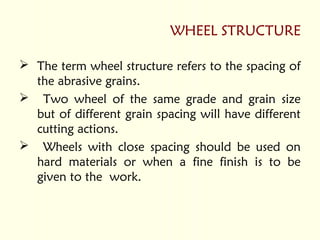

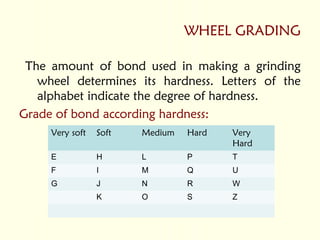

The document discusses abrasive machining processes, specifically grinding. It describes how grinding uses abrasive wheels to smoothly finish surfaces and achieve high accuracy. Grinding involves removing small amounts of material using abrasive grains. Proper wheel selection depends on factors like the material, stock removal needs, required finish, and machine. There are different types of grinding like cylindrical, surface, and form grinding that produce various surface geometries and levels of precision.