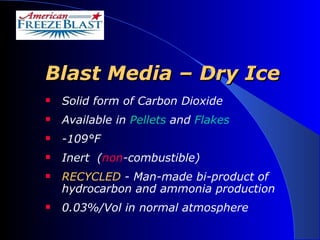

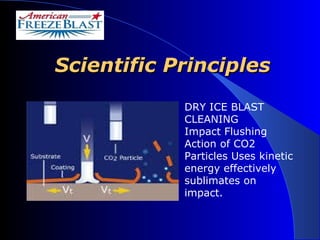

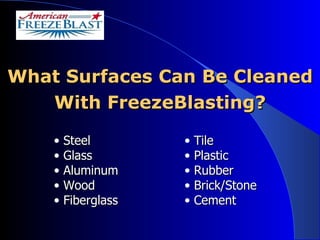

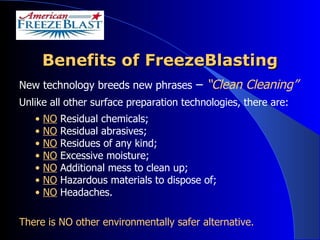

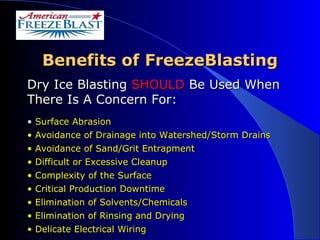

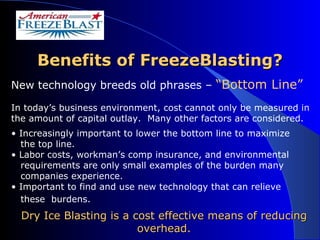

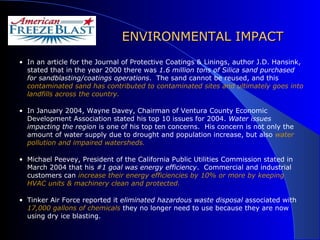

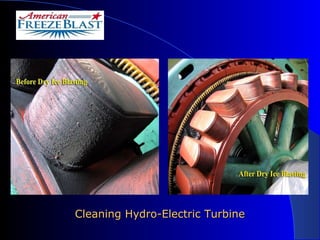

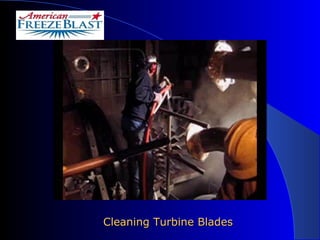

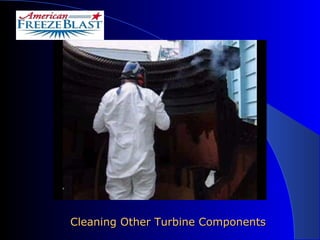

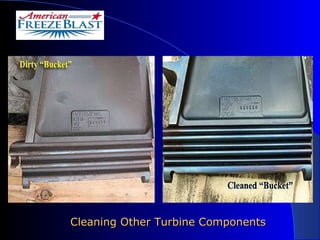

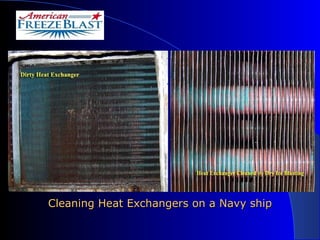

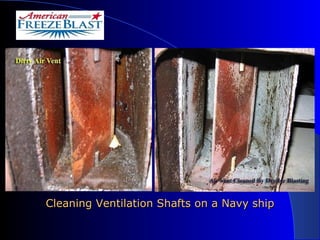

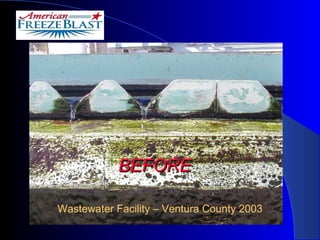

American Freezeblast, Inc. offers dry ice blasting services to clean various surfaces without using hazardous materials. This environmentally friendly method involves using solid carbon dioxide to effectively remove organic and industrial contaminants while avoiding excess moisture and waste. The technology is designed to lower overhead costs and can serve numerous industries, including aerospace, automotive, and food processing.

![American FreezeBlast, Inc. 1409 Kuehner Dr., #112 Simi Valley, California 93063 www.freezeblast.com Toll Free: (800) 649-5045 Fax: (818) 346-3101 Contact Us Email: Marketing & Sales: [email_address] Customer Service: [email_address] Operations & Dispatch: [email_address] FreezeBlast ® is registered trademark of American FreezeBlast](https://image.slidesharecdn.com/afbpowerpointpresentation2011-110423171900-phpapp02/85/PowerPoint-Presentation-2011-40-320.jpg)