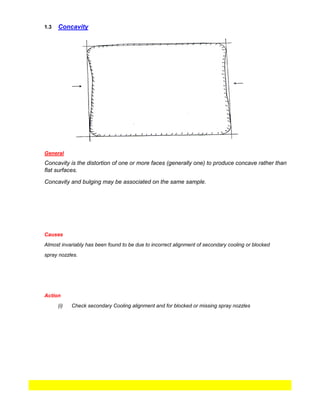

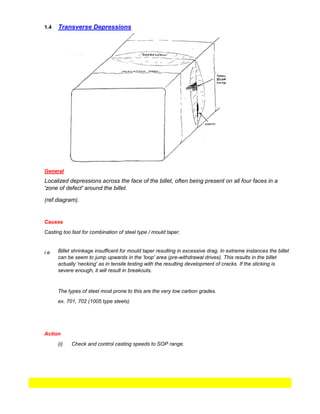

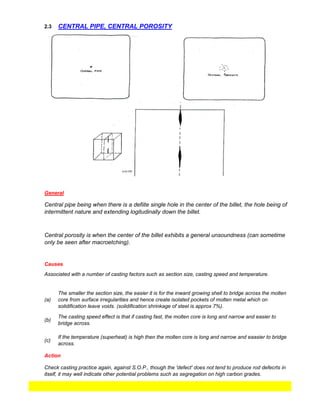

This document describes various defects that can occur in steel billets during the continuous casting process. Section I defines shape defects such as rhomboidity, bulging, concavity, and transverse depression. Section II covers internal defects like diagonal cracking, intercolumnar cracks, and central porosity/pipe. Section III outlines surface defects including bleed outs, reciprocation marks, and scoring. For each defect, the document provides details on causes and recommended actions to check things like mould alignment, secondary cooling, casting speeds, and lubrication.

![(b)

Hydrogen arises from two sources, the use of organic binders in cold tundish lining tiles and from the

natural gas use as the shrouding gas on the tuyeres of the converters. It does not normally cause

blowholes by itself but in conjunction with [O] and [N], the higher [H] at start of cast (on a new

tundish) from tile pick up can result in from end blowholes on the first billets from each strand.

Special case

In addition to [O], [N] and [H] can alos casue rimming in the mould and subsequent subsurface

blowholes.

( ii )

The solubility of [N] in pure Fe is 0.043 by weight i.e. 430 ppm. This can result in substantial nitrogen

gain on low carbon steels depending upon steelmaking and LTS practices. In practice for [N], values

of greater than approximately 140ppm [N], are sufficient to cause blowholes. The actual level at

which subsurface blowholes due to [N] will occur will also be dependent upon the residual [O] values

which are dependent upon the Mn and Si levels.

Cause](https://image.slidesharecdn.com/billetdefects-210913124209/85/Billet-defects-12-320.jpg)