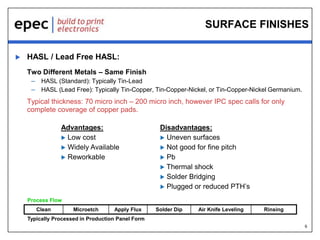

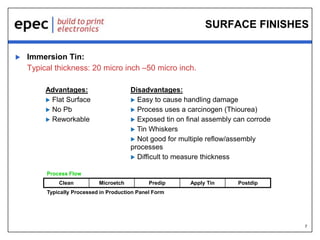

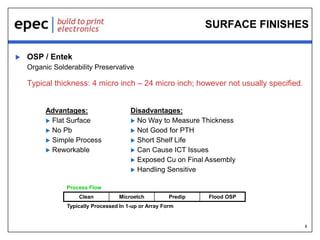

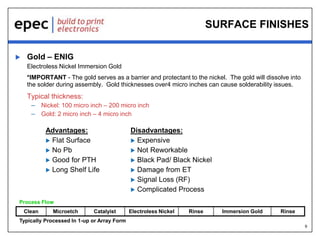

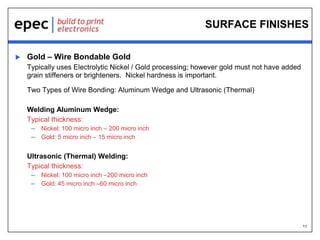

The document provides an overview of various surface finishes used on printed circuit boards (PCBs), highlighting their functions, advantages, disadvantages, and typical processing methods. It examines options such as HASL, immersion tin, OSP, and different types of gold finishes, along with considerations for selecting an appropriate finish. Additionally, it outlines Epec's quality and delivery advantages in PCB manufacturing and offers contact information for further inquiries.