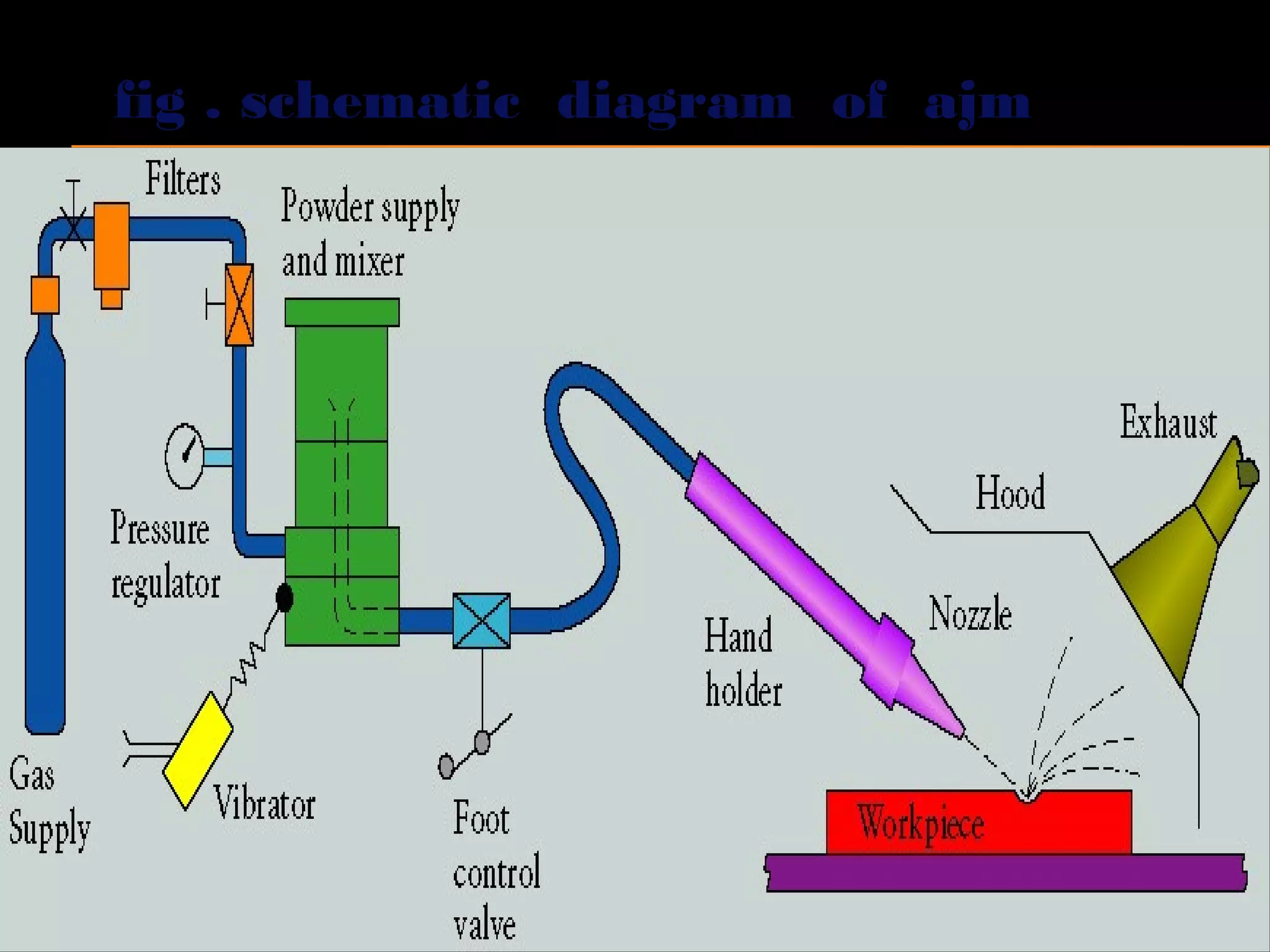

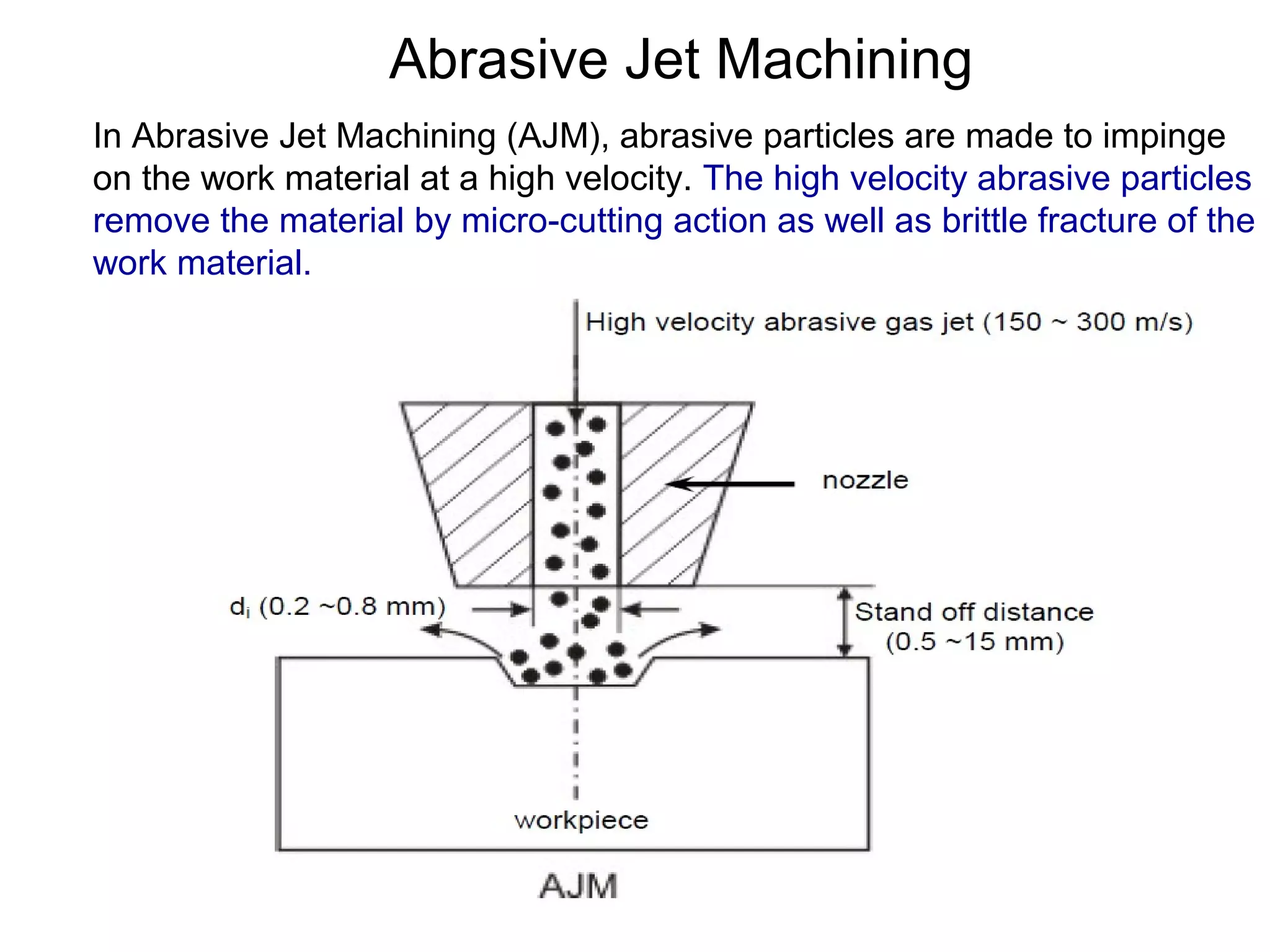

Abrasive jet machining uses a high-velocity stream of abrasive particles suspended in a gas or liquid to erode material from a workpiece. It involves an abrasive delivery system, control system, pump, nozzle, mixing tube, and motion system to direct the abrasive jet. The abrasive particles impact the workpiece surface at high velocities and remove material primarily through brittle fracture or microcutting. Key factors that influence the material removal rate include abrasive type and size, jet velocity and pressure, stand-off distance, and impingement angle. Abrasive jet machining can precisely machine many materials and offers advantages like fast setup times and no heat affected zones.