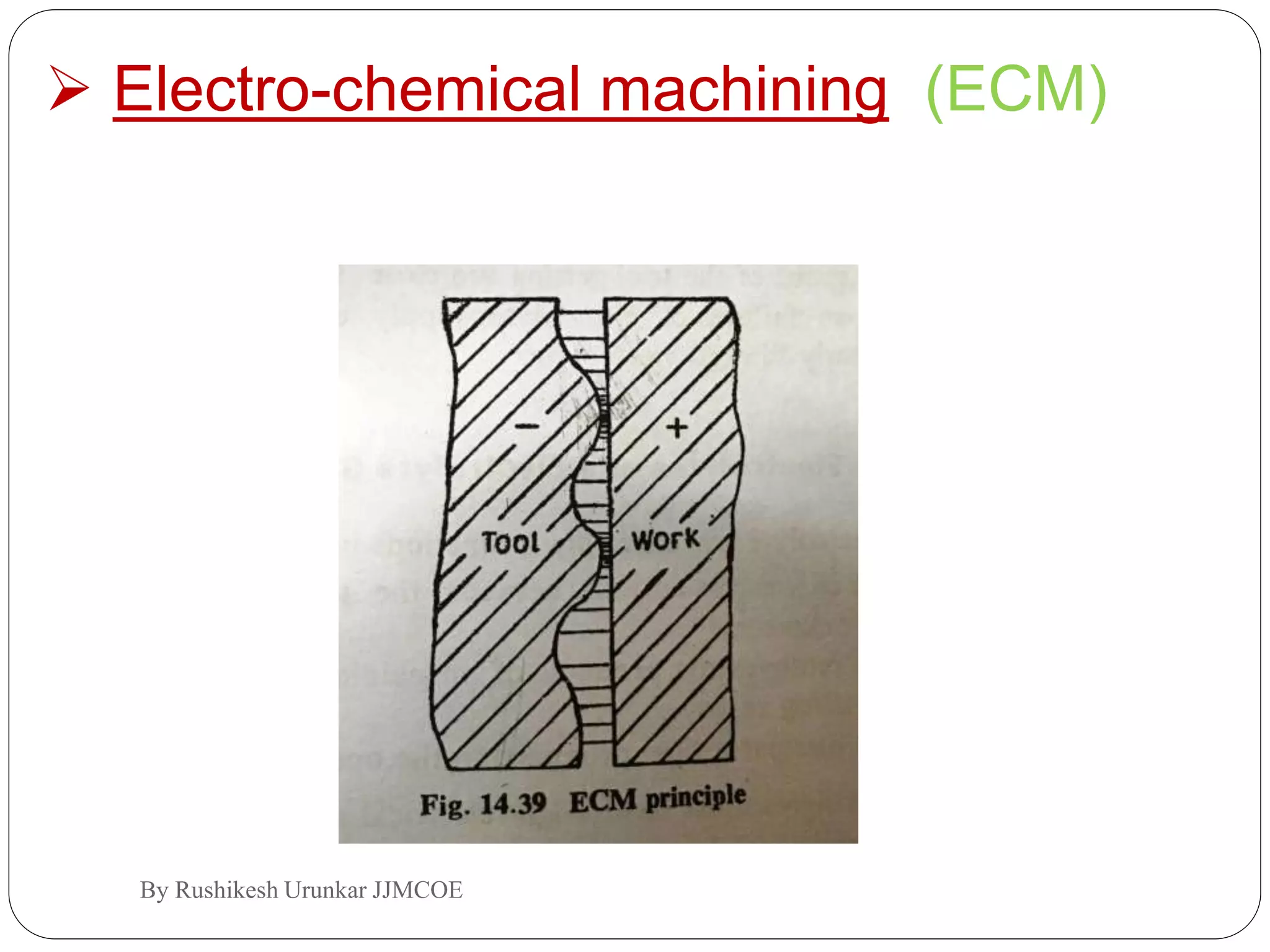

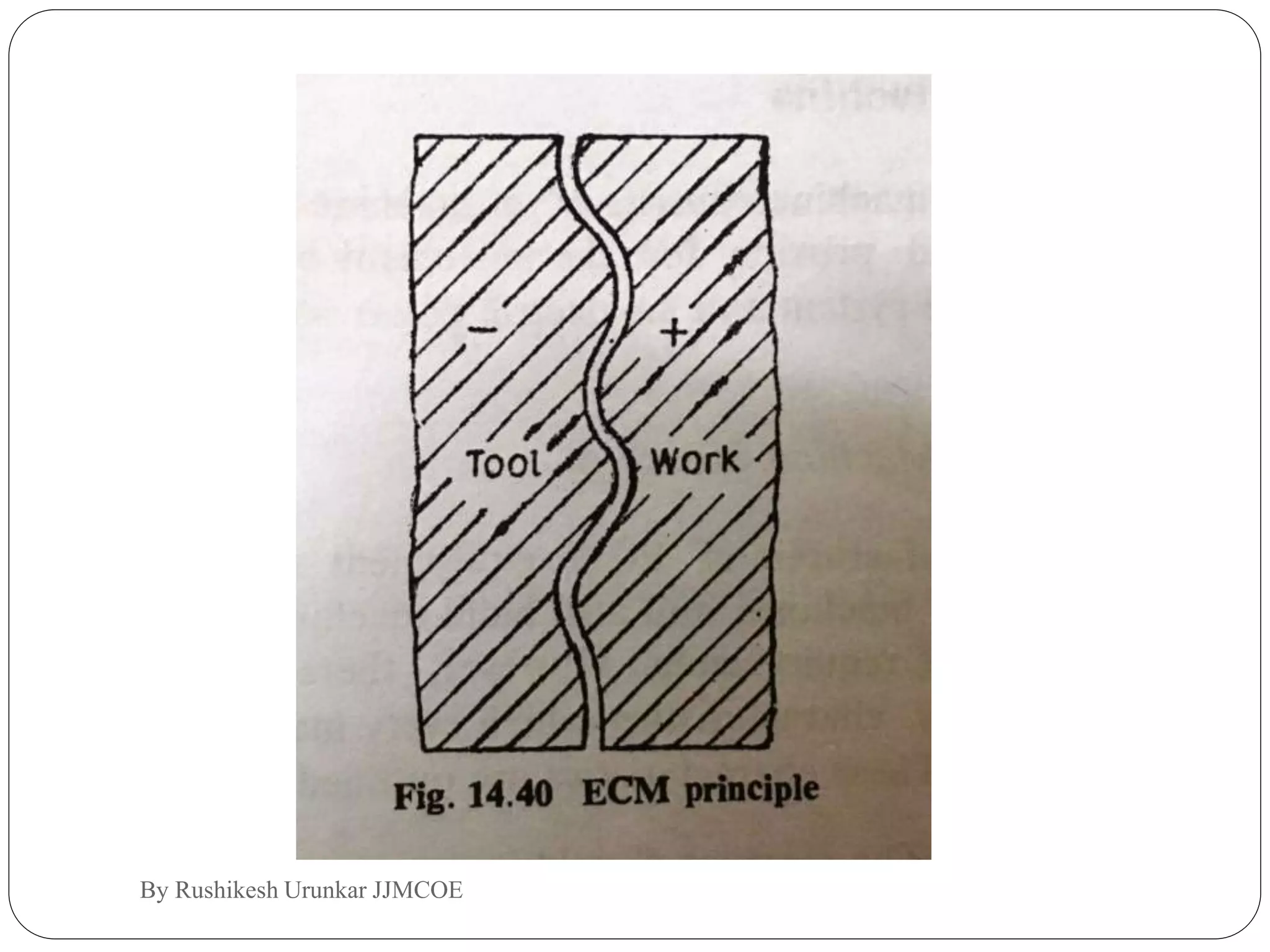

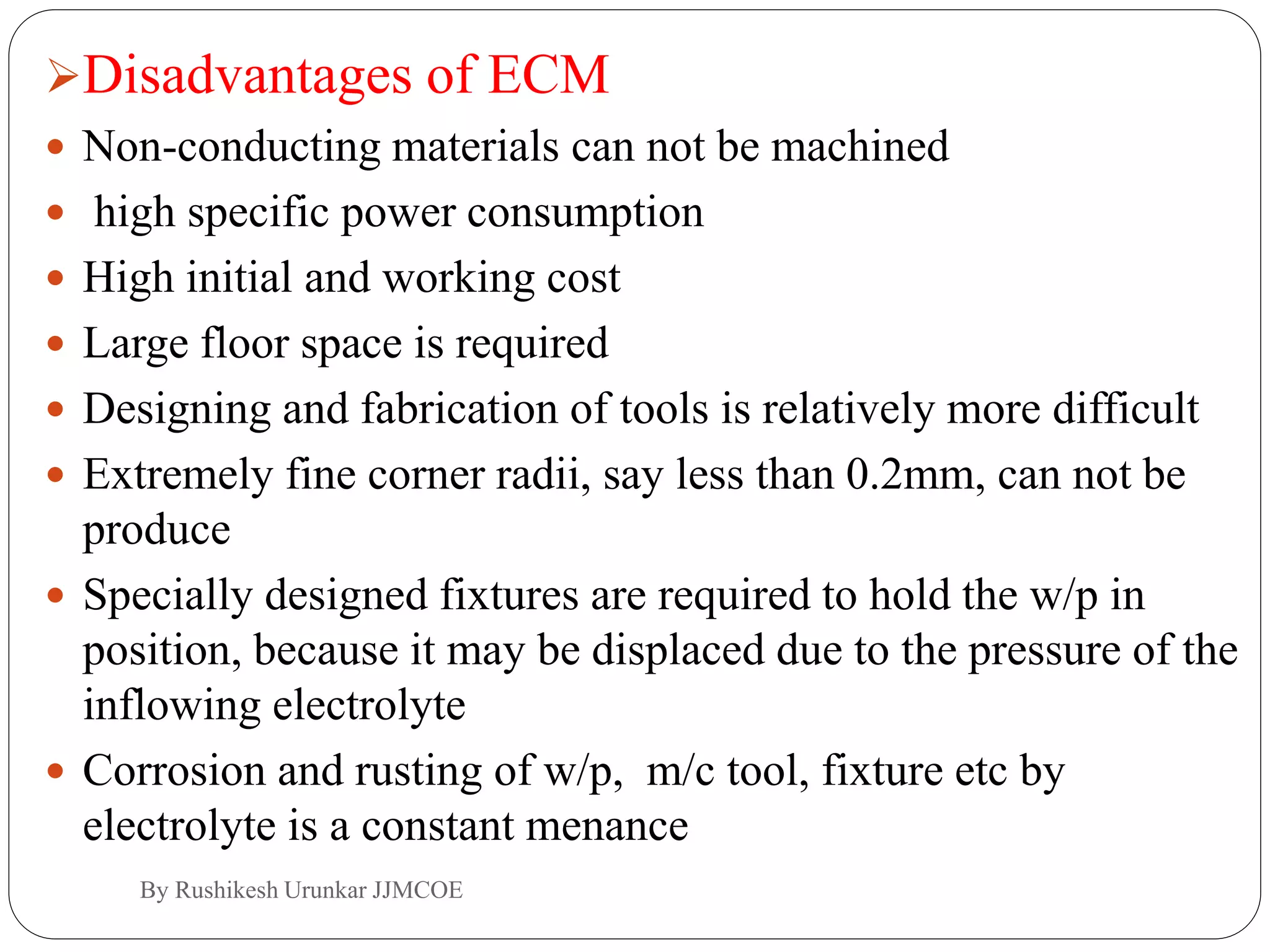

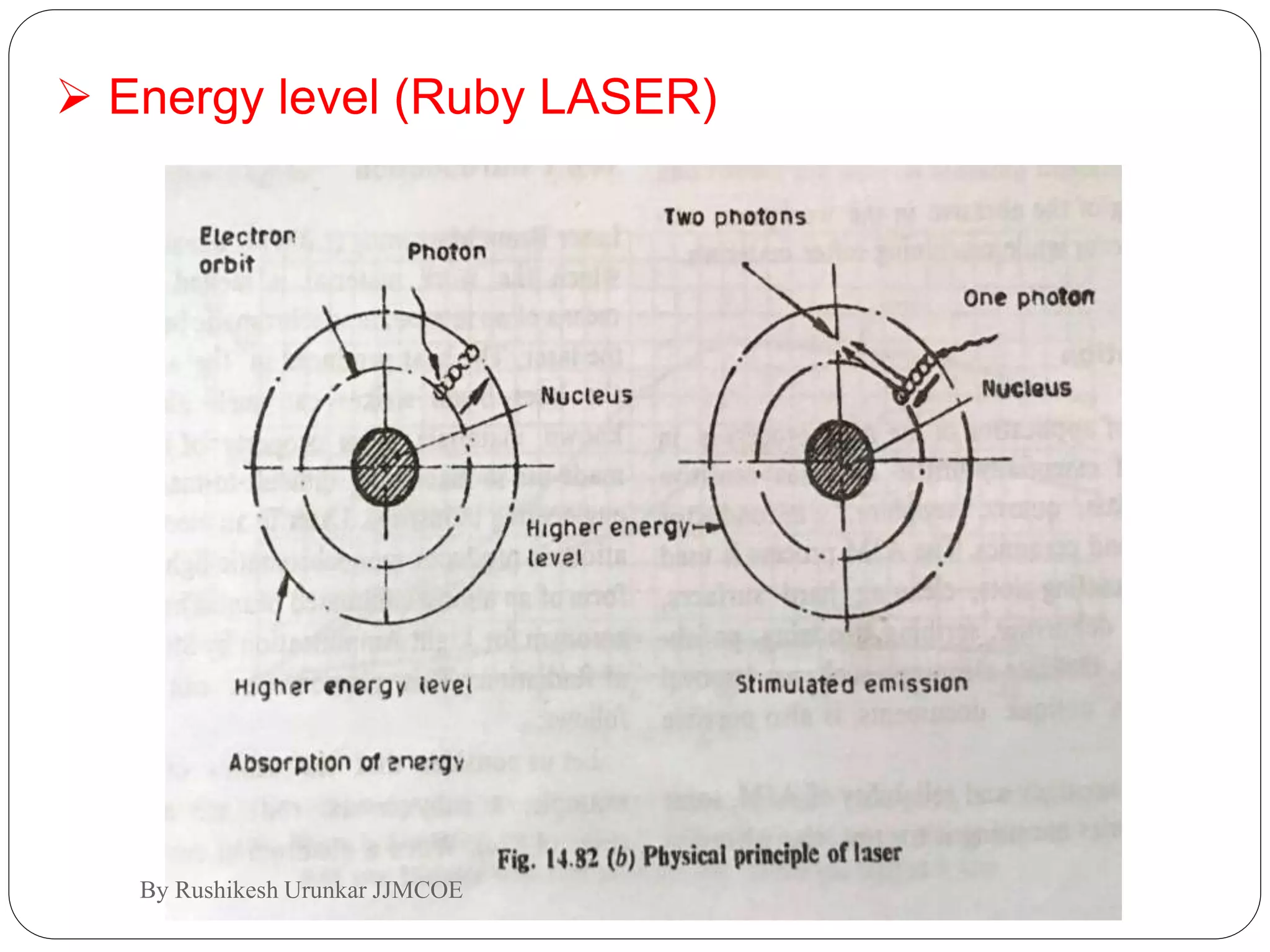

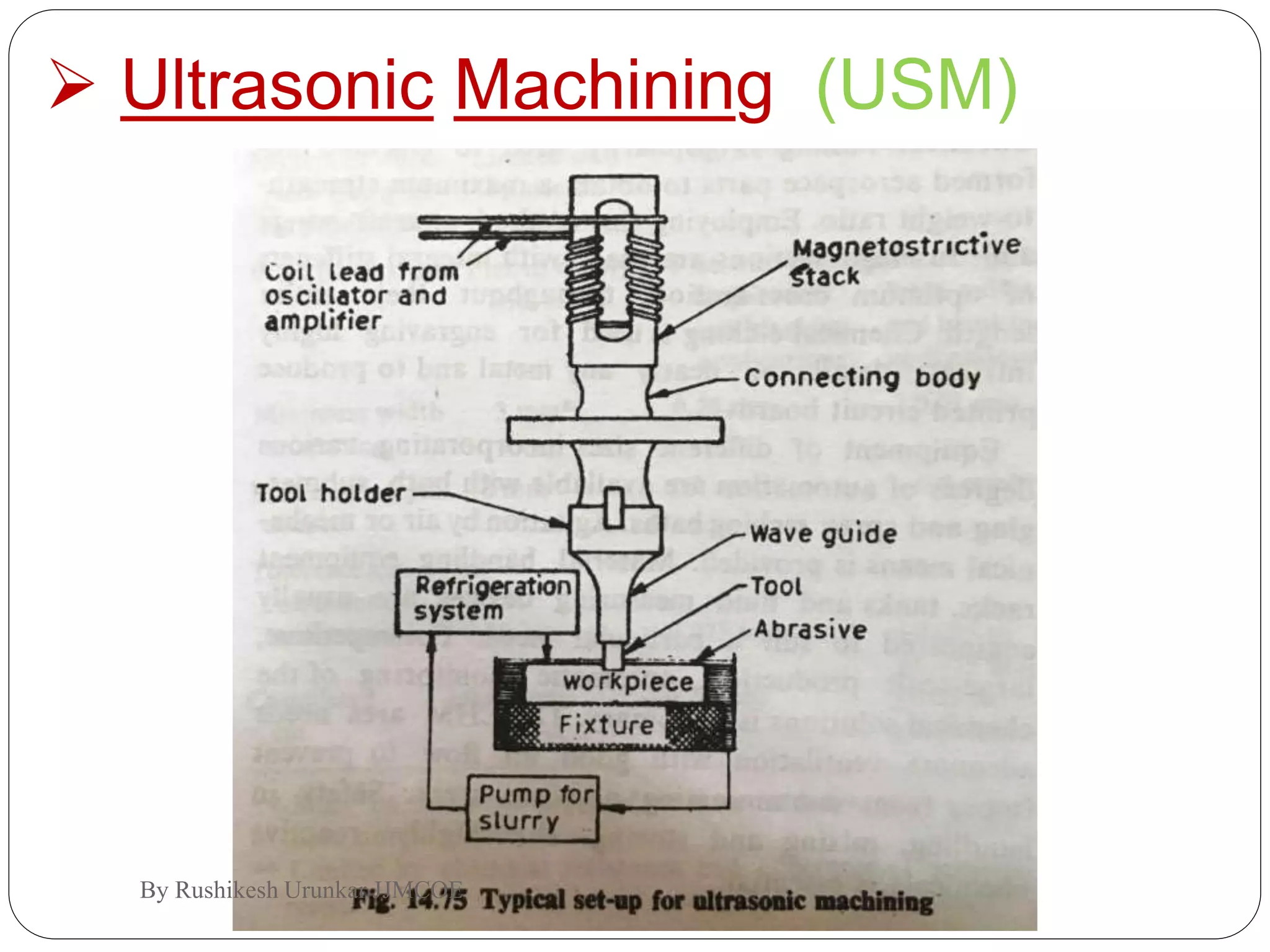

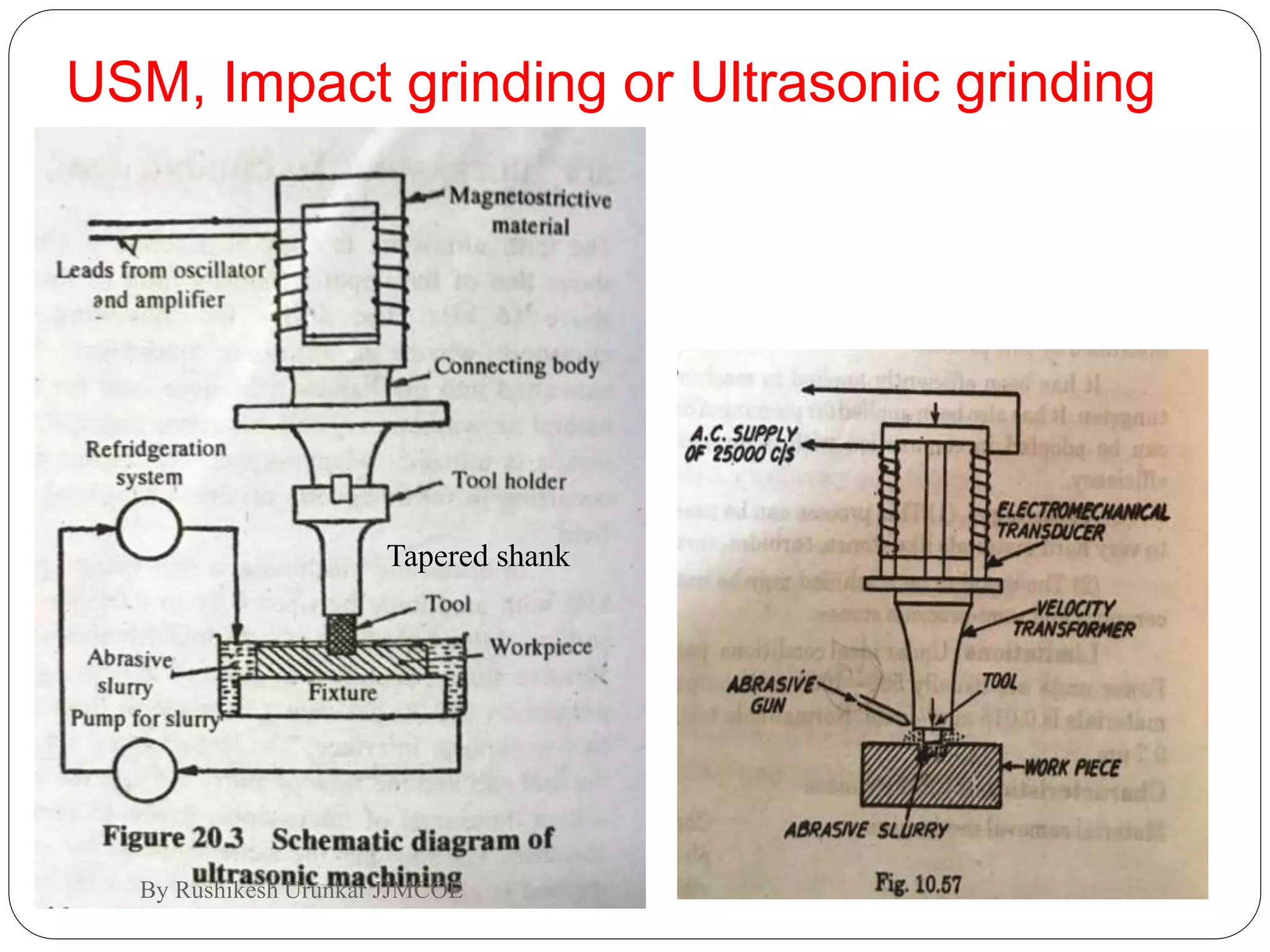

The document provides an overview of various nonconventional machining processes such as Abrasive Jet Machining (AJM), Electrical Discharge Machining (EDM), Electro-Chemical Machining (ECM), Laser Beam Machining (LBM), Ultrasonic Machining (USM), and Water Jet Machining (WJM). Each process is described with details regarding their operation, advantages, limitations, and applications, highlighting their unique capabilities for machining hard and brittle materials. The text serves as a comprehensive reference for understanding these advanced machining techniques and their industrial applications.